Abstract

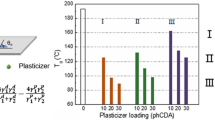

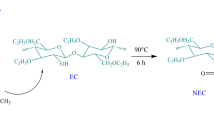

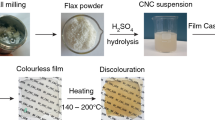

As a promising biodegradable polymer, cellulose triacetate (CTA) was synthesized and plasticized with ionic liquids to produce flexible biocomposite films multi-end-use. Initially, CTA polymer was synthesized from industrial waste cotton using a heterogeneous pathway. Subsequently, four ionic liquids, namely 3-hexyl-1-methyl imidazolium acetate [C6MIM][Ac], 3-hexyl-1-methyl imidazolium hexafluorophosphate [C6MIM][PF6], N-hexyl N,N,N-triethylammonium acetate [N2226][Ac] and N-hexyl N,N,N-triethylammonium hexafluorophosphate [N2226][PF6] were synthesized and used as plasticizer materials of CTA film. Indeed, the films were prepared at room temperature using the solution-casting method, and the effects of ionic liquids on their morphological, mechanical, and thermal properties were evaluated. Morphological results indicated that the prepared films had smooth surfaces and high transparency. The addition of ionic liquids significantly reduced the crystallinity of CTA film and made it ductile. The Mechanical and thermal results showed that the ionic liquid anion has a significant effect on the properties of the film. CTA films plasticized with ionic liquids based on [PF6]− were more flexible than the others, with an elongation of 18.22% instead of 1.97%. The climate ageing test, on the other hand, confirmed that the used ILs could indeed maintain the plasticized state during aging with a better stability of the hydrophobic IL in the polymer matrix compared to the hydrophilic IL. There are self-extinguishing with a final residue of about 97 wt%, allowing CTA films to be used for thermal insulation and fire protection, as well as packaging applications.

Graphical Abstract

Similar content being viewed by others

References

Gandini A (2011) The irruption of polymers from renewable resources on the scene of macromolecular science and technology. Green Chem 13:1061–1083. https://doi.org/10.1039/C0GC00789G

Tharanathan RN (2003) Biodegradable films and composite coatings: past, present and future. Trends Food Sci Technol 14:71–78. https://doi.org/10.1016/S0924-2244(02)00280-7

Silva NH, Vilela CM, Marrucho I, Freire CS, Neto CP, Silvestre A (2014) Protein-based materials: from sources to innovative sustainable materials for biomedical applications. J Mater Chem B 2:3715–3740. https://doi.org/10.1039/C4TB00168K

Klemm D, Heublein B, Fink HP, Bohn A (2005) Cellulose: fascinating biopolymer and sustainable raw material. Angew Chem Int Ed 44:3358–3393. https://doi.org/10.1002/anie.200460587

Edgar KJ (2007) Cellulose esters in drug delivery. Cellulose 14:49–64. https://doi.org/10.1007/s10570-006-9087-7

Edgar KJ, Buchanan CM, Debenham JS, Rundquist PA, Seiler BD, Shelton MC, Tindall D (2001) Advances in cellulose ester performance and application. Prog Polym Sci 26:1605–1688. https://doi.org/10.1016/S0079-6700(01)00027-2

Fan X, Liu ZW, Lu J, Liu ZT (2009) Cellulose triacetate optical film preparation from ramie fiber. Ind Eng Chem Res. https://doi.org/10.1021/ie801703x

Tang LG, Hon DNS, Zhu YQ (1997) An investigation in solution acetylation of cellulose by microscopic techniques. J Appl Polym Sci. https://doi.org/10.1002/(SICI)1097-4628(19970606)64:10%3c1953::AID-APP10%3e3.0.CO;2-Z

Hummel A (2004) 3.2 Industrial processes. In Macromolecular Symposia,WILEY‐VCH Verlag, Weinheim.

Hindi SSZ, Abohassan RA (2015) Cellulose triacetate synthesis from cellulosic wastes by heterogeneous reactions. BioResources

Handayani AS, Chrisvynlia Doohan T, Christwardana Enjarlis M (2019) Cellulose triacetate synthesis from empty fruit bunches of oil palm’s cellulose. AIP Conf Proc doi 10(1063/1):5134639

Nabili A, Fattoum A, Brochier-Salon MC, Bras J, Elaloui E (2017) Synthesis of cellulose triacetate-I from microfibrillated date seeds cellulose (Phoenix dactylifera L.). Iran Polym J. https://doi.org/10.1007/s13726-017-0505-5

Malucelli LC, Lomonaco D, Marco Filho ASC, Magalhães WL (2020) Cellulose triacetate from different sources: modification assessment through thermal and chemical characterization. Holzforschung. https://doi.org/10.1515/hf-2019-0035

Sun X, Bourham M, Barrett DG, Pal L, McCord M (2020) Sustainable atmospheric- pressure plasma treatment of cellulose triacetate (CTA) films for electronics. J Appl Phys doi 10(1063/5):0013633

Im SJ, Jeong G, Jeong S, Cho J, Jang A (2020) Fouling and transport of organic matter in cellulose triacetate forward-osmosis membrane for wastewater reuse and seawater desalination. Chem Eng J. https://doi.org/10.1016/j.cej.2019.123341

Baczynska M, Rzelewska M, Regel-Rosocka M, Wisniewski M (2016) Transport of iron ions from chloride solutions using cellulose triacetate matrix inclusion membranes with an ionic liquid carrier. Chem Pap. https://doi.org/10.1515/chempap-2015-0198

Lee SH, Shiraishi N (2001) Plasticization of cellulose diacetate by reaction with maleic anhydride, glycerol, and citrate esters during melt processing. J Appl Polym Sci. https://doi.org/10.1002/app.1435

Quintana R, Persenaire O, Lemmouchi Y, Sampson J, Martin S, Bonnaud L, Dubois P (2013) Enhancement of cellulose acetate degradation under accelerated weathering by plasticization with eco-friendly plasticizers. Polym Degrad Stab. https://doi.org/10.1016/j.polymdegradstab.2013.06.032

Schilling M, Bouchard M, Khanjian H, Learner T, Phenix A, Rivenc R (2010) Application of chemical and thermal analysis methods for studying cellulose ester plastics. Acc Chem Res. https://doi.org/10.1021/ar1000132

Liu P, Guo X, Nan F, Duan Y, Zhang J (2017) Modifying mechanical, optical properties and thermal processability of iridescent cellulose nanocrystal films using ionic liquid. ACS Appl Mater Interfaces. https://doi.org/10.1021/ah”csami.6b12953

Ning W, Xingxiang Z, Haihui L, Benqiao H (2009) 1-Allyl-3-methylimidazolium chloride plasticized-corn starch as solid biopolymer electrolytes. Carbohydr Polym. https://doi.org/10.1016/j.carbpol.2008.11.005

Dai Z, Noble RD, Gin DL, Zhang X, Deng L (2016) Combination of ionic liquids with membrane technology: a new approach for CO2 separation. J Membr Sci 497:1–20. https://doi.org/10.1016/j.memsci.2015.08.060

Lethesh KC, Evjen S, Venkatraman V, Shah SN, Fiksdahl A (2020) Highly efficient cellulose dissolution by alkaline ionic liquids. Carbohydr Polym. https://doi.org/10.1016/j.carbpol.2019.115594

Wang H, Gurau G, Rogers RD (2012) Ionic liquid processing of cellulose. Chem Soc Rev 41:1519–1537. https://doi.org/10.1039/C2CS15311D

Hossain MI, Samir BB, El-Harbawi M, Masri AN, Mutalib MA, Hefter G, Yin CY (2011) Development of a novel mathematical model using a group contribution method for prediction of ionic liquid toxicities. Chemosphere 85:990–994. https://doi.org/10.1016/j.chemosphere.2011.06.088

Dissanayake N, Thalangamaarachchige VD, Thakurathi M, Knight M, Quitevis EL, Abidi N (2019) Dissolution of cotton cellulose in 1: 1 mixture of 1-butyl-3- methylimidazolium methylphosphonate and 1-alkylimidazole co-solvents. Carbohydr Polym. https://doi.org/10.1016/j.carbpol.2019.05.071

Xu A, Zhang Y, Lu W, Yao K, Xu H (2014) Effect of alkyl chain length in anion on dissolution of cellulose in 1-butyl-3-methylimidazolium carboxylate ionic liquid. J Mol Liq. https://doi.org/10.1016/j.molliq.2014.05.018

Zhang X, Xiao N, Chen M, Wei Y, Liu C (2020) Functional packaging films originating from hemicelluloses laurate by direct transesterification in ionic liquid. Carbohydr Polym. https://doi.org/10.1016/j.carbpol.2019.115336

Domene-López D, Delgado-Marín JJ, Martin-Gullon I, García-Quesada JC, Montalbán MG (2019) Comparative study on properties of starch films obtained from potato, corn and wheat using 1-ethyl-3-methylimidazolium acetate as plasticizer. Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2019.06.004

Tomé LC, Silva NH, Soares HR, Coroadinha AS, Sadocco P, Marrucho IM, Freire CS (2015) Bioactive transparent films based on polysaccharides and cholinium carboxylate ionic liquids. Green Chem. https://doi.org/10.1039/C5GC00416K

Chen BK, Wu TY, Chang YM, Chen AF (2013) Ductile polylactic acid prepared with ionic liquids.Chem Eng J. https://doi.org/10.1016/j.cej.2012.11.078

Li Z, Liu N, Yao Y, Chen S, Wang H (2015) Thermal behavior of cellulose diacetate melt using ionic liquids as plasticizers. RSC adv. https://doi.org/10.1039/C4RA10618K

Bendaoud A, Chalamet Y (2014) Plasticizing effect of ionic liquid on cellulose acetate obtained by melt processing. Carbohydr polym. https://doi.org/10.1016/j.carbpol.2014.03.023

Rynkowska E, Fatyeyeva K, Kujawa J, Dzieszkowski K, Wolan A, Kujawski W (2018) The effect of reactive ionic liquid or plasticizer incorporation on the physicochemical and transport properties of cellulose acetate propionate-based membranes. Polymers. https://doi.org/10.3390/polym10010086

Rani MSA, Hassan NH, Ahmad A, Kaddami H, Mohamed NS (2016) Investigation of biosourced carboxymethyl cellulose-ionic liquid polymer electrolytes for potential application in electrochemical devices. Ionics. https://doi.org/10.1007/s11581-016-1728-8

Carissimi M, Flôres SH, Rech R (2018) Effect of microalgae addition on active biodegradable starch film. Algal res. https://doi.org/10.1016/j.algal.2018.04.001

Sajid L, Azmami O, Ahmadi ZE, Benayada A, Boukhriss A, Majid S, Gmouh S (2021) Extraction and application of cellulose microfibers from Washingtonia palm as reinforcement of starch film. J Plast Film Sheeting. https://doi.org/10.1177/87560879211023093

Vedove TM, Maniglia BC, Tadini CC (2021) Production of sustainable smart packaging based on cassava starch and anthocyanin by an extrusion process. J Food Eng. https://doi.org/10.1016/j.jfoodeng.2020.110274

Marzec A, Laskowska A, Boiteux G, Zaborski M, Gain O, Serghei A (2014) Study on weather aging of nitrile rubber composites containing imidazolium ionic liquids. Macromol Symp 342:25–34. https://doi.org/10.1002/masy.201300231

Kuśmierek M, Szadkowski B, Marzec A (2020) The essential role of 1-butyl-3-methylimidazolium-based ionic liquids in the development of transparent silica-filled elastomer systems. Materials 13(19):4337. https://doi.org/10.3390/ma13194337

Cheng HN, Dowd MK, Selling GW, Biswas A (2010) Synthesis of cellulose acetate from cotton byproducts. Carbohydr polym. https://doi.org/10.1016/j.carbpol.2009.11.048

El Nemr A, Ragab S, El Sikaily A (2017) Rapid synthesis of cellulose triacetate from cotton cellulose and its effect on specific surface area and particle size distribution. Iran Polym J. https://doi.org/10.1007/s13726-017-0516-2

Bentis A, Boukhriss A, Boyer D, Gmouh S (2017) Development of flame retardant Cotton fabric based on ionic liquids via sol-gel technique. IOP Conf Ser: Mater Sci Eng

Aghmih K, Wakrim H, Boukhriss A, El Bouchti M, Majid S, Gmouh S (2021) Rheological study of microcrystalline cellulose/pyridinium-based ionic liquids solutions. Polym Bull. https://doi.org/10.1007/s00289-021-03917-1

Videki B, Klebert S, Pukanszky B (2007) External and internal plasticization of cellulose acetate with caprolactone: structure and properties. J Polym Sci Part B: Polym Phys. https://doi.org/10.1002/polb.21121

Guo JH (1993) Effects of plasticizers on water permeation and mechanical properties of cellulose acetate: antiplasticization in slightly plasticized polymer film. Drug Dev Ind Pharm 19:541–1555. https://doi.org/10.3109/03639049309069325

Fedosse Zornio C, Livi S, Duchet-Rumeau J, Gerard JF (2019) Ionic liquid nanostructured poly (Methyl Methacrylate). Nanomaterials. https://doi.org/10.3390/nano9101376

Hema M, Selvasekerapandian S, Hirankumar G, Sakunthala A, Arunkumar D, Nithya H (2009) Structural and thermal studies of PVA: NH4I. J Phys Chem Solids 70:1098–1103. https://doi.org/10.1016/j.jpcs.2009.06.005

Benazzouz A, Dudognon E, Correia NT, Molinier V, Aubry JM, Descamps M (2017) Interactions underpinning the plasticization of a polymer matrix: a dynamic and structural analysis of DMP-plasticized cellulose acetate. Cellulose 24:487–503. https://doi.org/10.1007/s10570-016-1148-y

Baczyńska M, Waszak M, Nowicki M, Prządka D, Borysiak S, Regel-Rosocka M (2018) Characterization of polymer inclusion membranes (PIMs) containing phosphonium ionic liquids as Zn (II) carriers. Ind Eng Chem Res 57:5070–5082. https://doi.org/10.1021/acs.iecr.7b04685

Ghasemlou M, Khodaiyan F, Oromiehie A (2011) Rheological and structural characterisation of film-forming solutions and biodegradable edible film made from kefiran as affected by various plasticizer types. Int J Biol Macromol 49:814–821. https://doi.org/10.1016/j.ijbiomac.2011.07.018

Ramesh S, Shanti R, Morris E (2012) Plasticizing effect of 1-allyl-3-methylimidazolium chloride in cellulose acetate-based polymer electrolytes. Carbohydr Polym 87:2624–2629. https://doi.org/10.1016/j.carbpol.2011.11.037

Liu N, Zhang JW, Wang HP (2014) Plasticization of cellulose diacetate by Ionic liquid. J Adv Mater Res 936:1002–1006. https://doi.org/10.4028/www.scientific.net/AMR.936.1002

Khaldia S, Lamia B, Yasmina K, Lahcene B (2020) Preparation, characterization and antioxidant activity of microspheres made of cellulose triacetate (CTA) to control the release of vitamin C. J Chem Technol Biotechnol. https://doi.org/10.1002/jctb.6378

Basiak E, Lenart A, Debeaufort F (2017) Effect of starch type on the physico-chemical properties of edible films. Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2017.01.122

Zhang B, Xie F, Shamshina JL, Rogers RD, McNally T, Wang DK, Chen L (2017) Facile preparation of starch-based electroconductive films with ionic liquid. ACS Sustain Chem Eng. https://doi.org/10.1021/acssuschemeng.7b00788

Nawab A, Alam F, Haq MA, Lutfi Z, Hasnain A (2017) Mango kernel starch-gum composite films: physical, mechanical and barrier properties. Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2017.02.054

Chen M, Runge T, Wang L, Li R, Feng J, Shu XL, Shi QS (2018) Hydrogen bonding impact on chitosan plasticization. Carbohydr polym. https://doi.org/10.1016/j.carbpol.2018.07.062

Haq MA, Habu Y, Yamamoto K, Takada A, Kadokawa JI (2019) Ionic liquid induces flexibility and thermoplasticity in cellulose film. Carbohydr polym. https://doi.org/10.1016/j.carbpol.2019.115058

Gonçalves SM, Dos Santos DC, Motta JFG, Dos Santos RR, Chávez DWH, de Melo NR (2019) Structure and functional properties of cellulose acetate films incorporated with glycerol. Carbohydr polym. https://doi.org/10.1016/j.carbpol.2019.01.031

Muscat D, Adhikari B, Adhikari R, Chaudhary DS (2012) Comparative study of film forming behaviour of low and high amylose starches using glycerol and xylitol as plasticizers. J Food Eng. https://doi.org/10.1016/j.jfoodeng.2011.10.019

Xu J, Chen Y, Tian Y, Yang Z, Zhao Z, Du W, Zhang X (2021) Effect of ionic liquid 1- buyl-3-methylimidazolium halide on the structure and tensile property of PBS/corn starch blends. Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2021.01.062

Wang H, Du Y, Wang Z, Yu W, Zhang L, Wu C, Zhang J (2021) Preparation of eco- friendly composite food packaging films based on gelatin and matrine coconut acids ionic liquid. New J Chem. https://doi.org/10.1039/D1NJ02859F

Almeida CM, Magalhães JM, Souza HK, Gonçalves MP (2018) The role of choline chloride-based deep eutectic solvent and curcumin on chitosan films properties. Food Hydrocoll. https://doi.org/10.1016/j.foodhyd.2018.03.025

Lewandowska K (2020) Effect of an ionic liquid on the physicochemical properties of chitosan/poly (vinyl alcohol) mixtures. Int J Biol Macromol. https://doi.org/10.1016/j.ijbiomac.2019.10.084

Cheong JY, Ahn J, Seo M, Nam YS (2015) Flame-retardant, flexible vermiculite polymer hybrid film. RSC adv. https://doi.org/10.1039/C5RA08382F

Phanthuwongpakdee J, Harimoto T, Babel S, Dwivedi S, Takada K, Kaneko T (2021) Flame retardant transparent films of thermostable biopolyimide metal hybrids. Polym Degrad Stab. https://doi.org/10.1016/j.polymdegradstab.2021.109571

Dehbi A, Mourad AHI, Djakhdane K, Hilal-Alnaqbi A (2015) Degradation of thermomechanical performance and lifetime estimation of multilayer greenhouse polyethylene films under simulated climatic conditions. Polym Eng Sci 55:287–298. https://doi.org/10.1002/pen.23895

Zhang B, Xie F, Zhang T, Chen L, Li X, Truss RW, Rogers RD (2016) Different characteristic effects of ageing on starch-based films plasticised by 1-ethyl-3- methylimidazolium acetate and by glycerol. Carbohydr Polym 146:67–79. https://doi.org/10.1016/j.carbpol.2016.03.056

Sharma A, Ghorai PK (2016) Effect of water on structure and dynamics of [BMIM][PF6] ionic liquid: an all-atom molecular dynamics simulation investigation. J Chem Phys 144:114505. https://doi.org/10.1063/1.4944083

Wang H, Gurau G, Kelley SP, Myerson AS, Rogers RD (2013) Hydrophobic vs. hydrophilic ionic liquid separations strategies in support of continuous pharmaceutical manufacturing. RSC Adv 3:10019–10026. https://doi.org/10.1039/C3RA41082J

Marzec A, Szadkowski B, Rogowski J, Maniukiewicz W, Zaborski M (2019) New organic-inorganic hybrids as multifunctional additives to improve ethylene-norbornene (EN) composite stability. Polym Degrad Stab 160:110–119. https://doi.org/10.1016/j.polymdegradstab.2018.12.012

Lam B, Wei M, Zhu L, Luo S, Guo R, Morisato A, Lin H (2016) Cellulose triacetate doped with ionic liquids for membrane gas separation. Polymer. https://doi.org/10.1016/j.polymer.2016.02.033

Huddleston JG, Visser AE, Reichert WM, Willauer HD, Broker GA, Rogers RD (2001) Characterization and comparison of hydrophilic and hydrophobic room temperature ionic liquids incorporating the imidazolium cation. Green Chem. https://doi.org/10.1039/B103275P

Maton C, De Vos N, Stevens CV (2013) Ionic liquid thermal stabilities: decomposition mechanisms and analysis tools. Chem Soc Rev 42:5963–5977. https://doi.org/10.1039/C3CS60071H

Sam ST, Nuradibah MA, Chin KM, Hani N (2016) In Natural Polymers Current application and challenges on packaging industry based on natural polymer blending. Springer, Cham. https://doi.org/10.1007/978-3-319-26414-1_6

Sharma S, Sharma B, Manral A, Bajpai PK, Jain P (2020) In Biopolymers and their Industrial Applications Biopolymers in the automotive and adhesive industries. Elsevier. https://doi.org/10.1016/B978-0-12-819240-5.00011-0

Nishita R, Kuroda K, Ota S, Endo T, Suzuki S, Ninomiya K, Takahashi K (2019) Flame- retardant thermoplastics derived from plant cell wall polymers by single ionic liquid substitution. New J Chem. https://doi.org/10.1039/C8NJ04797A

Bentis A, Boukhriss A, Grancaric AM, El Bouchti M, El Achaby M, Gmouh S (2019) Flammability and combustion behavior of cotton fabrics treated by the sol gel method using ionic liquids combined with different anions. Cellulose. https://doi.org/10.1007/s10570-018-2206-4

Xu S, Li SY, Zhang M, Zeng HY, Wu K, Tian XY, Pan Y (2020) Fabrication of green alginate-based and layered double hydroxides flame retardant for enhancing the fire retardancy properties of polypropylene. Carbohydr polym. https://doi.org/10.1016/j.carbpol.2020.115891

Rashid M, Chetehouna K, Cablé A, Gascoin N (2021) Analysing flammability characteristics of green biocomposites: an overview. Fire Technol 57:31. https://doi.org/10.1007/s10694-020-01001-0

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Aghmih, K., Boukhriss, A., El Bouchti, M. et al. Introduction of Ionic Liquids as Highly Efficient Plasticizers and Flame Retardants of Cellulose Triacetate Films. J Polym Environ 30, 2905–2918 (2022). https://doi.org/10.1007/s10924-022-02407-3

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-022-02407-3