Abstract

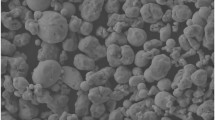

In this paper, Cu/SAC-15Ag/Cu 3D package solder joints were prepared by transient liquid phase (TLP) bonding technology. The effects of bonding time on the microstructure and shear property of solder joints were investigated. The results indicated that the microstructure of solder joints is coarsened with increasing bonding time. The intermetallic compounds (IMCs) in the interfacial reaction zone consist of Cu3Sn and Cu6Sn5 phase, and the IMCs in the in situ reaction zone include Ag3Sn phase, Sn-rich phase, and Ag particles. The thickness of interfacial IMCs layer initially decreases due to the volume contraction caused by the transformation from Cu6Sn5 to Cu3Sn, and then increases as a result of the coarsen of Cu3Sn. The minimum porosity of the solder joints reaches 0.24% under bonding time of 30 min. The shear strength of solder joints increases first and then declines with the extension of bonding time, and the maximum shear strength of 45.3 MPa is obtained by bonding for 30 min. The shear fracture mechanism of solder joints changes from ductile fracture to ductile–brittle mixed fracture, and then changes to brittle fracture. Cracks nucleate at the voids and propagate quickly with prolonging bonding time, and the cracks could be restrained by the voids.

Similar content being viewed by others

References

L.A. Navarro, X. Perpina, P. Godignon, J. Montserrat, V. Banu, M. Vellvehi, X. Jorda, I.E.E.E.T. Power, Electr. 29, 2261 (2014)

W. Zhou, X. Zhong, K. Sheng, I.E.E.E.T. Power, Electr. 29, 2329 (2014)

R. Wang, D. Boroyevich, P. Ning, Z. Wang, F. Wang, P. Mattavelli, K.D.T. Ngo, K. Rajashekara, I.E.E.E.T. Power, Electr. 28, 555 (2013)

J.F. Li, P.A. Agyakwa and C.M, Acta Mater. 59, 1198 (2011)

H. Shao, A. Wu, Y. Bao, Y. Zhao, L. Liu, G. Zou, Ultrason. Sonochem. 37, 561 (2017)

H. Shao, A. Wu, Y. Bao, Y. Zhao, G. Zou, Mat. Sci. Eng. A-Struct. 680, 221 (2017)

H. Shao, A. Wu, Y. Bao, Y. Zhao, G. Zou, T. Nonferr, Metal. Soc. 27, 722 (2017)

H. Liu, K. Wang, K.E. Aasmundtveit, N. Hoivik, J. Electron. Mater. 41, 2453 (2012)

C. Hang, Y. Tian, R. Zhang, D. Yang, J. Mater. Sci-Mater. El. 24, 3905 (2013)

H. Shao, A. Wu, Y. Bao, Y. Zhao, J. Mater. Sci. 52, 3508 (2017)

K. Chu, Y. Sohn, C. Moon, Scripta. Mater. 109, 113 (2015)

N.S. Bosco, F.W. Zok, Acta Mater. 53, 2019 (2005)

X. Liu, S. He, H. Nishikawa, Scripta. Mater. 110, 101 (2016)

B. Liu, Y. Tian, J. Feng, C. Wang, J. Mater. Sci. 52, 1943 (2017)

M. He, F. Wu, W. Zhang, Y. Wu, B. An, Electronic quality. 08, 25 (2006)

L. Yang, J. Ge, Y. Zhang, J. Dai, Y. Jing, J. Mater. Sci-Mater. El. 26, 613 (2015)

L. Sun, M. Chen, L. Zhang, F. Yang, Acta metalica Sinica. 53, 615 (2017)

F. Wang, L. Zhou, X. Wang, P. He, J. Alloy. Compd. 688, 639 (2016)

Q.K. Zhang, Z.F. Zhang, Mater. Sci. Eng. A-Struct. 530, 452 (2011)

F. Li, X. Li, Y. Yan, Fail. Anal. Prev. 1, 23 (2008)

L. Yang, L. Zhu, Y. Zhang, S. Zhou, Y. Xiong, P. Wu, Mater. Res. Express. 5, 1 (2018)

H.P.R. Frederikse, R.J. Fields, A. Feldman, J. Appl. Phys. 72, 2879 (1992)

K.N. Tu, U. Gösele, Appl. Phys. Lett. 86, 093111 (2005)

Y. Bao, A. Wu, H. Shao, J. Mater. Sci-Mater. El 29, 10246 (2018)

A. Paul, C. Ghosh, W.J. Boettinger, Metall. Mater. Trans. A. 42, 952 (2011)

M.J.M. Hermans, M.H. Biglari, The ELFNET Book on Failure Mechanisms, Testing Methods, and Quality Issues of Lead-Free Solder Interconnects (Verlag London Limited, Springer, 2011), pp. 105–122

H. Sun, Q. Li, Y.C. Chan, J. Mater, Sci-Mater. El. 25, 4380 (2014)

P. Liu, P. Yao, J. Liu, J. Alloy. Compd. 486, 474 (2009)

C. Yu, Y. Yang, K. Wang, J. Xu, J. Chen, H. Lu, J. Mater. Sci-Mater. El. 23, 124 (2012)

H.T. Lee, M.H. Chen, H.M. Jao, T.L. Liao, Mat. Sci. Eng. A-Struct. 358, 134 (2003)

J. Lau, S. Erasmus and S. Pan, in 52nd Electronic Components and Technology Conference (2002), pp. 992–1000

Acknowledgements

This work is supported by the National Natural Science Foundation of China (Grant No. 51865006), Natural Science Foundation of the Jiangsu Higher Education Institutions of China (Grant Nos. 19KJA430001 and 18KJA460001), and Guangxi Natural Science Foundation Project (Grant No. 2020GXNSFAA297004).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We declare that we do not have any commercial or associative interest that represents a conflict of interest in connection with the work submitted.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, L., Xu, Y., Zhang, Y. et al. Effect of bonding time on the microstructure and shear property of Cu/SAC-15Ag/Cu 3D package solder joint fabricated by TLP. J Mater Sci: Mater Electron 32, 8387–8395 (2021). https://doi.org/10.1007/s10854-021-05434-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-05434-3