Abstract

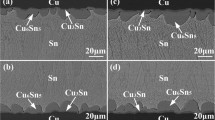

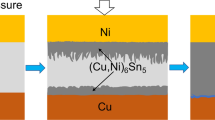

In this paper, the electric current density of 1.44 × 104 A cm−2 was imposed to assemble Cu/(30μm) Sn/Cu interconnection systems without flux at ambient temperature to fabricate Cu–Sn interconnects within 180 ms. From the three-dimensional microstructural observation of interfacial intermetallic compounds (IMCs) at different bonding times, the rod-like Cu6Sn5 formed at the initial stage was changed into dendritic Cu6Sn5 due to constitutional supercooling. When the joule heat-induced temperature was increased above the melting point of Cu6Sn5, the dendritic Cu6Sn5 were melted and then totally converted into Cu3Sn, resulting in the formation of homogeneous Cu3Sn intermetallic joints. The ultrarapid microstructure evolution of the interfacial IMCs was caused by enhanced solid–liquid interdiffusion kinetics, which can be attributed to the joule heating effect as well as the solid–liquid electromigration of Cu in molten Sn with the passage of electric current. In addition, the mechanical analysis shows that the microstructure changes of interfacial IMCs can strongly influence the shear strength as well as the fracture mechanism of the resulted joints. The dendritic network of Cu–Sn IMCs enhanced the shear strength of resulted joints due to the interlocking effect, meanwhile, the homogeneous Cu3Sn joint exhibited the highest shear strength of 67.3 MPa.

Similar content being viewed by others

References

Xiao G, Yang X, Yuan G, Li Z, Shu X (2015) Mechanical properties of intermetallic compounds at the Sn–3.0Ag–0.5Cu/Cu joint interface using nanoindentation. Mater Des 88:520–527

Goh Y, Haseeb A, Liew HL, Sabri MFM (2015) Deformation and fracture behaviour of electroplated Sn–Bi/Cu solder joints. J Mater Sci 50:4258–4269. doi:10.1007/s10853-015-8978-0

Zhong WH, Chan YC, Wu BY, Alam MO, Guan JF (2007) Multiple reflow study of ball grid array (BGA) solder joints on Au/Ni metallization. J Mater Sci 42:5239–5247. doi:10.1007/s10853-006-1234-x

Chiu WL, Liu CM, Haung YS, Chen C (2014) Formation of nearly void-free Cu3Sn intermetallic joints using nanotwinned Cu metallization. Appl Phys Lett 104:171902

Hsiao HY, Liu CM, Lin HW, Liu TC, Lu CL, Huang YS, Chen C, Tu K (2012) Unidirectional growth of microbumps on (111)-oriented and nanotwinned copper. Science 336:1007–1010

Huang M, Yang F (2014) Size effect model on kinetics of interfacial reaction between Sn−xAg−yCu solders and Cu substrate. Sci Rep 4:7117

Chen C, Yu D, Chen KN (2015) Vertical interconnects of microbumps in 3D integration. MRS Bull 40:257–263

Mo L, Chen Z, Wu F, Liu C (2015) Microstructural and mechanical analysis on Cu–Sn intermetallic micro-joints under isothermal condition. Intermetallics 66:13–21

Choudhury SF, Ladani L (2016) Miniaturization of micro-solder bumps and effect of IMC on stress distribution. J Electron Mater 45:3683–3694

Choudhury SF, Ladani L (2015) Effect of intermetallic compounds on the thermomechanical fatigue life of three-dimensional integrated circuit package microsolder bumps: finite element analysis and study. J Electron Packag 137:041003

Choudhury SF, Ladani L (2016) Local shear stress-strain response of Sn–3.5Ag/Cu solder joint with high fraction of intermetallic compounds: experimental analysis. J Alloy Compd 680:665–676

Yang M, Li M, Wang L, Fu Y, Kim J, Weng L (2011) Cu6Sn5 morphology transition and its effect on mechanical properties of eutectic Sn–Ag solder joints. J Electron Mater 40:176–188

Mohd Salleh MAA, McDonald SD, Yasuda H, Sugiyama A, Nogita K (2015) Rapid Cu6Sn5 growth at liquid Sn/solid Cu interfaces. Scr Mater 100:17–20

Yu HB, Sun Y, Alpay S, Aindow M (2016) Solidification microstructures in Ag3Sn–Cu3Sn pseudo-binary alloys. J Mater Sci 51:6474–6487. doi:10.1007/s10853-016-9947-y

Xia Y, Xie X, Lu C (2006) Intermetallic compounds evolution between lead-free solder and cu-based lead frame alloys during isothermal aging. J Mater Sci 41:2359–2364. doi:10.1007/s10853-006-4501-y

Li M, Li Z, Xiao Y, Wang C (2013) Rapid formation of Cu/Cu3Sn/Cu joints using ultrasonic bonding process at ambient temperature. Appl Phys Lett 102:094104

Li Z, Li M, Xiao Y, Wang C (2014) Ultrarapid formation of homogeneous Cu6Sn5 and Cu3Sn intermetallic compound joints at room temperature using ultrasonic waves. Ultrason Sonochem 21:924–929

Cheng HC, Yu CF, Chen WH (2012) Strain- and strain-rate-dependent mechanical properties and behaviors of Cu3Sn compound using molecular dynamics simulation. J Mater Sci 47:3103–3114. doi:10.1007/s10853-011-6144-x

Li J, Agyakwa P, Johnson C (2011) Interfacial reaction in Cu/Sn/Cu system during the transient liquid phase soldering process. Acta Mater 59:1198–1211

Zhang R, Tian Y, Hang C, Liu B, Wang C (2013) Formation mechanism and orientation of Cu3Sn grains in Cu–Sn intermetallic compound joints. Mater Lett 110:137–140

Hang C, Tian Y, Zhang R, Yang D (2013) Phase transformation and grain orientation of Cu–Sn intermetallic compounds during low temperature bonding process. J Mater Sci 24:3905–3913. doi:10.1007/s10854-013-1337-5

Ji H, Qiao Y, Li M (2015) Rapid formation of intermetallic joints through ultrasonic-assisted die bonding with Sn–0.7 Cu solder for high temperature packaging application. Scripta Mater 110:19–23

Ma H, Kunwar A, Sun J, Guo B, Ma H (2015) In situ study on the increase of intermetallic compound thickness at anode of molten tin due to electromigration of copper. Scr Mater 107:88–91

Gu Y, Shen P, Yang NN, Cao KZ (2014) Effects of direct current on the wetting behavior and interfacial morphology between molten Sn and Cu substrate. J Alloy Compd 586:80–86

Liu C, Hu Y, Liu Y, Tseng H, Huang T, Lu C, Chuang Y, Cheng S (2013) Epitaxial Cu–Sn bulk crystals grown by electric current. Acta Mater 61:5713–5719

Huang J, Tsai C, Lin Y, Kao C (2008) Pronounced electromigration of Cu in molten Sn-based solders. J Mater Res 23:250–257

Huang ML, Zhou Q, Zhao N, Liu XY, Zhang ZJ (2014) Reverse polarity effect and cross-solder interaction in Cu/Sn–9Zn/Ni interconnect during liquid-solid electromigration. J Mater Sci 49:1755–1763. doi:10.1007/s10853-013-7862-z

Zhou Y, Gorman P, Tan W, Ely K (2000) Weldability of thin sheet metals during small-scale resistance spot welding using an alternating-current power supply. J Electron Mater 29:1090–1099

Tan W, Zhou Y, Kerr H, Lawson S (2004) A study of dynamic resistance during small scale resistance spot welding of thin Ni sheets. J Phys D Appl Phys 37:1998

Munir ZA, Quach DV, Ohyanagi M (2011) Electric current activation of sintering: a review of the pulsed electric current sintering process. J Am Ceram Soc 94:1–19

Munir Z, Anselmi TU, Ohyanagi M (2006) The effect of electric field and pressure on the synthesis and consolidation of materials: a review of the spark plasma sintering method. J Mater Sci 41(3):763–777. doi:10.1007/s10853-006-6555-2

Ke JH, Chuang HY, Shih WL, Kao CR (2012) Mechanism for serrated cathode dissolution in Cu/Sn/Cu interconnect under electron current stressing. Acta Mater 60:2082–2090

Liu C, Chen J, Chuang Y, Ke L, Wang S (2007) Electromigration-induced Kirkendall voids at the Cu/Cu3Sn interface in flip-chip Cu/Sn/Cu joints. Appl Phys Lett 90:2114

Wang YW, Lin YW, Kao CR (2009) Kirkendall voids formation in the reaction between Ni-doped SnAg lead-free solders and different Cu substrates. Microelectron Reliab 49:248–252

Knödler H (1957) Der strukturelle Zusammenhang zwischen γ-und ε-Phase im System Kupfer-Zinn. Acta Crystallogr 10:86–87

Kim H, Tu K (1996) Kinetic analysis of the soldering reaction between eutectic SnPb alloy and Cu accompanied by ripening. Phys Rev B 53:16027

Zou HF, Yang HJ, Zhang ZF (2008) Morphologies, orientation relationships and evolution of Cu6Sn5 grains formed between molten Sn and Cu single crystals. Acta Mater 56:2649–2662

Tian Y, Zhang R, Hang C, Niu L, Wang C (2014) Relationship between morphologies and orientations of Cu6Sn5 grains in Sn3.0 Ag0.5 Cu solder joints on different Cu pads. Mater Charact 88:58–68

Reed T, LaFleur W (1964) Constitutional supercooling in iodine vapor crystal growth. Appl Phys Lett 5:191–193

Jackson KA (2004) Constitutional supercooling surface roughening. J Cryst Growth 264:519–529

Ben JE, Garik P (1990) The formation of patterns in non-equilibrium growth. Nature 343:523–530

Tiller WA, Jackson KA, Rutter JW, Chalmers B (1953) The redistribution of solute atoms during the solidification of metals. Acta Mater 1:428–437

Cheng T (2000) The mechanism of grain refinement in TiAl alloys by boron addition-an alternative hypothesis. Intermetallics 8:29–37

Xian JW, Belyakov SA, Britton TB, Gourlay CM (2015) Heterogeneous nucleation of Cu6Sn5 in Sn–Cu–Al solders. J Alloy Compd 619:345–355

Zhao J, Cheng CQ, Qi L, Chi CY (2009) Kinetics of intermetallic compound layers and shear strength in Bi-bearing SnAgCu/Cu soldering couples. J Alloy Compd 473:382–388

Pang HLJ, Tan KH, Shi XQ, Wang ZP (2001) Microstructure and intermetallic growth effects on shear and fatigue strength of solder joints subjected to thermal cycling aging. Mat Sci Eng A-Struct 307:42–50

Man HC, Zhao NQ (2006) Enhancing the adhesive bonding strength of NiTi shape memory alloys by laser gas nitriding and selective etching. Appl Surf Sci 253:1595–1600

Man H, Zhao N, Cui Z (2005) Surface morphology of a laser surface nitrided and etched Ti-6Al-4 V alloy. Surf Coat Tech 192:341–346

Mei Z, Sunwoo A, Morris J (1992) Analysis of low-temperature intermetallic growth in copper-tin diffusion couples. Metall Mater Trans A 23:857–864

Lee HT, Chen MH, Jao HM, Liao TL (2003) Influence of interfacial intermetallic compound on fracture behavior of solder joints. Mat Sci Eng A-Struct 358:134–141

Acknowledgements

The authors are grateful for financial support from the National Natural Science Foundation of China (Grant No. 51522503) and support from Program for New Century Excellent Talents in University (NCET-13-0175).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Liu, B., Tian, Y., Feng, J. et al. Enhanced shear strength of Cu–Sn intermetallic interconnects with interlocking dendrites under fluxless electric current-assisted bonding process. J Mater Sci 52, 1943–1954 (2017). https://doi.org/10.1007/s10853-016-0483-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0483-6