Abstract

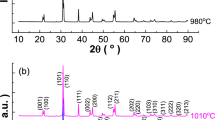

In this work, by an aqueous suspension milling process, boric acid (H3BO3), calcium hydroxide [Ca(OH)2], strontium carbonate (SrCO3) and barium hydroxide octahydrate [Ba (OH)2·8H2O] are mixed with strontium carbonate (SrCO3) and kaolin (Al2O3·2SiO2·2H2O) to prepare SrAl2Si2O8 ceramics with a sintering temperature of 950 °C. According to chemical compositions of flux agents B2O3, CaO·2B2O3, SrO·2B2O3 and BaO·2B2O3, raw materials boric acid, calcium hydroxide, strontium carbonate and barium hydroxide octahydrate were introduced to the suspension slurries of strontium carbonate and kaolin to decrease the densification sintering temperature of SrAl2Si2O8 ceramics. In addition, the Sr element in SrAl2Si2O8 ceramics are partly substituted with Ba and Ca elements, respectively, to investigate the low-temperature sintering behavior of partly substituted SrAl2Si2O8 ceramics. The results indicated that the addition of flux agents to SrAl2Si2O8 ceramics can availably achieve the densification sintering of SrAl2Si2O8 ceramics at 950 °C, whereas the substitution of Sr with Ca or Ba have a great effect on sintering behaviors and dielectric properties of SrAl2Si2O8 ceramics. Additionally, main crystal phases of the SrAl2Si2O8 ceramics are monoclinic- SrAl2Si2O8 and small quartz, but the evolution of crystal phases also depend on flux agents.

Similar content being viewed by others

References

H. Yu, J. Liu, W. Zhang, S. Zhang, Ultra-low sintering temperature ceramics for LTCC applications: a review. J. Mater. Sci. Mater. Electron. 26, 9414–9423 (2015)

G. Dou, M. Guo, Y. Li, J. Lin, Effects of low melting point materials on sinterability and microwave dielectric properties of X2SiO4–CaTiO3 (X=Mg, Zn) for LTCC. J. Mater. Sci. Mater. Electron. 26, 9195–9199 (2015)

L.A. Orlova, N.V. Popovich, N.E. Uvarova, A. Paleari, P.D. Sarkisov, High-temperature resistant glass-ceramics based on Sr-anorthite and tialite phase. Ceram. Int. 38, 6629–6634 (2012)

M.M. Krzmanc, M. Valant, D. Suvorov, The synthesis and microwave dielectric properties of Sr x Ba1−x Al2Si2O8 and CayBa1−y Al2Si2O8 ceramics. J. Eur. Ceram. Soc. 27, 1181–1185 (2007)

D. Long-Gonzalez, J. Lopez-Cuevas, C.A. Gutierrez-Charria, P. Pena, C. Baudin, X. Turrillas, Synthesis of monoclinc celsian from coal fly ash by using a one-step solid-state reaction process. Ceram. Int. 36, 661–672 (2010)

C.M. Lopez, J. Lopez-Cuevas, J.L. Rodriguez-Galicia, C.A. Gutierrez-Chavarria, M.I. Pech-Canul, Influence of mechanical activation on the synthesis of Sr-Celsian employing a precursor mixture containing coal fly ash. Bol. Soc. Esp. Ceram. Vidr. 52, 98–104 (2013)

Y. Kobayashi, M. Inagaki, Preparation of reactive Sr-celasin powders by solid-state reaction and their sintering. J. Eur. Ceram. Soc. 24, 399–404 (2004)

T. Matsumoto, Y. Goto, Formation process of Sr-celsian from precursor zeolites. J. Ceram. Soc. Jpn. 117, 748–752 (2009)

S. Rajesh, H. Jantunen, M. Letz, Low temperature sintering and dielectric properties of alumina-filled glass composites for LTCC applications. Int. J. Appl. Ceram. Technol. 9, 52–59 (2012)

R.E. Chinn, M.J. Haun, C.Y. Kim, D.B. Price, Low-temperature transient glass-phase processing of monoclinic SrAl2Si2O8. J. Am. Ceram. Soc. 81, 2285–2293 (1998)

S. Chen, D.G. Zhu, X.S. Cai, Low-temperature densification sintering and properties of monoclinic-SrAl2Si2O8 ceramics. Metall. Mater. Trans. A 45, 3995–4001 (2014)

K. Sumi, Y. Kobayashi, E. Kato, Low-temperature fabrication of cordierite ceramics from kaolinite and magnesium hydroxide mixtures with boron oxide additions. J. Am. Ceram. Soc. 82, 783–785 (1999)

S.D. Ross, Barium borate preparation. United States Patent (patent number: 4,897,249) (1990)

S. Chen, D.G. Zhu, P.Q. Sun, H.L. Sun, Sintering behavior and dielectric properties of SrB2Si2O8 ceramics. J. Mater. Sci. Mater. Electron. 24, 4593–4599 (2013)

E.M. Levin, H.F. McMurdie, in Phase diagrams for ceramists, ed. by M.K. Reser (The Aercian Ceramic Society, Columbus, 1956)

H. Witzmann, G. Herzog, Luminescence-optical behavior of alkaline earth borate luminophors. Z. Phys. Chem. 225, 197–208 (1964)

S. Chen, D. Zhu, Phase formation and properties of the BaO–B2O3–SiO2 and –Al2O3 Ceramics prepared via an aqueous suspension rout. J. Alloy Compd. 536, 73–79 (2012)

A.B. Meshalkin, A.B. Kaplun, Study of phase equilibria in system BaO–B2O3 from 32 to 67 mol% B2O3. J. Cryst. Growth 275, e301–e305 (2005)

D.N. Yoon, W.J. Huppmann, Grain growth and densification during liquid phase sintering of W-Ni. Acta Metall. 27, 693–6981 (1979)

C. Ferone, B. Liguori, A. Marocco, S. Anaclerio, M. Pansini, C. Colella, Monoclinic (Ba, Sr)-celsian by thermal treatment of (Ba, Sr)-exchanged zeolite A. Microporous Mesoporous Mater. 134, 65–71 (2010)

Acknowledgments

The researches are supported by the Fundamental Research Funds for the Central Universities from the Government of the People’s Republic of China (Grant No. A0920502051513-5).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, S., Zhu, Dg. Low-temperature sintering behavior and properties of monoclinic-SrAl2Si2O8 ceramics prepared via an aqueous suspension milling process. J Mater Sci: Mater Electron 27, 11127–11136 (2016). https://doi.org/10.1007/s10854-016-5230-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-016-5230-x