Abstract

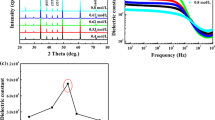

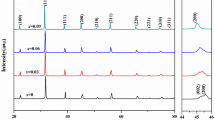

Bi4Ti3O12 (BTO) materials were prepared by the sol–gel method via the acetic acid method (AAM) or the ethylene glycol method (EGM). BTO powders prepared by EGM are composed of the main phase without purity phases when annealed at 650 °C. BTO powders prepared by AAM are composed of the main phase without secondary phases when annealed at 625 °C. BTO ceramics prepared by AAM have denser microstructure and greater grain size than those prepared by EGM. BTO ceramics prepared by two methods exhibit well typical P–E loops for ferroelectrics. The remnant polarization of BTO ceramics prepared by AAM is greater than those prepared by EGM. And the coercive field and dielectric loss of BTO ceramics prepared by AAM are smaller than those prepared by EGM. BTO ceramics prepared by AAM have better ferroelectric and dielectric properties than those prepared by EGM.

Similar content being viewed by others

References

M.Y. Deng, X.L. Li, Z.H. Zhao, T. Li, Y.J. Dai, H.M. Ji, J. Mater. Sci. Mater. El. 25, 1873–1879 (2014)

J.Y. Chen, Y. Qi, W. Gao, Y.L. Bai, C.H. Nie, S.F. Zhao, Mater. Lett. 136, 11–14 (2014)

X.S. Lv, C.P. Cheng, Y.G. Xiao, M.H. Tang, Z.H. Tang, H.Q. Cai, Y.C. Zhou, R.W. Li, Mater. Lett. 100, 7–10 (2013)

K. Drogowska, S. Flege, D. Rogalla, H.W. Becker, E. Lonescu, N.T.H. Kim-Ngan, A.G. Balogh, Solid State Ion. 235, 32–35 (2013)

P.E. Janolin, J. Mater. Sci. 44, 5025–5048 (2009)

Q.H. Deng, Y.C. Fan, L.J. Wang, Z. Xiong, H.Z. Wang, Y.G. Li, Q.H. Zhang, A. Kawasaki, W. Jiang, Jpn. J. Appl. Phys. 51(1R), 011501 (2012)

K.P. Chen, F.L. Zhang, J.Q. Zhou, X.W. Zhang, C.W. Li, L.A. An, Ceram. Int. 41, 10232–10236 (2015)

P.K. Panda, Review: environmental friendly lead-free piezoelectric materials. J. Mater. Sci. 44, 5049–5062 (2009)

J. Rodel, W. Jo, K.T.P. Seifert, E.M. Anton, T. Granzow, D. Damjanovic, J. Am. Ceram. Soc. 92, 1153–1177 (2009)

J. Roedel, K.G. Webber, R. Dittmer, W. Jo, M. Kimura, D. Damjanovic, J. Eur. Ceram. Soc. 35, 1659–1681 (2015)

K. Kumar, N. Sinha, S. Bhandari, B. Kumar, Ceram. Int. 41, 10237–10242 (2015)

T. Takenaka, H. Nagata, J. Eur. Ceram. Soc. 25, 2693–2700 (2005)

T.P. Gujar, V.R. Shinde, S.S. Kulkarni, H.M. Pathan, C.D. Lokhande, Appl. Surf. Sci. 252, 3585–3590 (2006)

S.H. Jo, S.G. Lee, S.H. Lee, Mater. Res. Bull. 47, 409–412 (2012)

S.C. Yang, A. Kumar, V. Petkov, S. Priya, J. Appl. Phys. 113, 144101 (2013)

R.F. Zhang, C.Y. Deng, L. Ren, Z. Li, J.P. Zhou, J. Electron. Mater. 43, 1043–1047 (2014)

A.I. Ali, K. Park, A. Ullah, R. Huh, Y.S. Kim, Thin Solid Films 551, 127–130 (2014)

V.S. Puli, D.K. Pradhan, D.B. Chrisey, M. Tomozawa, G.L. Sharma, J.F. Scott, R.S. Katiyar, J. Mater. Sci. 48, 2151–2157 (2013)

R.A. Bucur, I. Badea, A.I. Bucur, S. Novaconi, J. Alloy. Compd. 630, 43–47 (2015)

J. Schiemer, R.L. Withers, Y. Liu, Z.G. Yi, J. Solid State Chem. 195, 55–62 (2012)

B.C. Sun, H. Wang, J.W. Xu, L. Yang, S.J. Zhou, Y.P. Zhang, Z.D. Li, Microelectron. Eng. 113, 1–4 (2014)

D. Thomazini, M.V. Gelfuso, J.A. Eiras, Powder Technol. 222, 139–142 (2012)

M. Roy, I. Bala, S.K. Barbar, S. Jangid, P. Dave, J. Phys. Chem. Solids 72, 1347–1353 (2011)

V.B.D. Santos, J.C.M. Peko, V.R. Mastelaro, J. Alloy. Compd. 510, 60–65 (2012)

M. Aghayan, A.K. Zak, M. Behdani, A.M. Hashim, Ceram. Int. 40, 16141–16146 (2014)

S. Sharma, K. Shamim, A. Ranjan, R. Rai, P. Kumari, S. Sinha, Ceram. Int. 41, 7713–7722 (2015)

P. Zheng, J. Zhang, Y. Tan, C. Wang, Acta Mater. 60, 5022–5030 (2012)

C. Chen, H.R. Zhuang, X.N. Zhu, K.C. Zhou, D. Zhang, Ceram. Int. 41, 9893–9898 (2015)

M. Chandraiah, P.K. Panda, Ceram. Int. 41, 8040–8045 (2015)

Y. Zhang, L.Q. Wang, D.F. Xue, Powder Technol. 217, 629–633 (2012)

T. Wei, C.Z. Zhao, C.P. Li, Y.B. Lin, X. Yang, H.G. Tan, J. Alloy. Compd. 577, 728–733 (2013)

C.S. Chou, R.Y. Yang, J.H. Chen, S.W. Chou, Powder Technol. 199, 264–271 (2010)

Z.H. Peng, Q. Chen, Y. Chen, D.Q. Xiao, J.G. Zhu, Mater. Res. Bull. 59, 125–130 (2014)

Z.H. Chen, J.F. Qiu, C. Liu, J.N. Ding, Y.Y. Zhu, Ceram. Int. 36, 241–244 (2010)

R. Bokolia, O.P. Thakur, V.K. Rai, S.K. Sharma, K. Sreenivas, Ceram. Int. 41, 6055–6066 (2015)

W.F. Liu, X.B. Ren, Phys. Rev. Lett. 103, 257602 (2009)

P. Wang, Y.X. Li, Y.Q. Lu, J. Eur. Ceram. Soc. 31, 2005–2012 (2011)

D.Z. Xue, Y.M. Zhou, H.X. Bao, C. Zhou, J.H. Gao, X.B. Ren, J. Appl. Phys. 109, 054110 (2011)

J.P. Praveen, T. Karthik, A.R. James, E. Chandrakala, S. Asthana, D. Das, J. Eur. Ceram. Soc. 35, 1785–1798 (2015)

G.B. Kumar, S. Buddhudu, Ceram. Int. 36, 1857–1861 (2010)

Z.C. Ling, H.R. Xia, W.L. Liu, H. Han, X.Q. Wang, S.Q. Sun, D.G. Ran, L.L. Yu, Mater. Sci. Eng. B 128, 156–160 (2006)

B.A. Golda, A. Marikan, D.P. Padiyan, Ceram. Int. 37, 3731–3735 (2011)

Y. Zhang, H.J. Sun, W. Chen, Ceram. Int. 41, 8520–8532 (2015)

J.G. Hao, W.F. Bai, W. Li, J.W. Zhai, J. Am. Ceram. Soc. 95, 1998–2006 (2012)

H.Y. Park, J.Y. Choi, M.K. Choi, K.H. Cho, S. Nahm, H.G. Lee, H.W. Kang, J. Am. Ceram. Soc. 91, 2374–2377 (2008)

H.Y. Park, C.W. Ahn, K.H. Cho, S. Nahm, H.G. Lee, H.W. Kang, D.H. Kim, K.S. Park, J. Am. Ceram. Soc. 90, 4066–4069 (2007)

M. Jiang, Q. Lin, D.M. Lin, Q.J. Zheng, X.M. Fan, X.C. Wu, H.L. Sun, Y. Wan, L. Wu, J. Mater. Sci. 48, 1035–1041 (2013)

C.C. Leu, C.Y. Chen, C.H. Chien, M.N. Chang, F.Y. Hsu, C.T. Hu, Appl. Phys. Lett. 82, 3493–3495 (2003)

Acknowledgments

This work was supported by Anhui Provincial Natural Science Foundation (1308085ME59), Nippon Sheet Glass Foundation for Materials Science and Engineering of Japan (2012QTXM0079), the National Natural Science Foundation of China (51272060, 51472069).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shi, M., Shi, Y., Zuo, R. et al. Microstructure, ferroelectric and dielectric proprieties of Bi4Ti3O12 materials prepared by two methods. J Mater Sci: Mater Electron 27, 3361–3367 (2016). https://doi.org/10.1007/s10854-015-4166-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-015-4166-x