Abstract

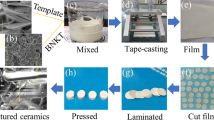

0.85Na0.5Bi0.5TiO3–0.04BaTiO3–0.11K0.5Bi0.5TiO3 (BNBK) lead-free piezoelectric ceramics with extensive [001]pc (pc: pseudo cubic) texture were fabricated by the reactive-templated grain growth method using anisotropic Bi4Ti3O12 (BIT) particles as templates. The degree of grain orientation increased with increasing heat treatment temperature (600–1,200 °C). The obtained textured ceramics showed dense and brick-wall like microstructure, giving a Lotgering factor of 0.6. A physical understanding of interaction between BIT templates and matrix powders and the mechanism of texture evolution were proposed and confirmed by experimental evidences of X-ray diffraction patterns, scanning electron microscope images and density measurements. The piezoelectric response was enhanced by the grain orientation, and the piezoelectric constant (d33) of the textured ceramics sintered at 1,170 °C attained a value of 254 pC/N, which was 41 % higher than random ceramics (180 pC/N).

Similar content being viewed by others

References

Y. Saito, H. Takao, T. Tani, T. Nonoyama, K. Takatori, T. Homma, T. Nagaya, M. Nakamura, Nature 432, 84–87 (2004)

T.R. Shrout, S.J. Zhang, J. Electroceram. 19, 113–126 (2007)

Z.Y. Shen, Y.M. Li, L. Jiang, R.R. Li, Z.M. Wang, Y. Hong, R.H. Liao, J. Mater. Sci. Mater. Electron. 22, 1071–1075 (2011)

G.Z. Zang, X.J. Yi, J. Du, Z.J. Xu, R.Q. Chu, P. Fu, W. Li, J. Mater. Sci. Mater. Electron. 22, 1282–1285 (2011)

J. Roedel, W. Jo, K.T.P. Seifert, E.M. Anton, J. Am. Ceram. Soc. 92, 1153–1177 (2009)

Y. Saito, H. Takao, J. Korean Phys. Soc. 51, 790–797 (2007)

F. Gao, C.S. Zhang, X.C. Liu, L.H. Cheng, C.S. Tian, J. Eur. Ceram. Soc. 27, 3453–3458 (2007)

F. Gao, X.C. Liu, C.S. Zhang, L.H. Cheng, C.S. Tian, Ceram. Int. 34, 403–408 (2008)

Y.K. Yan, H.P. Zhou, W. Zhao, D. Liu, J. Electroceram. 21, 246–250 (2008)

D. Maurya, A. Pramanick, K. An, S. Priya, Appl. Phys. Lett. 100, 172906 (2012)

H. Nagata, M. Yoshida, Y. Makiuchi, T. Takenaka, Jpn. J. Appl. Phys. 42, 7401–7403 (2003)

Y. Makiuchi, R. Aoyagi, Y. Hiruma, H. Nagata, T. Takenaka, Jpn. J. Appl. Phys. 44, 4350–4353 (2005)

S.J. Zhang, T.R. Shrout, H. Nagata, Y. Hiruma, T. Takenaka, IEEE T. Ultrason. Ferr. 54, 910–917 (2007)

J.F. Trelcat, C. Courtois, M. Rguiti, A. Leriche, P.H. Duvigneaud, T. Segato, Ceram. Int. 38, 2823–2827 (2012)

X.X. Wang, X.G. Tang, H.L.W. Chan, Appl. Phys. Lett. 85, 91–93 (2004)

S.T. Zhang, B. Yang, W.W. Cao, Acta Mater. 60, 469–475 (2012)

Y.J. Dai, X.W. Zhang, K.P. Chen, Int. J Appl. Ceram. Tec. 8, 423–429 (2011)

Y.J. Dai, S.J. Zhang, T.R. Shrout, X.W. Zhang, J. Am. Ceram. Soc. 93, 1108–1113 (2010)

T. Sun, Y.J. Dai, H.Q. Wang, Key Eng. Mater. 512–515, 1355–1358 (2012)

D. Maurya, Y. Zhou, Y.K. Yan, S. Priya, J. Mater. Chem. C 1, 2102–2111 (2013)

X.H. Du, J.H. Zheng, U. Belegundu, K. Uchino, Appl. Phys. Lett. 72, 2421–2423 (1998)

F.K. Lotgering, J. Inorg. Nucl. Chem. 9, 113–123 (1959)

Y.M. Kan, P.L. Wang, Y.X. Li, Y.B. Cheng, D.S. Yan, J. Eur. Ceram. Soc. 23, 2163–2169 (2003)

T. Takenaka, K. Maruyama, K. Sakata, Jpn. J. Appl. Phys. 30, 2236–2239 (1991)

W.F. Bai, J.G. Hao, F. Fu, W. Li, B. Shen, J.W. Zhai, Mater. Lett. 97, 137–140 (2013)

W. Zhao, J. Ya, Y. Xin, L.E.D. Zhao, H.P. Zhou, J. Am. Ceram. Soc. 92, 1607–1609 (2009)

T. Watanabe, H. Funakubo, M. Osada, Y. Noguchi, M. Miyayama, Appl. Phys. Lett. 80, 100–102 (2002)

Acknowledgments

This work was supported by funding from the National Natural Science Foundation of China (51208357).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Deng, M., Li, X., Zhao, Z. et al. Crystallographic textured evolution in 0.85Na0.5Bi0.5TiO3–0.04BaTiO3–0.11K0.5Bi0.5TiO3 ceramics prepared by reactive-templated grain growth method. J Mater Sci: Mater Electron 25, 1873–1879 (2014). https://doi.org/10.1007/s10854-014-1813-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-014-1813-6