Abstract

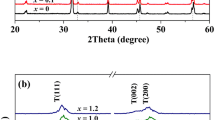

Ba0.85Ca0.15Ti0.90Zr0.10O3 + xmol% MnO2 lead-free ceramics have been prepared by a conventional sintering method and the effects of MnO2 and sintering temperature on microstructure, ferroelectric, and piezoelectric properties of Ba0.85Ca0.15Ti0.90Zr0.10O3 lead-free ceramics have been studied. The addition of 0.25 mol% MnO2 promotes grain growth, improves the ferroelectricity of the ceramics and strengthens ferroelectric tetragonal–ferroelectric orthorhombic phase transition near 40 °C. Because of the coexistence of tetragonal and orthorhombic phases and the combinatory effects of soft and hard doping of Mn ions, the ceramic with x = 0.25 exhibits the optimum piezoelectric properties (d 33 = 306 pC/N and k p = 42.2 %, respectively). Excess MnO2 inhibits the grain growth and degrades the ferroelectric and piezoelectric properties of the ceramics. Sintering temperature has an important influence on the microstructure, tetragonal–orthorhombic phase transition near 40 °C, ferroelectric and piezoelectric properties of the ceramics. The increase in sintering temperature leads to large grains and more noticeable tetragonal–orthorhombic phase transition near 40 °C, enhances ferroelectricity and thus improves effectively the piezoelectricity of the ceramics. The Ba0.85Ca0.15Ti0.90Zr0.10O3 ceramic sintered at 1350 °C possesses the optimum piezoelectric constant d 33 value of 373 pC/N.

Similar content being viewed by others

References

Kuang SJ, Tang XG, Li LY, Jiang YP, Liu QX (2009) Scr Mater 61:68

Wei X, Wan X, Xi Y (2008) J Electroceram 21:226

Haertiling GH (1999) J Am Ceram Soc 82:797

Bechmann R (1956) J Acoust Soc Am 28:347

Liu W, Ren X (2009) Phys Rev Lett 103:257602

Li W, Xu Z, Chu R, Fu P, Zang G (2010) Mater Lett 64:2325

Zhang SW, Zhang HL, Zhang BP, Yang S (2010) J. Alloys Compd 506:131

Wu J, Xiao D, Wu W, Chen Q, Zhu J, Yang Z, Wang J (2011) Scr Mater 65:771

Li W, Xu Z, Chu R, Fu P, Zang G (2011) Mater Sci Eng, B 176:65

Wang P, Li Y, Lu Y (2011) J Eur Ceram Soc 31:2005

Wu J, Xiao D, Wu W, Zhu J, Wang J (2011) J Alloys Compd 509:L359

Su S, R. Zuo Z, Lu SB, Xu ZK, Wang XH, Li LT (2011) Curr Appl Phys 11:120–121

Li G, Zheng L, Yin Q (2005) J Appl Phys 98:064108

Hou Y, Zhu M, Gao F, Wang H, Wang B, Yan H, Tian C (2004) J Am Ceram Soc 87:847

Yu CS, Hsieh HL (2005) J Eur Ceram Soc 25:2425

Li SM, Lee SH, Yoon CB, Kim HE, Lee KW (2007) J Electroceram 18:311

Yan Y, Cho KH, Priya S (2011) J Am Ceram Soc 94:3953

Mgbemere HE, Herber RP, Schneider GA (2009) J Eur Ceram Soc 29:1729

Nagata H, Takenaka T (2001) J Eur Ceram Soc 21:1299

Fan X, Wang Y, Jiang Y (2011) J Alloys Compd 509:6652

Qiao L, Bi X (2009) J Eur Ceram Soc 29:1995

Buixaderas E, Bovtun V, Kempa M, Savinov M, Nuzhnyy D, Kadlec F, Vaněk P, Petzelt J, Eriksson M, Shen Z (2010) J Appl Phys 107:014111

Park Y, Lee WJ, Kim HG (1997) J Phys: Condens Matter 9:9445

Chattopadhyay S, Ayyub P, Palkar VR, Multani M (1995) Phys Rev B 52:13177

Damjanovic D, Demartin M (1997) J Phys: Condens Matter 9:4943

Zhang L, Zhong WL, Wang CL, Zhang PL, Wang YG (1998) Phys Stat Sol (a) 168:543

Martirenat HT, Burfoot JC (1974) J Phys C: Solid State Phys 7:1974

Cao W, Randall CA (1996) J Phys Chem Solids 57:1505

Randall CA, Kim N, Kucera JP, Cao W, Shrout TR (1998) J Am Ceram Soc 81:677

Demartin M, Damjanovic D (1996) Appl Phys Lett 68:3046

Damjanovic D (1998) Rep Prog Phys 61:1267

Acknowledgements

This study was supported by the projects of Education Department of Sichuan Province (11ZA104), Science and Technology Bureau of Sichuan Province (2010JQ0046) and the Open Projects of State Key Laboratory Cultivation Base for Nonmetal Composites and Functional Materials of Southwest University of Science and Technology (10zxfk27) and State Key Laboratory of Electronic Thin Films and Integrated Devices of University of Electronic Science and Technology of China (KFJJ201108).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Jiang, M., Lin, Q., Lin, D. et al. Effects of MnO2 and sintering temperature on microstructure, ferroelectric, and piezoelectric properties of Ba0.85Ca0.15Ti0.90Zr0.10O3 lead-free ceramics. J Mater Sci 48, 1035–1041 (2013). https://doi.org/10.1007/s10853-012-6835-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6835-y