Abstract

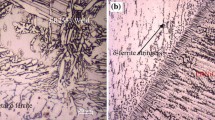

The impact of medium- and high-entropy alloy fillers (4E MEA- Al0.25Fe0.25Ni0.25Cu0.25, and 5E HEA-Al0.20Fe0.20Ni0.20Cu0.20Ti0.20) on the microstructures and corrosion behaviour of AA5083 plates, joined through the GTAW process, is investigated. MEA and HEA fillers were fabricated using the CCW method, and ER5356 filler was used for comparison. This study delves into the alloy fillers’ influence on the resultant microstructural characteristics and corrosion resistance of the welded joints. XRD results on weld samples showcased the presence of FCC and BCC phases. The weldment EBSD data revealed unique grain morphologies: long columnar grains, coarse grains, and fine equiaxed grains in WZ, HAZ, and BM, respectively. Microstructural investigations of the weldment revealed heterogeneous structures with finely distributed grains and strong bonding between the AA5083 base metal and filler wires, influenced by constitutional elements. MEA and HEA weldments showed no intermetallic compounds or precipitates. In the ambient temperature potentiodynamic polarisation test, HEA’s polarisation resistance was 3.76 times greater, while MEA’s was 3.15 times higher than ER5356. The higher corrosion resistance is due to grain refinement, increased grain boundaries, and the formation of a strong passive film. Conversely, in the higher-temperature corrosion experiment, the mass loss for the 5E-HEA and MEA weldments was 4.87 and 3.09 times lower than that of the ER5356 weldments. The corroded surface morphology revealed that the ER5356 weldment had deeper pits, while the MEA and 5E-HEA weldments had pits of smaller sizes. The formation of oxidation film layers on the corroded surface improves the corrosion resistance. X-ray photoelectron spectroscopy (XPS) findings showed metal oxide layer depositions for all the weldments. Researchers observed that equimolar MEA and HEA filler wires can increase durability and be employed in shipbuilding sectors.

Graphical Abstract

Similar content being viewed by others

Code availability

Not applicable.

Abbreviations

- GTAW:

-

Gas Tungsten Arc Welding

- EBSD:

-

Electron Backscatter Diffraction

- 4E MEA:

-

Four Elements Medium-Entropy Alloy

- AFM:

-

Atomic Force Microscopy

- 5E HEA:

-

Five Elements High-Entropy Alloy

- AAs:

-

Aluminium alloys

- CCW:

-

Combined Cable Wire

- XPS:

-

X-ray photoelectron spectroscopy

- XRD:

-

X-ray Diffraction

- SS:

-

Solid Solution

- FCC:

-

Face-Centred Cubic

- WZ:

-

Weld zone

- BCC:

-

Body-Centred Cubic

- HAZ:

-

Heat-Affected Zone

- AAs:

-

Aluminium Alloys

- OES:

-

Optical Emission Spectrometer

- BM:

-

Base Metal

- SEM:

-

Scanning Electron Microscope

- OM:

-

Optical Microstructures

References

Dursun T, Soutis C (2014) Recent developments in advanced aircraft aluminium alloys. Mater Des 56:862–871. https://doi.org/10.1016/j.matdes.2013.12.002

Tamasgavabari R, Ebrahimi AR, Abbasi SM, Yazdipour AR (2020) Effect of harmonic vibration during gas metal arc welding of AA-5083 aluminum alloy on the formation and distribution of intermetallic compounds. J Manuf Process 49:413–422

Krishna K, Sekhar KC, Tejas R, Krishna NN, Sivaprasad K, Narayanasamy R, Venkateswarlu K (2015) Effect of cryorolling on the mechanical properties of AA5083 alloy and the Portevin–Le Chatelier phenomenon. Mater Des 67:107–117

Wahid MA, Siddiquee AN, Khan ZA (2020) Aluminum alloys in marine construction: characteristics, application, and problems from a fabrication viewpoint. Mar Syst Ocean Technol 15:70–80

Akinlabi ET, Osinubi AS, Madushele N, Akinlabi SA, Ikumapayi OM (2020) Data on microhardness and structural analysis of friction stir spot welded lap joints of AA5083-H116. Data Br 33:106585

Zhou L, Hyer H, Park S, Pan H, Bai Y, Rice KP, Sohn Y (2019) Microstructure and mechanical properties of Zr-modified aluminum alloy 5083 manufactured by laser powder bed fusion. Addit Manuf 28:485–496

Donatus U, Thompson GE, Omotoyinbo JA, Alaneme KK, Aribo S, Agbabiaka OG (2017) Corrosion pathways in aluminium alloys. Trans Nonferrous Met Soc China 27:55–62

Krishnamurthy SC, Arseenko M, Kashiwar A, Dufour P, Marchal Y, Delahaye J, Idrissi H, Pardoen T, Mertens A, Simar A (2023) Controlled precipitation in a new Al-Mg-Sc alloy for enhanced corrosion behavior while maintaining the mechanical performance. Mater Charact 200:112886

Esteves L, Witharamage CS, Christudasjustus J, Walunj G, O’Brien SP, Ryu S, Borkar T, Akans RE, Gupta RK (2021) Corrosion behavior of AA5083 produced by high-energy ball milling. J Alloys Compd 857:158268

Tang K, Wei L, Huang H, Wang J, Li D, Jiang H, Zhang W, Liang L, Liu S (2023) Effect of grain size and second phase on the corrosion behavior of MIG-welded Al–Mg–Si–Mn–Cr alloy. J Mater Sci 58(26):10782–10801

Fu ZH, Yang BJ, Shan ML, Li T, Zhu ZY, Ma CP, Zhang X, Gou GQ, Wang ZR, Gao W (2020) Hydrogen embrittlement behavior of SUS301L-MT stainless steel laser-arc hybrid welded joint localized zones. Corros Sci 164:108337. https://doi.org/10.1016/j.corsci.2019.108337

Panchuk M, Sładkowski A, Panchuk A, Semianyk I (2021) New technologies for hull assemblies in shipbuilding, NAŠE MORE Znan. Časopis Za More i Pomor 68:48–57

Lopes JG, Rocha P, Santana DA, Shen J, Maawad E, Schell N, Coury FG, Oliveira JP (2023) Impact of arc-based welding on the microstructure evolution and mechanical properties in newly developed Cr 29.7 Co 29.7 Ni 35.4 Al 4 Ti 1.2 multi-principal element alloy. Adv Eng Mater 25(13):2300109. https://doi.org/10.1002/adem.202300109

Shen J, Agrawal P, Rodrigues TA, Lopes JG, Schell N, He J, Zeng Z, Mishra RS, Oliveira JP (2023) Microstructure evolution and mechanical properties in a gas tungsten arc welded Fe42Mn28Co10Cr15Si5 metastable high entropy alloy. Mater Sci Eng A 867:144722. https://doi.org/10.1016/j.msea.2023.144722

Padmanaban G, Balasubramanian V (2011) Optimization of pulsed current gas tungsten arc welding process parameters to attain maximum tensile strength in AZ31B magnesium alloy. Trans Nonferrous Met Soc China 21:467–476

Prakash C, Singh S, Singh M, Gupta MK, Mia M, Dhanda A (2019) Multi-objective parametric appraisal of pulsed current gas tungsten arc welding process by using hybrid optimization algorithms. Int J Adv Manuf Technol 101:1107–1123

Baskoro AS, Amat MA, Pratama AI, Kiswanto G, Winarto W (2019) Effects of tungsten inert gas (TIG) welding parameters on macrostructure, microstructure, and mechanical properties of AA6063-T5 using the controlled intermittent wire feeding method. Int J Adv Manuf Technol 105:2237–2251

Chen L, Hu YN, He EG, Wu SC, Fu YN (2018) Microstructural and failure mechanism of laser welded 2A97 Al–Li alloys via synchrotron 3D tomography. Int J Light Mater Manuf 1:169–178

Ashkenazi D (2019) How aluminum changed the world: a metallurgical revolution through technological and cultural perspectives. Technol Forecast Soc Change 143:101–113

Liao D, Zhu S-P, Keshtegar B, Qian G, Wang Q (2020) Probabilistic framework for fatigue life assessment of notched components under size effects. Int J Mech Sci 181:105685. https://doi.org/10.1016/j.ijmecsci.2020.105685

Yuhua C, Yuqing M, Weiwei L, Peng H (2017) Investigation of welding crack in micro laser welded NiTiNb shape memory alloy and Ti6Al4V alloy dissimilar metals joints. Opt Laser Technol 91:197–202. https://doi.org/10.1016/j.optlastec.2016.12.028

Zhu Q, Chen J, Gou G, Chen H, Li P (2017) Ameliorated longitudinal critically refracted—attenuation velocity method for welding residual stress measurement. J Mater Process Technol 246:267–275. https://doi.org/10.1016/j.jmatprotec.2017.03.022

Ramkumar KR, Natarajan S (2018) Investigations on microstructure and mechanical properties of TiO2 nanoparticles addition in Al 3003 alloy joints by gas tungsten arc welding. Mater Sci Eng A 727:51–60

Li J, Meng X, Wan L, Huang Y (2021) Welding of high entropy alloys: progresses, challenges and perspectives. J Manuf Process 68:293–331

Shen Q, Kong X, Chen X (2021) Fabrication of bulk Al-Co-Cr-Fe-Ni high-entropy alloy using combined cable wire arc additive manufacturing (CCW-AAM): microstructure and mechanical properties. J Mater Sci Technol 74:136–142

Tsai M-H, Yeh J-W (2014) High-entropy alloys: a critical review. Mater Res Lett 2:107–123

Zhang Y, Jiang X, Fang Y, Fang Y, Liu B, Sun H, Shao Z, Song T (2021) Research and development of welding methods and welding mechanism of high-entropy alloys: a review. Mater Today Commun 28:102503

Li J, Huang Y, Meng X, Xie Y (2019) A review on high entropy alloys coatings: fabrication processes and property assessment. Adv Eng Mater 21:1900343

Praveen S, Kim HS (2018) High-entropy alloys: potential candidates for high-temperature applications–an overview. Adv Eng Mater 20:1700645

Wang Z, Huang Y, Yang Y, Wang J, Liu CT (2015) Atomic-size effect and solid solubility of multicomponent alloys. Scr Mater 94:28–31

Cann JL, De Luca A, Dunand DC, Dye D, Miracle DB, Oh HS, Olivetti EA, Pollock TM, Poole WJ, Yang R (2021) Sustainability through alloy design: challenges and opportunities. Prog Mater Sci 117:100722

Zang C, Rivera P (2022) High entropy alloy strengthening modelling. Model Simul Mater Sci Eng 30(6):063001

Shen J, Lopes JG, Zeng Z, Choi YT, Maawad E, Schell N, Kim HS, Mishra RS, Oliveira JP (2023) Deformation behavior and strengthening effects of an eutectic AlCoCrFeNi2.1 high entropy alloy probed by in-situ synchrotron X-ray diffraction and post-mortem EBSD. Mater Sci Eng A 872:144946. https://doi.org/10.1016/j.msea.2023.144946

Shen J, Zhang W, Lopes JG, Pei Y, Zeng Z, Maawad E, Schell N, Baptista AC, Mishra RS, Oliveira JP (2024) Evolution of microstructure and deformation mechanisms in a metastable Fe42Mn28Co10Cr15Si5 high entropy alloy: A combined in-situ synchrotron X-ray diffraction and EBSD analysis. Mater Des 238:112662. https://doi.org/10.1016/j.matdes.2024.112662

Asadikiya M, Yang S, Zhang Y, Lemay C, Apelian D, Zhong Y (2021) A review of the design of high-entropy aluminum alloys: a pathway for novel Al alloys. J Mater Sci 56:12093–12110

Kumar A, Singh A, Suhane A (2022) Mechanically alloyed high entropy alloys: existing challenges and opportunities. J Mater Res Technol 17:2431–2456

Murali N, Sokoluk M, Li X (2021) Study on aluminum alloy joints welded with nano-treated Al-Mg-Mn filler wire. Mater Lett 283:128739

Tasalloti H, Eskelinen H, Kah P, Martikainen J (2016) An integrated DFMA–PDM model for the design and analysis of challenging similar and dissimilar welds. Mater Des 89:421–431

Kaviyarasan K, Soundararajan R, Sivasankaran S (2023) Metallurgical enhancement and mechanical performance of GTAW of AA5083 plates using medium and high-entropy fillers. Mater Charact 204:113167

Sokkalingam R, Muthupandi V, Sivaprasad K, Prashanth KG (2019) Dissimilar welding of Al0. 1CoCrFeNi high-entropy alloy and AISI304 stainless steel. J Mater Res 34:2683–2694

Wu Y, Chen J, Zhang L, Ji J, Wang Q, Zhang S (2022) Effect of boron on the structural stability, mechanical properties, and electronic structures of γ′-Ni3Al in TLP joints of nickel-based single-crystal alloys. Mater Today Commun 31:103375. https://doi.org/10.1016/j.mtcomm.2022.103375

Wang L, Suo Y, Liang Z, Wang D, Wang Q (2019) Effect of titanium powder on microstructure and mechanical properties of wire+ arc additively manufactured Al-Mg alloy. Mater Lett 241:231–234

Sokkalingam R, Sivaprasad K, Duraiselvam M, Muthupandi V, Prashanth KG (2020) Novel welding of Al0. 5CoCrFeNi high-entropy alloy: Corrosion behavior. J Alloys Compd 817:153163

Mustafa U, Chandra M, Paulraj S (2018) Influence of filler wire diameter on mechanical and corrosion properties of AA5083-H111 Al–Mg alloy sheets welded using an AC square wave GTAW process. Trans Indian Inst Met 71:1975–1983

Esteves L, Christudasjustus J, O’Brien SP, Witharamage CS, Darwish AA, Walunj G, Stack P, Borkar T, Akans RE, Gupta RK (2021) Effect of V content on corrosion behavior of high-energy ball milled AA5083. Corros Sci 186:109465

Niu X, Zhu S-P, He J-C, Liao D, Correia JAFO, Berto F, Wang Q (2022) Defect tolerant fatigue assessment of AM materials: size effect and probabilistic prospects. Int J Fatigue 160:106884. https://doi.org/10.1016/j.ijfatigue.2022.106884

Ramachandran DC, Murugan SP, Kim Y-M, Kim D, Kim G-G, Nam D-G, Jeong C, Do Park Y (2020) Effect of microstructural constituents on fusion zone corrosion properties of GMA welded AA 5083 with novel Al–Mg welding wires of high Mg contents. Met Mater Int 26:1341–1353

Zhao Q, Pan Z, Wang X, Luo H, Liu Y, Li X (2022) Corrosion and passive behavior of AlxCrFeNi3− x (x= 0.6, 0.8, 1.0) eutectic high entropy alloys in chloride environment. Corros Sci 208:110666

Mishra RK, Sahay PP, Shahi RR (2019) Alloying, magnetic and corrosion behavior of AlCrFeMnNiTi high entropy alloy. J Mater Sci 54:4433–4443

Zhang X, Guo J, Zhang X, Song Y, Li Z, Xing X, Kong D (2019) Influence of remelting and annealing treatment on corrosion resistance of AlFeNiCoCuCr high entropy alloy in 3.5% NaCl solution. J Alloys Compd 775:565–570

Xu Z, Zhang H, Du X, He Y, Luo H, Song G, Mao L, Zhou T, Wang L (2020) Corrosion resistance enhancement of CoCrFeMnNi high-entropy alloy fabricated by additive manufacturing. Corros Sci 177:108954

Soundararajan R, Ramkumar KR, Sivasankaran S, Kim HS (2022) Enhancement of tensile strength in AA 6061–T6 plates joined by gas tungsten arc welding using high entropy alloy filler sheet. Mater Sci Eng A 832:142481

Hao X, Dong H, Xia Y, Li P (2019) Microstructure and mechanical properties of laser welded TC4 titanium alloy/304 stainless steel joint with (CoCrFeNi) 100-xCux high-entropy alloy interlayer. J Alloys Compd 803:649–657

Wang G, Yang Y, He R, Tan C, Huttula M, Cao W (2020) A novel high entropy CoFeCrNiCu alloy filler to braze SiC ceramics. J Eur Ceram Soc 40:3391–3398

Wang G, Yang Y, Wang M, He R, Tan C, Cao W, Xu H (2021) Brazing ZrB2-SiC ceramics to Nb with a novel CoFeNiCrCu high entropy alloy. J Eur Ceram Soc 41:54–61

Bridges D, Zhang S, Lang S, Gao M, Yu Z, Feng Z, Hu A (2018) Laser brazing of a nickel-based superalloy using a Ni-Mn-Fe-Co-Cu high entropy alloy filler metal. Mater Lett 215:11–14

Tillmann W, Ulitzka T, Wojarski L, Manka M, Ulitzka H, Wagstyl D (2020) Development of high entropy alloys for brazing applications. Weld World 64:201–208

Yin S, Li W, Song B, Yan X, Kuang M, Xu Y, Wen K, Lupoi R (2019) Deposition of FeCoNiCrMn high entropy alloy (HEA) coating via cold spraying. J Mater Sci Technol 35:1003–1007

Li Y, Shi Y (2021) Microhardness, wear resistance, and corrosion resistance of AlxCrFeCoNiCu high-entropy alloy coatings on aluminum by laser cladding. Opt Laser Technol 134:106632

Li Y, Shi Y (2020) Phase assemblage and wear resistance of laser-cladding Al0.8FeCoNiCrCu0.5Six high-entropy alloys on aluminum. Mater Res Express 7:86504

Wang J, Shen Q, Kong X, Chen X (2021) Arc additively manufactured 5356 aluminum alloy with cable-type welding wire: microstructure and mechanical properties. J Mater Eng Perform 30:7472–7478

Alshataif YA, Sivasankaran S, Al-Mufadi FA, Alaboodi AS, Ammar HR (2020) Synthesis, structure, and mechanical response of Cr0.26Fe0.24Al0.5 and Cr0.15Fe0.14Al0.30Cu0.13Si0.28 nanocrystallite entropy alloys. Adv Powder Technol 31:2161–2177

Ammar HR, Sivasankaran S, Alaboodi AS, Al-Mufadi FA (2021) Synthesis, microstructural investigation and compaction behavior of Al0.3CrFeNiCo0.3Si0.4 nanocrystalline high entropy alloy. Adv Powder Technol 32:398–412. https://doi.org/10.1016/j.apt.2020.12.016

Alshataif YA, Sivasankaran S, Al-Mufadi FA, Alaboodi AS, Ammar HR (2021) Synthesis, microstructures and mechanical behaviour of Cr0.21Fe0.20Al0.41Cu0.18 and Cr0.14Fe0.13Al0.26Cu0.11Si0.25Zn0.11 nanocrystallite entropy alloys prepared by mechanical alloying and hot-pressing. Met Mater Int 27:139–155

Sheng GUO, Liu CT (2011) Phase stability in high entropy alloys: Formation of solid-solution phase or amorphous phase. Prog Nat Sci Mater Int 21:433–446

Poonguzhali V, Umar M, Sathiya P (2020) Corrosion and creep properties of weld beads produced on AA5083-H111 alloy sheets using SpinArc GMAW process. Met Mater Int 26:115–129

Oliveira JP, Curado TM, Zeng Z, Lopes JG, Rossinyol E, Park JM, Schell N, Fernandes FMB, Kim HS (2020) Gas tungsten arc welding of as-rolled CrMnFeCoNi high entropy alloy. Mater Des 189:108505

Wang XF, Zhang Y, Qiao Y, Chen GL (2007) Novel microstructure and properties of multicomponent CoCrCuFeNiTix alloys. Intermetallics 15:357–362

Wang W-R, Wang W-L, Wang S-C, Tsai Y-C, Lai C-H, Yeh J-W (2012) Effects of Al addition on the microstructure and mechanical property of AlxCoCrFeNi high-entropy alloys. Intermetallics 26:44–51

Ammar HR, Sherif EM, Sivasankaran S, Almufadi FA, Mekky AH (2023) Developing improved corrosion-resistant AA5083—BN/WC composites for tribological applications. Materials (Basel) 16:1663

Raza A, Abdulahad S, Kang B, Ryu HJ, Hong SH (2019) Corrosion resistance of weight reduced AlxCrFeMoV high entropy alloys. Appl Surf Sci 485:368–374

Qiu Y, Thomas S, Fabijanic D, Barlow AJ, Fraser HL, Birbilis N (2019) Microstructural evolution, electrochemical and corrosion properties of AlxCoCrFeNiTiy high entropy alloys. Mater Des 170:107698

Wang Y, Jin J, Zhang M, Wang X, Gong P, Zhang J, Liu J (2021) Effect of the grain size on the corrosion behavior of CoCrFeMnNi HEAs in a 05 M H2SO4 solution. J Alloys Compd 858:157712

Orłowska M, Ura-Bińczyk E, Adamczyk-Cieślak B, Olejnik L, Lewandowska M (2021) Evolution of pitting corrosion resistance and mechanical properties in ultrafine-grained commercially pure aluminium during annealing. J Mater Sci 56:16726–16744

Rani A, Bala N, Gupta CM (2017) Accelerated hot corrosion studies of D-gun-sprayed Cr2O3–50% Al2O3 coating on boiler steel and Fe-based superalloy. Oxid Met 88:621–648

Cuevas Arteaga C, Sotelo-Mazón O, Rodríguez JA, Clemente CM (2021) Comparison of the corrosion performance of alloys HP40 and T22 exposed to molten salts at high temperature. Mater High Temp 38:123–138

Wu H, Gong P, Hu S, Xiang L, Wang E, Xiao H, Wan Y, Ning H, Xie Z (2021) Hot corrosion damage mechanism of Ti6Al4V alloy in marine environment. Vacuum 191:110350

Kannan AR, Rajkumar V, Prasad CD, Shanmugam NS, Yoon J (2023) Microstructure and hot corrosion performance of stainless steel 347 produced by wire arc additive manufacturing. Vacuum 210:111901

Bagheri B, Abbasi M, Dadaei M (2020) Effect of water cooling and vibration on the performances of friction-stir-welded AA5083 aluminum joints. Metallogr Microstruct Anal 9:33–46

T. Sonar, M. Ivanov, E. Trofimov, A. Tingaev, I. Suleymanova, A critical review on solid-state welding of high entropy alloys–processing, microstructural characteristics and mechanical properties of joints, Def. Technol. (2023).

Alil A, Popović M, Bajat J, Romhanji E (2018) Mechanical and corrosion properties of AA5083 alloy sheets produced by accumulative roll bonding (ARB) and conventional cold rolling (CR). Mater Corros 69:858–869

Fattah-Alhosseini A, Naseri M, Gholami D, Imantalab O, Attarzadeh FR, Keshavarz MK (2019) Microstructure and corrosion characterization of the nugget region in dissimilar friction-stir-welded AA5083 and AA1050. J Mater Sci 54:777–790

Yang Y, Zhou W, Tong Z, Chen L, Yang X, Larson EA, Ren X (2019) Electrochemical corrosion behavior of 5083 aluminum alloy subjected to laser shock peening. J Mater Eng Perform 28:6081–6091

Jebaraj AV, Aditya KVV, Kumar TS, Ajaykumar L, Deepak CR (2020) Mechanical and corrosion behaviour of aluminum alloy 5083 and its weldment for marine applications. Mater Today Proc 22:1470–1478

Arunnellaiappan T, Baskaran S, Arun S, Prithivirajan R (2021) Corrosion behaviour of detonation gun sprayed cermet coatings on AA5083. Surf Eng 37:263–270

Kumar PSSR, Jyothi S (2019) High temperature corrosion study on CVD-MWCNT reinforced aluminium nanocomposites. Mater Res Express 6:115623

Acknowledgements

The corrosion equipment was financially supported by the DST—Science and Engineering Research Board (SERB). Corrosion tests were conducted in this study.

Funding

The authors declare no funding was provided.

Author information

Authors and Affiliations

Contributions

KK performed formal analysis, validation, and roles/writing—original draft. RS contributed to visualization, investigation, data curation, resources, and project administration. SS contributed to conceptualization, methodology, investigation, writing—review and editing. AS contributed to resources, funding acquisition, and project administration.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Data Availability

The experimental datasets obtained from this research work, and then the analysed results during the current study are available from the corresponding author upon reasonable request.

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Additional information

Handling Editor: Megumi Kawasaki.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kaviyarasan, K., Soundararajan, R., Sivasankaran, S. et al. Influence of medium- and high-entropy alloy fillers on microstructures and corrosion behaviour of AA5083 plates joined by GTAW process. J Mater Sci 59, 7998–8021 (2024). https://doi.org/10.1007/s10853-024-09654-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-024-09654-w