Abstract

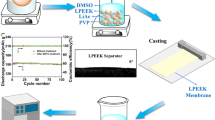

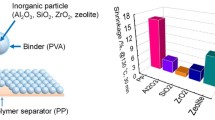

Recent surge of thermal stable polymeric separators for LIBs has demonstrated potential success by utilizing phase inversion approach. However, via phase inversion, there are typically two types of morphologies, the finger-like and sponge-like, whose impact to the performance of the LIBs at high temperature has not yet been analyzed. In this paper, we attempted to clarify the importance of the morphology of a thermal stable PEEK separator in LIBs. Both finger-like (F-PEEK) and sponge-like (S-PEEK) structure were prepared via immersion precipitation and vapor-induced phase separation. Furthermore, a sponge-like structure with high pore connectivity was realized by addition of polyvinyl pyrrolidone (PVP) (S-PEEK/PVP). The intrinsic thermal resistance of PEEK attributes separators with dimension stability at 180 °C. Comparing to F-PEEK and S-PEEK, S-PEEK/PVP separator showed excellent electrolyte uptake, high porosity, high ionic conductivity (1.65 mS cm−1) and good electrochemical stability up to 5.5 V. Inferior performance of S-PEEK separator was probably caused by the low pore connectivity. At 45 °C, S-PEEK/PVP separator incorporated LIBs showed higher discharge capacity and better cycle property than LIBs with S-PEEK, F-PEEK and PP separators. Autopsy of failed LIBs with F-PEEK showed collapse of finger structure. For S-PEEK/PVP separator, intact anode material attributed to a capacity retention rate 97.9% after cycling for 150 cycles. The results indicated the importance of the sponge-like morphology for preparing the thermal stable separators for LIBs via phase inversion method.

Graphical abstract

Similar content being viewed by others

References

Liu M, Zhang S, Li G et al (2021) A cross-linked gel polymer electrolyte employing cellulose acetate matrix and layered boron nitride filler prepared via in situ thermal polymerization. J Power Sources 484:229235. https://doi.org/10.1016/j.jpowsour.2020.229235

Zhou Q, Li Q, Liu S, Yin X, Huang B, Sheng M (2021) High Li-ion conductive composite polymer electrolytes for all-solid-state Li-metal batteries. J Power Sources 482:228929. https://doi.org/10.1016/j.jpowsour.2020.228929

Hu J, Wang W, Zhu X et al (2021) Composite polymer electrolytes reinforced by hollow silica nanotubes for lithium metal batteries. J Membr Sci 618:118697. https://doi.org/10.1016/j.memsci.2020.118697

Wang XZ, Zhang YB, Zhang X et al (2018) Lithium-salt-rich PEO/Li0.3La0.557TiO3 interpenetrating composite electrolyte with three-dimensional ceramic nano-backbone for all-solid-state lithium-ion batteries. ACS Appl Mater Interfaces 10:24791–24798. https://doi.org/10.1021/acsami.8b06658

Yao XY, Huang N, Han FD et al (2017) High-performance all-solid-state lithium-sulfur batteries enabled by amorphous sulfur-coated reduced graphene oxide cathodes. Adv Energy Mater 7:1602923. https://doi.org/10.1002/aenm.201602923

l’Abee R, DaRosa F, Armstrong MJ, Hantel MM, Mourzagh D (2017) High temperature stable Li-ion battery separators based on polyetherimides with improved electrolyte compatibility. J Power Sources 345:202–211. https://doi.org/10.1016/j.jpowsour.2017.02

Nitta N, Wu FX, Lee JT, Yushin G (2015) Li-ion battery materials: present and future. Mater Today 18:252–264. https://doi.org/10.1016/j.mattod.2014.10.040

Evans T, Lee JH, Bhat V, Lee SH (2015) Electrospun polyacrylonitrile microfiber separators for ionic liquid electrolytes in Li-ion batteries. J Power Sources 292:1–6. https://doi.org/10.1016/j.jpowsour.2015.05.022

Yoneda H, Nishimura Y, Doi Y, Fukuda M, Kohno M (2010) Development of microporous PE films to improve lithium ion batteries. Polym J 42:425–437. https://doi.org/10.1038/pj.2010.25

Li H, Wu D, Wu J, Dong LY, Zhu YJ, Hu X (2017) Flexible, high-wettability and fire-resistant separators based on hydroxyapatite nanowires for advanced lithium-ion batteries. Adv Mater. https://doi.org/10.1002/adma.201703548

Shin WK, Kim DW (2013) High performance ceramic-coated separators prepared with lithium ion-containing SiO2 particles for lithium-ion batteries. J Power Sources 226:54–60. https://doi.org/10.1016/j.jpowsour.2012.10.082

Zhang SS, Xu K, Foster DL, Ervin MH, Jow TR (2004) Microporous gel electrolyte Li-ion battery. J Power Sources 125:114–118. https://doi.org/10.1016/j.jpowsour.2003.07.008

Yang M, Hou J (2012) Membranes in lithium ion batteries. Membranes 2:367–383. https://doi.org/10.3390/membranes2030367

Rae PJ, Brown EN, Orler EB (2007) The mechanical properties of poly(ether-ether-ketone) (PEEK) with emphasis on the large compressive strain response. Polymer 48:598–615. https://doi.org/10.1016/j.polymer.2006.11.032

Huang XS (2012) A lithium-ion battery separator prepared using a phase inversion process. J Power Sources 216:216–221. https://doi.org/10.1016/j.jpowsour.2012.05.019

Li Z, Cao TT, Zhang Y, Han Y, Xu SM, Xu ZH (2017) Novel lithium ion battery separator based on hydroxymethyl functionalized poly(ether ether ketone). J Membr Sci 540:422–429. https://doi.org/10.1016/j.memsci.2017.06.045

Hsu CY, Liu RJ, Hsu CH, Kuo PL (2016) High thermal and electrochemical stability of PVDF-graft-PAN copolymer hybrid PEO membrane for safety reinforced lithium-ion battery. RSC Adv 6:18082–18088. https://doi.org/10.1039/c5ra26345j

Miao L, Wu Y, Hu JW et al (2019) Hierarchical aramid nanofibrous membranes from a nanofiber-based solvent-induced phase inversion process. J Membr Sci 578:16–26. https://doi.org/10.1016/j.memsci.2019.02.025

Chen Y, Qiu LL, Ma XY et al (2020) Electrospun PMIA and PVDF-HFP composite nanofibrous membranes with two different structures for improved lithium-ion battery separators. Solid State Ionics 347:115253. https://doi.org/10.1016/j.ssi.2020.115253

Liu X, Song K, Lu C et al (2018) Electrospun PU@GO separators for advanced lithium ion batteries. J Membr Sci 555:1–6. https://doi.org/10.1016/j.memsci.2018.03.027

Zhang H, Sheng L, Bai Y et al (2020) Amino-functionalized Al2O3 particles coating separator with excellent lithium-ion transport properties for high-power density lithium-ion batteries. Adv Eng Mater 22:1901545. https://doi.org/10.1002/adem.201901545

Ahn JH, Kim H-M, Lee Y-J et al (2021) Nanostructured reactive alumina particles coated with water-soluble binder on the polyethylene separator for highly safe lithium-ion batteries. J Power Sources 506:230119. https://doi.org/10.1016/j.jpowsour.2021.230119

Heo J, Choi Y, Chung KY, Park JH (2016) Controlled pore evolution during phase inversion from the combinatorial non-solvent approach: application to battery separators. J Mater Chem A 4:9496–9501. https://doi.org/10.1039/c6ta02472f

Zhang J, Yang L, Wang Z et al (2019) A highly permeable loose nanofiltration membrane prepared via layer assembled in-situ mineralization. J Membr Sci 587:117159. https://doi.org/10.1016/j.memsci.2019.05.083

Deng JH, Cao DQ, Li LJ, Chen YP, Zhang GQ, Yang XQ (2021) Electrospun nanofiber separator derived from nano-SiO2-modified polyimide with superior mechanical flexibility for high-performance lithium-ion battery. J Mater Sci 56:15215–15228. https://doi.org/10.1007/s10853-021-06201-9

Tung SO, Fisher SL, Kotov NA, Thompson LT (2018) Nanoporous aramid nanofibre separators for nonaqueous redox flow batteries. Nat Commun 9:1–9. https://doi.org/10.1038/s41467-018-05752-x

Liu J, Kong X, Jiang J (2018) Solvent nanofiltration through polybenzimidazole membranes: unravelling the role of pore size from molecular simulations. J Membr Sci 564:782–787. https://doi.org/10.1016/j.memsci.2018.07.086

Lu W, Yuan Z, Zhao Y, Zhang H, Zhang H, Li X (2017) Porous membranes in secondary battery technologies. Chem Soc Rev 46:2199–2236. https://doi.org/10.1039/c6cs00823b

Min HS, Ko JM, Kim DW (2003) Preparation and characterization of porous polyacrylonitrile membranes for lithium-ion polymer batteries. J Power Sources 119:469–472. https://doi.org/10.1016/S0378-7753(03)00206-4

Huang ZH, Chen JM, Huo YP, Zhao JW (2021) Heat resistant microporous membranes based on soluble poly(aryl ether ketone) copolymers for lithium ion battery separator. J Appl Polym Sci 138:1–10. https://doi.org/10.1002/app.50895

Li D, Shi DQ, Feng K, Li XF, Zhang HM (2017) Poly (ether ether ketone) (PEEK) porous membranes with super high thermal stability and high rate capability for lithium-ion batteries. J Membr Sci 530:125–131. https://doi.org/10.1016/j.memsci.2017.02.027

Li H, Zhang B, Lin B, Yang YZ, Zhao Y, Wang L (2018) Electrospun poly(ether ether ketone) nanofibrous separator with superior performance for lithium-ion batteries. J Electrochem Soc 165:A939–A946. https://doi.org/10.1149/2.0611805jes

T He (2016) In: Drioli E, Giorno L (eds) Encyclopedia of membranes. Springer, Berlin

Pan J, Gao L, Sun W, Wang S, Shi X (2021) Length effects of short alkyl side chains on phase-separated structure and dynamics of hydrophobic association hydrogels. Macromolecules 54:5962–5973. https://doi.org/10.1021/acs.macromol.1c00471

Boom RM, Wienk IM, van den Boomgaard T, Smolders CA (1992) Microstructures in phase inversion membranes. Part 2. The role of a polymeric additive. J Membr Sci 73:277–292. https://doi.org/10.1016/0376-7388(92)80135-7

Smolders CA, Reuvers AJ, Boom RM, Wienk IM (1992) Microstructures in phase-inversion membranes. Part 1. Formation of macrovoids. J Membr Sci 73:259–275. https://doi.org/10.1016/0376-7388(92)80134-6

Li J, Niu X, Song J et al (2019) Harvesting vapor by hygroscopic acid to create pore: morphology, crystallinity and performance of poly (ether ether ketone) lithium ion battery separator. J Membr Sci 577:1–11. https://doi.org/10.1016/j.memsci.2019.01.045

Degennes PG (1971) Reptation of a polymer chain in presence of fixed obstacles. J Chem Phys 55:572–579. https://doi.org/10.1063/1.1675789

Song JF, Li XM, Zhang YY et al (2014) Hydrophilic nanoporous ion-exchange membranes as a stabilizing barrier for liquid-liquid membrane extraction of lithium ions. J Membr Sci 471:372–380. https://doi.org/10.1016/j.memsci.2014.08.010

Song JF, Li XM, Li ZS et al (2015) Stabilization of composite hollow fiber nanofiltration membranes with a sulfonated poly(ether ether ketone) coating. Desalination 355:83–90. https://doi.org/10.1016/j.desal.2014.10.011

Burgal JD, Peeva L, Livingston A (2017) Negligible ageing in poly(ether-ether-ketone) membranes widens application range for solvent processing. J Membr Sci 525:48–56. https://doi.org/10.1016/j.memsci.2016.10.015

van de Witte P, Dijkstra PJ, van den Berg JWA, Feijen J (1996) Phase separation processes in polymer solutions in relation to membrane formation. J Membr Sci 117:1–31. https://doi.org/10.1016/0376-7388(96)00088-9

Ji Y, Li X-M, Yin Y, Zhang Y-Y, Wang Z-W, He T (2010) Morphological control and cross-flow filtration of microfiltration membranes prepared via a sacrificial-layer approach. J Membr Sci 353:159–168. https://doi.org/10.1016/j.memsci.2010.02.041

Li XM, Ji Y, He T, Wessling M (2008) A sacrificial-layer approach to prepare microfiltration membranes. J Membr Sci 320:1–7. https://doi.org/10.1016/j.memsci.2008.03.059

Li X-M, Ji Y, Yin Y, Zhang Y-Y, Wang Y, He T (2010) Origin of delamination/adhesion in polyetherimide/polysulfone co-cast membranes. J Membr Sci 352:173–179. https://doi.org/10.1016/j.memsci.2010.02.013

Boom RM, van den Boomgaard T, Smolders Ca (1994) Mass transfer and thermodynamics during immersion precipitation for a two-polymer system. J Membr Sci 90:231–249. https://doi.org/10.1016/0376-7388(94)80074-x

Boom RM, Reinders HW, Rolevink HHW, van den Boomgaard T, Smolders CA (1994) Equilibrium thermodynamics of a quaternary membrane-forming system with two polymers. 2. Experiments. Macromolecules 27:2041–2044. https://doi.org/10.1021/ma00086a010

Tian M, Yin Y, Yang C et al (2015) CF4 plasma modified highly interconnective porous polysulfone membranes for direct contact membrane distillation (DCMD). Desalination 369:105–114. https://doi.org/10.1016/j.desal.2015.05.002

Venugopal G, Moore J, Howard J, Pendalwar S (1999) Characterization of microporous separators for lithium-ion batteries. J Power Sources 77:34–41. https://doi.org/10.1016/s0378-7753(98)00168-2

Xing LD, Wang CY, Li WS, Xu MQ, Meng XL, Zhao SF (2009) Theoretical insight into oxidative decomposition of propylene carbonate in the lithium ion battery. J Phys Chem B 113:5181–5187. https://doi.org/10.1021/jp810279h

Kostecki R, Norin L, Song XY, McLarnon F (2004) Diagnostic studies of polyolefin separators in high-power Li-ion cells. J Electrochem Soc 151:A522–A526. https://doi.org/10.1149/1.1649233

Kabir MM, Demirocak DE (2017) Degradation mechanisms in Li-ion batteries: a state-of-the-art review. Int J Energy Res 41:1963–1986. https://doi.org/10.1002/er.3762

Yang CC, Jiang JR, Karuppiah C et al (2018) LATP ionic conductor and in-situ graphene hybrid-layer coating on LiFePO4 cathode material at different temperatures. J Alloy Compd 765:800–811. https://doi.org/10.1016/j.jallcom.2018.06.289

Xie Y, Xiang HF, Shi PC, Guo JP, Wang HH (2017) Enhanced separator wettability by LiTFSI and its application for lithium metal batteries. J Membr Sci 524:315–320. https://doi.org/10.1016/j.memsci.2016.11.021

Funding

The research was partially supported by National Natural Science Foundation of China (No. 21978315, 21676290, 51861145313, 21808236), and Newton Advanced Fellowship (Grant No. NA170113).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Kyle Brinkman.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Niu, X., Li, J., Song, G. et al. Evidence of high temperature stable performance of polyether ether ketone (PEEK) separator with sponge-structured in lithium-ion battery. J Mater Sci 57, 7042–7055 (2022). https://doi.org/10.1007/s10853-022-07111-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-07111-0