Abstract

Effects of texture on micromechanics, texture evolution and macromechanics of AZ31 magnesium alloy sheets with tailored textures during plastic deformation are thoroughly investigated by visco-plastic self-consistent (VPSC) analysis. These simulated results confirm that as for in-plane tension (IPT), activities of basal < a > slip and \(\{ 10\overline{1}2\}\) extension twin (ET) are mainly responsible for the observed texture characteristics of all deformed samples. In addition, activities of prismatic < a > slip and \(\{ 10\overline{1}2\}\) ET in samples with bimodal texture are highly related to the loading direction. With regard to in-plane shear (IPS), sample with weak basal texture possesses the largest activity of prismatic < a > slip. Moreover, basal < a > slip and prismatic < a > slip collectively contribute to the rotation of tilted basal poles in (0002) pole figure, whereas pyramidal < c + a > slip and \(\{ 10\overline{1}2\}\) ET are advantageous to the rotation of tilted basal poles away from normal direction (ND) with increasing plastic strain. In terms of plane strain compression (PSC), \(\{ 10\overline{1}2\}\) ET and prismatic < a > slip largely participate in plastic deformation of samples with four-peak texture and annular (ring-shaped) texture, namely, \(\{ 10\overline{1}2\}\) ET leads to the rotation of tilted basal poles toward ND during PSC and prismatic < a > slip causes the formation of a small annular texture component after a relatively large plastic strain.

Similar content being viewed by others

References

Kabirian F, Khan AS, Herlod TG (2015) Visco-plastic modeling of mechanical responses and texture evolution in extruded AZ31 magnesium alloy for various loading conditions. Int J Plast 68:1–20. https://doi.org/10.1016/j.ijplas.2014.10.012

Hirsch J, Alsamman T (2013) Superior light metals by texture engineering: optimized aluminum and magnesium alloys for automotive applications. Acta Mater 61(3):818–843. https://doi.org/10.1016/j.actamat.2012.10.044

Song JF, She J, Chen DL, Pan FS (2020) Latest research advances on magnesium and magnesium alloys worldwide. J Magnes Alloy 8(1):1–41

Nakata T, Chao X, Ohashi H, Yoshida Y, Shigeharu K (2020) New Mg-Al based alloy sheet with good room-temperature stretch formability and tensile properties. Scr Mater 180:16–22. https://doi.org/10.1016/j.scriptamat.2020.01.015

Kang HD, Kim WD, Kim S, Geun TB, Kyeongmin K, Nack JK (2009) Relationship between stretch formability and work-hardening capacity of twin-roll cast Mg alloys at room temperature. Scr Mater 61(7):768–771. https://doi.org/10.1016/j.scriptamat.2009.06.026

Yang Q, Jiang B, Zhou G, Dai J, Pan FS (2014) Influence of an asymmetric shear deformation on microstructure evolution and mechanical behavior of AZ31 magnesium alloy sheet. Mat Sci Eng A 590(10):440–447. https://doi.org/10.1016/j.msea.2013.10.045

Wang Y, Li F, Li XW, Fang WB (2019) Unusual texture formation and mechanical property in AZ31 magnesium alloy sheets processed by CVCDE. J Mater Process Technol 275:116360. https://doi.org/10.1016/j.jmatprotec.2019.116360

Huang XS, Suzuki K, Saito N (2009) Microstructure and mechanical properties of AZ80 magnesium alloy sheet processed by differential speed rolling. Mat Sci Eng A 508(1–2):226–233. https://doi.org/10.1016/j.msea.2008.12.052

Huang XS, Suzuki K, Watazu A, Shigematsu I, Saito N (2008) Microstructure and texture of Mg-Al-Zn alloy processed by differential speed rolling. J Alloys Compd 457(1–2):408–412. https://doi.org/10.1016/j.jallcom.2007.02.144

Kuang J, Low TSE, Niezgoda SR, Li X, Geng Y, Luo AA, Tang G (2016) Abnormal texture development in magnesium alloy Mg-3Al-1Zn during large strain electroplastic rolling: effect of pulsed electric current. Int J Plast 87:86–99. https://doi.org/10.1016/j.ijplas.2016.09.004

Song DH, Zhou T, Tu J, Shi LX, Song B, Hu L, Yang MB, Chen Q, Lu L (2018) Improved stretch formability of AZ31 sheet via texture control by introducing a continuous bending channel into equal channel angular rolling. J Mater Process Technol 259:380–386. https://doi.org/10.1016/j.jmatprotec.2018.05.012

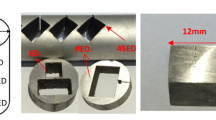

He JJ, Mao Y, Fu Y, Jiang B, Pan FS (2019) Improving the room-temperature formability of Mg-3Al-1Zn alloy sheet by introducing an orthogonal four-peak texture. J Alloys Compd 797:443–455. https://doi.org/10.1016/j.jallcom.2019.05.087

Padmeya PI, Shahmeer B, Robert P, Shailendra PJ (2020) Predicting textural variability effects in the anisotropic plasticity and stability of hexagonal metals: application to magnesium and its alloys. Int J Plast 132:102762. https://doi.org/10.1016/j.ijplas.2020.102762

Wang BS, Xin RL, Huang GS, Liu Q (2012) Effect of crystal orientation on the mechanical properties and strain hardening behavior of magnesium alloy AZ31 during uniaxial compression. Mat Sci Eng A 534(1):588–593. https://doi.org/10.1016/j.msea.2011.12.013

Chapuis A, Liu P, Liu Q (2013) An experimental and numerical study of texture change and twinning-induced hardening during tensile deformation of an AZ31 magnesium alloy rolled plate. Mat Sci Eng A 561(20):167–173. https://doi.org/10.1016/j.msea.2012.11.018

Wang Z, Chapuis A, Liu Q (2015) Simulation of mechanical behavior of AZ31 magnesium alloy during twin-dominated large plastic deformation. Trans Nonferrous Met Soc China 25(11):3595–3603. https://doi.org/10.1016/S1003-6326(15)64000-6

Yao J, Wang B, Deng L, Chapuis A, Li Q, Liu Q (2015) Simulation of texture evolution and deformation mechanism in Mg-3Al-1Zn alloy during uniaxial compression. Sci China: Technol Sci 58(12):2052–2059. https://doi.org/10.1007/s11431-015-5937-6

Chen Y, Hu L, Shi LX, Zhou T, Yang MB (2019) Effect of texture types on microstructure evolution and mechanical properties of AZ31 magnesium alloy undergoing uniaxial tension deformation at room temperature. Mat Sci Eng A 769:138497. https://doi.org/10.1016/j.msea.2019.138497

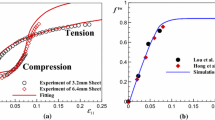

Lou XY, Li M, Boger RK, Agnew SR, Wagoner RH (2007) Hardening evolution of AZ31B Mg sheet. Int J Plast 23(1):44–86. https://doi.org/10.1016/j.ijplas.2006.03.005

Chapuis A, Wang BS, Liu Q (2014) A comparative study between uniaxial compression and plane strain compression of Mg-3Al-1Zn alloy using experiments and simulations. Mat Sci Eng A 597(12):349–358. https://doi.org/10.1016/j.msea.2014.01.021

Lebensohn RA, Tomé CN (1993) A self-consistent anisotropic approach for the simulation of plastic deformation and texture development of polycrystals: application to zirconium alloys. Acta Metall Mater 41(9):2611–2624. https://doi.org/10.1016/0956-7151(93)90130-K

Luo J, Hu WW, Jin QQ, Yan H, Chen RS (2017) Unusual cold rolled texture in an Mg-2. 0Zn-0. 8Gd sheet. Scr Mater 127:146–150. https://doi.org/10.1016/j.scriptamat.2016.08.025

Tomé CN, Lebensohn RA, Kocks UF (1991) A model for texture development dominated by deformation twinning: application to zirconium alloys. Acta Metall Mater 39(11):2667–2680. https://doi.org/10.1007/s10802-014-9888-3

Li H, Zhang HQ, Yang H, Fu MW, Yang H (2017) Anisotropic and asymmetrical yielding and its evolution in plastic deformation: titanium tubular materials. Int J Plast 90:177–211. https://doi.org/10.1016/j.ijplas.2017.01.004

Chapuis A, Wang ZQ, Liu Q (2016) Influence of material parameters on modeling plastic deformation of Mg alloys. Mat Sci Eng A 655:244–250. https://doi.org/10.1016/j.msea.2015.12.067

Hielscher R, Schaeben H (2010) A novel pole figure inversion method: specification of the MTEX algorithm. J Appl Crystallogr 41(6):1024–1037. https://doi.org/10.1107/S0021889808030112

Li LT, Lin YC, Li L, Shen LM, Wen DX (2015) Three-dimensional crystal plasticity finite element simulation of hot compressive deformation behaviors of 7075 Al alloy. J Mater Eng Perform 24(3):1294–1304. https://doi.org/10.1007/s11665-015-1395-3

Tu J, Zhou T, Liu L, Shi LX, Hu L, Song DH, Song B, Yang MB, Chen Q, Pan FS (2018) Effect of rolling speeds on texture modification and mechanical properties of the AZ31 sheet by a combination of equal channel angular rolling and continuous bending at high temperature. J Alloys Compd 768:598–607. https://doi.org/10.1016/j.jallcom.2018.07.242

Wang BS, Deng LP, Chapuis A, Guo N, Xu ZR, Li Q (2015) Relationship between textures and deformation modes in Mg-3Al-1Zn alloy during uniaxial tension. Mater Charact 108:42–50. https://doi.org/10.1016/j.matchar.2015.08.014

Zhao LY, Guo XQ, Chapuis A, Xin YC, Liu Q, Wu PD (2019) Strain-path dependence of 10–12 twinning in a rolled Mg-3Al-1Zn alloy: influence of twinning model. Metall Mater Trans A 50(1):118–131. https://doi.org/10.1007/s11661-018-4955-y

Zhao J, Jiang B, Tang A, Chai YF, Pan FS (2019) Deformation behavior and texture evolution in an extruded Mg-Li sheet with non-basal texture during tensile deformation. Mater Charact 159:110041. https://doi.org/10.1016/j.matchar.2019.110041

Lian Y, Hu L, Zhou T, Yang MB, Zhang J (2019) Numerical investigation of secondary deformation mechanisms on plastic deformation of AZ31 magnesium alloy using viscoplastic self-consistent model. https://doi.org/10.3390/met9010041

Chapuis A, Liu Q (2015) Simulations of texture evolution for HCP metals: Influence of the main slip systems. Comput Mater Sci 97:121–126. https://doi.org/10.1016/j.commatsci.2014.10.017

Nave M, Barnett M (2004) Microstructures and textures of pure magnesium deformed in plane-strain compression. Scr Mater 51(9):881–885. https://doi.org/10.1016/j.scriptamat.2004.07.002

Styczynski A, Hartig C, Bohlen J, Letzig D (2004) Cold rolling textures in AZ31 wrought magnesium alloy. Scr Mater 50(7):943–947. https://doi.org/10.1016/j.scriptamat.2004.01.010

Guo XQ, Chapuis A, Wu PD, Liu Q, Mao XB (2016) Experimental and numerical investigation of anisotropic and twinning behavior in Mg alloy under uniaxial tension. Mater Des 98(15):333–343. https://doi.org/10.1016/j.matdes.2016.03.045

Funding

This study was funded by the National Natural Science Foundation of China (Grant Nos. 51805064, 51701034, 51822509), the Basic and Advanced Research Project of Chongqing Science and Technology Commission (Grant Nos. cstc2018jcyjAX0035, cstc2017jcyjAX0062), the Qingnian project of science and technology research program of Chongqing Education Commission of China (Grant No. KJQN201801137), the Chongqing University Key Laboratory of Micro/Nano Materials Engineering and Technology (Grant No. KFJJ2003).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: P. Nash.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hu, L., Shi, L., Zhou, T. et al. A visco-plastic self-consistent analysis of tailored texture on plastic deformation behavior of AZ31 magnesium alloy sheet. J Mater Sci 56, 19199–19215 (2021). https://doi.org/10.1007/s10853-021-06493-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06493-x