Abstract

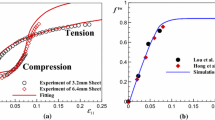

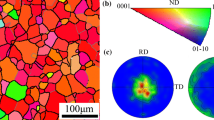

The evolutions of strain-rate sensitivity (SRS) in two slip modes, basal <a> and prismatic <a> in AZ31B alloy sheet, were studied at different temperatures with both experiments and simulations. With increasing deformation temperature, the AZ31B alloy sheet becomes more sensitive to strain rate under rolling direction tension. Meanwhile, the anisotropy (r-value) also presents a clearly increasing trend with loading rate at temperatures above 150 °C. Numerical simulation results based on crystal plasticity suggest that the difference in SRSs is responsible for the strain-rate dependence of the r-value at high temperatures, which may present different evolution trends with temperature. The effects of strain rate on slip-mode activities and texture evolution are also further analyzed.

Similar content being viewed by others

References

S.R. Agnew, and Ö. Duygulu, Int. J. Plast. 21(6), 1161. (2005).

G. Zhou, M.K. Jain, P. Wu, Y. Shao, D. Li, and Y. Peng, Int. J. Plast. 79, 19. (2016).

Z. Li, G. Zhou, D. Li, M.K. Jain, P. Wu, and Y. Peng, Int. J. Plast. 79, 19. (2020).

A.S. Khan, A. Pandey, T. Gnäupel-Herold, and R.K. Mishra, Int. J. Plast. 27(5), 688. (2011).

S. Kurukuri, M.J. Worswick, D. Ghaffari Tari, R.K. Mishra, and J.T. Carter, Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 372(2015), 20130216. (2014).

H. Watanabe, and K. Ishikawa, Mater. Sci. Eng. A 523(1–2), 304. (2009).

Z. Zhang, T. Jun, T.B. Britton, and F. Dune, Acta Mater. 118, 317. (2016).

W.A. Spitzig, and A.S. Keh, Acta Metall. 18, 1021. (1970).

J.A. Del Valle, and O.A. Ruano, Scr. Mater. 55(9), 775. (2006).

E. Karimi, A. Zarei-Hanzaki, M.H. Pishbin, H.R. Abedi, and P. Changizian, Mater. Des. 49, 173. (2013).

A.R. Antoniswamy, E.M. Taleff, L.G. Hector, and J.T. Carter, Mater. Sci. Eng. A 631, 1. (2015).

S.A. Habib, A.S. Khan, T. Gnäupel-Herold, J.T. Lloyd, and S.E. Schoenfeld, Int. J. Plast. 95, 163. (2017).

A.G. Beer, and M.R. Barnett, Mater. Sci. Eng. A 423(1–2), 292. (2006).

R.A. Lebensohn, and C.N. Tomé, Acta Metal. Mater. 41(9), 2611. (1993).

I.J. Beyerlein, and C.N. Tomé, Int. J. Plast. 24(5), 867. (2008).

A. Chapuis, and Q. Liu, Int. J. Solid. Struct. 152, 217. (2018).

H. Wang, P. Wu, S. Kurukuri, M.J. Worswick, Y. Peng, D. Tang, and D. Li, Int. J. Plast. 107, 207. (2018).

A. Chapuis, and Q. Liu, J. Magn. Alloys 7, 433. (2019).

G. Zhou, Z. Li, D. Li, Y. Peng, H. Wang, and P. Wu, Mater. Sci. Eng. A 730, 438. (2018).

H. Wang, B. Raeisinia, P.D. Wu, S.R. Agnew, and C.N. Tomé, Int. J. Solid. Struct. 47(21), 2905. (2010).

D. Pellegrini, A. Ghiotti, and S. Bruschi, Int. J. Mater. Form. 2(1), 275. (2009).

B. Hutchinson, M.R. Barnett, A.G. Haderi, P. Cizek, and I. Sabirov, Int. J. Mater. Res. 100(4), 556. (2009).

A.J. Carpenter, A.R. Antoniswamy, J.T. Carter, L.G. Hector Jr., and E.M. Taleff, Acta Mater. 68, 254. (2014).

J. Koike, R. Ohyama, T. Kobayashi, M. Suzuki, and K. Maruyama, Mater. Trans. 44(4), 445. (2003).

N. Stanford, K. Sotoudeh, and P.S. Bate, Acta Mater. 59(12), 4866. (2011).

Acknowledgements

The authors from SJTU would like to acknowledge the support of the National Natural Science Foundation of China (No. 51775337, 51675331). P.D. Wu was supported by the Natural Sciences and Engineering Research Council of Canada (NSERC, project No: RGPIN-2016-06464).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhou, G., Liu, R., Tang, W. et al. Strain-Rate Sensitivities of Different Deformation Mechanisms in AZ31B Magnesium Alloy Sheet at Various Temperatures. JOM 73, 1419–1427 (2021). https://doi.org/10.1007/s11837-021-04609-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-04609-x