Abstract

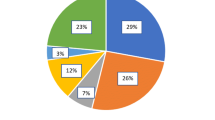

The aim of this paper is to review the literature in the field of supplier selection under supply chain risk management. Collected papers from 2003 to 2014 are analyzed and classified, first, according to the characteristics of the problem they deal with, secondly, according to the approach they propose, and thirdly, according to the techniques they use. The papers have been grouped into five categories: the first group relates to quantitative approaches to supplier selection, the second concerns qualitative approaches, the third consists of hybrid approaches that blend two or more different approaches together, the fourth relates to simulation approaches and the last group to artificial intelligence. The techniques used in each category are outlined. The different approaches and their associated techniques are analyzed and some recommendations are made on improving their efficiency and performance. This paper is thus a systematic scope review of journal articles and conference papers issued during this period. It brings together a collection of 124 papers on the topic of supplier selection under supply chain risk management.

Similar content being viewed by others

References

Ahiska, S. S., Appaji, S. R., King, R. E., & Warsing, D. P, Jr. (2013). A Markov decision process-based policy characterization approach for a stochastic inventory control problem with unreliable sourcing. International Journal of Production Economics, 144, 485–496.

Alinezad, A., Seif, A., & Esfandiari, N. (2013). Supplier evaluation and selection with QFD and FAHP in a pharmaceutical company. International Journal Advanced Manufacturing Technology, 68, 355–364. doi:10.1007/s00170-013-4733-3.

Arcelus, F. J., Kumar, S., & Srinivasan, G. (2012). Risk tolerance and a retailer’s pricing and ordering policies within a newsvendor framework. Omega, 40, 188–198.

Arkan, A., Hejazi, S. R., & Golmah, V. (2011). Supplier selection in supply chain management with disruption risk and credit period concepts. Journal of Industrial Engineering International, 7(15), 51–59.

Awasthi, A., Chauhan, S. S., Goyal, S. K., & Proth, J. M. (2009). Supplier selection problem for a single manufacturing unit under stochastic demand. International Journal of Production Economics, 117, 229–233.

Azadeh, A., & Alem, S. A. (2010). A flexible deterministic, stochastic and fuzzy data envelopment analysis approach for supply chain risk and vendor selection problem: Simulation analysis. Expert Systems with Applications, 37, 7438–7448.

Azaron, A., Brown, K. N., Tarim, S. A., & Modarres, M. (2008). A multi-objective stochastic programming approach for supply chain design considering risk. International Journal of Production Economics, 116, 129–138.

Baghalian, A., Rezapour, S., & Farahani, R. Z. (2013). Robust supply chain network design with service level against disruptions and demand uncertainties: A real-life case. European Journal of Operational Research, 227, 199–215.

Berger, P. D., Gerstenfeld, A., & Zeng, A. Z. (2004). How many suppliers are best? A decision-analysis approach. Omega, 32, 9–15.

Berger, P. D., & Zeng, A. Z. (2006). Single versus multiple sourcing in the presence of risks. Journal of the Operational Research Society, 57, 250–261.

Bhattacharya, A., Geraghty, J., & Young, P. (2010). Supplier selection paradigm: An integrated hierarchical QFD methodology under multiple-criteria environment. Applied Soft Computing, 10, 1013–1027.

Bilsel, R. U., & Ravindran, A. (2011). A multiobjective chance constrained programming model for supplier selection under uncertainty. Transportation Research Part B, 45, 1284–1300.

Burke, G. J. (2009). Sourcing decisions, with stochastic supplier reliability and stochastic demand. Production and Operations Management, 18(4), 475–484.

Burke, G. J., Carrillo, J., & Vakharia, A. J. (2008). Heuristics for sourcing from multiple suppliers with alternative quantity discounts. European Journal of Operational Research, 186, 317–329.

Burke, G. J., Erenguc, S. S., & Vakharia, A. J. (2008). Optimal requirement allocation among quantity-discount quoting suppliers. Operations Management Research, 1, 53–60.

Carrera, D. A., & Mayorga, R. V. (2008). Supply chain management: A modular Fuzzy Inference System approach in supplier selection for new product development. Journal of Intelligent Manufacturing, 19, 1–12.

Chai, J., James, N. K. L., & Eric, W. T. N. (2013). Application of decision-making techniques in supplier selection: A systematic review of literature. Expert Systems with Applications, 40, 3872–3885.

Chamodrakas, I., Batis, D., & Martakos, D. (2010). Supplier selection in electronic marketplaces using satisficing and fuzzy AHP. Expert Systems with Applications, 37, 490–498.

Chan, F. T. S., & Kumar, N. (2007). Global supplier development considering risk factors using fuzzy extended AHP-based approach. Omega, 35, 417–431.

Chen, J., Zhao, X., & Zhou, Y. (2012). A periodic-review inventory system with a capacitated backup supplier for mitigating supply disruptions. European Journal of Operational Research, 219, 312–323.

Chen, K., & Zhuang, P. (2011). Disruption management for a dominant retailer with constant demand-stimulating service cost. Computers & Industrial Engineering, 61, 936–946.

Chen, Y.S., Cheng, C.H., & Lai, C.J. (2012). Extracting performance rules of suppliers in the manufacturing industry: An empirical study, Journal of Intelligent Manufacturing, 2037–2045. doi:10.1007/s10845-011-0530-8

Cheng, L., Wan, Z., & Wang, G. (2009). Bilevel newsvendor models considering retailer with CVaR objective. Computers & Industrial Engineering, 57, 310–318.

Chiu, M. C., & Okudan, G. (2014). An investigation on the impact of product modularity level on supply chain performance metrics: an industrial case study. Journal of Intelligent Manufacturing, 25, 129–145.

Choi, T.-M., Li, D., & Yan, H. (2008). Mean-variance analysis of a single supplier and retailer supply chain under a returns policy. European Journal of Operational Research, 184, 356–376.

Choudhary, D., & Shankar, R. (2013). Joint decision of procurement lot-size, supplier selection, and carrier selection. Journal of Purchasing & Supply Management, 19, 16–26.

Choudhary, D., & Shankar, R. (2014). A goal programming model for joint decision making of inventory lot-size, supplier selection and carrier selection. Computers & Industrial Engineering, 71, 1–9.

Davarzani, H., Zegordi, S. H., & Norrman, A. (2011). Contingent management of supply chain disruption: Effects of dual or triple sourcing. Scientia Iranica E, 18(6), 1517–1528.

Demirtas, E. A., & Ustun, O. (2006). An integrated multi-objective decision making process for supplier selection and order allocation. Omega-International Journal of Management Science, 36(1), 79–90

Demirtas, E. A., & Ustun, O. (2009). Analytic network process and multi-period goal programming integration in purchasing decisions. Computers & Industrial Engineering, 56, 677–690.

Dickson, G. W. (1966). An analysis of vendor selection systems and decisions. Journal of Purchasing, 2(1), 5–17.

Duan, Q., & Liao, T. W. (2013). Optimization of replenishment policies for decentralized and centralized capacitated supply chains under various demands. International Journal of Production Economics, 142, 194–204.

Eng, S.W.L., Chew, E.P., & Lee, L.H. (2013). Impacts of supplier knowledge sharing competences and production capacities on radical innovative product sourcing. European Journal of Operational Research. doi:10.1016/j.ejor.2013.06.031.

Federgruen, A., & Yang, N. (2008). Selecting a portfolio of suppliers under demand and supply risks. Operations Research, 56(4), 916–936.

Finke, G.R., Schmitt, A.J., Singh, M. (2010). Modeling and simulating supply chain schedule risk. In: Proceedings of the Winter Simulation Conference.

Gan, X., Sethi, S. P., & Yan, H. (2005). Channel coordination with a risk-neutral supplier and a downside-risk-averse retailer. Production and Operations Management, 14, 80–89.

Giri, B. C. (2011). Managing inventory with two suppliers under yield uncertainty and risk aversion. International Journal of Production Economics, 133, 80–85.

Guo, C., & Li, X. (2014). A multi-echelon inventory system with supplier selection and order allocation under stochastic demand. International Journal of Production Economics, 151, 37–47.

Hammami, R., Frein, Y., & Hadj-Alouane, A. B. (2012). An international supplier selection model with inventory and transportation management decisions. journal of Flexible Service Manufacturing, 24, 4–27.

Hammami, R., Temponi, C., & Frein, Y. (2014). A scenario-based stochastic model for supplier selection in global context with multiple buyers, currency fluctuation uncertainties, and price discounts. European Journal of Operational Research, 233, 159–170.

He, Y., & Zhao, X. (2012). Coordination in multi-echelon supply chain under supply and demand uncertainty. International Journal of Production Economics, 139, 106–115.

Hou, J., Zeng, A. Z., & Zhao, L. (2010). Coordination with a backup supplier through buy-back contract under supply disruption. Transportation Research Part E, 46, 881–895.

Hsieh, C. C., Chang, Y. L., & Wu, C. H. (2014). Competitive pricing and ordering decisions in a multiple-channel supply chain. International Journal of Production Economics, 154, 156–165.

Hsieh, C.-C. H., & Lu, Y.-T. (2010). Manufacturer’s return policy in a two-stage supply chain with two risk-averse retailers and random demand. European Journal of Operational Research, 207, 514–523.

Jain, R., Singh, A. R., Yadav, H. C., & Mishra, P. K. (2014). Using data mining synergies for evaluating criteriaat pre-qualification stage of supplier selection. Journal of Intelligent Manufacturing, 25, 165–175. doi:10.1007/s10845-012-0684-z.

Juttner, U., Peck, H., & Christopher, M. (2003). Supply chain risk management: Outlining an agenda for future research. International Journal of Logistics Research Application, 6(4), 197–210.

Kang, H. Y., Lee, A. H. I., & Yang, C. Y. (2012). A fuzzy ANP model for supplier selection as applied to IC packaging. Journal of Intelligent Manufacturing, 23, 1477–1488.

Kar, A.K., (2010). Risk in supply chain management. http://business-fundas.com/2010/riskin-supply-chain-management/

Klimov, R.A., Merkuryev, Y.A. (2006). Simulation-based risk measurement in supply chains, In: Proceeding of 20th European conference in modeling and simulation.

Kokangul, A., & Susuz, Z. (2009). Integrated analytical hierarch process and mathematical programming to supplier selection problem with quantity discount. Applied Mathematical Modelling, 33(3), 1417–1429.

Kubat, C., & Yuce, B. (2012). A hybrid intelligent approach for supply chain management system. Journal of Intelligent Manufacturing, 23, 1237–1244. doi:10.1007/s10845-010-0431-2.

Kull, T., & Closs, D. (2008). The risk of second-tier supplier failures in serial supply chains: Implications for order policies and distributor autonomy. European Journal of Operational Research, 186, 1158–1174.

Kull, T. J., & Talluri, S. (2008). A supply risk reduction model using integrated multicriteria decision making. IEEE Transactions on Engineering Management, 55(3), 409.

Le, H. Q., Arch-int, S., Nguyen, H. X., & Arch-int, N. (2013). Association rule hiding in risk management for retail supply chain collaboration. Computer Industry, 2013. doi:10.1016/j.compind.04.011

Lee, A. H. L. (2009). A fuzzy supplier selection model with the consideration of benefits, opportunities, costs and risks. Expert Systems with Applications, 36, 2879–2893.

Li, J., Wang, S., & Cheng, T. C. E. (2010). Competition and cooperation in a single-retailer two-supplier supply chain with supply disruption. International Journal of Production Economics, 124, 137–150.

Li, L., & Zabinsky, Z. B. (2011). Incorporating uncertainty into a supplier selection problem. International Journal of Production Economics, 134, 344–356.

Li, B., Chen, P., Li, Q., Wang, W. (2014). Dual-channel supply chain pricing decisions with a risk averse retailer. doi:10.1080/00207543.2014.939235

Li, S., & Zeng, W. (2014). Risk analysis for the supplier selection problem using failure modes and effects analysis (FMEA). Journal of Intelligent Manufacturing. doi:10.1007/s10845-014-0953-0

Ma, L., Liu, F., Li, S., & Yan, H. (2012). Channel bargaining with risk-averse retailer. International Journal of Production Economics, 139, 155–167.

Ma, L., Zhao, Y., Xue, W., Cheng, T. C. E., & Yan, H. (2012). Loss-averse newsvendor model with two ordering opportunities and market information updating. International Journal of Production Economics, 140, 912–921.

Manerba, D., & Mansini, R. (2014). An effective matheuristic for the capacitated total quantity discount problem. Computers & Operations Research, 41, 1–11.

Mansini, R., Savelsbergh, M. W. P., & Tocchella, B. (2012). The supplier selection problem with quantity discounts and truckload shipping. Omega, 40, 445–455.

Meena, P. L., & Sarmah, S. P. (2013). Multiple sourcing under supplier failure risk and quantity discount: A genetic algorithm approach. Transportation Research Part E, 50, 84–97.

Meena, P. L., Sarmah, S. P., & Sarkar, A. (2011). Sourcing decisions under risks of catastrophic event disruptions. Transportation Research Part E, 47, 1058–1074.

Mirahmadi, N., Saberi, E., & Teimoury, E. (2012). Determination of the optimal number of suppliers considering the risk: Emersun Company as a case study. Advanced Materials Research, 433–440, 5873–5880.

Nejad, A. E., Niroomand, I., & Kuzgunkaya, O. (2014). Responsive contingency planning in supply risk management by considering congestion effects. Omega, 48, 19–35.

Pal, B., Sana, S. S., & Kripasindhu, K. (2012). A multi-echelon supply chain model for reworkable items in multiple-markets with supply disruption? Economic Modelling, 29, 1891–1898.

Pang, B., & Bai, S. (2013). An integrated fuzzy synthetic evaluation approach for supplier selection based on analytic network process. Journal of Intelligent Manufacturing, 24, 163–174. doi:10.1007/s10845-011-0551-3.

Peidro, D., Mula, J., Jiménez, M., & Botella, M. D. M. (2010). A fuzzy linear programming based approach for tactical supply chain planning in an uncertainty environment. European Journal of Operational Research, 205, 65–80.

Pinto, R., Mettler, T., & Taisch, M. (2013). Managing supplier delivery reliability risk under limited information: Foundations for a human-in-the-loop DSS. Decision Support Systems, 54, 1076–1084.

Qi, L. (2013). A continuous-review inventory model with random disruptions at the primary supplier. European Journal of Operational Research, 225, 59–74.

Ravindran, A. V., Bilsel, R. U., Wadhwa, V. V., & Yang, T. (2010). Risk adjusted multicriteria supplier selection models with applications. International Journal of Production Research, 48(2), 405–424.

Ray, P., & Jenamani, M. (2014). Sourcing decision under disruption risk with supply and demand uncertainty: A newsvendor approach. Annal Operation Research. doi:10.1007/s10479-014-1649-8.

Ruiz-Torres, A. J., & Mahmoodi, F. (2007). The optimal number of suppliers considering the costs of individual supplier failures. Omega, 35, 104–115.

Ruiz-Torres, A. J., & Mahmoodi, F. (2006). A supplier allocation model considering delivery failure, maintenance and supplier cycle costs. International Journal of Production Economics, 103, 755–766.

Ruiz-Torres, A. J., Mahmoodi, F., & Zeng, A. Z. (2013). Supplier selection model with contingency planning for supplier failures. Computers & Industrial Engineering, 66, 374–382.

Sanayei, A., Mousavi, S. F., & Yazdankhah, A. (2010). Group decision making process for supplier selection with VIKOR under fuzzy environment. Expert Systems with Applications, 37, 24–30.

Sarkar, A., & Mohapatra, P. K. J. (2009). Determining the optimal size of supply base with the consideration of risks of supply disruptions. International Journal of Production Economics, 119, 122–135.

Sawik, T. (2011a). Selection of supply portfolio under disruption risks. Omega, 39, 194–208.

Sawik, T. (2013a). Selection of resilient supply portfolio under disruption risks. Omega, 41, 259–269.

Sawik, T. (2014). Optimization of cost and service level in the presence of supply chain disruption risks: Single vs. multiple sourcing. Computers & Operations Research, 51, 11–20.

Sawik, T. (2014). Joint supplier selection and scheduling of customer orders under disruption risks: Single vs. dual sourcing. Omega, 43, 83–95.

Sawik, T. (2010). Single vs. multiple objective supplier selection in a make to order environment. Omega, 38, 203–212.

Sawik, T. (2011b). Supplier selection in make-to-order environment with risks. Mathematical and Computer Modelling, 53, 1670–1679.

Sawik, T. (2013b). Integrated selection of suppliers and scheduling of customer orders in the presence of supply chain disruption risks. International Journal of Production Research, 51, 23–24.

Sayın, F., Karaesmen, F., & Özekici, S. (2014). Newsvendor model with random supply and financial hedging: Utility-based approach. International Journal of Production Economics, 154, 178–189.

Schmitt, A. J. (2011). Strategies for customer service level protection under multi-echelon supply chain disruption risk. Transportation Research Part B, 45, 1266–1283.

Schmitt, A.J., & Singh M. (2009) Quantifying supply chain disruption risk using Monte Carlo and discrete-event simulation, In: Proceedings of the winter simulation conference.

Schmitt, A. J., & Singh, M. (2012). A quantitative analysis of disruption risk in a multi-echelon supply chain. International Journal of Production Economics, 139, 22–32.

Schmitt, A. J., & Snyder, L. V. (2012). Infinite-horizon models for inventory control under yield uncertainty and disruptions. Computers & Operations Research, 39, 850–862.

Schmitt, A. J., Snyder, L. V., & Shen, Z.-J. M. (2010). Inventory systems with stochastic demand and supply: Properties and approximations. European Journal of Operational Research, 206, 313–328.

Şen, A., Yaman, H., Güler, K., & Körpeoğlu, E. (2014). Multi-period supplier selection under price uncertainty. Journal of the Operational Research Society, 65, 1636–1648.

Serel, D. A. (2007). Capacity reservation under supply uncertainty. Computers & Operations Research, 34, 1192–1220.

Serel, D. A. (2008). Inventory and pricing decisions in a single-period problem involving risky supply. International Journal of Production Economics, 116, 115–128.

Sharma, S., & Balan, S. (2013). An integrative supplier selection model using Taguchi loss function. TOPSIS and multi criteria goal programming. Journal of Intelligent Manufacturing, 24, 1123–1130. doi:10.1007/s10845-012-0640-y.

Shina, H., Benton, W. C., & Jun, M. (2009). Quantifying suppliers’ product quality and delivery performance: A sourcing policy decision model. Computers & Operations Research, 36, 2462–2471.

Silbermayr, L., & Minner, S. (2014). A multiple sourcing inventory model under disruption risk. International Journal of Production Economics. doi:10.1016/j.ijpe.2013.03.025

Song, D.-P., Dong, J.-X., & Xu, J. (2014). Integrated inventory management and supplier base reduction in a supply chain with multiple uncertainties. European Journal of Operational Research, 232, 522–536.

Sun, G., Liu, Y., & Lan, Y. (2011). Fuzzy two-stage material procurement planning problem. Journal of Intelligent Manufacturing, 22, 319–331. doi:10.1007/s10845-009-0306-6.

Tabrizi, B. H., & Razmi, J. (2013). Introducing a mixed-integer non-linear fuzzy model for risk management in designing supply chain networks. Journal of Manufacturing Systems, 32, 295–307.

Tai-Yue Wang, T. Y., & Yang, Y. H. (2009). A fuzzy model for supplier selection in quantity discount environments. Expert Systems with Applications, 36, 12179–12187.

Talluri, S., Narasimhan, R., & Chung, W. (2010). Manufacturer cooperation in supplier development under risk. European Journal of Operational Research, 207, 165–173.

Tapiero, C. S., & Kogan, K. (2007). Risk and quality control in a supply chain: Competitive and collaborative approaches. Journal of the Operational Research Society, 58, 1440–1448.

Taskin, S., & Lodree, E. L, Jr. (2010). Inventory decisions for emergency supplies based on hurricane count predictions. International Journal of Production Economics, 126, 66–75.

Tehrani, M. B., Xu, S. H., Kumara, S., & Li, H. (2011). A single-period analysis of a two-echelon inventory system with dependent supply uncertainty. Transportation Research Part B, 45, 1128–1151.

Tomlin, B. (2006). On the value of mitigation and contingency strategies for managing supply chain disruption risks. Management Science, 52(5), 639–657.

Tse, Y. K., & Tan, K. H. (2012). Managing product quality risk and visibility in multi-layer supply chain. International Journal of Production Economics, 139, 49–57.

Ustun, O., & Demirtas, E. A. (2008). An integrated multi-objective decision-making process formulti-period lot-sizing with supplier selection. Omega, 36, 509–521.

Vinodh, S., Ramiya, R. A., & Gautham, S. G. (2011). Application of fuzzy analytic network process for supplier selection in a manufacturing organization. Expert Systems with Applications, 38, 272–280.

Viswanadham, N., & Gaonkar, R. A. (2003). Conceptual and analytical framework for the management of risk in supply chains. In: Proceedings of IT-MLS December 15–16.

Wang, Q. (2013). A periodic-review inventory control policy for a two-level supply chain with multiple retailers and stochastic demand. European Journal of Operational Research, 230, 53–62.

Waters, D. (2007). Global logistics new directions in supply chain management. London and Philadelphia: Kogan Page.

Weber, C. A., Current, Jr, & Benton, W. C. (1991). Vendor selection criteria and methods. European Jurnal of Operational Research, 50, 2–18.

Wu, D., & Olson, D. L. (2008). Supply chain risk, simulation, and vendor selection. International Journal of Production Economics, 114, 646–655.

Wu, D., Wu, D. D. W., Zhang, Y., & Olson, D. L. (2013). Supply chain outsourcing risk using an integrated stochastic-fuzzy optimization approach. Information Sciences, 235, 242–258.

Wu, D. D., Zhang, Y., Wu, D., & Olson, D. L. (2010). Fuzzy multi-objective programming for supplier selection and risk modeling: A possibility approach. European Journal of Operational Research, 200, 774–787.

Wu, T., Blackhurst, J., & Chidambaram, V. (2006). A model for inbound supply risk analysis. Computers in Industry, 57, 350–365.

Xanthopoulos, A., Vlachos, D., & Iakovou, E. (2012). Optimal newsvendor policies for dual-sourcing supply chains: A disruption risk management framework. Computers & Operations Research, 39, 350–357.

Xiang, W., Song, F., & Ye, F. (2014). Order allocation for multiple supply demand networks within a cluster. Journal of Intelligent Manufacturing, 25, 1367–1376. doi:10.1007/s10845-013-0735-0.

Xiao, T., Jin, J., Chen, G., Shi, J., & Xie, M. (2010). Ordering, wholesale pricing and lead-time decisions in a three-stage supply chain under demand uncertainty. Computers & Industrial Engineering, 59, 840–852.

Xiao, T., & Yang, D. (2008). Price and service competition of supply chains with risk-averse retailers under demand uncertainty. International Journal of Production Economics, 114, 187–200.

Xiao, Z., Chen, W., & Li, L. (2012). An integrated FCM and fuzzy soft set for supplier selection problem based on risk evaluation. Applied Mathematical Modelling, 36, 1444–1454.

Yang, S., Yang, J., & Abdel-Malek, L. (2007). Sourcing with random yields and stochastic demand: A newsvendor approach. Computers & Operations Research, 34, 3682–3690.

Yan, & Nishi, (2014). A supply chain planning model with supplier selection under uncertain demands and asymmetric information. Procedia CIRP, 17, 639–644.

Yu, H., Zeng, A. Z., & Zhao, L. (2009). Single or dual sourcing: Decision-making in the presence of supply chain disruption risks. Omega, 37, 788–800.

Zegordi, S. H., & Davarzani, H. (2012). Developing a supply chain disruption analysis model: Application of colored Petri-nets. Expert Systems with Applications, 39, 2102–2111.

Zhang, J. L., & Zhang, M. Y. (2011). Supplier selection and purchase problem with fixed cost and constrained order quantities under stochastic demand. International Journal of Production Economics, 129, 1–7.

Zhang, J.-L., & Chen, J. (2013). Supplier selection and procurement decisions with uncertain demand, fixed selection costs and quantity discounts. Computers & Operations Research, 40, 2703–2710.

Zhang, D. Y., Cao, X., Wang, L., & Zeng, Z. (2012). Mitigating the risk of information leakage in a two-level supply chain through optimal supplier selection. Journal Intelligent Manufacturing, 23, 1351–1364.

Zhu, J., & Fu, S. (2013). Ordering policies for a dual sourcing supply chain with disruption risks. Journal of Industrial Engineering and Management, 6(1), 380–399.

Zouggari, A., & Benyoucef, L. (2012). Simulation based fuzzy TOPSIS approach for group multi-criteria supplier selection problem. Engineering Applications of Artificial Intelligence, 25, 507–519.

Author information

Authors and Affiliations

Corresponding author

Appendix

Rights and permissions

About this article

Cite this article

Hamdi, F., Ghorbel, A., Masmoudi, F. et al. Optimization of a supply portfolio in the context of supply chain risk management: literature review. J Intell Manuf 29, 763–788 (2018). https://doi.org/10.1007/s10845-015-1128-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10845-015-1128-3