Abstract

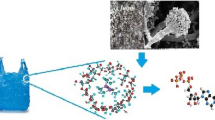

To date, enumerable fungi have been reported to participate in the biodegradation of several notorious plastic materials following their isolation from soil of plastic-dumping sites, marine water, waste of mulch films, landfills, plant parts and gut of wax moth. The general mechanism begins with formation of hydrophobin and biofilm proceding to secretion of specific plastic degarding enzymes (peroxidase, hydrolase, protease and urease), penetration of three dimensional substrates and mineralization of plastic polymers into harmless products. As a result, several synthetic polymers including polyethylene, polystyrene, polypropylene, polyvinyl chloride, polyurethane and/or bio-degradable plastics have been validated to deteriorate within months through the action of a wide variety of fungal strains predominantly Ascomycota (Alternaria, Aspergillus, Cladosporium, Fusarium, Penicillium spp.). Understanding the potential and mode of operation of these organisms is thus of prime importance inspiring us to furnish an up to date view on all the presently known fungal strains claimed to mitigate the plastic waste problem. Future research henceforth needs to be directed towards metagenomic approach to distinguish polymer degrading microbial diversity followed by bio-augmentation to build fascinating future of waste disposal.

Similar content being viewed by others

Introduction

The use of plastics is deeply embedded in our daily lives; as a result the global polymer production has increased from 1.5 to 2 million metric tonnes (MMT) in 1950 to 380 MMT by 2015 and is expected to double by 2050 (Gross and Enck 2021). Reasons behind such high popularity are low cost, water insolubility, corrosion and electricity resistance, easiness of fabrication by heating and molding, highly versatility and resilience as well as light in weight. These attributes have made plastic products better and user-friendly than other materials in a range of fields including packaging, garments, transports, consumer products, electronics, construction and industrial machinery (Urbanek et al. 2018). Recently, the demand has even been exaggerated during SARS-CoV-2 outbreak as one-time use latex gloves, surgical and face masks played important roles in protecting people from the virus (Yuan et al. 2021). The major issue with plastics is that 90% of the production consists of synthetic polymers such as polyethylene (PE), polypropylene (PP), polystyrene (PS), polyethylene terephthalate (PET), polyvinyl chloride (PVC) and polyurethane (PU) which take hundreds of years to decompose (Shams et al. 2021). For instance, plastic straw, PET water bottle, single-use diaper and PS foam are estimated to have lifetimes of 200, 450, 500 and beyond 5000 years in the milieu, respectively. Such inherent resistance to degradation coupled with excessive use has now raised a major concern regarding disposal of plastic waste (Kannan and Vimalkumar 2021).

At present, landfilling is the most widely followed technique to treat the trash that in turn causes hazards to our environment. Other practices such as incineration, recycling, pyrolysis and photo-degradation are currently showing great hope. But they are neither sufficient nor sustainable and thus has stressed on the need for more justifiable waste management protocols (Huang et al. 2022). As such, lack of proper treatment has led to the buildup of mismanaged plastic litter in all ecosystems such as soil, lakes and rivers ultimately reaching the oceans (Zeghal et al. 2021). The situation has now compelled researchers to look for alternative methods to curb plastic waste pollution. One such solution comes in the form of biodegradation that has now received great attention due to its sustainable nature and affordability (Ganesh Kumar et al. 2020). The process encompasses decomposition of plastic materials into H2O, CO2 and biomass where living organisms, microbes in particular, play a key role (Shah et al. 2008). In this context, application of fungi holds great promise as they can form biofilms on the hydrophobic plastic surface and secrete a wide range of hydrolytic enzymes that can cleave chemical bonds of the polymers. They are thus prone to attack high molecular weight (Mw) compounds and transport the small fragments through plasma membrane for further intracellular break down. Notably fungi are often regarded as better plastic degrader than bacteria as illustrated by Moyses et al. 2021; Urbanek et al. 2021; Radwan et al. 2020; Muhonja et al. 2018. Scientists across the globe are hence on the lookout for potent fungi and utilize their prowess. Till date more than 70 species, belonging predominantly to Ascomycetes, have been identified for their ability to deteriorate different synthetic as well as biodegradable plastic types (Hyde et al. 2019). Despite that, most of the reviews are focused on the fate of plastics including microplastics (MPs) (Ge et al. 2021; Issifu et al. 2020); while viewpoints and congregation of findings on polymer degradation by fungi is limited (Zimmermann 2021; Zeghal et al. 2021; Sánchez 2019). Based on the needs, the present review explicated all plastic degrading fungal strains, their enzymes and effect on different kinds of polymers. Also, a detailed understanging of fungal degradation mechanism of different kinds of plastics is brought out. Finally we confer directions of future research for succeeding widespread remedial aspect.

Biodegradation or biotic degradation or bioremediation

The continuous rising of plastic demand, human population, urbanization and economic growth led to the plastic waste production every year at an alarming rate (Miandad et al. 2019). Controlling such polymer trash is critical as unmanaged waste is not only an eyesore, but can be a breeding ground for pathogens and block sewer networks as well as water drains leading to flood. Requisite for scientific disposal of the waste was however recognized in the 1980s and since then, various attempts have been taken by numerous researchers to identify suitable methods of plastic waste management. Current techniques for addressing the problem include landfill, incineration, recycling and pyrolysis which are not only costly but also put more burdens on our environment (Huang et al. 2022). According to a study by Burt et al. (2020), the cost of mechanical removal of 25 tonnes of plastic waste was $224,537. Recently, efforts have focused on the biodegradation method being economically cheaper and more effective technique than any other traditional process of waste disposal (Zahra et al. 2010) (Fig. 1). Generally, abiotic techniques such as photo-oxidation, erosion, hydrolysis and thermal as well as mechanical stresses pave the way for biodegradation of polymers. However, the sustainable approach is largely dependent on action of microorganisms as they release hydrolytic or oxidative enzymes as well as metabolic by-products like acids (Moore-Kucera et al. 2014). Thus the process produces some economically valuable secondary products which are of great advantageous (Sanniyasi et al. 2021). Aerobic biodegradation is thus an environmentally sound method where microbial population quickly degrades heterogeneous organic matter in presence of oxygen under controlled conditions (DSouza et al. 2021).

The course eventually causes change in optical, mechanical and electrical properties of plastics that can be assessed by measuring alteration in molar mass and tensile strength, formation of cracks, splitting, discoloration, and delamination, synthesis of new products and observing microorganism growth on the polymer substrate (Janczak et al. 2018). However, the process is governed by several factors such as polymer features and the environment where polymers are placed or disposed of (Emadian et al. 2017) (Supplementary Fig. 1). Rate of the process is also known to be affected by the type of microbes growing on the surface and their proteins. In this view, fungi have often been reported as efficient degraders of polymeric substances as the amount of proteins produced and secreted by them is significantly higher than that of bacteria (Ren et al. 2021).

Fungi: a major recycler in the environment

Fungi are a diverse group of microorganisms that inhabit various ecosystems and act as decomposers of complex constituents of plant remains, including cellulose and lignin. Indeed several species dwelling in various natural habitats and belonging to different classes has been validated to deteriorate plastics (Amobonye et al. 2021). Most of them have been reported almost exclusively from India, Pakistan and Japan (Fig. 2) (Sheth et al. 2019). Majority of the investigated taxa have been collected from marine environments due to their high abundance and ability to live on different types of floating aquatic substrates (Balabanova et al. 2018). Currently, 1901 species have been enlisted in the marine fungi website (http://www.marinefungi.org), belonging to 769 genera; although Jones (2011) suggested there may be as many as 10,000 specimens highlighting that data on fungi is still lacking. In this backdrop, Lacerda et al. (2020) designed experiments to elucidate myco-diversity associated with polymers, including micro and meso-plastics, sampled from surface water of Western South Atlantic and Antarctic Peninsula. The analysis revealed total of 64 fungal orders related with the polymers where 32 taxa were found in both the sampling locations, 21 specimens were unique to Western South Atlantic and 11 were exclusive to Antarctic Peninsula. Amongst all the specimens, genus Aspergillus was found to be the most prevalent taxon. Besides, Cladosporium and Wallemia have also been detected in both the places. The investigation further highlighted that some fungal groups, such as Aphelidomycota, Zoopagomycota, Mucoromycota and Blastocladiomycota had first time been reported to populate polymer in the ocaenic circumference. The observation was in accord to Wang et al. (2021) characterizing the fungal communities on three types of plastics incubated in freshwater in China. As a result, the members of Ascomycota, Basidiomycota, Blastocladiomycota and Mucoromycota were found to be the predominant communities on the tested polymers. De Tender et al. (2017) unveiled taxonomic composition of the fungal groups associated with PE sheets and dolly ropes exposed to marine environment for nearly 1 year at a harbor and an offshore place in Belgian part of North Sea. Intriguingly, no known bacterial species were detected in connection with plastic degradation; however the researchers did notice three fungal Operational Taxonomic Unit (OTU)s namely Cladosporium cladosporioides, Fusarium redolens (in higher abundance) and Mortierella alpine. Apart from the aquatic environment, plastic deteriorating fungi have been reported from various other sources also, like plastic dumping sites and mangrove rhizosphere soil where members belonging to the phylum of Ascomycetes and Basidiomycetes have been detected as the exceedingly potent taxa (Hock et al. 2019). Amongst them, Penicillium sp. and Aspergillus sp. have been identified as the most frequently isolated specimens possessing ability to deteriorate both biodegradable and conventional polymers (Tamoor et al. 2021) (Supplementary Table 1 and Fig. 2). Thus, reducing and eliminating plastic wastes through fungal strains represent a sustainable solution to the serious issues of environmental pollution, thanks to their unique strategies adapted for polymer disintegration and surviving ability in stressful growth conditions (Sheik et al. 2015). Detailed exploration of their potency would be extremely valuable to build unique combinations of organisms and/or enzymes to curb the problem (Sheth et al. 2019).

Effect of fungal activity on PET

To mitigate the escalating problem of PET pollution, biodegradation merits greater attention due to its environmental friendliness and sustainability. Despite that, only few reports have been published describing ability of fungi to cause changes in the structure of PET. Malafatti-Picca et al. (2019) enumerated that two isolates of filamentous fungus namely Microsphaeropsis arundinis CBMAI 2109 and CBMAI 2110 could reduce PET mass by 0.5 and 0.16% respectively after 14 days of incubation. While, Penicillium funiculosum resulted 0.08% weight loss in PET when grown in sugar free minimal mineral medium for 84 days (Nowak et al. 2011). In a separate study, Yarrowia lipolytica IMUFRJ 50,682 emerged as a potent PET biodegradable organism as the yeast was found to convert PET into mono-(2-hydroxyethyl)terephthalic acid (MHET) where the PET monomers might acted as inducers in lipase production (Da Costa et al. 2020). Liu et al. (2021) engineered a PETase-expressing Y. lipolytica strain that hydrolyzed bis(2-hydroxyethyl) terephthalate (BHET) and PET powder into the monomers. Herrero Acero et al. (2011) showed that cutinases from Humicola insolens, Pseudomonas mendocina, Fusarium solani, Thermobifida cellulosilytica and Thermobifida fusca were able to hydrolyze PET. The previous studies thus suggest that enhancing catalytic activity of fungal carboxylic ester hydrolases such as cutinase and lipase could open new avenues for PET dedradation.

Effect of fungal activity on PE

PE polymers consist of amorphous crystalline structure and are highly notorious to biodegradation due to its hydrophobicity, long carbon chains, high Mw as well as lack of functional groups resisting mineralization (Sheik et al. 2015). However, the polymers can easily be broken down via direct attack by microorganisms where the speed of degradation can be enhanced by prior UV irradiation (photo-oxidation), thermal and chemical oxidation (Ameen et al. 2015). In this context, a growing body of literature has illustrated ability of fungi to disintegrate PE of different kinds irrespective of prior treatments (Table 1). For instance Sangale et al. (2019) collected sample from plastic waste dumping sites at mangrove area. Amongst the total 109 fungal isolates, Aspergillus terreus and Aspergillus sydowii exhibited great potency in reducing plastic weight and tensile strength after 60 d of incubation. The degradation was further authenticated by scanning electron microscopy (SEM) analysis where disturbances on PE surface such as formation of cracks, scions, fissures and holes were observed confirming corrosion by the fungal strains. The similar behaviour has also been reported in case of Zalerion maritimum, a marine fungus, which was found to grow in minimum growth medium in presence of PE MPs (Paço et al. 2017). Fusarium sp. showed high potency for the degradation of PE pieces, when cultured in basal salts medium at 30 °C and 150 rpm for 2 months (Shah et al. 2009). In a separate study, Yamada-Onodera et al. (2001) suggested pretreatment of PE using Penicillium simplicissimum makes the deterioration process easier and faster. Similar experiments have also been performed by the same group using P. simplicissimum collected from local dumpsite soil in India. The organism was able to degrade UV-treated PE (38%) more efficiently than autoclaved (16%) and surface sterilized (7.7%) after 3 months of incubation. The weight loss results were in accordance to SEM observation and FT-IR analysis. Enzymes responsible for PE degradation were identified as laccase and manganese-dependent peroxidase (MnP) (Sowmya et al. 2015).

Pretreatment has also been found to be an important tool for HDPE degradation by fungi as reported in earlier studies (Supplementary Fig. 3). For instance, exposure of Cephalosporium sp. caused 7.18% weight loss of HDPE polymer, pretreated with nitric acid, after 20 days of incubation period. Moreover, decrease in crystallinity and pH of liquid culture media as well as increase in total dissolved solid (TDS) and conductivity further confirmed ability of the fungus to utilize HDPE for growth (Chaudhary and Vijayakumar 2020a). Earlier, Mathur et al. (2011) investigated on ability of Aspergillus niger to degrade HDPE that was subjected to thermal treatment by placing the plastic at 70 °C for 10 days. After 1 month incubation, heavy colonization, hyphal penetration in the film, reduction in mass (3.44%) and tensile strength (61%) of PE were observed. Further analyses showed cracks on the surface of polymer and decrease in amount of carbonyl residues indicating great possibility of the fungus to degrade HDPE. In contrast, some studies have shown that fungi can break down HDPE without any prior treatments. As an example, incubation of Aspergillus tubingensis and Aspergillus flavus with HDPE for 1 month resulted 6.02 and 8.51% weight loss of the plastic respectively signifying higher efficiency of A. flavus. Moreover, biofilm formation, changes in surface topography of the film and chemical alterations such as decrease in carbonyl index were also recorded. Experiment was also performed to enquire effect of mineral oil on the colonization efficacy where results suggested that presence of the light white oil stimulated hydrophobic interaction between the taxa and polymer surface promoting rate of biodegradation (Devi et al. 2015). In another work, A. flavus isolated from gut contents of wax moth Galleria mellonella, have been reported to degrade HDPE MPs into particles of low Mw after 28 d of incubation where the process was might be triggered by laccase-like multicopper oxidases (Zhang et al. 2020). Thus, it could be predicted that fungi are gradually adapting toward HDPE biodegradation by natural evolution.

In respect to LDPE bio-degradation, the genus Aspergillus has emerged as an efficient organism where Muhonja et al. (2018) attributed the effect to Aspergillus oryzae. They have also elucidated fungi as better degraders of PE in comparison to bacteria which could be due to higher production of laccase and esterase. In another study, Trichoderma viride and Aspergillus nomius were found as potent plastic degrader as they reduced weight of the LDPE film by 5.13% and 6.63% respectively after 45 d of cultivation in mineral salt agar medium supplemented with 0.5% glucose. While, tensile strength of the treated films was reduced significantly by 58% and 40%. Analyses of electron micrograph exhibited formation of grove and rough on the surface of LDPE. Comparatively, the outcome was found to be lower than that of Aspergillus japonicus and A. niger as they showed 12% and 8% LDPE degradation ability respectively under laboratory conditions within 1 month period. SEM analysis further confirmed the efficacy as evident by fragility and presence of porosity on the fungal degraded PE surface (Raaman et al. 2012). Aspergillus niger and A. terreus were isolated from a mangrove in Ecuador and they degraded up to 35.3% and 22.14% of LDPE films weight over a period of 77 days (Sáenz et al. 2019). However the outcome was comparatively lower than that of Aspergillus clavatus as the fungus caused 35% weight loss of LDPE films after 2 months of incubation. Further, 2.32 g/l CO2 production was found when the specimen was incubated with the plastic for 1 month (Gajendiran et al. 2016). The findings are similar with Shah et al. (2009) reporting 1.85 g/l CO2 evolution after 1 month period of incubation with Fusarium sp. on LDPE films. The Ascomycetes was also capable of adhering to the PE surface manifested by increase in mycelial growth, when cultured in basal salts medium at 30 °C and 150 rpm for 2 months. Further, morphological changes in PE pieces like appearance of pits, cracks and erosion were detected as well indicating ability of the fungus of utilizing PE as the source of carbon and energy. Earlier, an extensive study has been reported by Ameen et al. (2015) that was designed to isolate potent LDPE degrading fungal isolates from the marine water. At per the results, six isolates were able to grow profusely on the film along with production of more ligninolytic enzymes and release of CO2. The overall effect was found to be in the decreasing order of Alternaria alternata > A. terreus > Eupenicillium hirayamae > Paecilomyces variotii > Phialophora alba and Aspergillus caespitosus. Interestingly, consortium of all these isolates portrayed the best degradation effect suggesting a synergistic consequence of the fungi.

In contrast to previous findings, few studies have reported on fungal degradation of LDPE pretreated in various ways. For instance, Sheik et al. (2015) irradiated PE with different doses of radiation (0–1000 kGy) and incubated with endophytic fungi for 90 days. The specimens namely Aspergillus sp., Paecilomyces lilacinus and Lasiodiplodia theobromae caused decrease in intrinsic viscosity and average Mw of the LDPE strips. Further, the fungi were able to grow profusely over hydrophobic surface of plastic films which might be aided by laccase. In another study, Fusarium sp. was found to grow better in mineral salt medium with LDPE pieces pretreated with UV for about 250 h followed by nitric acid at 80 °C for 6 days (Hasan et al. 2007) suggesting combination of physical pretreatment with myco-remediation could significantly enhance the overall efficiency of the process.

Effect of fungal activity on PVC

Till date, only few studies have been published identifying fungal strains with PVC degradable ability. Ali et al. (2014b) performed soil burial experiment and asserted P. chrysosporium, L. tigrinus, A. niger and A. sydowii to flourish on PVC film after 10 months of incubation. The findings were further verified by shake flask method where P. chrysosporium caused maximum biomass production, better CO2 release (7.85 g/l) and reduction in Mw of the film by about 1 kDa. The same fungus has been used in another study where it exhibited better potency in degradation of starch blended PVC. As such, the incubation for 1 month resulted decrase of Mw of the polymer by around 2 kDa along with 7.31 g/l CO2 release (Ali et al. 2014a). These observations are substantially in line with other studies where researchers treated cellulose blended PVC with cellulolytic fungi like Trichocladium sp. and Chaetomium sp. (Kaczmarek and Bajer 2007). So far, only few studies have documented the participation of fungal ligninolytic enzymes in PVC biodegradation (Khatoon et al. 2019); however effort on quantification and purification of the enzyme is limited.

Effect of fungal activity on PP

Presence of methyl group in β position makes PP a hardly biodegradable plastic, particularly in absence of pretreatment processes. Therefore, finding potent microorganisms with PP deterioration activity is highly required; though very few studies have been reported till date. Sheik et al. (2015) designed an experiment where PP films were irradiated at different doses of gamma radiation ranging from 0 to 100 kGy to understand effect of pretreatment on the polymer degradation by fungi. Amongst the investigated species, only L. theobromae inoculated film showed weight loss after 3 months of incubation where the effect was more prominent from 40 kGy dose onwards. Further, a discernible decrease in Mw and viscosity of the PP films was also recorded. FT-IR data revealed that carbonyl groups appeared from 60 to 100 kGy in gamma irradiated film indicating that higher doses can increase sensitivity of plastics towards the fungi. In a separate study, A. fumigatus has been reported to degrade up to 18.08% of PP over a period of 6 months (Oliya et al. 2020). To date, there has been no investigation into the utilization of fungal enzymes for the biodegradation of PP at per our knowledge.

Effect of fungal activity on PS

Reports of PS destruction in nature are scarce and typically indicate only little degradation. However, fungi could represent promising candidates for PS biodegradation due to their numerous unspecific and powerful extracellular oxidation mechanisms (Krueger et al. 2017). Tian et al. (2017) synthesized two different types of 14 C-labelled PS polymers and investigated effect of Penicillium variabile CCF3219 as well as ozonation on the mineralisation process. The results showed that the specimen mineralised both labelled polymers, and the [U-ring-14 C]-PS with a lower Mw led to a higher mineralisation rate. GPC analysis further showed that Mw of the ozonated [β-14 C]-PS decreased after incubation. The investigation hence suggests that the pretreatment could be a potential approach for PS waste degradation and remediation of plastic-contaminated locations. Recently Chaudhary and Vijayakumar (2020b) reported that incubation of Cephalosporium sp. and Mucor sp. with PS for 2 months resulted a weight loss of 2.17% and 1.81% respectively. The same time duration has also been used by Oviedo-Anchundia et al. (2021) reporting 8.39% and 6.82% PS degradation abilities of Penicillium sp. and Geomyces sp. respectively; in contrast to that Mortierella sp. degraded the polymeric material only by 2.19%. Further, it was inferred that the investigated fungi were more active on aged polymer, possibly due to the molecular alterations induced by pretreatment with UV radiation.

Effect of fungal activity on PU

Recent research has portrayed that PU in acidic and neutral soil is susceptible to microbial attacks where fungi can act as the predominant degrading microbes (Cosgrove et al. 2007). Various studies across the globe have conveyed potent PU degrading fungi isolated from sand, dumping areas, contaminated soils, compost, plastic waste, wall paint and plastic debris floating near lakeshores (Ren et al. 2021). Several types of PU materials such as polyether urethane foam, thermoplastic polyester and PU waterborne dispersion of polyester PU have been appeared as sensitive to fungal degradation. One example is the research of Cosgrove et al. (2007) who reported on the fungal communities associated with in situ degradation of polyester PU buried in two sandy loam soils for 5 months. Phoma sp. was identified as the main cultivable organism collected from the PU surface buried in neutral soil (pH 6.7). Whilst, PU buried in acidic soil (pH 5.5) was found to be dominated by Geomyces pannorum and Nectria sp. indicating that the soil type plays an important role on the composition of plastic degrading fungal communities. Both the fungi represented >80% of cultivable colonies from each plastic and degraded Impranil (an anionic and aromatic polyether-PU dispersion) also. In a previous study, Curvularia senegalensis was observed to possess better PU-degrading activity and further analysis lead to purification of an extracellular polyurethanase displaying esterase activity (Crabbe et al. 1994). Esterase production has also been found in Monascus ruber, Monascus sanguineus and Monascus sp. where the researchers indicated a correlation between enzyme synthesis by the fungal strains and sampling sites (El-Morsy et al. 2017). Russell et al. (2011) isolated endophytes from Ecuadorian Amazonian plants to screen for their ability to degrade PU where all active fungi were found to belong to Ascomycota. Amongst them, Pestalotiopsis microspora was identified as the better PU degrader under both aerobic and anaerobic conditions. The endophytic fungus appeared to produce extracellular and diffusible serine hydrolase responsible for PU degradation. Putative polyurethanases have been isolated from protein extracts of Candida rugosa as well with reaction optima of pH 7 and 35 °C which may help to develop bioreactors for real-time application to manage PU trash (Gautam et al. 2007). Recently, F. solani was screened from soil contaminated with explosive rocket propellant material. Results indicated that the fungus was able to cause 25.8% mass loss for PU after 2 months along with morphological changes. Two possible degradation enzymes, namely lipase and esterase, were found to be synthesized by the specimen (Ren et al. 2021). The same enzymes have also been detected in A. tubingensis that was able to grow on the surface of PU film degrading the polymer (Khan et al. 2017). Additional studies identified F. solani and Candida ethanolica as PU degraders (Zafar et al. 2013); although associated enzymes have not yet been identified from them.

Effect of fungal activity on polyamide (PA) or nylon

PA is generally considered as non-biodegradable polymers; but recent studies have enumerated metabolism of PA by numerous microbes. Friedrich et al. (2007) conducted research on several fungi for their ability to degrade nylon fibres. Amongst them, Bjerkandera adusta disintegrated the fibres most efficiently after incubation for several weeks. MnP was detected in the liquid phase and presumed to be responsible for the degradation. The observation was in accord to Deguchi et al. (1998) as they found a nylon-degrading enzyme of Mw of 43 kDa in the extracellular medium of a ligninolytic culture of a white rot fungus. The protein was further purified that showed identical characteristics to those of MnP; however the activity of the native and purified enzyme varied from that of lignolytic enzyme. Structural degeneration of the nylon-66 membranes further confirmed the polymer-degrading activity. In a separate study, nylon 4 films were immersed in the broths containing minerals and Fusarium sp. As a result, weight of the films was found to decrease and disappear within 2 months. However, isolation and characterization of the associated enzyme remained elusive (Tachibana et al. 2010).

Effect of fungal activity on biodegradable plastics (BPs)

Recently, many researchers have confirmed that fungi have great potential to degrade several BPs including poly(lactic acid) (PLA) (Torres et al. 1996) and poly (L-lactide) (PLLA) (Jarerat and Tokiwa 2001) (Fig. 3). It showed that most of PLA film was degraded after 14 days of cultivation at 30 °C by the addition of gelatin. Some researchers have also explored ability of fungi for degradation of PLA in soil and compost (Karamanlioglu et al. 2013; Saadi et al. 2012). The research depicted temperature as a key parameter governing the fungal degradation of PLA. In addition, Lipsa et al. (2016) assessed biodegradation of PLA and some plasticized PLA with Trichoderma viride in liquid medium and controlled laboratory conditions. Degradation of low-Mw PLA has also been investigated with lipase from Rhizopus delemer (Fukuzaki et al. 1989). In contrast to PLA, several studies have been carried out to evaluate the biodegradation of poly(ε-caprolactone) (PCL). Tokiwa et al. (1976) isolated Penicillium sp. utilizing PCL for its growth and found PCL depolymerase activity in extracellular and intracellular fractions. The break down of PCL has also been manifested by lipase of Candida antarctica and cutinase of F. solani (Shi et al. 2020). In a recent study, Kosiorowska et al. (2021) aimed for co-expression of heterologous cutinase and native lipase in Y. lipolytica that resulted efficient degradation of PCL at 28 °C.

Poly(butylene succinate) (PBS) and its copolymers poly(butylene succinate-co-adipate) (PBSA) are comparatively recent and their fungal degradation has not been studied in detail. For instance, Li et al. (2011) prepared a UV mutant Aspergillus sp. XH0501-a that exhibited 38.89% better PBS degradation ability than that of wild-type strain. Further, a novel extracellular PBS-degrading enzyme with Mw of 44.7 kDa was purified. The optimum temperature and pH for the enzyme activity was 40 °C and 8.6 respectively. It was found that Fe2+ and Ca2+ enhanced the function, whereas Cu2+ and Hg2+ inhibited it. Chien et al. (2022) selected two elite PBSA-degrading Aspergillus strains, namely, A. terreus HC and A. fumigatus L30, from soil samples in Taiwan and incubated in carbon-free basal medium. Results showed that A. fumigatus and A. terreus deteriorated PBSA films by about 26% and 42% respectively within 1 month. In the soil burial test, A. terreus exhibited more than 90% and 75% degradation rates for summer and winter soil respectively; where further adding of mycelia to the winter soil, improved the degradation efficacy of PBSA. Further, the process of degradation or inclusion of fungal mycelia did not cause any adverse effect on growth of Chinese cabbage indicating non-toxic effect of the method. Kitamoto et al. (2011) reported potency of various strains of Pseudozyma and Cryptococcus to degrade PBS and PBSA films. Further, approximately a 22 kDa plastic-degrading enzyme was found to be secreted by the type strain, P. antarctica and Pseudozyma spp. In another approach, P. antarctica exhibited a strong degradation activity for BPs such as agricultural mulch films. An enzyme consisting of 198 amino acids was further isolated that degraded solid films of PBSA, PBS, PCL and PLA (Shinozaki et al. 2013b).

Indeed, it has been observed that several fungi have the ability to decompose more than one type of bioplastic, for instance, Urbanek et al. (2017) found eight fungal strains as PLA, PBS, PBSA or PCL degraders among 24 tested strains. Further, these strains were identified as species of Clonostachys rosea and Trichoderma that exhibited PCL degradation by 52.91% and 21.54% after 1 month incubation at 28 °C respectively. Penkhrue et al. (2015) described that C. cladosporioides and Purpureocillium lilacinum could form clear zones on PLA, PBS and PCL agar plates. This could be due to capcity of the fungi to excrete enzymes that can diffuse through agar and degrade the polymer into water soluble materials. Antipova et al. (2018) found that F. solani VKM F-4202 that could degrade about 90% of PCL within 30 days of cultivation. During the process, a culture medium containing peptones was selected, that facilitated synthesis of depolymerases decomposing PLA. On the other hand, Parengyodontium album VKM F-3028 and Aspergillus calidoustus VKM F-2909 efficiently degraded PLA samples within 1 month of cultivation. Jeszeová et al. (2018) investigated on the microbial communities responsible for degradation of PLA/PHB blend foils and for that they performed 1 year long laboratory soil burial experiments. Several PLA/PHB blend degrading microorganisms were isolated belonging to the genera Aureobasidium, Mortierella, Fusarium, Absidia, Bjerkandera, Actinomucor, Trichoderma and Penicillium. Sameshima-Yamashita et al. (2016) isolated an enzyme from Paraphoma like fungus strain B47-9 that could degrade commercial biodegradable films within eight h. Paraphoma-related fungal strain B47-9 secreted a BP-degrading enzyme belonging to the cutinase family; thus, it was named Paraphomarelated fungus cutinase-like enzyme (PCLE). It degraded various types of BP films, such as PBS, PBSA, poly(butylene adipate-co-terephthalate), PCL, and poly(DL-lactic acid). It has a molecular mass of 19.7 kDa, and an optimum pH and temperature for degradation of emulsified PBSA of 7.2 and 45 °C, respectively (Suzuki et al. 2014). Shinozaki et al. (2013a, b) described that esterases from Pseudozyma antarctica (PaE) was able to degrade BPs. The degradation profiles of plastic films composed of poly(butylene succinate), poly(butylene succinate-co-adipate), or poly(-butylene adipate) by these enzymes as charcterized by liquid chromatography-mass spectrometry and size exclusion chromatography (Sato et al. 2017). Oda et al. (1995) isolated five fungi from soil and amongst them, P. lilacinus was identified as efficient degrader of BPs as evident by formation of of 3-hydroxybutyrate from PHB and ɛ-caprolactone from PCL after incubation. The fungus was also found to excret PHB and PCL depolymerases in media containing either PHB, PCL or PHB plus PCL. A thermotolerant Aspergillus sp. ST-01 degraded more than 90% film samples of PHB and PCL at 50 °C. The degradation products were identified as succinic acid, butyric acid, valeric acid, and caproic acid (Sanchez et al. 2000). Overall, it was found that PHB and PCL-degrading microbes possess broader distribution in a wide range of environments than PLA degraders. Sankhla et al. (2020) enumerated distribution profile of the whole polymer-degrading microbes in soils as an order of PCL = PHB > PBS > PLA.

Sometimes, pro-oxidants (e.g. metal ions or oxides) and pro-degrading substances are included into the polymeric chain to augment photo- or thermo-oxidation and such polymers are called oxo-biodegradable polymers. The pro-oxidants helps in production of free radicals during photo-degradation, also termed pro-oxidant photocatalytic oxidation, resulting scission in the polymer chain promoting microbial degradation (Kitamoto et al. 2011). Till date, only few fungi have been reported to possess striking capacity to deteriorate such BPs. For instance, P. ostreatus has been found to form biofilm and break down oxo-BPs deprived of any previous physical treatment. The oxidation was suspected to be mainly due to laccase activity (da Luz et al. 2013). As a follow up study, the mushroom was subjected to oxo-BPs bags that were exposed to sunlight for up to 120 days. Results showed that P. ostreatus was able to grow using the plastics as a source of carbon and energy (da Luz et al. 2014). On oxo-biodegradable PE samples kept humid for 1 year, Ojeda et al. (2009) found formation of biofilms comprising species of Aspergillus and Penicillium. Moreover, Moore-Kucera et al. (2014) reported growth of majority of members belonged to the family Trichocomaceae including species of Aspergillus and Penicillium on BP mulch surfaces in field soil buried for 6 months.

Fungal mechanism for plastic degradation

Plastic biodegradation requires fungi to metabolize all organic components of the polymer which involves several key steps (Supplementary Fig. 4).

Attachment on plastic surface by hydrophobin

According to previous studies, attachment of fungal cell on the polymer surface acts as the initial step in plastic decomposition process. The event is mainly mediated by hydrophobin, a family of low Mw (≤ 20 kDa), small and globular proteins secreted by filamentous fungi. They are characterized by eight cysteine residues organized in a conserved array with four disulphide bridges and typical amphipathic nature possessing both hydrophilic and hydrophobic parts (Berger and Sallada 2019). They are comprised of 70–350 amino acids including signal peptide sequence that helps in translocation of the protein across endoplasmic reticulum and eventually is cleaved by specific peptidases (Khalesi et al. 2015). The proteins are accumulated on the surface of mycelia, spores and aerial parts of fungi, as they play a crucial role in fungal growth and development as well as survival and adaptation in any environment (Linder et al. 2005). They are involved in formation of hydrophobic aerial structures and mediate attachment of hyphae to hydrophobic solid supports (Scholtmeijer et al. 2005). As a result, hydrophobins also help in anchoring mycelia on the polymer surface paving the way of biodegradation as illustrated by several researchers in case of LDPE deterioration by fungi (Santacruz-Juárez et al. 2021; Zahra et al. 2010) and such capacity makes the organism as better plastic degraders than bacteria (Ghatge et al. 2020). The attachment step eventually makes plastic film surface more hydrophilic which further aids in microbial colonization (Han et al. 2020).

Colonization and biofilm formation

Biofilms are cellular consortia embedded in and/or attached to an extracellular polymeric matrix (Atanasova et al. 2021). It rapidly develops on any surface where water, nutrient and a source of carbon as well as energy are accessible. However, substratum properties such as hydrophobicity, crystallinity, roughness, melting temperature, elasticity modulus and glass transition temperature may influence selection of the microbial community during early stages of colonization. Previous studies have reported that agents like mineral oil and Tween 80 may improve hydrophobic interaction between the polymer and microbes, enhancing the rate of biofilm formation and degradation of PE (Devi et al. 2015). All in all, the prerequisite step for biodegradation is formation of biofilm on the plastic surface (De Tender et al. 2017).

After initial attachment of fungi to material surfaces, they can rapidly colonize and penetrate the substrates via their strong hyphal systems (Tamoor et al. 2021). Harding et al. (2009) indicated that filamentous fungi go through six steps for the development of biofilms: (a) deposition of spores on the surface of substrate (b) secretion of adhesive materials by spores and active germination (c) hyphal ramification (d) formation of dense hyphal and micelle network (e) enlargement in aerial growth of the colony, necessary for reproduction and (f) release of spores repeating the cycle.

Primary plastic degradation through extracellular fungal enzymes

Fungi produce a wide range of extracellular and membrane bound enzymes that have the potency to break down chemical bonds of the plastic polymers (Supplementary Table 2). These proteins belong to two main classes, namely hydrolases and oxidases (Atanasova et al. 2021; Ren et al. 2021). Hydrolases (EC 3.1.x) are the group of enzymes that catalyze cleavage of chemical bond in presence of water resulting breakage of a larger molecule into smaller ones. Hydrophobic cleft present near active site of the enzyme can accommodate hydrophobic groups in the polymer facilitating accessibility of the enzyme to plastic (Kaushal et al. 2021). Two examples of hydrolases are esterases and lipases (EC 3.1.1.X) that can cleave ester bonds in the carbon chain and are active chiefly on aliphatic polyesters. Cutinases (EC 3.1.1.74) are a sub-class of esterase that possesses ability to hydrolyze polyesters with high molar mass and thus have gained increased attention. These carboxylic ester hydrolases were originally extracted from plant pathogen, F. solani pisi (Mohanan et al. 2020). Both these enzymes are attributed to degrade PET and PU owing to presence of hydrolysable chemical bond in the plastics (Temporiti et al. 2022). Recently, a 20.4 kDa BP-degrading esterase was isolated from P. antarctica JCM10317 that degraded PBSA and PCL more rapidly than PBS and PLA indicating preference of the enzyme for C6 acyl chains (Shinozaki et al. 2013a, b). Another BP-degrading cutinase similar esterase has also been isolated from Paraphoma sp. B47-9 that can degrade PBS, PBSA, and PCL films (Koitabashi et al. 2012, 2016). González-Márquez et al. (2021) reported that dibutyl phthalate, one of the most abundantly used plasticizers, can stimulate Fusarium culmorum and Fusarium oxysporum to release esterase in liquid culture indicating their anticipated utilization in the mitigation of environmental pollution. Proteases (EC 3.4.X) function to hydrolyze peptide and urethane bonds and thus are active on polyamides including different type of nylons (Atanasova et al. 2021). Another proteolytic enzyme is urease (EC 3.5.1.5) that has been enumerated to degrade polyester PU. Indeed, Aspergillus, Trichoderma, Penicillium and Fusarium sp. have been depicted to produce urease associated with PU degradation (Loredo-Treviño et al. 2011).

Peroxidases (EC 1.11.1.x) are a group of oxidoreductases that utilize H2O2 to catalyze oxidative reactions. Amongst the members, MnP (EC 1.11.1.13) and lignin peroxidase (LiP) (EC 1.11.1.14) play a significant role in biodegradation of complex polymeric constituents such as lignin that has structure similarity with synthetic plastics (Khatoon et al. 2017). MnP is a glycosylated heme containing enzyme that catalyzes oxidation of Mn2+ to Mn3+ in a H2O2-dependent reaction attacking both phenolic and non-phenolic compounds (Zhao et al. 2015). LiP is a monomeric hemoprotein with molecular mass of around 40 kDa that catalyzes H2O2-dependent oxidative depolymerization of lignin (Ghosh and Pal 2021). The protein activity was first observed in case of Phanerochaete chrysosporium growing under limited nitrogen condition. LiP in general operates at an optimal reaction condition of 25–35 °C and 2–5 pH (Khatoon et al. 2017). Another pertinent fungal enzyme is laccase (EC 1.10.3.2), a blue and multicopper containing protein, that catalyzes one-electron oxidation of a broad range of phenolic compounds as well as aromatic amines by reducing molecular oxygen to water (Zeghal et al. 2021). Fujisawa et al. (2001) have reported that lac-mediator system along with 1-hydroxybenzotriazole as a mediator could degrade high Mw PE and nylon-66 membrane. Several studies have demonstrated the production of majority of laccase from various higher fungi like Coriolopsis polyzona, Cerrena maxima, Lentinus tigrinus, Pleurotus eryngii, Trametes sp., and among others. Additionally, laccases occur in some saprophytic Ascomycetes as well, such as Myceliophthora thermophila and Chaetomium thermophile (Sumathi et al. 2016). Both laccase and peroxidases input O2 in the main chain of PE and disturb strong electrical balance within polymer structure. As a result, carbonyl groups are formed and CH2 chain becomes hydrophilic making it liable to enzymatic break down (Ghosh and Pal 2021). Recent studies have shown that both Ascomycota and Basidiomycota can produce oxygenase where a large number of white-rot fungi, including Phanerochaete chrysosporium, Trametes versicolor, Pleurotus ostreatus, Bjerkandera sp. and others, have been reported to produce both MnP and LiP (Kang et al. 2019; Khatoon et al. 2019; Zhao et al. 2015). While, Phlebia radiata has been ascribed to produce Laccase and LiP (Kantelinen et al. 1989). It has been reported that PE can be effectively degraded through the use of enzymes such as amylase, laccase, LiP and MnP. These enzymes can cleave their carbon bonds, create functional groups and enable utilization of the PE films by the microorganisms. Nevertheless, fungi can produce other enzymes also such as glucosidase, cellulase, pectinase and hemicellulase that may play a remarkable role in degradation of polymers in soil resulting formation of small fragments (El-Morsy et al. 2017). All these enzymes are able to cleave polymeric materials into water soluble, small fragmented elements of 10–50 carbon atoms with concomitant production of highly reactive free radicals. These short chains are then transported into the cell for further metabolism (Khatoon et al. 2019). Overall, enzymatic degradation is an optimal plastic trash treatment strategy, particularly from industrial point of view, which not only hastens the process in a controllable mean but also recycles hydrolysate (Li et al. 2011).

Final degradation of plastic

It is considered that five functional groups namely hydroxyl, carbonyl, carboxyl, sulfhydryl and phosphate are essential to support the chemistry of life. Micro(nano)plastics having any of them may thus easily enter into the fungal cells owing to their small size (Maity et al. 2021). Assimilation of higher n-alkanes is common amongst Ascomycetous and Basidiomycetous species and this is mainly believed to be due to the action of cytochromes P450, especially CYP52 family members (Cowan et al. 2022). CYP450 monooxygenases hydroxylate both alkanes and polyaromatic hydrocarbons, but their oxidized derivatives are then degraded via different mechanisms. The oxidized alkanes undergo β-oxidation and are further oxidized resulting in formation of the final products like CO2 and biomass (Ganesh Kumar et al. 2020). Indeed, synthetic polymers act as potent energy and carbon sources for microbial organisms. It has been deduced that complete oxidation of PE produces usable energy varying from − 422 to − 425 kJ per mole of O2. On the other hand, the usable energy generated from glucose is − 479 kJ per mole O2 indicating complete oxidation of PE results around the same energy as glucose (Asiandu et al. 2021).

As a consequence, the physicochemical properties of plastic films modify; evident by alterations in functional groups, crystallinity and Mw distribution. However, the magnitude of degradation is widely assessed by calculating weight loss of the plastic polymer. Special emphasis is also given to the carbonyl index (CI), i.e., ratio of absorbance peak at 1712 cm–1 to that of CH2 at 1462 cm–1 (Maity et al. 2021). On the other hand, decrease of water contact angle (WCA) is a hallmark of hydrophilicity increment of the polymer surface that can be detected by a contact angle measuring device (Awasthi et al. 2017). Besides, plastic superficial topography can be observed using SEM to identify surface destruction represented by formation of pits, scars, cracks, holes, erosions and cavities (Han et al. 2020). It also results in increase of TDS of media which is the sum of all organic and inorganic substances such as salts and various nutrients present in colloidal, molecular or suspended form (Chaudhary and Vijayakumar 2020a). Consequently, consumption of O2 (respirometric test) or estimation of the end product, CO2, (Sturm test) are good indicators for plastic deterioration and thus are the frequently used laboratory tests to designate biodegradation (Osman et al. 2018).

Conclusion and directions for future research

Plastics are versatile materials offering many benefits for the future; despite that, the present solutions addressing plastic waste crisis are neither adequate nor eco-friendly. To solve the problem related to plastic waste accumulation, production of BPs from suitable renewable resources is a fruitful notion. Use of these substances should be recommended especially for food item packaging and manufacturing agricultural films, fishery materials as well as medical items. However, suitable management of their leftover and littering control is also crucial to take benefit of such polymers in the community. Thus, the search for competent, sustainable and low-cost waste management technology is in continuation.

In this context, biodegradation of plastics by fungal strains could be the most innovative and economically as well as environmentally beneficial way to tackle the waste problem and reduce native impact on the environment. Till date, many Ascomycetous fungal strains namely Aspergillus, Candida, Fusarium, Cladosporium, Paecilomyces, Penicillium and so forth have been acknowledged as strong degraders of a widespread range of plastics where most of the studies have been published focusing mainly on degradation of PE by fungi; while fate of other polymer types as well as micro-nano forms remain comparatively neglected. Besides, lesser attention has been paid on elucidation of the mechanism of action which so far been understood to occur through attachment of fungal hyphae on polymer surface by hydrophobin, formation of biofilm and secretion of extensive enzymes that can break down polymers into small fragments. Indeed, research suggests that PE including HDPE and LDPE as well as PVC, PS and nylon can be decomposed by laccase; while PBS, PBSA, PCL and PET can be deteriorated by ester hydrolases, i.e., lipases, esterases and cutinases synthesized by fungi. Enzyme engineering thus may aid to speed up biodegradation process as long period of the method is a key limitation for practical application. Some researchers also have illustrated that overexpression of these enzymes in heterologous host and genetic modifications can be helpful to improve natural capacity of fungi for plastic degradation; however, real-world application using high population of such mutant types may cause an imbalance in the ecosystem.

The present review also highlights that the total number of investigated specimens is much lower than the actual number of fungi present around the globe indicating many taxa still remain unexplored. It might be due to the prevalence of uncultured fungal species creating challenge to identify them from the respective plastic degrading environment. To overcome this problem, metagenomic study of microbial population in plastishere is highly advisable as in nature they might be working synergistically rather than individually. Further, bio-augmentation of potant organisms is necessary that can be spread over the plastic contaminated place to mitigate the problem. For better consideration, high-throughput omics approaches such as meta-genomics, meta-transcriptomics, meta-proteomics, metabolomics, fluxomics and bioinformatics investigations can be employed. These methods may open up the scope for mining genes or enzymes engaged in polymer degradation. Thus, further research on myco-diversity, enzymatic degradation mechanisms and related metabolism will be necessary to reduce global plastic pollutants and offer good health for future generations.

References

Ahsan A, Ashraf M, Ali S, Aslam R, Rahman SU, Zubair M (2016) Isolation and screening of polyethylene degrading fungi from solid waste material. J Agric Basic Sci 1:1–6

Ali MI, Ahmed S, Javed I et al (2014a) Biodegradation of starch blended polyvinyl chloride films by isolated Phanerochaete chrysosporium PV1. Int J Environ Sci Technol 11:339–348. https://doi.org/10.1007/s13762-013-0220-5

Ali MI, Ahmed S, Robson G et al (2014b) Isolation and molecular characterization of polyvinyl chloride (PVC) plastic degrading fungal isolates. J Basic Microbiol 54:18–27. https://doi.org/10.1002/jobm.201200496

Ameen F, Moslem M, Hadi S, Al-Sabri AE (2015) Biodegradation of low density polyethylene (LDPE) by mangrove fungi from the red sea coast. Prog Rubber Plast Recycl Technol 31(2):125–144. https://doi.org/10.1177/147776061503100204

Amobonye A, Bhagwat P, Singh S, Pillai S (2021) Plastic biodegradation: frontline microbes and their enzymes. Sci Total Environ 759:143536. https://doi.org/10.1016/j.scitotenv.2020.143536

Antipova TV, Zhelifonova VP, Zaitsev KV et al (2018) Biodegradation of poly-ε-caprolactones and poly-l-lactides by fungi. J Polym Environ 26:4350–4359. https://doi.org/10.1007/s10924-018-1307-3

Artham T, Doble M (2010) Biodegradation of physicochemically treated polycarbonate by fungi. Biomacromolecules 11:20–28. https://doi.org/10.1021/bm9008099

Asiandu AP, Wahyudi A, Sari SW (2021) Biodegradation of plastics waste using fungi: a review. Curr Res Environ Appl Mycol 11(1):1–15. https://doi.org/10.5943/cream/11/1/1

Atanasova N, Stoitsova S, Paunova-Krasteva T, Kambourova M (2021) Plastic degradation by extremophilic bacteria. Int J Mol Sci 22:5610. https://doi.org/10.3390/ijms22115610

Awasthi S, Srivastava N, Singh T et al (2017) Biodegradation of thermally treated low density polyethylene by fungus Rhizopus oryzae NS 5. 3 Biotech 7(1):73. https://doi.org/10.1007/s13205-017-0699-4

Balabanova L, Slepchenko L, Son O, Tekutyeva L (2018) Biotechnology potential of marine fungi degrading plant and algae polymeric substrates. Front Microbiol 9:1527. https://doi.org/10.3389/fmicb.2018.01527

Balasubramanian V, Natarajan K, Rajeshkannan V, Perumal P (2014) Enhancement of in vitro high-density polyethylene (HDPE) degradation by physical, chemical and biological treatments. Environ Sci Pollut Res Int 21:12549–12562. https://doi.org/10.1007/s11356-014-3191-2

Berger BW, Sallada ND (2019) Hydrophobins: multifunctional biosurfactants for interface engineering. J Biol Eng 13:10. https://doi.org/10.1186/s13036-018-0136-1

Brunner I, Fischer M, RuÈthi J et al (2018) Ability of fungi isolated from plastic debris floating in the shoreline of a lake to degrade plastics. PLoS ONE 13(8):e0202047. https://doi.org/10.1371/journal.pone.0202047

Burt AJ, Raguain J, Sanchez C et al (2020) The costs of removing the unsanctioned import of marine plastic litter to small island states. Sci Rep 10:14458. https://doi.org/10.1038/s41598-020-71444-6

Butnaru E, Darie-Niţă RN, Zaharescu T et al (2016) Gamma irradiation assisted fungal degradation of the polypropylene/biomass composites. Radiat Phys Chem 125:134–144. https://doi.org/10.1016/j.radphyschem.2016.04.003

Chaudhary AK, Vijayakumar RP (2020a) Effect of chemical treatment on biological degradation of high-density polyethylene (HDPE). Environ Dev Sustain 22:1093–1104. https://doi.org/10.1007/s10668-018-0236-6

Chaudhary AK, Vijayakumar RP (2020b) Studies on biological degradation of polystyrene by pure fungal cultures. Environ Dev Sustain 22:4495–4508. https://doi.org/10.1007/s10668-019-00394-5

Chaudhary AK, Chaitanya K, Dalmia R, Vijayakumar RP (2021) Synergistic effect of UV, thermal, and chemical treatment on biological degradation of low-density polyethylene (LDPE) by Thermomyces lanuginosus. Environ Monit Assess 193:513. https://doi.org/10.1007/s10661-021-09296-4

Chien H-L, Tsai Y-T, Tseng W-S et al (2022) Biodegradation of PBSA films by elite Aspergillus isolates and farmland soil. Polymers 14:1320. https://doi.org/10.3390/polym14071320

Cosgrove L, McGeechan PL, Robson GD, Handley PS (2007) Fungal communities associated with degradation of polyester polyurethane in soil. Appl Environ Microbiol 73(18):5817–5824. https://doi.org/10.1128/AEM.01083-07

Cowan AR, Costanzo CM, Benham R et al (2022) Fungal bioremediation of polyethylene: challenges and perspectives. J Appl Microbiol 132(1):78–89. https://doi.org/10.1111/jam.15203

Crabbe JR, Campbell JR, Thompson L et al (1994) Biodegradation of a collodial ester-based polyurethane by soil fungi. Int Biodeter Biodegrad 33:103–113. https://doi.org/10.1016/0964-8305(94)90030-2

Da Costa AM, de Oliveira Lopes VR, Vidal L et al (2020) Poly(ethylene terephthalate)(PET) degradation by Yarrowia lipolytica: investigations on cell growth, enzyme production and monomers consumption. Process Biochem 95:81–90. https://doi.org/10.1016/j.procbio.2020.04.001

da Luz JMR, Paes SA, Nunes MD et al (2013) Degradation of oxo-biodegradable plastic by Pleurotus ostreatus. PLoS ONE 8(8):e69386. https://doi.org/10.1371/journal.pone.0069386

da Luz JMR, Paes SA, Bazzolli DMS et al (2014) Abiotic and biotic degradation of oxobiodegradable plastic bags by Pleurotus ostreatus. PLoS ONE 9(11):e107438. https://doi.org/10.1371/journal.pone.0107438

da Luz JMR, Paes SA, Ribeiro KVG et al (2015) Degradation of green polyethylene by Pleurotus ostreatus. PLoS ONE 10(6):e0126047. https://doi.org/10.1371/journal.pone.0126047

Dąbrowska GB, Garstecka Z, Olewnik-Kruszkowska E et al (2021) Comparative study of structural changes of polylactide and poly(ethylene terephthalate) in the presence of Trichoderma viride. Int J Mol Sci 22:3491. https://doi.org/10.3390/ijms22073491

Das MP, Kumar S (2014) Microbial deterioration of low density polyethylene by aspergillus and Fusarium sp. Int J ChemTech Res 6:299–305

de Oliveira TA, Barbosa R, Mesquita ABS et al (2020a) Fungal degradation of reprocessed PP/PBAT/thermoplastic starch blend. J Mater Res Technol 9(2):2338–2349. https://doi.org/10.1016/j.jmrt.2019.12.065

De Silva JKA, Jayasekera GAU, Nanayakkara CM (2019) Identification of potential fungal degraders of low-density polyethylene (LDPE). J Sci 10(2):1–10. https://doi.org/10.4038/jsc.v10i2.20

De Tender C, Devriese LI, Haegeman A et al (2017) Temporal dynamics of bacterial and fungal colonization on plastic debris in the North Sea. Environ Sci Technol 51(13):7350–7360. https://doi.org/10.1021/acs.est.7b00697

Deepika S, Jaya MR (2015) Biodegradation of low density polyethylene by microorganisms from garbage soil. J Exp Biol Agric Sci 3:15–21

Deguchi T, Kitaoka Y, Kakezawa M, Nishida T (1998) Purification and characterization of a nylon-degrading enzyme. Appl Environ Microbiol 64:1366–1371

Devi SR, Kannan RV, Nivas D et al (2015) Biodegradation of HDPE by Aspergillus sp. from marine ecosystem of Gulf of Mannar. India. Mar Pollut Bull 96:32–40. https://doi.org/10.1016/j.marpolbul.2015.05.050

DSouza GC, Sheriff RS, Ullanat V et al (2021) Fungal biodegradation of low-density polyethylene using consortium of aspergillus species under controlled conditions. Heliyon 7(5):e07008. https://doi.org/10.1016/j.heliyon.2021.e07008

El-Morsy EM, Hassan HM, Ahmed E (2017) Biodegradative activities of fungal isolates from plastic contaminated soils. Mycosphere 8(8):1071–1087. https://doi.org/10.5943/mycosphere/8/8/13

El-Shafei HA, El-Nasser NHA, Kansoh AL, Ali AM (1998) Biodegradation of disposable polyethylene by fungi and Streptomyces species. Polym Degrad Stab 62:361–365

Emadian SM, Onay TT, Demirel B (2017) Biodegradation of bioplastics in natural environments. Waste Manage 59:526–536. https://doi.org/10.1016/j.wasman.2016.10.006

Esmaeili A, Pourbabaee AA, Alikhani HA et al (2013) Biodegradation of low density polyethylene (LDPE) by mixed culture of Lysinibacillus xylanilyticus and aspergillus niger in soil. PLoS ONE 8(9):e71720. https://doi.org/10.1371/journal.pone.0071720

Filip Z (1979) Polyurethane as the sole nutrient source for Aspergillus niger, and Cladosporium herbarum. Appl Microbiol Biotechnol 7:277–280. https://doi.org/10.1007/bf00498022

Friedrich J, Zalar P, Mohorcic M et al (2007) Ability of fungi to degrade synthetic polymer nylon-6. Chemosphere 67(10):2089–2095. https://doi.org/10.1016/j.chemosphere.2006.09.038

Fujisawa M, Hirai H, Nishida T (2001) Degradation of polyethylene and nylon-66 by the laccase-mediator system. J Polym Environ 9(3):103–108

Fukuzaki H, Yoshida M, Asano M, Kumakra M (1989) Synthesis of copoly (D, L-lactic acid) with relative low molecular weight and in vitro degradation. Eur Polym J 25:1019. https://doi.org/10.1016/0014-3057(89)90131-6

Gajendiran A, Krishnamoorthy S, Abraham J (2016) Microbial degradation of low-density polyethylene (LDPE) by Aspergillus clavatus strain JASK1. 3 Biotech 6:52. https://doi.org/10.1007/s13205-016-0394-x

Ganesh Kumar A, Anjana K, Hinduja M et al (2020) Review on plastic wastes in marine environment–biodegradation and biotechnological solutions. Mar Pollut Bull 150:110733. https://doi.org/10.1016/j.marpolbul.2019.110733

Gao R, Liu R, Sun C (2022) A marine fungus Alternaria alternata FB1 efficiently degrades polyethylene. J Hazard Mater 431:128617. https://doi.org/10.1016/j.jhazmat.2022.128617

Gautam R, Bassi AS, Yanful EK (2007) Candida rugosa lipase catalyzed polyurethane degradation in aqueous medium. Biotechnol Lett 29:1081–1086. https://doi.org/10.1007/s10529-007-9354-1

Ge J, Li H, Liu P et al (2021) Review of the toxic effect of microplastics on terrestrial and aquatic plants. Sci Total Environ 791:148333. https://doi.org/10.1016/j.scitotenv.2021.148333

Ghatge S, Yang Y, Ahn J–H, Hur H–G (2020) Biodegradation of polyethylene: a brief review. Appl Biol Chem 63:27. https://doi.org/10.1186/s13765-020-00511-3

Ghosh SK, Pal S (2021) De-polymerization of LDPE plastic by Penicillium simplicissimum isolated from municipality garbage plastic and identified by ITSs locus of rDNA. Vegetos 34(1):57–67. https://doi.org/10.1007/s42535-020-00176-9

González-Márquez A, Volke-Sepulveda T, Díaz R, Sánchez C (2021) Enhanced esterase activity during the degradation of dibutyl phthalate by Fusarium species in liquid fermentation. J Ind Microbiol Biotechnol 48(9–10):kuab062. https://doi.org/10.1093/jimb/kuab062

Gross L, Enck J (2021) Confronting plastic pollution to protect environmental and public health. PLoS Biol 19(3):e3001131. https://doi.org/10.1371/journal.pbio.3001131

Han YN, Wei M, Han F et al (2020) Greater biofilm formation and increased biodegradation of polyethylene film by a microbial consortium of Arthrobacter sp. and Streptomyces sp. Microorganisms 8(12):1979. https://doi.org/10.3390/microorganisms8121979

Harding MW, Marques LLR, Howard RJ, Olson ME (2009) Can filamentous fungi form biofilms? Trends Microbiol 17:475–480. https://doi.org/10.1016/j.tim.2009.08.007

Hasan F, Shah AA, Hameed A, Ahmed S (2007) Synergistic effect of photo and chemical treatment on the rate of biodegradation of low density polyethylene by Fusarium sp. AF4. J Appl Polym Sci 105(3):1466–1470. https://doi.org/10.1002/app.26328

Herrero Acero E, Ribitsch D, Steinkellner G et al (2011) Enzymatic surface hydrolysis of PET: effect of structural diversity on kinetic properties of cutinases from Thermobifida. Macromolecules 44:4632–4640. https://doi.org/10.1021/ma200949p

Hock OG, Lum HW, Qin DD et al (2019) The growth and laccase activity of edible mushrooms involved in plastics degradation. Curr Top Toxicol 15:57–62

Huang S, Wang H, Ahmad W et al (2022) Plastic waste management strategies and their environmental aspects: a scientometric analysis and comprehensive review. Int J Environ Res Public Health 19(8):4556. https://doi.org/10.3390/ijerph19084556

Hyde KD, Xu J, Rapior S et al (2019) The amazing potential of fungi: 50 ways we can exploit fungi industrially. Fungal Divers 97:1–136. https://doi.org/10.1007/s13225-019-00430-9

Indumathi A, Gayathri T (2016) Plastic degrading ability of Aspergillus oryzae isolated from the garbage dumping sites of Thanjavur, India. Int J Curr Microbiol Appl Sci Spec Issue 3:8–13

Issifu I, Sumaila UR (2020) A review of the production, recycling and management of marine plastic pollution. J Mar Sci Eng 8:945. https://doi.org/10.3390/jmse8110945

Janczak K, Hrynkiewicz K, Znajewska Z, Dabrowska G (2018) Use of Rhizosphere microorganisms in the biodegradation of PLA and PET polymers in compost soil. Int Biodeter Biodegrad 130:65–75. https://doi.org/10.1016/j.ibiod.2018.03.017

Jarerat A, Tokiwa Y (2001) Degradation of poly(L-lactide) by a fungus. Macromol Biosci 1:136e140. https://doi.org/10.1002/1616-5195(20010601)1:43.0.CO;2-3

Jeeva Dharshni S, Kanchana M (2021) Microbial degradation of low-density polyethylene (LDPE) by fungus isolated from landfill soil. Plant Arch 21(1):809–815

Jeszeová L, Puškárová A, Bučková M et al (2018) Microbial communities responsible for the degradation of poly(lactic acid)/poly(3-hydroxybutyrate) blend mulches in soil burial respirometric tests. World J Microbiol Biotechnol 34(7):101. https://doi.org/10.1007/s11274-018-2483-y

Jones EBG (2011) Are there more marine fungi to be described? Bot Mar 54:343–354. https://doi.org/10.1515/bot.2011.043

Kaczmarek H, Bajer K (2007) Biodegradation of plasticized poly(vinyl chloride) containing cellulose. J Polym Sci 45:903–919. https://doi.org/10.1002/polb.21100

Kang BR, Kim SB, Song HA, Lee TK (2019) Accelerating the biodegradation of high-density polyethylene (HDPE) using Bjerkandera adusta TBB-03 and lignocellulose substrates. Microorganisms 7:304. https://doi.org/10.3390/microorganisms7090304

Kannan K, Vimalkumar K (2021) A review of human exposure to microplastics and insights into microplastics as obesogens. Front Endocrinol 12:724989. https://doi.org/10.3389/fendo.2021.724989

Kantelinen A, Hatakka A, Viikari L (1989) Production of lignin peroxidase and laccase by Phlebia radiata. Appl Microbiol Biotechnol 31:234–239

Karamanlioglu M, Robson GD (2013) The influence of biotic and abiotic factors on the rate of degradation of poly(lactic) acid (PLA) coupons buried in compost and soil. Polym Degrad Stab 98:2063–2071. https://doi.org/10.1016/j.polymdegradstab.2013.07.004

Kaushal J, Khatri M, Arya SK (2021) Recent insight into enzymatic degradation of plastics prevalent in the environment: a mini–review. Clean Eng Technol 2:100083. https://doi.org/10.1016/j.clet.2021.100083

Khalesi M, Gebruers K, Derdelinckx G (2015) Recent advances in fungal hydrophobin towards using in industry. Protein J 34:243–255. https://doi.org/10.1007/s10930-015-9621-2

Khan S, Nadir S, Shah ZU et al (2017) Biodegradation of polyester polyurethane by Aspergillus tubingensis. Environ Pollut 225:469–480. https://doi.org/10.1016/j.envpol.2017.03.012

Khatoon N, Sahar NI, Ndu U et al (2017) High-throughput production of peroxidase and its biodegradation potential toward polymeric material. Int J Environ Sci Technol 14:755–766. https://doi.org/10.1007/s13762-016-1182-1

Khatoon N, Jamal A, Ali MI (2019) Lignin peroxidase isoenzyme: a novel approach to biodegrade the toxic synthetic polymer waste. Environ Technol 40:1366–1375. https://doi.org/10.1080/09593330.2017.1422550

Khruengsai S, Sripahco T, Pripdeevech P (2021) Low-density polyethylene film biodegradation potential by fungal species from Thailand. J Fungi 7:594. https://doi.org/10.3390/jof7080594

Kitamoto HK, Shinozaki Y, Cao XH et al (2011) Phyllosphere yeasts rapidly break down biodegradable plastics. AMB Express 1:44. https://doi.org/10.1186/2191-0855-1-44

Koitabashi M, Noguchi MT, Sameshima-Yamashita Y et al (2012) Degradation of biodegradable plastic mulch films in soil environment by phylloplane fungi isolated from gramineous plants. AMB Express 2:40. https://doi.org/10.1186/2191-0855-2-40

Koitabashi M, Yamashita YS, Koike H et al (2016) Biodegradable-plastic-degrading activity of various species of Paraphoma. J Oleo Sci 65:621–627. https://doi.org/10.5650/jos.ess16067

Kosiorowska KE, Połomska X, Wang G et al (2021) Efficient biodegradation of aliphatic polyester by genetically engineered strains of the yeast Yarrowia lipolytica. Int J Biodeter Biodegrad 161:105232. https://doi.org/10.1016/j.ibiod.2021.105232

Krueger MC, Seiwert B, Prager A et al (2017) Degradation of polystyrene and selected analogues by biological fenton chemistry approaches: opportunities and limitations. Chemosphere 173:520–528. https://doi.org/10.1016/j.chemosphere.2017.01.089

Kunlere IO, Fagade OE, Nwadike BI (2019) Biodegradation of low density polyethylene (LDPE) by certain indigenous bacteria and fungi. Int J Environ Stud 76(3):428. https://doi.org/10.1080/00207233.2019.1579586

Lacerda ALDF, Proietti MC, Secchi ER, Taylor JD (2020) Diverse groups of fungi are associated with plastics in the surface waters of the Western South Atlantic and the Antarctic Peninsula. Mol Ecol 29(10):1903–1918. https://doi.org/10.1111/mec.15444

Li F, Hu X, Guo Z et al (2011) Purification and characterization of a novel poly(butylene succinate)-degrading enzyme from asperillus sp. XH0501-a. World J Microbiol Biotechnol 27:2591–2596. https://doi.org/10.1007/s11274-011-0731-5

Li F, Yu D, Lin X et al (2012) Biodegradation of poly (ε-caprolactone) (PCL) by a new Penicillium oxalicum strain DSYD05-1. World J Microbiol Biotechnol 28(10):2929–2935. https://doi.org/10.1007/s11274-012-1103-5

Lii SBW, Wong C, Al-Obaidi JR et al (2017) Ability of endophytic fungi isolated from Nepenthes ampullaria to degrade polyurethane. Malays J Microbiol 13(3):172–179

Linder MB, Szilvay GR, Nakari-Setälä T, Penttilä ME (2005) Hydrophobins: the protein-amphiphiles of filamentous fungi. FEMS Microbiol Rev 29(5):877–896. https://doi.org/10.1016/j.femsre.2005.01.004

Lipsa R, Tudorachi N, Darie-Nita RN et al (2016) Biodegradation of poly(lactic acid) and some of its based systems with Trichoderma viride. Int J Biol Macromolec 88:515–526. https://doi.org/10.1016/j.ijbiomac.2016.04.017

Liu P, Zhang T, Zheng Y et al (2021) Potential one-step strategy for PET degradation and PHB biosynthesis through co-cultivation of two engineered microorganisms. Eng Microbiol 1:100003. https://doi.org/10.1016/j.engmic.2021.100003

Loredo-Treviño A, García G, Velasco-Téllez A et al (2011) Polyurethane as substrate for fungal strains. Adv Biosci Biotechnol 2(2):52–58. https://doi.org/10.4236/abb.2011.22009

Magnin A, Hoornaert L, Pollet E et al (2019) Isolation and characterization of different promising fungi for biological waste management of polyurethanes. Microb Biotechnol 12(3):544–555. https://doi.org/10.1111/1751-7915.13346

Mahalakshmi V, Andrew SN (2012) Assessment of physicochemically treated plastic by fungi. Ann Biol Res 3:4374–4381

Maity S, Banerjee S, Biswas C et al (2021) Functional interplay between plastic polymers and microbes: a comprehensive review. Biodegrad 32(5):487–510. https://doi.org/10.1007/s10532-021-09954-x

Malafatti-Picca L, de Barros Chaves MR, de Castro AM et al (2019) Hydrocarbon-associated substrates reveal promising fungi for poly (ethylene terephthalate) (PET) depolymerization. Braz J Microbiol 50(3):633–648. https://doi.org/10.1007/s42770-019-00093-3

Mathur G, Mathur A, Prasad R (2011) Colonization and degradation of thermally oxidized high-density polyethylene by Aspergillus niger (ITCC No. 6052) isolated from plastic waste dumpsite. Bioremediat J 15(2):69–76. https://doi.org/10.1080/10889868.2011.570281

Matsumiya Y, Murata N, Tanabe E et al (2010) Isolation and characterization of an ether-type polyurethane-degrading microorganism and analysis of degradation mechanism by Alternaria sp. J Appl Microbiol 108:1946–1953. https://doi.org/10.1111/j.1365-2672.2009.04600.x

Miandad R, Rehan M, Barakat MA et al (2019) Catalytic pyrolysis of plastic waste: moving toward pyrolysis based biorefineries. Front Energy Res 7:27. https://doi.org/10.3389/fenrg.2019.00027

Mihreteab M, Stubblefield BA, Gilbert ES (2019) Microbial bioconversion of thermally depolymerized polypropylene by Yarrowia lipolytica for fatty acid production. Appl Microbiol Biotechnol 103:7729–7740. https://doi.org/10.1007/s00253-019-09999-2

Mohanan N, Montazer Z, Sharma PK, Levin DB (2020) Microbial and enzymatic degradation of synthetic plastics. Front Microbiol 11:580709. https://doi.org/10.3389/fmicb.2020.580709

Moore-Kucera J, Cox SB, Peyron M et al (2014) Native soil fungi associated with compostable plastics in three contrasting agricultural settings. Appl Microbiol Biotechnol 98(14):6467–6485. https://doi.org/10.1007/s00253-014-5711-x

Moriyama Y, Kimura N, Inoue R, Kawaguchi A (1993) Examination of fungal deterioration on plasticized polyvinyl chloride by cryo-scanning electron microscopy. Int Biodeter Biodegrad 31:231–239. https://doi.org/10.1016/0964-8305(93)90008-p

Moyses DN, Teixeira DA, Waldow VA et al (2021) Fungal and enzymatic bio-depolymerization of waste post-consumer poly(ethylene terephthalate) (PET) bottles using Penicillium species. 3 Biotech 11(10):435. https://doi.org/10.1007/s13205-021-02988-1

Muhonja CN, Makonde H, Magoma G, Imbuga M (2018) Biodegradability of polyethylene by bacteria and fungi from Dandora dumpsite Nairobi-Kenya. PLoS ONE 13(7):e0198446. https://doi.org/10.1371/journal.pone.0198446

Munir E, Harefa RSM, Priyani N, Suryanto D (2018) Plastic degrading fungi Trichoderma viride and Aspergillus nomius isolated from local landfill soil in Medan. IOP Conf Ser: Earth Environ Sci 126:012145. https://doi.org/10.1088/1755-1315/126/1/012145

Murphy CA, Cameron JA, Huang SJ, Vinopal RT (1996) Fusarium polycaprolactone depolymerase is cutinase. Appl Environ Microbiol 62:456–460

Nowak B, Pająk J, Łabużek S, Rymarz G, Talik E (2011) Biodegradation of poly(ethylene terephthalate) modified with polyester Bionolle by Penicillium funiculosum. Polimery 56:35–44. https://doi.org/10.14314/polimery.2011.035

Oda Y, Asari H, Urakami T, Tonomura K (1995) Microbial degradation of poly(3-hydroxybutyrate) and polycaprolactone by filamentous fungi. J Ferment Bioeng 80:265–269. https://doi.org/10.1016/0922-338X(95)90827-M

Ojeda TFM, Dalmolin E, Forte MMC et al (2009) Abiotic and biotic degradation of oxo-biodegradable polyethylenes. Polym Degrad Stab 94:965–970. https://doi.org/10.1016/j.polymdegradstab.2009.03.011

Ojha N, Pradhan N, Singh S et al (2017) Evaluation of HDPE and LDPE degradation by fungus, implemented by statistical optimization. Sci Rep 7:39515. https://doi.org/10.1038/srep39515

Oliveira J, Belchior A, da Silva VD et al (2020b) Marine environmental plastic pollution: mitigation by microorganism degradation and recycling valorization. Front Mar Sci 7:567126. https://doi.org/10.3389/fmars.2020b.567126

Oliya P, Singh S, Goel N, Singh UP, Srivastava AK (2020) Polypropylene degradation potential of microbes isolated from solid waste dumping site. Pollut Res 39(2):268–277

Oprea S, Potolinca VO, Gradinariu P, Oprea V (2018) Biodegradation of pyridine-based polyether polyurethanes by the Alternaria tenuissima fungus. J Appl Polym Sci 135:46096. https://doi.org/10.1002/app.46096

Orhan Y, Büyükgüngör H (2000) Enhancement of biodegradability of disposable polyethylene in controlled biological soil. Int Biodeter Biodegrad 45:49–55. https://doi.org/10.1016/S0964-8305(00)00048-2

Osman M, Satti SM, Luqman A et al (2018) Degradation of polyester polyurethane by Aspergillus sp. strain S45 isolated from soil. J Polym Environ 26:301–310. https://doi.org/10.1007/s10924-017-0954-0

Oviedo-Anchundia R, Castillo DSD, Naranjo-Morȧn J et al (2021) Analysis of thedegradation of polyethylene, polystyrene and polyurethane mediated by three filamentous fungi isolated from the Antarctica. Afr J Biotechnol 20(2):66–76. https://doi.org/10.5897/AJB2020.17200

Paço A, Duarte K, da Costa JP et al (2017) Biodegradation of polyethylene microplastics by the marine fungus Zalerion maritimum. Sci Total Environ 586:10–15. https://doi.org/10.1016/j.scitotenv.2017.02.017

Penkhrue W, Khanongnuch C, Masaki K et al (2015) Isolation and screening of biopolymer-degrading microorganisms from northern Thailand. World J Microbiol Biotechnol 31(9):1431–1442. https://doi.org/10.1007/s11274-015-1895-1

Pramila R, Vijaya Ramesh K (2011) Biodegradation of low-density polyethylene (LDPE) by fungi isolated from marine water—a SEM analysis. Afr J Microbiol Res 5:5013–5018. https://doi.org/10.5897/AJMR11.670

Raaman N, Rajitha N, Jayshree A, Jegadeesh R (2012) Biodegradation of plastic by Aspergillus spp. isolated from polythene polluted sites around Chennai. J Acad Ind Res 1(6):313–316

Radwan O, Lee JS, Stote R et al (2020) Metagenomic characterization of microbial communities on plasticized fabric materials exposed to harsh tropical environments. Int Biodeter Biodegrad 154:105061. https://doi.org/10.1016/j.ibiod.2020.105061

Raghavendra VB, Uzma M, Govindappa M et al (2016) Screening and identification of polyurethane (PU) and low density polyethylene (LDPE) degrading soil fungi isolated from municipal solid waste. Int J Curr Res 8:34753–34761

Ren GC, Pang AM, Gao Y et al (2021) Polyurethane-degrading fungi from soils contaminated with rocket propellant and their ability to decompose alkyne terminated polybutadiene with urethane. Stud Fungi 6(1):224–239. https://doi.org/10.5943/sif/6/1/15

Russell JR, Huang J, Anand P et al (2011) Biodegradation of polyester polyurethane by endophytic fungi. Appl Environ Microbiol 77(17):6076–6084. https://doi.org/10.1128/AEM.00521-11

Saadi Z, Rasmont A, Cesar G et al (2012) Fungal degradation of poly(l-lactide) in soil and in compost. J Polym Environ 20:273–282. https://doi.org/10.1007/s10924-011-0399-9

Sabev HA, Handley PS, Robson GD (2006) Fungal colonization of soil buried plasticized polyvinyl chloride (pPVC) and the impact of incorporated biocides. Microbiology 152:1731–1739. https://doi.org/10.1099/mic.0.28569-0

Sáenz M, Borodulina T, Diaz L, Banchon C (2019) Minimal conditions to degrade low density polyethylene by aspergillus terreus and niger. J Ecol Eng 20(6):44–51. https://doi.org/10.12911/22998993/108699

Sameshima-Yamashita Y, Koitabashi M, Tsuchiya W et al (2016) Enhancement of biodegradable plastic-degrading enzyme production from Paraphoma-like Fungus, strain B47-9. J Oleo Sci 65(3):257–262. https://doi.org/10.5650/jos.ess15207