Abstract

Nanomaterials have been rapidly developed during the last decades, yet many nanoparticles synthesized by classical methods are toxic and their synthesis procedure is not sustainable. Here we review the green synthesis of nanoparticles from biomass and waste with a focus on synthetic mechanisms and applications in energy production and storage, medicine, environmental remediation, and agriculture and food. Biomass use for synthesis include microorganisms, fungi, plants, and agro-industrial bio-waste. Compared to conventional synthesis, green synthesis allows a 30% reduction in energy consumption, cost savings of up to 40%, and a 50% increase in production output. Biomedical applications comprise antibacterials, anticancers, antioxidants, and drug delivery mechanisms. Carbon quantum dots and photovoltaics are discussed in the energy section. Agricultural and food applications focus on nanofertilization, pest control, and food quality. Environmental remediation includes water and soil purification.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

In recent years, nanoparticle synthesis has witnessed a remarkable shift toward sustainable and environmentally friendly approaches. Conventional nanoparticle synthesis methods frequently involve using hazardous chemicals and high-energy processes, raising environmental concerns, and producing toxic by-products. On the other hand, green synthesis methods provide a viable solution by utilizing bio-based materials such as microorganisms, plants, and agricultural waste as environmentally friendly sources for nanoparticle synthesis (Karim et al. 2023; Xu et al. 2023). Numerous studies have shown that green synthesis methods effectively produce nanoparticles with desirable properties. Microbial-mediated synthesis has shown great promise because microorganisms can reduce metal ions and form nanoparticles. Furthermore, fungal and algal-mediated synthesis have emerged as viable alternatives, offering sustainable and scalable methods for nanoparticle production (Subramaniyam et al. 2015; Wang et al. 2021). Plant-mediated synthesis has received significant attention because of plant species abundance and diversity, which provide a rich source of bioactive compounds for nanoparticle synthesis (Monga et al. 2020; Rashwan et al. 2023a). Plant parts such as leaves, roots, and seeds have been studied for their ability to reduce metal ions and facilitate the formation of nanoparticles. Furthermore, the valorization of agro-industrial bio-waste has pioneered a novel method for converting agricultural residues and industrial byproducts into bio-nanosorbents, bio-nanocatalysts, and bio-nanodisinfectants (Bishnoi et al. 2018; Omran 2020; Tavker et al. 2021).

Green-synthesized nanoparticles exhibit vast applications due to their biocompatibility and ability to release substances in a controlled manner (Rashwan et al. 2022a, b). In the realm of biomedicine, these nanoparticles hold great promise for applications in drug delivery systems (Fang et al. 2019; Owoseni-Fagbenro et al. 2019), cancer treatment (Devanesan et al. 2021; Yusefi et al. 2021), and diagnostic imaging. Moreover, their utilization extends to agriculture, where they play a pivotal role in safeguarding crops, delivering nutrients, and bolstering plant growth. These applications enhance agricultural practices and uphold sustainability, minimizing adverse environmental effects. Green nanoparticles have also been found used in environmental remediation, such as water and soil purification, antimicrobial agents, and air pollution control (Debnath et al. 2020; Fahimmunisha et al. 2020; Jain et al. 2021; Kalaba et al. 2021; Uddin et al. 2021). Their ability to remove contaminants and improve remediation processes helps to make the environment greener and cleaner. Furthermore, green nanoparticles have shown promise in photovoltaics and energy storage applications, improving the efficiency and performance of solar cells and storage devices, and thus contributing to developing sustainable energy solutions. Furthermore, these nanoparticles are versatile in fields other than those mentioned above. They provide opportunities in the cosmetics and food industries for improved formulations and safer products (Kumar et al. 2019; Gao et al. 2020). They also function as sensors, enabling the precise detection and monitoring of various substances. Furthermore, in the domains of textiles and electronics, they elevate functional attributes and open doors to inventive applications (Barzinjy et al. 2020). Green nanoparticles offer broader utility and innovation potential, spanning fields like nanoelectronics, nanosorbents, and catalysis, as shown in Fig. 1.

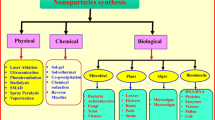

Nanoparticle synthesis and applications. Numerous techniques are employed to synthesize nanoparticles, including physical, chemical, and biological methods. Green nanoparticles could result from sources such as plant extracts, organisms, enzymes, agricultural waste, and ultrasound- and microwave-assisted synthesis. A spectrum of green synthesis techniques yields nanoparticles like liposomes, niosomes, nanoemulsions, and nanogels. These eco-friendly nanoparticles find applications in fields such as agriculture, biomedicine, environment, food, feed, and energy

Therefore, the novelty of this review lies in its comprehensive exploration of green synthesis methods and their diverse applications. This review highlights the use of green-synthesized nanoparticles in medicine, agriculture, environmental remediation, energy, and various other fields, demonstrating their potential to revolutionize industries and contribute to a more sustainable future. Green synthesis methods appeal to researchers and enterprises looking for greener alternatives because of their eco-friendliness, biocompatibility, and cost-effectiveness. However, addressing issues such as reproducibility, stability, and control over nanoparticle size and shape is critical to advance their practical application.

Resources for green synthesis of nanomaterials

Microbial, fungal, and algal-mediated synthesis

Traditional physical and chemical methods are recognized for their high energy and time costs and the use of environmentally harmful chemicals. Chemical synthesis techniques require a metal precursor, reducing agents, and a stabilizing agent, with various processes suggested, such as reducing silver nitrate in the presence of a stabilizing and reducing agent in an aqueous solution. Different reducing substances like citrate, ascorbate, borohydride, hydrogen gas, surfactants, and ligands, or polymers such as polyvinylpyrrolidone and polyethylene glycol are stabilizing agents. Factors like the starting concentration of the silver nitrate solution, the stabilizing agent's concentration, and the molar ratio of silver nitrate to the reducing agent significantly influence the size of the resulting nanoparticles (Gudikandula and Charya Maringanti 2016). Therefore, chemical approaches have limited advantages and lack environmentally friendly synthesis techniques.

Research has shifted toward cleaner and more eco-friendly synthesis processes. Using bio-based routes for synthesizing nanomaterials is widely recognized as a more advantageous alternative to conventional methods, offering significant potential in nanoparticle production. Numerous studies have highlighted the ability of microorganisms to synthesize nanomaterials. Certain bacterial species can accumulate these particles intracellularly for navigational purposes. Moreover, living organisms such as plants, algae, bacteria, fungi, and even animals play a crucial role in creating nanoparticles by utilizing specific biomolecules, including enzymes, for in situ reduction of metal ions, such as silver ions, to produce silver nanoparticles (Gupta et al. 2023; Kulkarni et al. 2023). Biological synthesis offers advantages in terms of the purity and safety of the resulting nanoparticles and the production of uniformly sized and well-defined nanoparticles, often surpassing physicochemical methods. These features of biological synthesis align with several core principles of green chemistry, making the biosynthesis process environmentally friendly. Additionally, using biomolecules as capping and stabilizing agents enhances the microbial activity of nanoparticles made through biological processes.

Due to the synergistic interaction among microorganisms, several advantageous traits can be observed, such as accelerated multiplication rates, the production of diverse secondary metabolites, rapid growth in confined spaces, and the capacity to synergistically deactivate pollutants. Consequently, microorganisms serve as a suitable medium for synthesizing nanozerovalent iron particles (Monga et al. 2020). Different acidophilic microbe strains show different capabilities for reducing iron oxide; moreover, the presence of electron donors and the choice of growth conditions can further modify the characteristics mentioned above (Wang et al. 2016; Xie et al. 2017). For instance, the reduction of uranium (VI) by zerovalent iron nanoparticles is improved by Bacillus subtilis, according to Ding et al. (2015). Furthermore, zerovalent iron nanoparticles containing Dehalobacter demonstrated an increase in the decomposition of trichloroethane by 14-fold (Lee et al. 2015). Microorganisms, with their advantageous traits and varying capabilities, serve as a suitable medium for synthesizing nanozerovalent iron particles, enhancing reduction processes and pollutant decomposition.

In addition, Chlorococcum sp. algae have been used to synthesize spherical-shaped nanoiron nanoparticles from iron chloride precursor, producing 20–50-nm nanoiron particles (Subramaniyam et al. 2015). Transmission electron microscopy analysis revealed that the synthesized nanoiron particles were predominantly found on the surface of the microalgal cells rather than being localized inside the cells. This observation suggests that the presence of biomolecules, specifically carbonyl and amine compounds derived from polysaccharides and glycoproteins within the algal cells, played a crucial role in synthesizing nanoiron. The Fourier transform infrared analysis further confirmed the involvement of these biomolecules in nanoiron synthesis. The microorganism route for synthesizing nanozerovalent nanoparticles is more advantageous than conventional methods.

Green nanoparticle synthesis mediated by fungi has numerous advantages, including simplicity and ease of amplification, ease of processing, economic feasibility, biomass processing, significant surface distance recovery, and optimal mycelium growth. As a result, fungi have enormous promise in the synthesis of nanoparticles. Wang et al. (2021) used Aspergillus sydowii culture supernatant to synthesize silver nanoparticles in vitro. Mohamed et al. (2021) employed Penicillium chrysogenum to develop in vitro microbial synthesis of medical zinc oxide and copper oxide nanoparticles. Overall, the synthesis of nanoparticles by living organisms has enormous promise (Kaur and Gupta 2009), as shown in Fig. 2.

Green synthesis of nanozerovalent iron using microorganisms, i.e., M and plants, i.e., P. Microbial culture is mixed with iron salt and incubated to produce nanoparticles. Aqueous plant extract produces nanoparticles with iron salt in situ. The obtained nanoparticles are centrifuged to get the solid nanoparticles from the suspension. The drying step and/or annealing is the final step to obtain the green synthesized nanoparticles. nZVI refers to nanozerovalent iron

Microorganisms play crucial roles in green nanoparticle synthesis, either directly or indirectly. However, the synthesis of nanoparticles through microbe-mediated processes often displays slow reaction rates, presenting difficulties in managing the diverse array of involved species. Furthermore, these particles typically exhibit heterogeneity in size distribution, necessitating the expertise of skilled personnel during production, consequently leading to substantial cost increments in scaling up the process (Saif et al. 2016). The following characteristics should be addressed while producing extremely stable and well-characterized iron nanoparticles:

-

When choosing an organism for synthesis, focus on its traits like enzyme activity and metabolic pathways, prioritizing those with high detoxification and metal accumulation capabilities.

-

It is critical to adjust the conditions for optimal development and activity conditions to increase enzyme activity, including pH, light, temperature, inoculum size, and buffer.

-

Ensuring the attainment of ideal reaction conditions, including incorporating sustainable alternatives such as microwaves or visible light, becomes crucial when scaling up procedures to a substantial level.

Green synthesesusing plant parts

Green nanoparticle synthesis utilizing different plant components has emerged as a sustainable and eco-friendly approach. This innovative method harnesses the inherent properties of plant extracts, such as leaves, stems, roots, and even fruits, to reduce metal salts and form nanoparticles. By avoiding harsh chemicals and energy-intensive processes, this technique minimizes environmental impact and produces nanoparticles with unique attributes. Interestingly, plant-mediated route synthesis of nanozerovalent iron is one of the most prominent biosynthetic techniques for assembling metal nanoparticles (Machado et al. 2015), as shown in Fig. 2.

Many phytochemical compounds with various functional groups are participating in reducing metal ions to iron nanoparticles. These compounds include polyphenols, metallothioneins, ascorbates, and glutathione, which can chelate metal ions and facilitate superoxide-driven processes, thereby promoting the formation of stable nanoparticles. A typical synthesis combines metal ions, e.g., ferric chloride or ferrous chloride, in an aqueous solution with a plant extract. The phenolic hydroxide groups present in the biomolecules of the extract form complexes with the ferric or ferrous ions, leading to their reduction to iron nanoparticles within a period ranging from a few minutes to several hours. These biomolecules also function as effective stabilizers, thus preventing the aggregation of nanoparticles (Monga et al. 2020); therefore, these molecules play a double role as they reduce the metal ions and act as capping and stabilizing agents.

Plant extracts offer several advantages in the synthesis of nanozerovalent iron. For instance, they are less toxic and exhibit improved water solubility. Additionally, plant extracts enable the production of a larger quantity of nanoparticles, which possess a longer lifespan and exhibit diverse shapes and structures, including round, square, and irregular forms (Wu et al. 2017). Using extracts from various plant components, such as leaves, stems, seeds, roots, and fruits, involves the reduction of metal ions mediated by a range of biomolecules. These plant components are rich in secondary metabolites, including enzymes, proteins, amino acids, vitamins, polysaccharides, alkaloids, polyphenols, flavonoids, and organic acids. These biomolecules, which are biodegradable and non-toxic in most cases, serve as reducing and capping agents, which promote the formation of nanoparticles while effectively inhibiting their agglomeration (Iravani 2011).

Several cases of plant extracts-mediated synthesis of nanozerovalent iron have been documented. For instance, Hoag et al. (2009) used a one-step, environmentally friendly biosynthetic process to effectively synthesize nanozerovalent iron. Green tea extract was mixed with an aqueous ferric chloride solution at room temperature for a few minutes, yielding stable nanoparticles. The dual role of polyphenols found in tea as reducing agents and stabilizers has been a notable discovery in this field. Huang et al. (2014a) conducted a study where they successfully synthesized nanozerovalent iron utilizing extracts from three distinct types of tea: green, oolong, and black tea. These synthesized nanoparticles were subsequently assessed for their efficiency in breaking down malachite green pollutants. Another study by Wang et al. (2014b) showcased the synthesis of polydisperse iron particles using extracts from green tea and Eucalyptus leaves. This process resulted in the formation of nanozerovalent iron characterized by quasi-spherical particles spanning a size range of 20–80 nm. Similarly, Machado et al. (2014) utilized natural extracts from various tree leaves to reduce ferric iron in an aqueous solution and generate nanozerovalent iron particles. In this study, the antioxidant capacity of the extract was evaluated to determine its purity and synthetic suitability. These findings demonstrate the potential of using plant extracts as reducing agents to produce nanozerovalent iron particles.

Furthermore, Machado et al. (2013a) investigated the suitability of twenty-six different plant leaves as prospective bio-reducers. Their investigation revealed that oak, pomegranate, and green tea had the highest antioxidant content. Notably, these extracts were effectively employed in synthesizing nanozerovalent iron particles. Furthermore, using various plant leaves to create nanozerovalent iron particles extended beyond tea extracts. This includes grapes, coffee, roses, gardenia, henna, and fruit trees like cherry, avocado, passionflower, and peach, which were harnessed in an environmentally conscious, one-step synthesis approach (Mondal et al. 2020). It is worthy of mention by many studies that the bio-based reductant agent should be carefully selected because of the incomplete reduction of ferric ions and the lower degradation capacity of the biogenic synthesized nanoparticles (Machado et al. 2013b). Numerous plant-derived constituents have been utilized to achieve in situ synthesis and surface modification of nanozerovalent iron, facilitating the stabilization of the iron particles. These components include guar and xanthan gums, cellulosic materials, riboflavin, starch, and others. For instance, grape seed extract stabilization produced nanozerovalent iron with a greater surface area and a substantially better degrading efficiency than nanozerovalent iron without a stabilizer (Gao et al. 2016). Using plant-mediated processes for nanoparticle synthesis offers a more environmentally friendly approach, resulting in the production of nanoparticles that are not only stabilized but also exhibit enhanced properties compared to conventionally synthesized counterparts. Through these studies, it can be found that plant extracts represent a promising and environmentally friendly approach for synthesizing nanozerovalent iron, facilitated by diverse biomolecules that contribute to the efficient formation and stabilization of nanoparticles.

Bio-fabrication of nanoparticles from agro-industrial bio-waste

A notable portion of municipal solid waste comprises agro-industrial bio-waste remnants, originating from both agricultural activities and industrial processes, particularly prevalent in developing nations (Omran 2020; Rashwan et al. 2023b). Addressing the issue of agro-industrial bio-waste and its detrimental effects through circular practices has become a critical concern, given the significant contributions of the agricultural and industrial sectors to global bio-waste emissions (Mohan and Katakojwala 2021). Additionally, these bio-wastes possess substantial untapped potential and can be reclaimed, repurposed, or transformed into valuable resources. Therefore, leveraging the inherent value of this waste to manufacture economically viable, high-value products plays a crucial role in establishing a sustainable closed-loop economy (Vickers 2017).

Unfortunately, gigantic quantities of agro-industrial bio-waste are annually outputted attained millions of tons, severely influencing the environment, air/water pollution, global warming, and harmful gas formation, among others (Jovanov et al. 2018). The commonly used method is to burn agricultural waste in farms after harvest, which releases harmful gases comprising carbon dioxide, methane, and nitrous oxide. In addition to the generated contaminants like carbon monoxide, ammonia, sulfur dioxide, volatile organic pollutants, and particulate matter, which decline the air quality and result in several health issues (Tyagi et al. 2016). At the same time, green treatment approaches of agro-industrial bio-waste intend to convert them to potential products, such as biodiesel and biochar, and extract bountiful vital components like proteins, antioxidants, carbohydrates, and functional lipids (Sagar et al. 2018). The bio-fabrication of nanomaterials utilizing agro-industrial bio-wastes has cost-effectiveness, low toxicity, and energy-saving features, surpassing the physical and chemical preparation ways (Omran 2020). Bio-wastes comprise natural biomolecules that could act as capping/stabilizing agents and stabilizers (Omran et al. 2021). Consequently, the bountiful and plentiful agro-industrial bio-wastes have been widely utilized to fabricate nanomaterials as follows:

Bio-nanosorbents

The heightened exacerbation of the wastewater issue complicates the scientific community’s search for an effective method to efficiently eliminate well-known pollutants from water (Eltaweil et al. 2023). Numerous remediation approaches have been advocated; nonetheless, adsorption has displayed many features in various manners (Abd El-Monaem et al. 2023). Hence, creating sorbents from abundant and cost-free sources such as agro-industrial materials emerges as an economical and effective solution to the wastewater challenge. In this context, Tavker et al. (2021) prepared silver nanoparticles and cellulose nanofiber from citrus sinensis to adsorb cadmium and chromium from wastewater. The transmission electron microscope images clarified that the average sizes of silver nanoparticles and cellulose nanofiber were 32 nm and 47 nm, respectively. The composite material comprising silver and cellulose nanofibers preferred removing chromium ions over cadmium ions. Precisely, the efficiency of eliminating chromium was measured at 83.5%, while the removal efficiency for cadmium was 32.2%.

In another attempt, Abdelghaffar (2021) developed a bio-sorbent from cellulosic banana peel to eliminate the reactive Orange 5 dye. A composite material of silver, cellulosic banana peel, and chitosan was carefully produced and extensively characterized to achieve this. This comprehensive analysis confirmed the composite's successful synthesis and a clear understanding of its physicochemical properties. Through experimentation, it was determined that the most effective conditions for adsorbing reactive Orange 5 were a pH value of three, an adsorption duration of approximately 90 min, a concentration of 8 g/L of the bio-synthesized composite, and a concentration of 50 mg/L of reactive Orange 5 dye. Notably, the cycling test demonstrated the remarkable regenerative capacity of the bio-fabricated composite. After the fourth cycle, the composite could still remove 95% of reactive Orange 5, indicating its sustained effectiveness over multiple uses.

Bio-nanocatalysts

Bio-nanocatalysts derived from agro-industrial wastes have displayed significant catalytic activity, making them promising for various applications due to their attributes, such as non-toxicity, high efficiency, simple processing, cost-effectiveness, and renewability. As a result, recent research efforts have been directed toward harnessing these bio-wastes to develop environmentally friendly nanocatalysts. An illustrative example is the work of Bishnoi et al. (2018), who utilized the inedible Cynometra ramiflora to synthesize iron oxide nanoparticles. These nanoparticles were employed for the photocatalytic degradation of methylene blue, a common dye pollutant. Experimental findings indicated that methylene blue underwent complete degradation within 110 min under sunlight exposure. Impressively, a reusability assessment demonstrated the sustained performance of the catalyst, with the degradation efficiency only declining to 4% after undergoing five consecutive cycles. This underscores the potential of such eco-friendly nanocatalysts in sustainable environmental applications.

Furthermore, Skiba and Vorobyova (2019) prepared silver nanoparticle-derived orange peel for fast-degrading methylene blue. Characterization analyses, comprising X-ray diffraction, implied the cubic structure of the bio-synthesized silver. Additionally, zeta potential depicted that the surface of silver was rich with negative charges of − 21.7 mV. Notably, the methylene blue degradation efficacy attained 99% during only 35 min, reflecting the superior catalytic property of this costless bio-synthesized catalyst. In another investigation, Narasaiah and Mandal (2020) exploited the cotton boll peels bio-wastes to prepare palladium bio-nanocatalyst for reducing tartrazine, methyl orange, sunset yellow, and Congo red in the presence of sodium boron hydride. Surprisingly, the palladium bio-nanocatalyst showed superior catalytic activity toward the dyes since the degradation rates of tartrazine, methyl orange, sunset yellow, and Congo red reached 96.1%, 96.4%, 97.2%, and 95.3%, respectively. Moreover, Kadam et al. (2020) highlighted the bio-preparation of silver photo-catalysts utilizing cauliflower wastes for methylene blue degradation. The transmission electron microscope image implied that the particles of silver nanocatalysts have a spherical shape in a nanosize of 5–50 nm. Furthermore, the bio-prepared silver exhibited a surface area of 19.2 m2/g and an average pore size of approximately 7.1 nm. Silver bio-nanocatalyst revealed high catalytic degradation toward methylene blue, reaching 97.6% with no metal leaching during the photocatalytic reaction.

To summarize, various agricultural and industrial biological waste has been effectively utilized as a valuable resource for the production of various nanoparticles through biological manufacturing. These nanoparticles derived from agricultural industrial waste have shown significant characteristics, including a considerable surface area and pore size. In addition, nanoparticles synthesized through biological methods exhibit extraordinary capabilities as efficient biological nanoadsorbents, biological nanocatalysts, and others. This trend not only helps to solve the problem of pollutants in wastewater but also provides new avenues for environmentally friendly and sustainable solutions. Extracting useful nanomaterials from waste not only aids in waste management but also facilitates resource reuse, thus contributing an important part to the environmental protection industry. These studies have shown the broad application prospects of biologically prepared nanoparticles, emphasizing their potential in sustainable environmental applications.

Mechanisms and principles

Green biosynthesis of nanoparticles

The green biosynthesis of nanoparticles involves utilizing biological systems, such as plants, bacteria, fungi, or other microorganisms, to facilitate the reduction of metal ions into nanoparticles. The inherent properties of biomolecules like enzymes, proteins, and metabolites in these organisms typically mediate this process. As enzymes can participate in catalytic reactions and complex synthesis, they have enormous potential in biotechnology research and applications, and additional research has shown that attaching enzymes or their substrates to the surface of nanoparticles can enhance catalysis (Bilal et al. 2022, 2023; Jin et al. 2023). In addition, enzymes play a crucial role in cellular activity by catalyzing metabolic reactions (Chapman and Stenzel 2019). The remarkable catalytic efficiency can be attributed mainly to the close interaction of the reaction components in the active site, which have been screened and ordered by nature. The chemical complementarity between folded nucleic acid and peptide enables them to successfully organize the necessary materials in the active site and activate heme (Liu et al. 2017). These findings have significant implications for the design of supramolecular enzyme mimics.

The distinctive catalytic properties of enzymes arise from the spatial organization of crucial functional groups within their active site, a consequence of their intricate three-dimensional folding (Sun et al. 2022). The obvious limitation in catalyst design is the difficulty of recreating the extraordinarily complex three-dimensional structure of the enzyme’s active site. Sun et al. (2022) designed a catalytic nanomaterial that mimics peroxidase. Components of polylysine and deoxyribonucleic acid have been found to exhibit synergistic effects that can enhance heme-catalyzed reactions. Additionally, Zhang et al. (2023) described a chimeric peptide deoxyribose system and introduced a novel design strategy for artificial metalloenzymes. The covalent bond between the g-quadruplex, heme, and an amino acid or oligopeptide determines the internal structure. Enzymes can be immobilized by attaching them to an active substrate or employing the appropriate chemical modifiers and linkers. This approach improves the heat and pH stability of enzymes while simultaneously lowering production costs. Vranish et al. (2017) used semiconductor quantum dots as model nanoparticle materials to link with prototype glucose peroxidase and horseradish peroxidase enzymes. The affinity of the semiconductor quantum dot surface to the substrate significantly affects enzyme activity when peroxidase binds to semiconductor quantum dots. Gu et al. (2022) prepared a co-immobilized dual enzyme biocatalyst with covalent binding. It has been determined that the dual enzyme biocatalyst has superior catalytic activity for the degradation of acridine in wastewater.

By combining enzymatic and chemical catalytic technologies, it is possible to efficiently eliminate pollutants from wastewater. However, their high cost constrains the industrial utilization of pure enzyme preparations. Ji et al. (2017) extracted a crucial enzyme from Pleurotus ostreatus intestines and immobilized it onto functionalized titanium dioxide nanoparticles. Notably, diluting the initial enzyme extract enhanced adsorption efficiency. In a separate study, Yuan et al. (2023) linked laccase to copper oxide@metal–organic frameworks, creating a stable composite through in situ microwave-assisted assembly and demonstrating synergistic catalytic capabilities. Introducing a novel approach, Chen et al. (2022) proposed an amino-functionalized enzyme–nanoparticle conjugate biocatalyst as an economically viable and environmentally benign solution for chlorophenol biodegradation. Notably, ferroferric oxide@silicon dioxide-amino showcased superior performance compared to free laccase across various aspects, encompassing temperature and storage stability, organic solvent resistance, and compatibility with metal ions.

The immobilization of enzymes on solid substrates can enhance enzymatic stability, versatility, and catalytic activity, thereby enhancing the cost-effectiveness of biocatalysis. Although the immobilization of enzymes has led to advancements in various fields, the design of immobilized platforms for biocatalysis involving large-sized substrates remains problematic because protein damage can occur during the generally severe reactions required for these processes. Farmakes et al. (2020) found that the coexistence of enzymes, metals, and compounds on the surface of graphite oxide can improve enzyme immobilization. The zero-curvature graphite oxide surface has a greater enzyme loading capacity than carbon nanotubes. Restricting enzymes to well-defined metal–organic framework compartments is feasible for simulating enzyme cellular environments and identifying structure–function correlations. Pan et al. (2023) used lysozyme as the nucleus of the metal–organic frameworks crystal scaffold, resulting in an unstructured space near the enzyme's outline and determining its relative direction and kinetics.

Microorganisms can generate nanoparticles through the adsorption or reduction of metal ions. This microbial synthesis can be categorized into two types, internal and external synthesis. The production of nanoparticles by different biological agents based on their reaction with diverse metal solutions. Several bacteria can generate a range of inorganic compounds, both within and outside their cells, exhibiting distinct intracellular and extracellular processes (Saravanan et al. 2021). Microbial synthesis notably diminishes the reliance on chemical reagents in nanoparticle production. A selection of instances illustrating extracellular and intracellular nanoparticle synthesis is provided in Table 1. The initial stage of nanoparticle synthesis within microorganisms involves the accumulation of metal particles either outside or inside the bacterial cells. Subsequently, enzymes catalyze the reduction of these metal particles into nanoparticles. Extracellular synthesis is more prevalent in comparison to intracellular synthesis. This preference is likely due to the easier purification and recycling of nanoparticles produced through extracellular synthesis. In contrast, nanoparticles synthesized within cells necessitate cell destruction using methods such as ultrasound for collection, which can complicate purification due to broken cells (Owaid and Ibraheem 2017).

The precise mechanism of microbial intracellular synthesis of nanoparticles is still unknown. An idea of the nanoparticle intracellular synthesis method is that the cell wall surface of microorganisms, negatively charged enzymes, or the cytoplasm of protein groups capture positively charged metal ions. The trapped metal ions are reduced to metal cores, and then different forms of nanoparticles are formed (Patil and Kim 2018). One advantage of using microalgae to generate nanoparticles is that it does not require any pretreatment of microalgae. This is because the formation process of nanoparticles in microalgae depends on metabolic pathways that may be responsible for syntheses, such as photosynthesis, respiration, and nitrogen fixation (Khanna et al. 2019). In addition, microalgae can be harvested year-round compared to other microorganisms, which makes them highly cost-effective and resource-efficient. When external conditions change, microalgae can regulate their metabolic pathways to adapt to environmental changes, and some components in the microalgae body also undergo corresponding changes during this process (Li et al. 2022). For the manufacture of nanoparticles, such properties have broad application prospects. Li et al. (2022) generated 20-nm gold nanospheres and gold hyperbranched nanostructures in Chromochloris zoffiensis.

Fungi and bacteria show the same tolerance and metal bioaccumulation ability, so they are often used to synthesize metal nanoparticles. Similar to the synthesis of nanoparticles by bacteria and microalgae, the fungal synthesis of nanoparticles can also be divided into two methods: extracellular and intracellular synthesis (Rajeshkumar and Sivapriya 2020). The consistency in the well-defined and square plate morphologies observed during the mycosynthesis process, in contrast to non-biologically formed microcrystals, suggests the involvement of a crucial ligand present in the fungal exudate in the controlled nucleation and growth of these particles. In other words, the biological components within the fungal exudate alter the chemical characteristics related to nanoparticle nucleation and development, ultimately leading to the formation of a uniform structure (Brady et al. 2023).

Given the flexibility and affordability of fungal growth on a large scale, extracellular or internal fungi extracts are attractive candidates for manufacturing metal nanoparticles. Several techniques and technologies are available for producing nanoparticles of gold from fungal components. Molnar et al. (2018) demonstrated and compared the outcomes of three different methods for producing gold nanoparticles using the external portion, autolysate, or intracellular components of 29 thermophilic fungi. Nanoparticles with diameters that range from 6 to 40 nm and standard deviations varying from 30 to 70% were produced. Zhang et al. (2019) employed Mariannaea sp. to produce selenium nanoparticles and discovered extracellular selenium nanoparticles in alkaline environments. Due to the difficulty of purification through intracellular culture, fungal-mediated cultivation of nanoparticles is still the majority through extracellular culture.

Ocean endophytic fungi represent an underexplored resource for nanoparticle synthesis and the production of secondary compounds. Manjunath et al. (2017a) improved a mechanism for the extracellular production of Cladosporium cladosporioides gold nanoparticles. Dependent reductases and phenolic compounds were discovered to participate in the biological reduction of gold metal salts into nanoparticles. Gold nanoparticles have potent antioxidant and antibacterial properties. Some fungi can produce nanoparticles through external and intracellular production. Manjunath Hulikere and Joshi (2019) employed Cladosporium cladosporioides to synthesize nanosilver ions, which were subsequently assessed for their antibacterial and antioxidant properties. Alfryyan et al. (2022) investigated the biosynthesis of metallic nanoparticles using two distinct methods. They also explored the structural characteristics and catalytic capabilities of the nanoparticles produced through these processes, employing various technologies.

In conclusion, the enzyme–nanoparticle/nanomaterial interactions field has experienced significant advancements. Researchers are increasingly drawn to microbial nanoparticle production owing to its environmental friendliness, cost-effectiveness, and simplicity. Selecting suitable microorganisms is crucial for practical metal nanoparticle synthesis, with growth rate, metabolic activity, and replication mechanisms playing pivotal roles. Studies have shown that modifying recombinant strains of bacterial species can enhance metal nanoparticle production. However, the creation of recombinant strains might contribute to increased nanoparticle production costs.

Use of reducing agents

The green solvent approach involves utilizing environmentally friendly solvents such as distilled water and ethanol, replacing conventional organic solvents for economical nanoparticle synthesis. These green solvents offer benefits, including environmental preservation, renewability, and low toxicity, minimizing harm to ecosystems and human health (Tilahun Bekele et al. 2021). Using hazardous and expensive compounds as reducing and capping agents may lead to larger particle sizes, driven by increased energy requirements. Green solvents can serve as alternatives to traditional organic solvents in diverse applications.

Ionic liquids are efficient solvents/media for lignocellulosic biomass utilization (Yoo et al. 2017). During the last few decades, ionic liquids have been investigated as potential substitutes. Because of the unique properties of liquids, they can dissolve and/or convert cellulose to a range of chemicals. Scientists and chemical engineers are becoming increasingly interested in the possible applications of ionic liquids. While the full potential of these exceptional solvents remains to be fully harnessed, the predominant application of ionic liquids has shifted from extraction to synthesis or catalysis. Initially utilized to extract biopolymers, these ionic liquids have found expanded use in the extraction of secondary metabolites. Polysaccharides and lignin are the primary biopolymers of interest (Avirdi et al. 2022). Vanda et al. (2018) examined the manufacturing and stability of silver nanoparticles in common ionic liquids as green media. Meanwhile, Nikfarjam et al. (2021) proposed antibacterial ionic liquid derivatives as monomers and polymers and discussed the antibacterial efficacy of ionic liquids.

Presently, the availability of low eutectic solvents is somewhat limited. Like ionic liquids, deep eutectic solvents comprise a few solid components and can form eutectic mixtures through chemical interactions. These mixtures yield deep eutectic solvents with lower melting points than the individual components. The efficient interaction of enzymes with eutectic solvents makes the enzyme/eutectic solvent system a promising approach for future biotransformation processes (Hooshmand et al. 2020). Juneja and Pandey (2022) categorized deep eutectic solvents for intramolecular in-dimer synthesis, aiding polymeric resolution. Maia et al. (2021) emphasized the diverse roles of deep eutectic solvents in synthesizing metal covalent organic frameworks. Ghigo et al. (2022) employed diazonium salts as substitutes for aryl halides to establish a mild, simple, and effective Ullmann reaction in deep eutectic solvents, showcasing their potential as environmentally friendly and sustainable solvent media.

Considering the toxicity and environmental damage caused by conventional ionic liquids, the introduction of the concept of natural deep eutectic solvents was evidently promising as it offered environmentally friendly alternatives. These mixtures have a significantly lower melting point than their components and a significantly lower melting point than the ambient temperature (Vanda et al. 2018). Components of natural deep eutectic solvents are sourced from nature and are believed to possess physiological or biological effects in their natural contexts. Frequently, these components are naturally present in foods. Unlike organic solvents, the fundamental structural elements of natural deep eutectic solvents are primarily governed by intermolecular interactions among their constituents. Consequently, the organic matrix of deep eutectic solvents is susceptible to various conditions (Liu et al. 2018).

Magnetic nanoparticles are being researched more deeply because of their unique chemical and physical characteristics. Ferrite is one of the most studied magnetic materials due to several critical physical features, such as a low melting point, high specific heat, and low saturated magnetic moment at low temperatures. For instance, Nasrollahzadeh et al. (2017a) described the ecologically friendly synthesis of copper/reduced graphene oxide/ferroferric oxide nanocomposites for an innovative catalytic system for aldehyde cyanidation to nitriles. This nanocomposite catalytic system utilizes an aqueous extract of Euphorbia officinalis leaves both as a reducing agent and a stabilizer. Under optimal conditions, it yields various substituted aryl nitriles in moderate to good yields. In a related study, Kombaiah et al. (2018) presented a straightforward and an environmentally friendly method for producing nanoparticles using “local” microwave heating. They also employed Abelmoschus esculentus gel as a reducing agent to synthesize cobalt iron oxide.

Ferrites have a regular spinel structure, and the connection between their magnetic and conductivity properties has caught the curiosity of numerous investigators caused of a broad spectrum of potential applications. Bashir et al. (2020) synthesized nickel ferrite nanoparticles using a Persa americano seed extract as a reducing agent. Physical and electrochemical characteristics of nickel ferrite nanoparticles were also investigated. Patil and Kim (2018) employed juice from Saccharum officinarum, a high-carbohydrate source, as a combustion fuel. The aldehyde functional group in the Saccharum officinarum juice acts as a reduction agent in the combustion cycle, while the precursor’s nitrate is an oxidant. This method simplifies the production of zinc ferrite nanoparticles, offering low cost and scalability. Similarly, Matinise et al. (2018) utilized a natural plant extract from Moringa oleifera as both a reducing and stabilizing agent during the overshoot phase in synthesizing zinc ferrite nanocomposites.

Zinc nanoparticles have a robust catalytic activity as a degradant of a wide range of chemical reactions generated by direct wide band gap photocatalysts. As a result, in addition to being antibacterial, zinc oxide holds excellent promise in photocatalysis and the introduction of industrial pollutant pigments. Chen et al. (2019) used Scutellaria baicalensis root extract as a lowering agent, indicating that other metabolites can be employed as end-cap compounds in the one-pot synthesis of zinc nanoparticles. Pai et al. (2019) utilized a water extract of Pterocarpus santalinus. Phenolic compounds within the leaf extract facilitated the conversion of zinc acetate into zinc oxide nanoparticles, forming the underlying principle. In a similar vein, Rupa et al. (2018) used polyphenols, flavonoids, and anthocyanins in the fruit of Rubus coreanus, to transform zinc oxide nanoparticles. Employing a green approach, Golmohammadi et al. (2020) synthesized zinc oxide nanoparticles using jujube fruit extract as both a reducing and stabilizing agent. In a remarkable achievement, they achieved a 92% degradation efficiency of methylene blue within 5 h.

An effective strategy for eliminating dye toxicity is photocatalytic degradation activity. The high specific surface area of zinc oxide nanoparticles renders them suitable for dye degradation. Chakraborty et al. (2020) synthesized zinc oxide nanoparticles from Averrhoa carambola and investigated their photocatalytic activity in Congo red dye. Averrhoa carambola biomolecules such as reducing sugar, flavonoids, and proteins are also critical green stabilizers. Rambabu et al. (2021) described a method for producing zinc oxide nanoparticles from discarded jujube pulp. Dye degradation investigations have shown that zinc oxide nanoparticles have amphoteric and fast photocatalytic activity and can break down hazardous dyes in synthetic wastewater. Mirgane et al. (2021) created zinc oxide nanoparticles from waste pineapple peel, which contains a variety of phytochemical substances and can be utilized as an agent for capping and reducing.

In summary, green solvents must adhere to strict criteria of non-toxicity, biodegradability, recyclability, sustainability, availability, and affordability to qualify as environmentally friendly media. Utilizing green solvents allows for producing superior products while mitigating the environmental harm associated with conventional methods employing organic solvents. Researchers exploring innovative green solvents opt for high-quality natural resources derived from plants, animals, microorganisms, and marine organisms. The search for potential components should extend beyond an increase in animal-based research and encompass biological or physiological processes within living organisms that can inspire concepts or serve as templates for simulation.

Plant extract-mediated synthesis

Numerous phytochemical compounds present in plants, such as flavonoids, alkaloid compounds, tannins, saponins, and others, significantly influence the production of nanomaterials (Mohammadzadeh et al. 2022). Secondary metabolites, which plants generate for therapeutic purposes, encompass diverse biological activities and can serve as crucial markers in nanoparticle synthesis. Extracts function similarly to stabilizers and reducing agents (Jadoun et al. 2021). The mechanism of nanoparticle production using lignin as both a reducing agent and stabilizer notably depends on pH, with lignin concentration affecting the size and dispersion of silver nanoparticles (Iravani and Varma 2020). Zinc oxide nanoparticles derived from Ficus microcarpa leaf extracts exhibited high larvicidal efficacy against mosquitoes and demonstrated antibacterial solid properties (Ragavendran et al. 2023).

Plants serve as abundant, non-toxic, and harmless sources with significant economic benefits. Plant extracts such as phenols, saponins, terpenoids, and vitamins have medical potential while being environmentally safe (Shanavas et al. 2020; Aslam et al. 2021). These plant extracts can manufacture nanoparticles as reducing agents and stabilizers. Garcinia L. plants are high in phenolic metabolites, potent antioxidants, and free radical scavengers. Compared to other plants, they can effectively lower nanoparticles (Demenciano et al. 2020; Sarip et al. 2022). Garcinia hanburyi is combined with silver nitrate, gold chloride, copper nitrate, and other metal salt solutions at room temperature and stably interacts with groups with functions or electrostatic interaction of nanoparticles (Lee et al. 2019; Akintelu et al. 2021). Table 2 lists the preparation of metal nanoparticles using different parts of different plants.

Some biological components found in plant extracts have a vital role in reducing the number of metal ions and forming the top layer of nanoparticles of gold. For example, Abdoli et al. (2021) produced gold nanoparticles from cornflower leaves. Similarly, Balalakshmi et al. (2017) suggested a green synthesis approach for gold nanoparticles based on low-cost Sphaeranthus indicus leaf extracts, in which leaf extract components act as blocking and lowering agents during the gold nanoparticles process. Hamelian et al. (2018) produced gold nanoparticles with Thymus serpyllum extract in a green and environmentally friendly manner. Desai et al. (2018) described a simple, fast, and environmentally friendly method of manufacturing photoluminescent gold nanoparticles with catalytic and antioxidant activities utilizing kokum fruit extract. Naraginti and Li (2017) synthesized environmentally sustainable multi-functional gold and silver nanoparticles using an Actinidia lindl extract and subsequently evaluated their efficacy against Pseudomonas aeruginosa.

Gold nanoparticles have numerous applications, such as sensing probes, imaging, therapeutic agents and drug administration, diagnosis, cancer treatment, catalysis, and environmental applications. Gold nanoparticle manufacturing through traditional processes is expensive and may also harm the environment. Plant-based gold nanoparticle manufacturing is less costly and more environmentally friendly. Hosny and Fawzy (2021) used water extracts from Persicaria salicifolia leaves to create gold nanoparticles in an immediate, one-step, economical, and ecologically friendly biosynthesis. Zhao et al. (2021) created gold nanoparticles from Tribulus terrestris extract. Natural oxygen-containing phytochemistry promotes the conversion of green-reducing ions of trivalent gold ions to matching nanoparticles, which are then stabilized by encapsulation. This alteration inhibits the gold nanoparticles from aggregating. Gangapuram et al. (2018) created spherical gold nanoparticles from Anna squamosa L. fruit waste as a depressant and stabilizer, with an extensive list of possibilities for treating hazardous industrial effluent.

Silver nanoparticles exhibit remarkable antibacterial properties, and there is a growing trend of using plants as biological sources for their synthesis. Giri et al. (2022) focused on creating and characterizing silver nanoparticles from fully matured Eugenia roxburghii leaves while assessing their efficacy in reducing biofilm formation. Abdi et al. (2019) bio-synthesized silver nanoparticles from aqueous extracts of Rhizophora mucronata stems, roots, and leaves, exploring their antibacterial attributes. Shah et al. (2021) generated silver nanoparticles from an aqueous crude extract of Plantago asiatica and examined their antibacterial and antioxidant properties. Gopu et al. (2022) successfully synthesized silver nanoparticles from a solution of silver nitrate using Momordica charantia leaf extract, with the change in color indicating the formation of silver nanoparticles.

The production of silver nanoparticles is gradually transitioning toward a less harmful biological approach, which holds promise for environmental benefits. Using plant extracts in the biological synthesis of metal nanoparticles seems to be a viable alternative alongside chemical and physical methods. Dogiparthi et al. (2021) described a bioreduction method for producing silver nanoparticles using an aqueous leaf extract of Micrargeria wightii. Madivoli et al. (2020) employed a water extract of Lantana camara L. to produce silver nanoparticles, which were subsequently tested for antibacterial activity. Vakili et al. (2022) used the leaves of Biarum chaduchrum to make 100-nm spherical silver nanoparticles. Kumavat and Mishra (2021) investigated silver nanoparticles with antimicrobial and antimicrobial properties in vitro using Borago officinalis leaf extracts as environmentally friendly reducing agents. This research introduces a simple, efficient, and rapid procedure. Plant extracts incorporate biological components that serve as stabilizers and reducers in nanoparticle synthesis.

Platinum, a valuable silver-white precious metal with high density, has piqued the interest of many researchers in its nanoparticle form produced from plants. The green attributes, sustainability, and economic significance of palladium nanoparticles derived from plants also have garnered significant attention among academicians. Lebaschi et al. (2017) developed a unique approach for reducing aqueous palladium ions utilizing biologically active palladium@Btea nanoparticle catalysts. The polyols and carbonyls are reduction factors in the water-based extract and blocking/stabilizing agents. Nasrollahzadeh and Sajadi (2016a) detailed the eco-friendly synthesis of palladium nanoparticles using water-based extracts from Euphorbia officinalis leaves. They also highlighted the notable catalytic efficacy of these nanoparticles in both the Stille and Hiyama crossover bonding processes, achieved without additional reagents. Aygun et al. (2020) used Nigella sativa L. extract as a reducing agent to synthesize spherical platinum nanoparticles with sizes between 1 and 6 nm.

Copper nanoparticles are functional in catalysis, water purification, data storage, and other applications. However, the conventional synthesis methods of copper nanoparticles are associated with environmental pollution and toxicity concerns. Nagar and Devra (2018) utilized Azadirachta indica mesophyll soup to synthesize copper nanoparticles and investigated the effect of reaction parameters on nanoparticle conversion efficiency and morphology. Rajesh et al. (2018) used Syzygium aromaticum and Syzygium aromatic bud extracts to produce copper nanoparticles through a simple and environmentally friendly green technique. They studied their structural, morphological, optical, and antibacterial properties. Nasrollahzadeh et al. (2017b) synthesized copper nanoparticles under eco-friendly reaction conditions using Plantago depressa leaves extract as a natural solvent and biological medium. Sharma et al. (2019b) discussed the application of Tinospora cardifolia leaf extract in producing copper nanoparticles. The studies highlighted the potential of biological agents for the green synthesis of copper nanoparticles with reduced toxicity and improved properties, suitable for various applications in drugs, health care, and the environment.

Zinc oxide is an inorganic material that acts as a semiconductor, and various studies have shown that zinc oxide nanoparticles produced using green synthesis processes have good antibacterial properties. Khatami et al. (2020) examined the biosynthesis of rod-shaped zinc oxide nanoparticles using Lilium brownii var. viridulum extract and the anti-Leishmania spp. impact of zinc oxide nanoparticles. Doan Thi et al. (2020) suggested a green production of zinc oxide nanoparticles using orange peel extract that is efficient, environmentally beneficial, and simple. Thakur et al. (2020) used extracts from Jatropha curcas and Tinospora cordifolia leaves to create zinc oxide nanoparticles utilizing a green synthesis approach. Antibacterial efficacy against Staphylococcus aureus was most remarkable in zinc oxide nanoparticles derived from jatropha plants. Kombaiah et al. (2017) produced rectangular zinc oxide nanoparticles in the 10–90 nm range using Stevia rebaudiana (Bertoni) Hemsl extract and investigated antimicrobial solid activity against Leishmania spp., S. aureus, and Escherichia coli. These studies have demonstrated the potential of green synthesis processes for producing zinc oxide nanoparticles.

The application of potentially hazardous components in chemical synthesis can be avoided using plant-based nanoparticle synthesis. Plant-based biosynthesis is not only inexpensive, but it also has high biocompatibility and minimal environmental toxicity. Thakur et al. (2020) developed the technology for manufacturing barium ferrite nanoparticles from Acorus calamus rhizome extract. They examined the antifungal activity of various dosages of barium ferrite nanoparticles against pathogenic fungi affecting multiple plant species. Madhukara et al. (2019) produced zinc ferrite nanoparticles from Limonia acidissima using the green synthesis method, and the resulting zinc ferrite nanoparticles demonstrated excellent photodegradation of Evans blue and methylene blue when exposed to visible light. In the work of Kombaiah et al. (2017), Opuntia mill plant extracts were used as organic reagents to synthesize nanoparticles. In the study, two approaches were used to synthesize zinc iron oxide nanoparticles, namely the conventional and microwave methods, using plant extracts to synthesize nanoparticles.

Incorporating plant-based approaches for nanoparticle synthesis is not the only avenue. Transforming biomass waste into value-added nanoparticle products can contribute to the circular bioeconomy. Due to their ability to efficiently extract pollutants from solutions using a magnetic field, magnetic oxides have great potential for water pollution remediation applications (Abdel Maksoud et al. 2022). For the first time, Osman et al. (2022) carried out an in-depth investigation on the application of fruit residue extract as a reducing agent in the synthesis of magnetite carbon composite nanoparticles, in addition to the manufacture of magnetite carbon composite materials by pyrolysis of biomass waste and waste plastic to remove crystal violet dye from water. Osman et al. (2020) utilized brewer’s spent grain to manufacture carbon in two ways, employing a new approach of a large surface area of carbon and hydrophilic carbon nanotubes to recover biomass waste raw materials, realizing the circular economy concept. In addition, El-Nahas et al. (2020) proposed converting waste aluminum and silica gel into active zeolite materials for water hardness treatment using standard household microwave ovens. This approach requires fewer chemical supplies, templates, and multi-step programs and is 70% less expensive than readily accessible zeolites.

In conclusion, plant extracts boast a rich reservoir of bioactive compounds, rendering them a highly explored avenue for green synthesis methods, particularly in heavy metal accumulation and detoxification. The efficiency and eco-friendliness of biosynthesis have led to the successful production of diverse nanoparticles utilizing plant extracts. This approach has been extensively investigated for its potential across various domains. Moreover, plants house a variety of distinctive compounds that expedite synthesis and enhance synthesis rates. The realm of green nanomaterial synthesis from plants stands as an intriguing facet of nanotechnology, significantly contributing to environmental sustainability and the progression of nanotechnology.

Green hybrid nanoparticles

Due to its excellent light stability, oxidation resistance, and high electron mobility, zinc oxide is a critical inorganic semiconductor component. Silver-doped zinc oxide, synthesized through green methods, possesses advantageous properties like high thermal conductivity, setting it apart from other precious metals. Mousavi-Kouhi et al. (2021) utilized the green approach of Verbascum speciosum to synthesize silver–zinc oxide nanoparticles and evaluated their cytotoxicity. Azizi et al. (2016) used Zingiber officinale roscoe essential oil to develop an innovative green method for producing zinc oxide silver core–shell nanocomposites. The essential oil serves dual roles, acting as a reaction medium for zinc oxide synthesis and a reducer for silver ions. Several plants have been successfully utilized for producing green mixed nanoparticles, as highlighted in Table 3.

Due to their remarkable antibacterial and antifungal properties, silver–zinc oxide nanocomposites are extensively studied for their medical applications, such as dye degradation reagents, dye absorbers, wound healing, cancer chemotherapy, and drug delivery. Sohrabnezhad and Seifi (2016) synthesized silver–zinc oxide nanocomposites using Urtica fissae leaves extract, incorporating silver metal nanoparticles to enhance their photocatalytic efficiency. Rajaboopathi and Thambidurai (2018) described the chemical coprecipitation synthesis of silver–zinc oxide nanoparticles mediated by Sargassum pallidum and its extracts. These nanoparticles exhibit potential as catalysts for the photodegradation of industrial dye effluents. Swati et al. (2020) utilized Moringa oleifera Lam. seeds extract to fabricate well-aligned, uniform silver–zinc oxide nanostructures.

Nanoparticles generated by doping two or more metal elements exhibit more substantial reduction effects than undoped oxide nanoparticles. For the first time, Khan et al. (2018) developed undoped zinc oxide nanoparticles from Cistanche deserticola water extract, as well as manganese-doped zinc oxide nanoparticles from Clerodendrum infortunatum and Clerodendrum inerme water extracts. These findings suggest that Clerodendrum informationatum and Clerodendrum inerme aqueous extracts are fantastic agents for reducing the environmentally friendly synthesis of undoped and copper-doped zinc oxide nanoparticles with potent antibacterial, antioxidant, and antifungal potential. Nasrollahzadeh et al. (2018) developed a unique and ecologically conscious method of producing copper nanoparticles loaded with manganese dioxide nanoparticles. Centella asiatica leaves extract was employed as a natural reducing agent without adding a stabilizer or surfactant. Phenolic hydroxyl groups from the leaf extract are hypothesized to reduce copper ions in the medium, leading to the formation of copper nanoparticles that are subsequently anchored to the outermost layer of the manganese dioxide nanoparticles. Nasrollahzadeh et al. (2018) developed copper nanoparticles held by sodium borosilicate glass using Acalypha indica L. leaf extract as a reducing agent and stabilizer, and they also investigated the potential for catalyst reuse in the decrease reaction.

Hybrid nanoparticles with more than two metal components have better photocatalytic activity than single nanoparticles. Pakzad et al. (2019) initially directed their attention toward employing phenolic compounds derived from Euphorbia pekinensis Rupr. extract. These compounds were utilized to reduce and obstruct copper oxide and nickel@ferroferric oxide nanoparticles during their biosynthesis. Subsequent investigations have delved into the photocatalytic detoxification of color-related biosynthetic nanoparticles. In a study by Sayadi et al. (2022), zinc oxide-stannic oxide nanocomposite nanoparticles were synthesized using an extract from Viscum album L. leaves. These nanoparticles were then utilized to degrade Congo red, biphenyl-A, and tetracycline. Remarkably, even after being used four times, the nanoparticles retained their effectiveness, highlighting the durability and recyclability of the zinc oxide-stannic oxide nanocomposite nanoparticles produced through this method. Somanathan et al. (2019) used a Tinospora cardifolia extract to manufacture cerium-nickel@ferric oxide utilizing a microwave-aided combustion technique. When compared to pure cerium-nickel@ferric oxide, cerium-nickel@ferric oxide had higher photocatalytic activity.

Creating cost-effective and environmentally friendly nanoparticles for contaminant removal is achievable through the eco-friendly synthesis of iron-based bimetallic nanoparticles using various plant extracts, which helps overcome certain synthesis limitations. In the work of Pakzad et al. (2019), eco-synthesized ferrum/nickel nanoparticles were employed to remove triclosan and copper ions from aqueous solutions. In the study of Lin et al. (2021), green tea functioned as a reducing and capping agent in synthesizing a composite of reduced graphite oxide loaded with iron-nickel nanoparticles. This composite exhibited the capability to eliminate trivalent antimony ions from aqueous solutions. Gao et al. (2019) employed Ginkgo biloba linn extract as a green stabilizer to create ferrum/cobalt bimetallic nanoparticles to remove triclosan from aqueous solutions. Through carbon green, Gong et al. (2022) produced ferrum/nickel nanoparticles to remove 17 β-estradiol. The effectiveness of estradiol removal exceeded 98.3% in their study.

In summary, the comparison between single nanoparticles produced through green synthesis and mixed nanoparticles reveals that mixed nanoparticles exhibit superior performance across all aspects. The green synthesis approach can amalgamate the attributes of various nanoparticles, yielding hybrid nanomaterials that harness the benefits of individual nanoparticles, as shown in Fig. 3. In contrast to conventional techniques, the green synthesis method for effectively creating mixed nanoparticles addresses synthesis constraints, diminishes environmental repercussions stemming from the synthesis process, minimizes production expenses related to nanoparticles, and facilitates the sustainable advancement of nanoparticle manufacturing.

Mechanisms of green synthesis of nanoparticles using plant extracts, bacteria, and fungi. The foremost goal of researchers has always been to produce green nanoparticles through eco-friendly methods. The synthesis of nanoparticles mediated by microorganisms and plants is a critical step in nanotechnology. Enzymes and other chemical substances in microorganisms and plants can act as reducing and blocking agents in biosynthesis. These methods can produce stable and capped nanoparticles with high yield. Many characterization techniques can be used to study the properties of produced nanoparticles. Green nanoparticles can be used in biomedical, agriculture, environmental, food industry, cosmetics, and energy applications

In conclusion, the increasing demand for environmentally friendly science and nanostructures has driven the adoption of green synthesis methods for crafting nanomaterials. This approach curbs pollution and reduces costs while enhancing nanoparticle stability and performance. This section has provided insights into the mechanisms and principles of green nanoparticle synthesis, covering aspects such as nanoparticle biosynthesis, biological reduction, extraction-mediated synthesis, and mixed nanoparticles. Future endeavors in green nanoparticle synthesis should prioritize improving preparation efficiency, bolstering nanoparticle stability, and maximizing the utilization of eco-generated nanoparticles.

Applications

Over the past decades, there have been remarkable advancements in green nanomaterials, positioning them as top contenders across various domains, including biomedical, agriculture, environmental, food, sensors, electronics, and more, as shown in Fig. 4 and Table 4. Whether used to improve medical diagnosis and treatment, enhance agricultural production efficiency, reduce environmental pollution, improve food quality, develop efficient sensors, or promote innovation in electronic technology, green nanoparticles have shown strong application prospects. The exceptional capabilities of nanoparticles in these diverse sectors stem from their small size, distinctive morphology, extensive surface area, and distinct physical and chemical attributes. This versatility and potential for widespread application have made green nanomaterials an important research direction in the fields of science and engineering.

Applications of nanomaterials in various sectors. Nanomaterials demonstrate significant promise in biomedicine, featuring attributes like antimicrobial, anticancer, and antioxidant properties, alongside drug delivery functions. In agriculture, nanomaterials primarily contribute to nanofertilizers and nanopesticides. Notably, they play a substantial role in water and soil purification. Within the food industry, nanoparticles are widely employed in nanopackaging, nanonutraceuticals, and nanocarriers

Biomedical applications

Antibacterial effect

Undoubtedly, harmful bacteria in our surroundings pose a significant health risk, as they can easily infiltrate the human body. Additionally, the excessive use of antibiotics has led to drug resistance, complicating the treatment of various infections. Hence, ongoing research aims to uncover effective antibacterial agents for these challenging infections. Green nanoparticles have shown promising antibacterial activity against a wide range of gram-negative and gram-positive bacteria. However, the mechanisms behind growth inhibition and bactericidal effects remain unclear. Notably, the properties of nanoparticles, including their morphology, size, and surface area, among others, play a crucial role in determining how they damage bacterial cells. This could involve interactions between nanoparticles and cell walls/membranes or the penetration of nanoparticles into bacterial cells, leading to their destruction.

Anand et al. (2019) fabricated zinc oxide nanoparticles from Prunus dulcis via the disk diffusion approach. The scanning electron microscopy, i.e., SEM showed the nearly spherical shape of zinc oxide with a size of around 25 nm. Moreover, the antibacterial action of zinc oxide was studied using the agar diffusion technique. The concrete results elucidated the propitious antibacterial activity of zinc oxide against gram-positive where its inhibition zones on S. aureus was 18 mm, while the diameter of the inhibition zones of zinc oxide on E. coli and Salmonella paratyphi was in the range of 32–25 mm. On the contrary, zinc oxide did not exhibit antibacterial activity toward gram-negative bacteria, such as Proteus mirabilius and Klebsiella pneumoniae (Anand et al. 2019). In another study, Stan et al. (2016) reported the synthesis of zinc oxide via a chemical approach and a green method from three green resources: garlic, basil, and rosemary. The experimental results showed a higher antibacterial action of the green zinc oxide than the chemically prepared zinc oxide. Furthermore, the maximal zone diameters of the as-fabricated zinc oxide from garlic, basil, and rosemary against S. aureus were 22.0 mm, 19.3 mm, and 19.2 mm, respectively.

In one more attempt, Behravan et al. (2019) prepared silver nanoparticles from Berberis vulgaris and studied their antibacterial action on two bacterial species: S. aureus and E. coli. The excellent antibacterial effect of silver nanoparticles against both bacterial species was deduced. More importantly, the antibacterial mechanism of silver involves impairing the respiratory process of bacteria through potential interactions between silver and thiol groups. In addition, the high affinity of silver nanoparticles toward sulfur and phosphate-containing membrane cells facilitates the interaction between silver nanoparticles and the bacterial cell membrane. This plausible mechanism was consistent with Sathishkumar et al. (2018), suggesting that magnetite's antibacterial effect against S. aureus and E. coli occurred via the collapse of the cell membrane. Besides, deoxyribonucleic acid, i.e., DNA destroying and reactive oxygen species formation mechanisms, contributed to the damage of bacterial cells.

In conclusion, green nanoparticles have demonstrated impressive antibacterial effects against numerous bacterial species. The antibacterial activity of nanoparticles is greatly influenced by their morphology, size, and surface area, which play a significant role in causing damage to bacterial cells. Typically, the breakdown of bacterial cells occurs through membrane disruption and/or damage to the deoxyribonucleic acid, along with the formation of reactive oxygen species. However, further research is needed to understand the precise interaction pathways between nanoparticles and bacterial cells.

Anticancer effect

Globally, a staggering number of deaths occur annually due to cancer. This has prompted ongoing research to develop effective therapies for this malignant ailment (Jahangirian et al. 2017). Treatment approaches such as chemotherapy, surgery, and radiotherapy entail substantial patient risks. These include potential harm to healthy cells, insufficient drug delivery to tumors, and drug instability (Garg et al. 2021). Consequently, finding an innovative therapeutic approach to address these drawbacks is paramount. Green nanoparticles have demonstrated remarkable anticancer properties against diverse cancer cell types.

In this context, Devanesan et al. (2021) examined the anti-tumor activity of the green-synthesized silver nanoparticles from Carica papaya against the human liver cancer cell line, such as HepG2. Cytotoxicity of the green silver nanoparticles revealed that half maximal inhibitory concentration, namely IC50 of silver nanoparticles to treat human breast cancer cell line, i.e., MCF-7 was about 10 μg/mL during 24 h, while it increased to threefold during the next 24 h. Furthermore, the anti-proliferation action of silver was scrutinized against MCF-7, implying a diminution in the volume of the cell line. It demonstrated the capacity of silver nanoparticles to induce apoptosis in the HepG2, MCF-7, and human lung cancer cell lines such as A549, as evidenced by acridine orange and ethidium bromide staining after 24–72 h. Moreover, Li et al. (2021) prepared gold nanoparticles from Mentha longifolia to kill breast cancer cells. Scanning electron microscopy elucidated the spheroidal morphology of the green gold nanoparticles with a size of 30–45 nm. Such a particle size is a preference for anti-tumor applications since it is less than 50 nm (Hemmati et al. 2020). Thence, gold nanoparticles exhibited promising anti-breast cancer actions against MCF-7, human mammary gland/breast adenocarcinoma cell line, i.e., Hs 578Bst, human mammary gland/breast adenocarcinoma cell line such as UACC-313, and breast cancer cells namly Hs 319.T without toxicity to the normal cell. In addition, the bio-fabricated magnetite with an extract concentration of 10 wt% revealed higher anti-tumor activity. In addition, the IC50 of the colon cancer and normal cells were 99.8 μg/mL and 140.8 μg/mL, respectively (Yusefi et al. 2021). Shortly, green nanoparticles elucidated an auspicious anti-tumor action against several cancer cells without cytotoxicity. This new therapeutic way opens a new avenue to finding the finest treatment for this deadly disease. Nevertheless, most of the studies lack the in vivo analysis to confirm the viability of these green nanoparticles as anti-tumor drugs.

Antioxidant effect

Antioxidants, whether natural or synthetic, play a crucial role in preserving biomolecules like sugars, nucleic acids, and proteins from damage caused by free radicals. These antioxidants can be categorized into two main groups: natural compounds, which encompass exogenous sources like vitamins, carotenoids, polyphenols, and metal elements, as well as endogenous sources like enzymatic and nonenzymatic substances. Furthermore, there exist synthetic antioxidants such as phenolic compounds and nanooxidants (Bendary et al. 2013). Notably, many antioxidant mechanisms, such as the scavenging of reactive oxygen species, depend on the number and position of active groups. In addition, an antioxidant also acts via the inhibition of enzymes, hydrogen peroxide/hydroperoxide decomposition, and metal ions chelation mechanism (Flieger et al. 2021).

In one study by Hosny et al. (2022), platinum nanoparticles were synthesized using Atriplex halimus for potential biological applications. The high-resolution transmission electron microscopy images displayed the spherical structure of these bio-synthesized platinum nanoparticles, characterized by a small particle size ranging from 1 to 3 nm. Interestingly, the study observed a significant increase in the scavenging percentage of the 1,1-diphenyl-2-picrylhydrazyl radical, namely DPPH when exposed to these platinum nanoparticles. The DPPH scavenging percentage rose dramatically from an initial value of 13.8% to a remarkable 72% as the concentration of the platinum nanoparticles increased from 12.5% to 50 mg/mL. Furthermore, the scavenging activity of A. halimus against DPPH was measured at 48.35% when the concentration of A. halimus was elevated to 50 mg/mL. The positive control group using vitamin C demonstrated a lower scavenging percentage against DPPH compared to the platinum nanoparticles and A. halimus. The scavenging rate of vitamin C reached 47.8% at a concentration of 50 mg/mL.

In another study, Vitta et al. (2020) tested the antioxidant actions of Eucalyptus robusta and the derived bio-synthesized zerovalent iron from it against DPPH radicals. The scavenging capacity of zerovalent iron nanoparticles was observed to be higher than pure Eucalyptus robusta. While assessing the scavenging capabilities of the extract and bio-fabricated zerovalent iron, it is essential to note that not all previous studies have concurred with these findings. Some investigations have suggested that the scavenging capacity of zerovalent iron nanoparticles is either lower or occasionally on par with that of the unaltered extract (Rosli et al. 2018; Ibrahim et al. 2019). It was detected that lower concentrations of polyphenols and flavonoids in zerovalent iron nanoparticles than in the pure extract reflected the contribution of these compounds to the reduction process during the fabrication of zerovalent iron nanomaterial. More importantly, the presented polyphenols and flavonoids in zerovalent iron nanoparticles could act as stabilizing agents.

In summary, antioxidants derived from environmentally friendly sources have shown remarkable effectiveness in neutralizing free radicals such as 1,1-diphenyl-2-picrylhydrazyl radical, namely DPPH. Nanoparticles synthesized from natural sources can capture free radicals through diverse mechanisms, including enzyme inhibition, chelation of metal ions, and the direct scavenging of reactive oxygen species. Notably, in certain instances, the inherent antioxidant potency of the unprocessed extract might surpass that of the synthesized nanoparticles, while in other scenarios, the opposite could hold. The antioxidative efficiency of these eco-friendly nanoparticles hinges on the concentrations of phenolic compounds and flavonoids present within the extract.

Drug delivery