Abstract

In this investigation, new porous adsorbent beads were formulated via the incorporation of graphene oxide (GO) into cellulose acetate beads (CA) for the adsorptive removal of methylene blue (MB) dye. The experimental results signified that the adsorption of MB dye increased with the increase in the GO ratio from 10 to 25%. In addition, the adsorption process obeyed PSO kinetic model and Langmuir isotherm model with a maximum adsorption capacity reaching 369.85 mg/g. More importantly, it was proposed that the adsorption mechanism of MB dye onto GO@CA proceeded via electrostatic interactions, H-bonding, van der Waals forces, n-π and π -π interactions. Besides, the fabricated beads exhibited an excellent ability to recycle and reuse after five successive cycles. In addition, there was a high selectivity of GO@CA beads towards MB molecules in the presence of co-existing cations such as Fe2+, Zn2+, Cu2+ and Ni2+.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Indeed, water pollution has become an immense environmental catastrophe as a result of recent industrial development. One of the biggest sources of industrial waste is synthetic dyes since they are frequently used in many industries such as cosmetics, textiles, printing, food, etc [1, 2]. As a result, about 280,000 tons of dyes are discharged yearly into the water bodies, causing great concern about human health and the environment [3, 4]. Amongst these toxic dyes, the cationic methylene blue (MB) which its decomposition generates sulfur oxides, nitrogen oxides, carbon monoxide and carbon dioxide, causing fatal diseases such as cancer, gastritis, hypertension, etc. [5,6,7]. Therefore, it is inevitable to pick out efficacious strategies for removing MB dye from wastewater. Bountiful physicochemical techniques have been developed such as flocculation [8], ultrafiltration [9], advanced oxidation [10], catalysis [11,12,13], microwave [14] and adsorption [15, 16] . However, the simplicity, low cost and high efficacy of the adsorption method make it the most impeccable choice for removing such detrimental contaminants from wastewater [17,18,19,20].

Many adsorbents have been utilized to outdo the hazards of MB including metal-organic frameworks [21], carbon materials [3, 22], layered double hydroxides [23], clays [24] and metal oxides/ferrites [25,26,27]. However, biopolymers have acquired a gigantic interest owing to their non-toxicity, availability, high efficacy, easy functionalization and possession of abundant active sites [20, 28,29,30]. Among these biopolymers, cellulose acetate (CA) has been fabricated via esterification of cellulose and potentially utilized in diverse applications such as gas separation, full cell, packaging, coating and especially water remediation [31,32,33]. Interestingly, CA has outstanding advantages including a special mechanical property, simple processing, biodegradability and plenty of OH groups in C2, C3 (secondary OH) and C6 (primary OH) positions [34, 35].

Graphene oxide (GO) is a carbonaceous material that is easily prepared via oxidation of graphite and possesses remarkable merits such as extremely high specific surface areas (theoretical SBET = 2620 m2/g), a good mechanical characteristic and plenty of oxygen functional groups on its surface [36,37,38]. In addition to its superb adsorption property toward the organic pollutants throughout its delocalized π-electron systems [39]. Besides, GO is highly hydrophilic, but also possesses a hydrophobic feature that facilitates the adsorption of the organic contaminants via π-π interaction [40]. Furthermore, it was reported that the incorporation of a low proportion of GO onto the polymer skeleton fosters the mechanical, flexibility, thermal properties and specific surface area of the polymer without affecting its porosity [41]. However, these efficient adsorbents suffer a vast drawback which is their imperfect separation after the adsorption process by the conventional techniques. Notably, shaping GO/polymer composites in an easily separable form like beads is the most viable solution to solve such an affair [42].

In this perspective, we aimed to fabricate porous GO@CA beads with a good adsorption behavior and easy separation advantage, exploiting the special durability and mechanical strength of the new CA beads that prevent the GO leaching during the adsorption process. A complete study of the adsorption of MB onto GO@CA beads was executed in a batch mode to assess the adsorption aptitude of the fabricated beads. In addition, the plausible adsorption mechanism of MB onto GO@CA beads was thoroughly explained based on XPS spectra. Besides, a recyclability test was implemented for five sequential cycles. Furthermore, the impact of co-existing cations on the adsorption aptitude of MB was assessed to infer the selectivity of the fabricated beads towards MB dye.

2 Experimental

2.1 Materials

Cellulose acetate (M.wt. 30,000) was bought from Sigma Aldrich Co. (Germany). Graphite powder, potassium permanganate and sodium nitrate were supplied by Alpha Chemika. Sulphuric acid, hydrogen peroxide and hydrochloric acid were bought from Loba Chemie (India). Ethanol, dimethyl sulfoxide, methanol and methylene blue dye were purchased from Rankem Co. (India). The specifications of MB were summarized in Table S1.

2.2 Synthesis of GO

Graphene oxide (GO) was synthesized according to the previously reported modified Hummers method [39]. In brief, accurate amounts of graphite (2 g) and sodium nitrate (1 g) were dissolved at 5 oC in concentrated H2SO4 (100 mL) under continuous stirring. Next, potassium permanganate (10 g) was added to the mixture and followed with a further stirring for 1 h. The temperature of the mixture was raised to 40 ˚C and kept under stirring for 30 min. Thereafter, deionized water (100 mL) was decanted into the mixture and followed by a further rise in the temperature up to 90 oC for 2 h. Finally, deionized water (280 mL) and H2O2 (30 mL) were added to terminate the reaction. The resultant GO was separated and washed using HCl (10%) and distilled water followed by drying for 24 h in an oven at 50 oC.

2.3 Synthesis of GO@CA beads

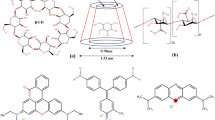

GO@CA beads were fabricated as follows; 1 g CA was dissolved into 5 mL DMSO under mechanical stirring for 30 min. In another beaker, GO (10–25 wt%) was suspended into 5 mL DMSO and sonicated for 30 min. Then, GO was added bit by bit to the CA solution under vigorous stirring. After 30 min, GO-CA composite was added to 250 mL distilled H2O drop by drop using a syringe. Finally, the obtained beads were cured for 15 min, collected and washed with distilled H2O. Besides, CA beads were fabricated with the same procedure, excluding the step related to adding GO to the polymer matrix. A schematic diagram describes the formulation of GO@CA beads and digital laboratory images for the freshly formulated beads were displayed in Fig. 1.

2.4 Characterization

GO, CA and GO@CA beads were characterized by X-ray diffractometer (XRD; MAC Science M03XHF) to inspect their crystal phases. The functional groups of the samples were explored by Fourier transform-infrared spectra (FTIR; Tensor II, Bruker). The thermal stability of the samples was investigated utilizing Thermogravimetric analyzer (TGA; Perkin-Elmer). Moreover, scanning electron microscope (SEM; S4800, Hitachi) was used to inspect the morphology of the samples. The surface charge of GO@CA beads was examined by Zeta-sizer (ZP; Malvern-UK). In addition, the elemental composition of the fabricated beads before and after the MB adsorption was scrutinized by X-ray photoelectron spectroscopy (XPS; Thermo scientific ESCALAB 250Xi VG).

2.5 Water uptake study

To investigate the water uptake behaviour of the developed adsorbent beads, an accurate 10 mg of tested sample was soaked in distilled water for 2 h at room temperature. Next, the swollen samples were separated, blotted carefully between two filter papers to eliminate the excess of the adhered surface water droplets and followed by weighing using a closed electronic balance. The percentage of the water uptake (WU; %) was calculated according to the following equation:

where, Ws and Wi represent the final swollen and initial weights of the tested sample, respectively.

2.6 Batch adsorption study

A series of experiments were executed to determine the optimum conditions of the MB adsorption onto GO@CA beads. Consequently, to detect the optimum pH, e MB adsorption was implemented at a wide pH range of 3–11. Moreover, to identify the impact of the dose of GO@CA beads on the MB adsorption efficacy, the process was examined using varying doses of the beads in a range of 5–20 mg. Besides, thermodynamics was studied at a temperature range of 25–55 °C, while the adsorption isotherms were studied at the Co range of 50–200 mg/L. Untimely, after each experiment, a sample of the un-adsorbed dye was withdrawn and measured using a spectrophotometer at λmax = 664 nm. The adsorption capacity and the removal % of MB were calculated by the following Equations;

where, Co and Ct (mg/L) symbolize the initial concentration of MB and the concentration at time t, respectively. m (g) and V (L) symbolize the mass of GO@CA beads and the volume of MB solution, respectively.

2.7 Recyclability test

To assess the ability of GO@CA beads to recycle and reuse many times, the beads were used for removing MB for five consecutive cycles as follows; after the adsorption run, GO@CA beads were collected and soaked onto 50 mL ethanol under stirring for 1 h. Then, the used beads were examined in the next adsorption/ desorption cycle.

3 Results and discussion

3.1 Characterization of GO@CA beads

3.1.1 FTIR

Fig. 2A represents the FTIR spectra of GO, CA and GO@CA beads. The FTIR spectrum of GO signalizes its typical absorption features at 1045, 1724, 1612, 3320 and 1385 cm− 1 which are ascribed to epoxy C-O, C = O, C = C, OH and C-OH, respectively [39, 43]. Furthermore, the FTIR spectrum of CA figures out the absorption peaks at 1031, 1490, 1220 and 1367 cm− 1 which are attributed to C-O, C = O, C-O-C and O = C-OR, respectively. While the characteristic peaks of C-H, CH2 and O-H were manifested at 2940, 1220 and 3478 cm− 1, respectively [44, 45]. The FTIR spectrum of GO@CA beads illustrates the distinguishing absorption peaks of GO and CA with a noticeable diminution in the peaks intensity, suggesting the homogeneity between GO and CA.

3.1.2 XRD

Fig. 2B depicts the crystalline phase of GO, CA and GO@CA beads. The XRD pattern of GO clarifies its discriminative peak at 2θ = 10.25° [46]. While the XRD pattern of CA points out the typical broad peak of CA at around 2θ = 20° [47]. Furthermore, the XRD pattern of GO@CA beads evinces the diffusion of GO onto the CA matrix since their characteristic peaks appeared.

3.1.3 TGA

TGA profiles (Fig. 2C) elucidate the thermal behaviors of GO, CA and GO@CA beads. All the analyzed samples reveal a mass loss between 30 and 100 °C which is attributed to the water vaporization. The TGA profile of GO signalizes a mass loss between 100 and 208 °C is most likely due to the removal of oxygen-functional groups. While the mass loss beyond 250 °C may be ascribed to the pyrolysis of more function groups [21, 48]. Moreover, the TGA profile of CA shows a significant mass loss between 308 and 398 °C which is assigned to the degradation of the polymer chains [49]. The TGA profile of GO@CA beads implies amelioration in the thermal stability compared to the pristine CA.

3.1.4 Zeta potential

ZP measurements implies the role of GO in boosting the surface charges of CA beads since ZP of CA beads and GO@CA beads are −35.7 and −40.04 mV, respectively, at neutral conditions (Fig. S1). These results may be attributed to the existence of abundant oxygen functional groups in GO (viz., OH and COOH), increasing the negative charges on the GO@CA surface. Thence, the adsorption performance of GO@CA beads towards the cationic contaminants like the noxious MB ought to be more enhanced than the pristine CA beads.

3.1.5 SEM

The SEM image (Fig. 3A) shows scrambled and stacked sheets of GO. The SEM image (Fig. 3B) reveals a spherical outer shell of CA beads, while the inner shell of CA (Fig. 3C) looks like interconnected tubular channels. The SEM of GO@CA beads (Fig. 3D) shows the non-spherical outer shell owing to the difference in the polarity between GO and CA. On the other hand, the cross-sectional image of GO@CA beads (Fig. 3E) clarifies the distributed GO onto the tubular cavities of CA beads.

3.2 Evaluation of the water uptake profile

It is recognized that water uptake property is mainly depending on the existence of hydrophilic functional groups in the matrix. Water uptake behavior of the fabricated composite beads was investigated as shown in Fig. S2. It was observed that increasing the GO content in GO@CA beads matrix from 10 to 20 slightly increased the water uptake value from 15 to 23%. In addition, native CA beads recorded a minimal water uptake value of 11% due to the hydrophobic nature of CA. Notably, the increasing in the water uptake with rising the embedded GO amount in CA beads could be ascribed to the increase in the number of the hydrophilic groups (OH and COOH), which induces the hydrophilicity of beads matrix. Neverthless, further increase in the GO content up to 25% reduced the water uptake value to 21% as a result of the increase in the density of GO@CA beads, which hinders the penetration of water molecules from the outer medium.

3.3 Optimization of the MB adsorption onto GO@CA beads

3.3.1 The impact of GO proportions

Fig. 4A elucidates the impact of the proportion of the incorporated GO onto CA beads on boosting the adsorbability of CA beads toward MB. The result clarifies the poor adsorption performance of CA beads since R% and q were 8.58% and 42.27 mg/g, respectively. It was observed a significant enhancement in the R% and q from 28.84% and 77.22 mg/g to 75.63% and 157.96 mg/g with the increase in the GO proportions from 10 to 25%, respectively. This behavior can be explained by the increase in the oxygen-functional groups (viz., OH and COOH) onto the surface of the beads that grasp the MB from the bulk solution via the electrostatic interactions. Furthermore, GO increments the surface area of CA beads, fostering the adsorption performance of the beads [21]. Thence, 25% GO@CA beads were picked out for the rest of the adsorption experiments.

3.3.2 The impact of pH

Emphatically, pH is the most effective key parameter on the efficacy of the adsorption process since it dominates the adsorbent surface charges. Hence, the MB adsorption onto GO@CA beads was studied at a wide pH range from 3 to 11. It is apparent from Fig. 4B that the adsorption efficiency of MB dramatically enhanced when pH was raised from 3 to 7 since R% and q increased from 47.65% to 105.96 mg/g to 75.63% and 157.96 mg/g respectively. Then, the adsorption efficacy of MB onto GO@CA is still almost constant when pH exceeded 7. Meanwhile, ZP measurements (Fig. 4C) elucidate that the surface of GO@CA beads is negatively charged with an enhancement in the amount of the negative charges on the surface by raising the pH medium. Thereby, such an increase in the adsorption aptitude of MB with raising the pH medium may be explained by the strong electrostatic interaction between the negatively charged GO@CA beads and the cationic MB [22]. This result was in line with Hurairah et al. study that also evinced the suitability of the neutral and alkaline media for the adsorptive removal of the detrimental MB [50].

3.3.3 The impact of the dose of GO@CA beads

Fig. 5A depicts a decline in the q values of MB onto GO@CA beads from 186.29 to 93.35 mg/g with the raising in the dose of GO@CA beads from 5 to 20 mg, respectively. This result may be ascribed to the aggregation of the adsorbent due to the further increase in its dose, resulting in a decrease in the available surface area [51]. On the contrary, this increase in the dose of GO@CA beads enhanced the R% values from 38.07 to 92.29% owing to the existence of abundant binding sites to adsorb the MB molecules [15].

3.3.4 The impact of temperature

Fig. 5B elucidates a diminution in R% and q of MB onto GO@CA beads from 75.60% and 157.96 mg/g to 32.16% and 82.95 mg/g with raising the process temperature from 25 to 55 oC, respectively. This behavior is most likely due to the increase in the thermal energy of the MB molecules with the increase in the system temperature, leading to the desorption of MB from the surface of the beads [52]. This finding suggests the exothermic adsorption nature of the MB molecules onto GO@CA beads.

3.3.5 The impact of the initial concentration of MB

Fig. 5C points out the raising in the MB concentration from 50 to 200 mg/L fostered q of MB onto GO@CA from 99.44 to 308.20 mg/g. This expected behavior may be assigned to the increment in the MB concentration that directly boosts the driving forces of the MB molecules to overcome the mass transfer resistance. Consequently, the movement of the MB molecules from their bulk solution to the GO@CA surface increases [17].

3.4 Kinetic study

To investigate the pathway and the rate-determining step of the MB adsorption onto GO@CA beads, the experimental data were examined by PFO and PSO (Fig. 6A). Table S3 summarizes the non-linear expressions of these models.

It was deduced from the calculated kinetic parameters (Table 1) that the adsorption of MB onto GO@CA beads obeys PSO since the calculated q values are almost equal to the experimental values. More importantly, the derived R2 values from PSO are larger than that of PFO. Moreover, the decline in the k2 with the increase in the MB concentration infers the chemical adsorption process.

3.5 Isotherm study

To scrutinize the MB adsorption nature onto GO@CA beads, the equilibrium data were examined by Langmuir, Freundlich, Temkin and D-R isotherm models (Fig. 6B). Table S4 listed the non-linear expressions of the isotherms models.

The calculated isotherm parameters (Table 2) indicate that the studied adsorption process best fits Freundlich model. Also, Temkin model evinces the physical adsorption as well since bT < 80 kJ/mol. While the calculated E value from D-R model suggests the participation of chemical interactions in the adsorption process as E > 8 kJ/mol. Generally, the n value indicates the favorability of the adsorption process; when n < 1, the process is unfavorable, and it is moderately difficult when the n value falls between 1 and 2, while it becomes more favorable when n exceeds 2 [15]. Hence, it was concluded the favorability of the MB adsorption onto the fabricated beads since the n value was found to be 2.04. These results explain the promising value of the maximum MB adsorption capacity onto GO@CA beads reaching 369.85 mg/g. Table 3 represnts a comparison study between the adsorption capacity of GO@CA beads and other relevant adsorbents toward MB dye.

3.6 Thermodynamic study

Indeed, the process temperature is a dynamic factor that greatly controls the adsorption aptitude [62]. Thereby, it was crucial to investigate the thermodynamic parameters to deduce the nature of the MB adsorption onto GO@CA beads (Table 4). Change in entropy (ΔSº), change in enthalpy (ΔHº) and change in free energy (ΔGº) were calculated from the summarized equations in Text S4.

It was deduced from van’t Hoff plot (Fig. 6C) that the MB adsorption onto GO@CA beads is an exothermic process since the calculated value of ΔHº was negative. In addition, the negative value of ΔSº implied that GO@CA beads are highly ordered at the liquid-solid interface. The negative ΔGº values evinced the feasibility and spontaneity of the MB adsorption process. Conversely, the increase in the process temperature over 318 K rendered the adsorption process feasible and nonspontaneous. This thermodynamic behavior was consistent with Zainal study [63].

3.7 Effect of co-existing ions

Certainly, real wastewater contains many types of co-existing ions that compete with the adsorbates for the adsorption sites of the adsorbents, decreasing the efficiency of the adsorption process. Consequently, the impact of interfering cations (viz., Fe2+, Zn2+, Ni2+ and Cu2+) on the MB adsorption aptitude was evaluated as elucidated in Fig. 7A. It was monitored a decline in the adsorption efficiency of MB in the existence of these co-existing cations owing to their strong competition with the cationic MB molecules for the binding sites of GO@CA beads. Furthermore, the negative impact of Fe2+ (q = 149.62 mg/g, R%= 70.80%) > Zn2+ (q = 150.12 mg/g, R%= 71.29%) > Cu2+ (q = 151.11 mg/g, R%= 71.24%) > Ni2+ (q = 152.11 mg/g, R%= 72.24%) on the MB adsorption efficiency (q = 157.96 mg/g, R%= 75.63%). Such results may be attributed to the fact that the higher ionic radii are the lower hydrated species, thereby the migration rate from the bulk solution to the beads surface of Fe2+ > Zn2+ > Cu2+ > Ni2+. This result agreed with Tripathy et al. study which also inferred the decrease in the adsorption efficiency of MB in the presence of Fe2+ > Zn2+ > Cu2+ > Ni2+ [64]. More importantly, the impact of co-existing cations was insignificant on the MB adsorption aptitude, reflecting the selectivity GO@CA beads towards MB.

3.8 Reusability study

Undoubtedly, the shaping of adsorbents in the beads form has efficiency and economic advantages, thus it was crucial to assess the ability of GO@CA beads to reuse many times after it was proved the efficacy of the beads. The recyclability test (Fig. 7B) points out a decline in R% and q of MB from 75.63% and 157.96 mg/g to 57.61% and 126.86 mg/g after the 5th cycle, respectively. This result indicates the propitious recyclability of GO@CA, reflecting its potentiality for bountiful applications.

3.9 The proposed adsorption mechanism

Kinetic and isotherm studies suggested the participation of both physical and chemical interactions on the MB adsorption process onto GO@CA beads. Therefore, XPS of GO@CA beads was studied before and after the MB adsorption for understanding the adsorption mechanism.

The XPS survey before the MB adsorption (Fig. 8A) illustrates that GO@CA beads consists of O1s and C1s. The C1s spectrum (Fig. 8B) reveals the characteristic peaks of C = O, C-O-C and C-H/C-C at 289.03, 287.53 and 284.74, respectively. Furthermore, the O1s spectrum (Fig. 8C) shows two peaks at 532.72 and 532.84 which are related to OH and COO, respectively. The XPS survey after the adsorption of MB reveals new peaks at 400.17 and 165.08 eV which are assigned to N1s and S2p, respectively, confirming the adsorption of MB onto the surface of GO@CA. The N1s-XPS spectrum (Fig. 8D) signalizes the belonging peaks to N-C and N = C of MB at 399.22 and 401.83 eV, respectively. Noteworthy, MB is a large molecule where its length is 13.82 or 14.47 Ao and width is 9.5 Ao , so the molecules partially diffuse into the adsorbent pores via the Lewis acid-base interaction. Furthermore, the peaks shift of O1s-XPS spectrum after the adsorption of MB (Fig. 8E) from 532.72 and 532.84 to 532.83 and 532.92 eV, respectively, suggests the electrostatic interaction contribution to the adsorption process. The impact of pH and ZP measurements assert the role of the electrostatic interaction in the MB adsorption process. In addition to the possibility of the H-bond formation between N atoms of MB and H atoms of GO@CA beads and H atoms of MB and O atoms of the beads. The π -π interactions between the aromatic rings of MB and the beads also contributed to the adsorption mechanism as shown in Fig. 9. Furthermore, it was reported in many research papers that the participation of n-π interactions and van der Waals force in the MB adsorption mechanism [65, 66]. Such physicochemical interactions could be inferred via the XPS peak shifting of the survey and O1s-spectrum after the adsorption process.

4 Conclusion

Overall, this study intended to present new easy separable, reusable and efficient dye adsorbent beads based on graphene oxide and cellulose acetate. The experimental results elucidated that incorporation of GO into the CA beads played a noteworthy role in the adsorption of MB dye compared to pure CA beads. Moreover, the adsorption process fitted Langmuir isotherm model with a maximum adsorption capacity of 369.85 mg/g and followed PSO kinetic model. Besides, the developed GO@CA beads demonstrated superb adsorption characteristics after reuse for five repeated cycles. In addition, it was recorded an insignificant decrease in the MB adsorption efficiency in the presence of co-existing cations (Fe2+, Zn2+, Ni2+ and Cu2+). The obtained results revealed that GO@CA beads is a good candidate for the removal of cationic dyes from wastewater.

Data Availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

A.H. Jawad, A.S. Abdulhameed, A. Reghioua, Z.M. Yaseen, Zwitterion composite chitosan-epichlorohydrin/zeolite for adsorption of methylene blue and reactive red 120 dyes. Int. J. Biol. Macromol. 163, 756–765 (2020)

A.M. Abdelfatah, M. Fawzy, A.S. Eltaweil, M.E. El-Khouly, Green synthesis of nano-zero-valent iron using ricinus communis seeds extract: characterization and application in the treatment of methylene blue-polluted water. ACS omega 6, 25397–25411 (2021)

H. Xue, X. Wang, Q. Xu, F. Dhaouadi, L. Sellaoui, M.K. Seliem, A.B. Lamine, H. Belmabrouk, A. Bajahzar, A. Bonilla-Petriciolet, Adsorption of methylene blue from aqueous solution on activated carbons and composite prepared from an agricultural waste biomass: A comparative study by experimental and advanced modeling analysis. Chem. Eng. J. 430, 132801 (2022)

M.A.A. Aljar, S. Rashdan, A. Abd El-Fattah, Environmentally friendly polyvinyl alcohol – alginate/bentonite semi-interpenetrating polymer network nanocomposite hydrogel beads as an efficient adsorbent for the removal of methylene blue from aqueous solution. Polymers 13, 4000 (2021)

S. Sahu, S. Pahi, S. Tripathy, S.K. Singh, A. Behera, U.K. Sahu, R.K. Patel, Adsorption of methylene blue on chemically modified lychee seed biochar: Dynamic, equilibrium, and thermodynamic study. J. Mol. Liq 315, 113743 (2020)

L.P. Lingamdinne, J. Singh, J.-S. Choi, Y.-Y. Chang, J.-K. Yang, R.R. Karri, J.R. Koduru, Multivariate modeling via artificial neural network applied to enhance methylene blue sorption using graphene-like carbon material prepared from edible sugar. J. Mol. Liq 265, 416–427 (2018)

L.P. Lingamdinne, J.-S. Choi, J.-K. Yang, Y.-Y. Chang, J.R. Koduru, J. Singh, Adsorptive removal of selected anionic and cationic dyes by using graphitic carbon material prepared from edible sugar: A study of kinetics and isotherms. Acta Chim. Slov. 65, 599–610 (2018)

Y. Sun, S. Zhou, S.-Y. Pan, S. Zhu, Y. Yu, H. Zheng, Performance evaluation and optimization of flocculation process for removing heavy metal. Chem. Eng. J. 385, 123911 (2020)

Y. Long, X. You, Y. Chen, H. Hong, B.-Q. Liao, H. Lin, Filtration behaviors and fouling mechanisms of ultrafiltration process with polyacrylamide flocculation for water treatment. Sci. Total Environ. 703, 135540 (2020)

J. Duan, S. Pang, Z. Wang, Y. Zhou, Y. Gao, J. Li, Q. Guo, J. Jiang, Hydroxylamine driven advanced oxidation processes for water treatment: A review. Chemosphere 262, 128390 (2021)

M. Hosny, M. Fawzy, E.M. El-Fakharany, A.M. Omer, E.M. Abd El-Monaem, R.E. Khalifa, A.S. Eltaweil, Biogenic synthesis, characterization, antimicrobial, antioxidant, antidiabetic, and catalytic applications of platinum nanoparticles synthesized from Polygonum salicifolium leaves. J. Environ. Chem. Eng. 10, 106806 (2022)

A.S. Eltaweil, A.M. Abdelfatah, M. Hosny, M. Fawzy, Novel biogenic synthesis of a Ag@ Biochar nanocomposite as an antimicrobial agent and photocatalyst for methylene blue degradation. ACS omega 7, 8046–8059 (2022)

M.M. Motawea, M.A. Hussein, M.M. Elsenety, H.M. Ali, T.A.S. El-Nasr, H. Gomaa, Mesoporous hierarchical ZrO2@ rice straw-derived SiO2 nanocomposite for rapid adsorption and sunlight-driven photocatalytic degradation of methylene blue. J. Photochem. Photobiol A 426, 113758 (2022)

X. Jiang, H. Xia, L. Zhang, J. Peng, S. Cheng, J. Shu, C. Li, Q. Zhang, Ultrasound and microwave-assisted synthesis of copper-activated carbon and application to organic dyes removal. Powder Technol. 338, 857–868 (2018)

A.S. Eltaweil, E.M. Abd El-Monaem, A.M. Omer, R.E. Khalifa, M.M. Abd El-Latif, G.M. El-Subruiti, Efficient removal of toxic methylene blue (MB) dye from aqueous solution using a metal-organic framework (MOF) MIL-101 (Fe): isotherms, kinetics, and thermodynamic studies, Desalin. Water Treat. 189, 395–407 (2020)

H. Gomaa, M.A. Shenashen, H. Yamaguchi, A.S. Alamoudi, M. Abdelmottaleb, M.F. Cheira, T.S. El-Naser, S.A. El-Safty, Highly-efficient removal of As-V, Pb2+, Fe3+, and Al3 + pollutants from water using hierarchical, microscopic TiO2 and TiOF2 adsorbents through batch and fixed-bed columnar techniques. J. Clean. Prod. 182, 910–925 (2018)

A.M. Omer, A. El-Monaem, M. Eman, G.M. El-Subruiti, A. El-Latif, M. Mona, A.S. Eltaweil, Fabrication of easy separable and reusable MIL-125 (Ti)/MIL-53 (Fe) binary MOF/CNT/Alginate composite microbeads for tetracycline removal from water bodies. Sci. Rep. 11, 1–14 (2021)

A. El-Monaem, M. Eman, A.M. Omer, G.M. El-Subruiti, M.S. Mohy-Eldin, A.S. Eltaweil, Zero-valent iron supported-lemon derived biochar for ultra-fast adsorption of methylene blue, Biomass Convers. Biorefin., 1–13 (2022). https://doi.org/10.1007/s13399-022-02362-y

C. Li, H. Xia, L. Zhang, J. Peng, S. Cheng, J. Shu, S. Zhang, Kinetics, thermodynamics, and isotherm study on the removal of methylene blue dye by adsorption via copper modified activated carbon. Res. Chem. Intermd 44, 2231–2250 (2018)

A.S. Eltaweil, E.M. Abd El-Monaem, H.M. Elshishini, H.G. El-Aqapa, M. Hosny, A.M. Abdelfatah, M.S. Ahmed, E.N. Hammad, G.M. El-Subruiti, M. Fawzy, Recent developments in alginate-based adsorbents for removing phosphate ions from wastewater: a review. RSC adv. 12, 8228–8248 (2022)

A.S. Eltaweil, I.M. Mamdouh, E.M. Abd El-Monaem, G.M. El-Subruiti, Highly efficient removal for methylene blue and Cu2 + onto UiO-66 metal–organic framework/carboxylated graphene oxide-incorporated sodium alginate beads. ACS omega 6, 23528–23541 (2021)

I.K. Basha, A. El-Monaem, M. Eman, R.E. Khalifa, A.M. Omer, A.S. Eltaweil, Sulfonated graphene oxide impregnated cellulose acetate floated beads for adsorption of methylene blue dye: optimization using response surface methodology. Sci. Rep. 12, 1–17 (2022)

Q. Wang, Z. Yu, Y. Liu, X. Zhu, R. Long, X. Li, Co-intercalation of TiO2 and LDH to reduce graphene oxide photocatalytic composite membrane for purification of dye wastewater. Appl. Clay Sci. 216, 106359 (2022)

N. Mundkur, A.S. Khan, M.I. Khamis, T.H. Ibrahim, P. Nancarrow, Synthesis and characterization of clay-based adsorbents modified with alginate, surfactants, and nanoparticles for Methylene blue removal, Environ. Nanotechnol. Monit. Manag., 100644 (2022)

N. Kumar, R. Kumar, Efficient adsorption of methylene blue on hybrid structural phase of MoO3 nanostructures. Mater. Chem. Phy 275, 125211 (2022)

K. Charradi, Z. Ahmed, M.A. BenMoussa, Z. Beji, A. Brahmia, I. Othman, M.A. Haija, R. Chtourou, S.M. Keshk, A facile approach for the synthesis of spinel zinc ferrite/cellulose as an effective photocatalyst for the degradation of methylene blue in aqueous solution (Cellulose, 2022), pp. 1–12

T. Tamer, W. Abou-Taleb, G. Roston, M. Mohyeldin, A. Omer, R. Khalifa, A. Hafez, Formation of zinc oxide nanoparticles using alginate as a template for purification of wastewater. Environ. Nanotechnol Monit. Manag 10, 112–121 (2018)

A.S. Eltaweil, A.M. Omer, H.G. El-Aqapa, N.M. Gaber, N.F. Attia, G.M. El-Subruiti, M.S. Mohy-Eldin, E.M. Abd El-Monaem, Chitosan based adsorbents for the removal of phosphate and nitrate: A critical review. Carbohydr. Polym. 274, 118671 (2021)

A.M. Omer, R. Dey, A.S. Eltaweil, E.M. Abd El-Monaem, Z.M. Ziora, Insights into recent advances of chitosan-based adsorbents for sustainable removal of heavy metals and anions. Arab. J. Chem. 15, 103543 (2022)

T.M. Tamer, A.M. Omer, M.A. Hassan, M.E. Hassan, M.M. Sabet, M.S.M. Eldin, Development of thermo-sensitive poly N-isopropyl acrylamide grafted chitosan derivatives. J. Appl. Pharm. Sci. 5, 001–006 (2015)

D. Wang, Y. Yue, Q. Wang, W. Cheng, G. Han, Preparation of cellulose acetate-polyacrylonitrile composite nanofibers by multi-fluid mixing electrospinning method: Morphology, wettability, and mechanical properties. Appl. Surf. Sci. 510, 145462 (2020)

A. Aldalbahi, M. El-Naggar, T. Khattab, M. Abdelrahman, M. Rahaman, A. Alrehaili, M. El-Newehy, Development of green and sustainable cellulose acetate/graphene oxide nanocomposite films as efficient adsorbents for wastewater treatment. Polymers 12, 2501 (2020)

T.E. Elmetwaly, S.S. Darwish, N.F. Attia, R.R. Hassan, A.A. El Ebissy, A.S. Eltaweil, A.M. Omer, H.R. El-Seedi, S.E. Elashery, Cellulose nanocrystals and its hybrid composite with inorganic nanotubes as green tool for historical paper conservation. Prog Org. Coat. 168, 106890 (2022)

S. Ye, M. Cheng, G. Zeng, X. Tan, H. Wu, J. Liang, M. Shen, B. Song, J. Liu, H. Yang, Insights into catalytic removal and separation of attached metals from natural-aged microplastics by magnetic biochar activating oxidation process. Water Res. 179, 115876 (2020)

E.M. Abd El-Monaem, A.M. Omer, R.E. Khalifa, A.S. Eltaweil, Floatable cellulose acetate beads embedded with flower-like zwitterionic binary MOF/PDA for efficient removal of tetracycline. J. Colloid Interface Sci. 620, 333–345 (2022)

A.M. Hassan, W.A.W. Ibrahim, M.B. Bakar, M.M. Sanagi, Z.A. Sutirman, H.R. Nodeh, M.A. Mokhter, New effective 3-aminopropyltrimethoxysilane functionalized magnetic sporopollenin-based silica coated graphene oxide adsorbent for removal of Pb (II) from aqueous environment. J. Environ. Manag 253, 109658 (2020)

L.P. Lingamdinne, J.R. Koduru, H. Roh, Y.-L. Choi, Y.-Y. Chang, J.-K. Yang, Adsorption removal of Co (II) from waste-water using graphene oxide. Hydrometallurgy 165, 90–96 (2016)

N.F. Attia, S.E. Elashery, A.M. Zakria, A.S. Eltaweil, H. Oh, Recent advances in graphene sheets as new generation of flame retardant materials. Mater. Sci. Engineering: B 274, 115460 (2021)

A.S. Eltaweil, E.M. Abd El-Monaem, G.M. El-Subruiti, M.M. Abd El-Latif, A.M. Omer, Fabrication of UiO-66/MIL-101 (Fe) binary MOF/carboxylated-GO composite for adsorptive removal of methylene blue dye from aqueous solutions. RSC Adv. 10, 19008–19019 (2020)

T. Tang, S. Cao, C. Xi, Z. Chen, Multifunctional magnetic chitosan-graphene oxide-ionic liquid ternary nanohybrid: An efficient adsorbent of alkaloids. Carbohydr. Polym. 255, 117338 (2021)

S. Javadian, Magnetic superhydrophobic polyurethane sponge loaded with Fe3O4@ oleic acid@ graphene oxide as high performance adsorbent oil from water. Chem. Eng. J. 408, 127369 (2021)

A.M. Omer, E.M. Abd El-Monaem, A.S. Eltaweil, Novel reusable amine-functionalized cellulose acetate beads impregnated aminated graphene oxide for adsorptive removal of hexavalent chromium ions. Int. J. Biol. Macromol. 208, 925–934 (2022)

A. Abd El-Fattah, H. Youssef, M.A.H. Gepreel, R. Abbas, S. Kandil, Surface morphology and mechanical properties of polyether ether ketone (PEEK) nanocomposites reinforced by nano-sized silica (SiO2) for prosthodontics and restorative dentistry. Polymers 13, 3006 (2021)

J. Li, L.-P. Zhang, F. Peng, J. Bian, T.-Q. Yuan, F. Xu, R.-C. Sun, Microwave-assisted solvent-free acetylation of cellulose with acetic anhydride in the presence of iodine as a catalyst. Molecules 14, 3551–3566 (2009)

M. Hosny, M. Fawzy, A.S. Eltaweil, Phytofabrication of bimetallic silver-copper/biochar nanocomposite for environmental and medical applications. J. Environ. Manag 316, 115238 (2022)

E.M.A. El-Monaem, M.M.A. El-Latif, A.S. Eltaweil, G.M. El-Subruiti, Cobalt nanoparticles supported on reduced amine-functionalized graphene oxide for catalytic reduction of nitroanilines and organic dyes. Nano 16, 2150039 (2021)

M. Mohiuddin, K.K. Sadasivuni, S. Mun, J. Kim, Flexible cellulose acetate/graphene blueprints for vibrotactile actuator. RSC Adv. 5, 34432–34438 (2015)

J.A. Luceño-Sánchez, A.M. Díez-Pascual, Grafting of polypyrrole-3-carboxylic acid to the surface of hexamethylene diisocyanate-functionalized graphene oxide. Nanomaterials 9, 1095 (2019)

N. Rosdi, N. Mohd Kanafi, N. Abdul Rahman, Preparation and Thermal Properties of Cellulose Acetate/Polystyrene Blend Nanofibers via Electrospinning Technique, Pertanika Journal of Science & Technology 26, (2018)

S.N. Hurairah, N.M. Lajis, A.A. Halim, Methylene blue removal from aqueous solution by adsorption on Archidendron jiringa seed shells. J. Geoscience Environ. Prot. 8, 128–143 (2020)

Ş Parlayici, Alginate-coated perlite beads for the efficient removal of methylene blue, malachite green, and methyl violet from aqueous solutions: kinetic, thermodynamic, and equilibrium studies. J. Anal. Sci. Technol. 10, 1–15 (2019)

A.M. Omer, E.M. Abd El-Monaem, M.M. Abd El-Latif, G.M. El-Subruiti, A.S. Eltaweil, Facile fabrication of novel magnetic ZIF-67 MOF@ aminated chitosan composite beads for the adsorptive removal of Cr (VI) from aqueous solutions. Carbohydr. Polym. 265, 118084 (2021)

H.M. Hassan, M. El-Aassar, M.A. El-Hashemy, M.A. Betiha, M. Alzaid, A.N. Alqhobisi, L.A. Alzarea, I.H. Alsohaimi, Sulfanilic acid-functionalized magnetic GO as a robust adsorbent for the efficient adsorption of methylene blue from aqueous solution. J. Mol. Liq 361, 119603 (2022)

H. Dai, Y. Huang, H. Huang, Eco-friendly polyvinyl alcohol/carboxymethyl cellulose hydrogels reinforced with graphene oxide and bentonite for enhanced adsorption of methylene blue. Carbohydr. Polym. 185, 1–11 (2018)

E. Tao, D. Ma, S. Yang, X. Hao, Graphene oxide-montmorillonite/sodium alginate aerogel beads for selective adsorption of methylene blue in wastewater. J. Alloys Comp. 832, 154833 (2020)

W. Chen, H. Ma, B. Xing, Electrospinning of multifunctional cellulose acetate membrane and its adsorption properties for ionic dyes. Int. J. Biol. Macromol. 158, 1342–1351 (2020)

L. Liu, B. Zhang, Y. Zhang, Y. He, L. Huang, S. Tan, X. Cai, Simultaneous removal of cationic and anionic dyes from environmental water using montmorillonite-pillared graphene oxide. J. Chem. Eng. Data 60, 1270–1278 (2015)

A.S. Ali, M. El-Aassar, F. Hashem, N. Moussa, Surface modified of cellulose acetate electrospun nanofibers by polyaniline/β-cyclodextrin composite for removal of cationic dye from aqueous medium. Fib. Poly. 20, 2057–2069 (2019)

Z. Wang, M. Gao, X. Li, J. Ning, Z. Zhou, G. Li, Efficient adsorption of methylene blue from aqueous solution by graphene oxide modified persimmon tannins. Mater. Sci. Eng: C 108, 110196 (2020)

J. Cheng, C. Zhan, J. Wu, Z. Cui, J. Si, Q. Wang, X. Peng, L.-S. Turng, Highly efficient removal of methylene blue dye from an aqueous solution using cellulose acetate nanofibrous membranes modified by polydopamine. ACS omega 5, 5389–5400 (2020)

S. Tahazadeh, H. Karimi, T. Mohammadi, H.B.M. Emrooz, M.A. Tofighy, Fabrication of biodegradable cellulose acetate/MOF-derived porous carbon nanocomposite adsorbent for methylene blue removal from aqueous solutions. J. Solid State Chem. 299, 122180 (2021)

K. Narasimharao, L.P. Lingamdinne, S. Al-Thabaiti, M. Mokhtar, A. Alsheshri, S.Y. Alfaifi, Y.-Y. Chang, J.R. Koduru, Synthesis and characterization of hexagonal MgFe layered double hydroxide/grapheme oxide nanocomposite for efficient adsorptive removal of cadmium ion from aqueous solutions: Isotherm, kinetic, thermodynamic and mechanism. J. Water Process. Eng. 47, 102746 (2022)

I.G. Zainal, Biosorption of Cr (VI) from AqueousSolution Using New Adsorbent: Equilibrium and Thermodynamic Study. E-J. Chem. 7, S488–S494 (2010)

S. Tripathy, S. Sahu, R.K. Patel, R.B. Panda, P.K. Kar, Novel Fe3O4-Modified Biochar Derived from Citrus Bergamia Peel: A Green Synthesis Approach for Adsorptive Removal of Methylene Blue. Chem. Select 7, e202103595 (2022)

A.H. Jawad, A.S. Abdulhameed, M.S. Mastuli, Acid-factionalized biomass material for methylene blue dye removal: a comprehensive adsorption and mechanism study. J. Taibah Uni Sci. 14, 305–313 (2020)

M. Zubair, N.D. Mu’azu, N. Jarrah, N.I. Blaisi, H.A. Aziz, M.A. Al-Harthi, Adsorption behavior and mechanism of methylene blue, crystal violet, eriochrome black T, and methyl orange dyes onto biochar-derived date palm fronds waste produced at different pyrolysis conditions. Water, Air, Soil Poll. 231, 1–19 (2020)

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB).

Author information

Authors and Affiliations

Contributions

The study conception and design were performed by Abdelazeem S. Eltaweil and Ahmed M. Omer. Material preparation, data collection and analysis were performed by Eman M. Abd El-Monaem, Bassma Ali, Abdelazeem S. Eltaweil, Gehan El-subruiti and Ahmed M. Omer. The first draft of the manuscript was written by Eman M. Abd El-Monaem, Abdelazeem S. Eltaweil, Ahmed M. Omer and Mona M. Abd El-Latif. The revision was done Eman M. Abd El-Monaem, Abdelazeem S. Eltaweil, Ahmed M. Omer, Bassma Ali and Gehan El-subruiti by and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Financial interests

The authors have no relevant financial or non-financial interests.

Conflect of interests

The authors declare that they have no conflect of interests.

Competing Interests:

The authors have no competing interests to declare that are relevant to the content of this article.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Eltaweil, A.S., Abd El-Monaem, E.M., El-Subruiti, G.M. et al. Graphene oxide incorporated cellulose acetate beads for efficient removal of methylene blue dye; isotherms, kinetic, mechanism and co-existing ions studies. J Porous Mater 30, 607–618 (2023). https://doi.org/10.1007/s10934-022-01347-6

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-022-01347-6