Abstract

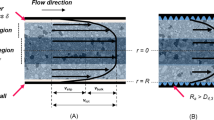

The ubiquitous wall slip behavior of viscoplastic fluids renders the characterization of their yield stress values a challenge but also presents an opportunity. Here, a new process for the determination of the yield stresses of viscoplastic fluids is introduced and demonstrated on concentrated suspensions subjected to steady torsional flow, i.e., parallel-disk viscometry based on the understanding of apparent wall slip. Four viscoplastic suspensions (particles with a maximum packing fraction, ϕm, of 0.86 mixed with a Newtonian binder at the volume fraction, ϕ, range of 0.62 to 0.78) were used. It is demonstrated that a step change in the slope of the torque versus apparent shear rate (or the rotational speed) occurs at a critical torque that corresponds to the yield stress of the suspension. Below the critical torque the behavior is governed by apparent slip and plug flow while above the critical torque the behavior is governed by continuous deformation and apparent slip. The yield stresses of the four concentrated suspensions were verified by comparisons with those obtained from other methods including from wall slip velocities at various shear stresses.

Similar content being viewed by others

References

Abbott JR, Tetlow N, Graham AL, Altobelli SA, Fukushima E, Mondy LA, Stephens TS (1991) Experimental observations of particle migration in concentrated suspensions: Couette flow. J Rheol 35:773–796

Aktaş S, Kalyon DM, Marín-Santibáñez BM, Pérez-González J (2014) Shear viscosity and wall slip behavior of a viscoplastic hydrogel. J Rheol 58:513–535

Altobelli SA, Fukushima E, Mondy LA (1997) Nuclear magnetic resonance imaging of particle migration in suspensions undergoing extrusion. J Rheol 41:1105–1116

Aral BK, Kalyon DM (1994) Effects of temperature and surface roughness on time-dependent development of wall slip in steady torsional flow of concentrated suspensions. J Rheol 38:957–972

Aral BK, Kalyon DM (1997) Viscoelastic material functions of noncolloidal suspensions with spherical particles. J Rheol 41:599–620

Arola DF, Barrall GA, Powell RL, McCarthy KL, McCarthy MJ (1997) Use of nuclear magnetic resonance imaging as a viscometer for process monitoring. Chem Eng Sci 52:2049–2057

Ballesta P, Besseling R, Isa L, Petekidis G, Poon WCK (2008) Slip and flow of hard-sphere colloidal glasses. Phys Rev Lett 101:258301

Ballesta P, Petekidis G, Isa L, Poon WCK, Besseling R (2012) Wall slip and flow of concentrated hard-sphere colloidal suspensions. J Rheol 56:1005–1037

Barnes H (1995) A review of the slip (wall depletion) of polymer solutions, emulsions and particle suspensions in viscometers: its cause, character, and cure. J Non-Newtonian Fluid Mech 56:221–251

Bird B, R Armstrong, O Hassager (1987) Dynamics of polymeric liquids, Volume 1, John Wiley NY

Bonn D, Denn MM (2009) Yield stress fluids slowly yield to analysis. Science 324:1401–1402

Bonn D, Rodts S, Groenink M, Rafaï S, Shahidzadeh-Bonn N, Coussot P (2008) Some applications of magnetic resonance imaging in fluid mechanics: complex flows and complex fluids. Annu Rev Fluid Mech 40:209–233

Brown E, Forman NA, Orellana CS, Zhang H, Maynor BW, Betts DE, Jaeger HM (2010) Generality of shear thickening in dense suspensions Nat. Mater 9:220

Brunn P, Vorwerk J (1993) Determination of the steady-state shear viscosity from measurements of the apparent viscosity for some common types of viscometers. Rheol Acta 32:380

Brunn P, Muller M, Bschorer S (1996) Slip of complex fluids in viscometry. Rheol Acta 35:242–251

Chang C, Powell RL (1993) Dynamic simulation of bimodal suspensions of hydrodynamically interacting spherical particles. J Fluid Mech 253:1–25

Cloitre M, Bonnecaze RT (2017) A review on wall slip in high solid dispersions. Rheol Acta 56:283–305

Cohen Y, Metzner AB (1985) Apparent slip flow of polymer solutions. J Rheol 29:67–102

Coussot P, Raynaud JS, Bertrand F, Moucheront P, Guilbaud JP, Huynh HT, Jarny S, Lesueur D (2002) Coexistence of liquid and solid phases in flowing soft-glassy materials. Phys Rev Lett 88:218301

Damianou Y, Georgiou GC, Moulitsas I (2013) Combined effects of compressibility and slip in flows of a Herschel-Bulkley fluid. J Non-Newtonian Fluid Mech 193:89–102

Dang A, Ooi L, Fales J, Stroeve P (2000) Yield stress measurements of magnetorheological Fluids in tubes. Ind Eng Chem Res 39:2269–2274

De Rosa ME, Winter HH (1994) The effect of entanglements on the rheological behavior of polybutadiene critical gels. Rheol Acta 33:220–237

Denkov ND, Subramanian V, Gurovich D, Lips A (2005) Wall slip and viscous dissipation in sheared foams: effect of surface mobility. Colloids Surf, A 263:129–145

Denn MM, Morris JF (2014) Rheology of non-Brownian suspensions. Annu Rev Chem Biomol Eng 5:203–228

Derzsi L, Filippi D, Mistura G, Pierno M, Lulli M, Sbragaglia M, Bernaschi M, Garstecki P (2017) Fluidization and wall slip of soft glassy materials by controlled surface roughness. Phys Rev E 95:0526202

Divoux T, Lapeyre V, Ravaine V, Manneville S (2015) Wall slip across the jamming transition of soft thermoresponsive particles. Phys Rev E 92:060301

Ferras LI, Nobrega JM, Pinto FT (2012) Analytical solutions for Newtonian and inelastic non-Newtonian flows with wall slip. J Non-Newtonian Fluid Mech 175–176:76–88

Frankel N, Acrivos A (1967) On the viscosity of a concentrated suspension of solid spheres. Chem Eng Sci 22:847–853

Gadala-Maria F, Acrivos A (1980) Shear-induced structure in a concentrated suspension of solid spheres. J Rheol 24:799–814

Ganapathi JI, Fisher FT, Kalyon DM (2016) Distributive mixing of carbon nanotubes in poly (caprolactone) via solution and melt processing: viscoelasticity and crystallization behavior versus mixing indices. J Polym Sci B 54:2254–2268

Giesekus H, Länger G (1977) Die bestimmung der wahren fliesskurven nicht-newtonscher flüssigkeiten und plastischer stoffe mit der methode der repräsentativen viscosität. Rheol Acta 16:1–22

He J, Lee S, Kalyon D (2019) Shear viscosity and wall slip behavior of dense suspensions of polydisperse particles. J Rheol 63:19–32

Hoffman RL (1972) Discontinuous and dilatant viscosity behavior in concentrated suspensions I Observation of a flow instability. J Rheol 16:155–173

Holenberg Y, Lavrenteva OM, Shavit U, Nir A (2012) Particle tracking velocimetry and particle image velocimetry study of the slow motion of rough and smooth solid spheres in a yield-stress fluid. Phys Rev E 86:066301

Jana S, Kapoor B, Acrivos A (1995) Apparent wall slip velocity coefficients in concentrated suspensions of noncolloidal particles. J Rheol 39:1123–1132

Jiang TQ, Young AC, Metzner AB (1986) The rheological characterization of HPG gels: measurement of slip velocities in capillary tubes. Rheol Acta 25:397–404

Kalyon DM (2005a) Letter to the Editor: comments on the use of rheometers with rough surfaces or surfaces with protrusions. J Rheol 49:1153–1155

Kalyon DM (2005b) Apparent slip and viscoplasticity of concentrated suspensions. J Rheol 49:621–640

Kalyon DM, Aktaş S (2014) Factors affecting the rheology and processability of highly filled suspensions. Annu Rev Chem Biomol Eng 5:229–254

Kalyon DM, Gevgilili H (2003) Wall slip and extrudate distortion of three polymer melts. J Rheol 47:683–699

Kalyon DM, Gokturk H, Yaras P, Aral BK (1995) Motion analysis of development of wall slip during die flow of concentrated suspensions. Annu Tech Conf Soc Plast Eng 41:1130–1134

Kalyon DM, Dalwadi D, Erol M, Birinci E, Tsenoglu C (2006) Rheological behavior of concentrated suspensions as affected by the dynamics of the mixing process. Rheol Acta 45:641–658

Kalyon DM (2021) Yield stress and other flow and wall slip parameters of viscoplastic fluids from steady torsional flow. arXiv:2106.13351. http://arxiv.org/abs/2106.13351

Kalyon DM, Yaras P, Aral B, Yilmazer U (1993) Rheological behavior of concentrated suspensions: a solid rocket fuel simulant. J Rheol 37:35–53

Kalyon DM, Lawal A, Yazici R, Yaras P, Railkar S (1999) Mathematical modeling and experimental studies of twin-screw extrusion of filled polymers. Polym Eng Sci 39:1139–1151

Kataoka T, Kitano T, Sasahara M, Nishijima K (1978) Viscosity of particle filled polymer melts. Rheol Acta 17:149–155

Kim JY, Song JY, Lee EJ, Park SK (2003) Rheological properties and microstructures of Carbopol gel network system. Colloid Polym Sci 281:614–623

Kitano T, Kataoka T, Shirota T (1981) An empirical equation of the relative viscosity of polymer melts filled with various inorganic fillers. Rheol Acta 20:207–209

Krieger IM, Dougherty TJ (1959) A mechanism for non-Newtonian flow in suspensions of rigid spheres. J Rheol 3:137–152

Krüger T, Kaoui B, Harting J (2014) Interplay of inertia and deformability on rheological properties of a suspension of capsules. J Fluid Mech 751:725–745

Küçük I, Gevgilili H, Kalyon DM (2013) Effects of dispersion and deformation histories on rheology of semidilute and concentrated suspensions of multiwalled carbon nanotubes. J Rheol 57:1491–1514

Kwon T, Ahn S (1995) Slip characterization of powder/binder mixtures and its significance in the filling process analysis of powder injection molding. Powder Technol 85:45–55

Le Merrer M, Lespiat R, Höhler R, Cohen-Addad S (2015) Linear and non-linear wall friction of wet foams. Soft Matter 11:368–381

Macosko C (1994) Rheology principles, measurements and applications. Wiley-VCH, New York, NY

Magnin A, Piau JM (1990) Cone and plate rheometry of yield stress fluids: study of an aqueous gel. J Non- Newtonian Fluid Mech 36:85–108

Mall-Gleissle SE, Gleissle W, McKinley GH, Buggisch H (2002) The normal stress behaviour of suspensions with viscoelastic matrix fluids. Rheol Acta 41:61–76

Mansard V, Bocquet L, Colin A (2014) Boundary conditions for soft glassy flows: slippage and surface fluidization. Soft Matter 10:6984–6989

Medina-Bañuelos EF, Marín-Santibáñez BM, Pérez-González J, Malik M, Kalyon DM (2017) Tangential annular (Couette) flow of a viscoplastic hydrogel with wall slip. J Rheol 61:1007–1022

Medina-Bañuelos EF, Marín-Santibáñez BM, Pérez-González J, Kalyon DM (2019) Rheo-PIV analysis of the vane in cup flow of a viscoplastic hydrogel. J Rheol 63:905–915

Meeker SP, Bonnecaze RT, Cloitre M (2004) Slip and flow in pastes of soft particles: direct observation and rheology. J Rheol 48:1295–1320

Metzner A (1985) Rheology of suspensions in polymeric liquids. J Rheol 29:739–775

Mooney M (1931) Explicit formulas for slip and fluidity. J Rheol 2:210–222

Moraczewski T, Tang H, Shapley NC (2005) Flow of a concentrated suspension through an abrupt axisymmetric expansion measured by nuclear magnetic resonance imaging. J Rheol 49:1409–1428

Mwasame PM, Wagner NJ, Beris AN (2016) Modeling the effects of polydispersity on the viscosity of noncolloidal hard sphere suspensions. J Rheol 60:225–240

Nickerson C, Kornfield J (2005) A novel ‘cleat’ geometry for suppressing wall slip. J Rheol 49:865–874

Ohl N, Gleissle W (1993) The characterization of the steady-state shear and normal stress functions of highly concentrated suspensions formulated with viscoelastic liquids. J Rheol 37:381–406

Paredes J, Shahidzadeh N, Bonn D (2015) Wall slip and fluidity in emulsion flow. Phys Rev E 92:042313

Pednekar S, Chun J, Morris JF (2018) Bidisperse and polydisperse suspension rheology at large solid fraction. J Rheol 62:513–526

Pemeja J, Géraud B, Barentin C (2019) and Le Merrer, Wall slip regimes in jammed suspensions of soft microgels. Phys Rev Fluids 4:0333301

Perez-Gonzalez J, Lopez-Duran JJ, Marın-Santibanez BM, Rodrıguez-Gonzalez F (2012) Rheo-PIV of a yield-stress fluid in a capillary with slip at the wall. Rheol Acta 51:937–946

Person TJ, Denn MM (1997) The effect of die materials and pressure-dependent slip on the extrusion of linear low-density polyethylene. J Rheol 41:249–265

Piau JM (2007) Carbopol gels: elastoviscoplastic and slippery glasses made of individual swollen sponges mesoand macroscopic properties, constitutive equations and scaling laws. J Non-Newtonian Fluid Mech 144:1–29

Poslinski A, Ryan M, Gupta R, Seshadri S, Frechette F (1988) Rheological behavior of filled polymeric systems I. Yield stress and shear-thinning effects. J Rheol 32:703–735

Probstein RF, Sengun M, Tseng TC (1994) Bimodal model of concentrated suspension viscosity for distributed particle sizes. J Rheol 38:811–829

Quan L, Kalyon D (2022) Parallel-disk viscometry of a viscoplastic hydrogel: yield stress and other parameters of shear viscosity and wall slip. Gels 8:230

Quemada D (1978) Rheology of concentrated disperse systems II. A model for non-Newtonian shear viscosity in steady flows Rheol. Acta 17:632–642

Raynaud JS, Moucheront P, Bertrand F, Guilbaud JP, Coussot P (2002) Direct determination by nuclear magnetic resonance of the thixotropic and yielding behavior of suspensions. J Rheol 46:709–732

Reiner M (1931) Slippage in a non-Newtonian liquid. J Rheol 2:337–350

Rueda MM, Auscher M-C, Fulchiron R, Périé T, Martin G, Sonntag P, Cassagnau P (2017) Rheology and applications of highly filled polymers: a review of current understanding. Prog Polym Sci 66:22–53

Seth JR, Cloitre M, Bonnecaze RT (2008) Influence of short-range forces on wall-slip in microgel pastes. J Rheol 52:1241–1268

Seth JR, Locatelli-Champagne C, Monti F, Bonnecaze RT, Cloitre M (2012) How do soft particle glasses yield and flow near solid surfaces. Soft Matter 8:140–148

Sierou A, Brady J (2002) Rheology and microstructure in concentrated noncolloidal suspensions. J Rheol 46:1031–1056

Singh A, Mari R, Denn MM, Morris JF (2018) A constitutive model for simple shear of dense frictional suspensions. J Rheol 62:457–468

Sinton SW, Chow AW (1991) NMR flow imaging of fluids and solid suspensions in Poiseuille flow. J Rheol 35:735–772

Soltani F, Yilmazer U (1998) Slip velocity and slip layer thickness in flow of concentrated suspensions. J Appl Polym Sci 70:515–522

Tang HS (2012) Analysis on creeping channel flows of compressible fluids subject to wall slip. Rheol Acta 51:421–439

Tang HS, Kalyon DM (2008a) Unsteady circular tube flow of compressible polymeric liquids subject to pressure-dependent wall slip. J Rheology 52(2):507–526

Tang H, Kalyon DM (2008b) Time-dependent tube flow of compressible suspensions subject to pressure dependent wall slip: ramifications on development of flow instabilities. J Rheol 52:1069–1090

Tsenoglou C (1989) Viscoplasticity of agglomerated suspensions. Rheol Acta 28:311–315

Tsenoglou C, Yang S (1990) Fluidity and optimum packing in suspensions of mixed dissimilar particles. Polym Eng Sci 30:1407–1412

Vand V (1948) Viscosity of solutions and suspensions I Theory. J Phys Chem 52:277–299

Vinogradov GV, Ivanova LI (1967) Viscous properties of polymer melts and elastomers exemplified by ethylene-propylene copolymer. Rheol Acta 6:209–222

Yaras P, Kalyon D, Yilmazer U (1994) Flow instabilities in capillary flow of concentrated suspensions. Rheol Acta 33:48–59

Yilmazer U, Kalyon DM (1989) Slip effects in capillary and parallel disk torsional flows of highly filled suspensions. J Rheol 33:1197–1212

Yilmazer U, Kalyon DM (1991) Dilatancy of concentrated suspensions with Newtonian matrices. Polym Compos 12:226–232

Yoshimura A, Prud’homme RK (1988) Wall slip corrections for Couette and parallel disk viscometers. J Rheol 32:53–67

Zhang X, Lorenceau E, Basset P, Bourouina T, Rouyer F, Goyon J, Coussot P (2017) Wall slip of soft-jammed systems: a generic simple shear process. Phys Rev Lett 119:208004

Zhang X, Lorenceau E, Bourouina T, Basset P, Oerther T, Ferrari M, Rouyer F, Goyon J, Coussot P (2018) Wall slip mechanisms in direct and inverse emulsions. J Rheol 62:1495–1513

Acknowledgements

The experimental data were collected at Stevens by Dr. Jing He as part of his PhD thesis with results reported in He et al. (2019).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1

Mixing, small-amplitude oscillatory shear data and parameters of Herschel–Bulkley equation

An intensive batch mixer/torque rheometer, with a mixing volume of 300 ml (EU-5 V manufactured by Haake Buchler Instruments, Inc., Saddle Brooke, NJ, USA), was used to mix the particles with the binder. This mixer has two intermeshing counter-rotating rotors and can impart relatively high stress magnitudes (the design of the intensive mixer is that of the Banbury mixer that is widely used for the compounding of elastomers in the rubber industry). Mixing was carried out at ambient temperature. The rotational speed of the rotors was kept at 32 rpm, and the degree of fill of the mixer (volume occupied by the suspension over the total available volume in the mixer) was 0.8. For each suspension, the mixing time was systematically varied (5-30 min). Sets of five specimens each were collected at regular time intervals of 5–10 min for the determination of mixing indices at various mixing times. This way, the mixtures could be prepared under reproducible conditions. Additional information can be found at He et al. (2019).

The linear viscoelastic material functions of suspensions prepared under various concentrations of the solid phase are shown in Fig. 7 (He et al. 2019). The dynamic properties suggest that G′ > > G″ and that the moduli are relatively insensitive to the frequency of the oscillatory shear deformation at relatively high solid concentrations, indicating that gel-like behavior (DeRosa and Winter 1994) will be approached with increasing ϕ.

A The storage moduli, G′, and b magnitude of complex viscosity, |η*|, of the dense suspensions as a function of frequency, ω, at the strain amplitude of 0.02% for different ϕ (He et al. 2019)

He et al. determined the parameters of the shear viscosity material function based on the Herschel–Bulkley equation of the four suspensions (He et al. 2019) as provided in Table 2.

The wall slip velocity \({U}_{s}\) is defined as the difference between the velocity of the fluid at the wall, and the velocity of the wall. The wall slip velocity is negative for the fluid found adjacent to a moving surface and is positive for the fluid adjacent to a stationary surface. He et al. determined the parameters of wall slip velocity, \({U}_{s}\), versus the shear stress, for the four suspensions given in Table 3:

These parameters were used for the determination of the torque values for each rotational speed and gap for the four suspensions.

Appendix 2

The calculated torque versus rotational speed and gap used in steady torsional flow via parallel disk viscometry

The torque versus Ω at various gaps and concentrations are further shown in Fig. 8. The data for ϕ = 0.72, 0.76, and 0.78 are consistent with the torque versus Ω and torque versus apparent shear rate data discussed in conjunction with Fig. 2. Overall, the torque does not depend on the gap used for the plug flow region as suggested by Eq. 14. Thus, the plug flow dynamics is wholly governed by the thickness of the apparent slip layer and the flow properties of the binder that constitutes the apparent slip layer. In the plug flow region the slope \(\frac{d\mathrm{ln}\mathfrak{I}}{d\mathrm{ln}\left(\mathrm{\Omega R}/\mathrm{H}\right)}\) is equal to 1 for all gaps for the different concentrations, accentuating the understanding that in the plug flow region the flow properties of the bulk suspension do not play a role. Since the binder is Newtonian the slope of torque versus rotational speed for the plug flow region is expected to be 1 ( Eq. 14).

The slope \(\frac{d\mathrm{ln}\mathfrak{I}}{d\mathrm{ln\Omega }}\) depends on the gap for the continuous deformation region, i.e., \(\left|{\uptau }_{\mathrm{z\theta }}\left(r\right)\right|>{\uptau }_{0}\) for all concentrations. This is expected on the basis of Eqs. 17 and 18, which represent that the torque values associated with the continuous deformation region are affected by both the apparent slip and the bulk deformation behavior of the suspensions. When the shear stress is significantly greater than the yield stress of the suspension, the slope \(\frac{d\mathrm{ln}\mathfrak{I}}{d\mathrm{ln\Omega }}\) will approach the power law index, n (the shear rate sensitivity index) of the Herschel–Bulkley fluid model that represents the shear viscosity of the viscoplastic fluid in the continuous deformation region (Eqs. 17 and 18).

Torque versus the apparent shear rate are shown in Fig. 9 for the solid volume fractions of 0.72, 0.76, and 0.78. It should be noted that in the plug flow region, the dependence shown on the gap is superficial and stems from the definition of the apparent shear rate having the gap in it, i.e., \({\dot{\gamma }}_{aR}=\mathrm{\Omega R}/H\). The slopes are all equal to 1 since \(\frac{d\mathrm{ln}\mathfrak{I}}{d\mathrm{ln}\left(\mathrm{\Omega R}/H\right)}=\frac{d\mathrm{ln}\mathfrak{I}}{d\mathrm{ln}\left(\Omega \right)}\). These figures are included since the dependencies shown below can be misconstrued.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Quan, L., He, J., Lee, S.S. et al. Yield stresses of concentrated suspensions of rigid particles in the volume fraction range of 0.62 to 0.78 via steady torsional flow. Rheol Acta 62, 111–127 (2023). https://doi.org/10.1007/s00397-022-01382-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00397-022-01382-9