Abstract

The morphology of quenched and compression molded samples of poly(lactic acid)/polycaprolactone (PLA/PCL) blend prepared by melt mixing was carefully characterized by the method reflecting eventual nonuniformity of the blend structure and/or broad particle size distribution. Determined number and volume average droplet radii for quenched samples were compared with theory, assuming that flow field in a mixing chamber can be substituted by the shear flow with effective shear rate. An increase in droplet radii during compression molding was compared with theory of the coalescence in quiescent state. Using the concept of effective shear flow to describe mixing leads to a strong disagreement between theory and experiment for the critical droplet radius of its breakup, and for the coalescence efficiency. The theory of coalescence in quiescent state provides fair description of an increase in the number average droplet radius during compression molding, but totally fails at prediction of an increase in the volume average droplet radius.

Similar content being viewed by others

References

Favis BD (2000) Factor influencing the morphology in immiscible polymer blends in melt processing. In: Paul DR, Bucknall CB (eds) Polymer blends, vol 1., FormulationsWiley, New York, pp 501–537

Fortelný I (2006) Theoretical aspects of phase morphology development. In: Harrats C, Thomas S, Groeninckx G (eds) Micro- and nanostructured multiphase polymer blends systems. Taylor and Francis, Boca Raton, pp 43–90

Huang HX (2011) Macro, micro and nanostructured morphologies of multiphase polymer systems. In: Boudenne A, Ibos L, Candau Y, Thomas S (eds) Handbook of multiphase polymer systems, vol 1. Wiley, Chichester, pp 161–249

Sundararaj U (2006) Phase morphology development in polymer blends. In: Harrats C, Thomas S, Groeninckx G (eds) Micro- and Nanostructured Multiphase Polymer Blends Systems. Taylor and Francis, Boca Raton, pp 133–164

Fortelný I (2001) Analysis of the effect of breakup frequency on the steady droplet size in flowing polymer blends. Rheol Acta 40:485–489. doi:10.1007/s003970100174

Rother AM, Davis RH (2001) The effect of slight deformation on droplet coalescence in linear flow. Phys Fluids 13:1178–1190. doi:10.1063/1.1358871

Fortelný I, Jůza J (2012) Modeling of the influence of matrix elasticity on coalescence probability of colliding droplets in shear flow. J Rheol 56:1393–1411. doi:10.1122/1.4739930

Jůza J, Fortelný I (2013) Flow induced coalescence in polymer blends. Chem Chem Technol 7:53–60 (issn: 1996-4196)

Fortelný I, Jůza J (2013) Modeling of interface mobility in the description of flow-induced coalescence in immiscible polymer blends. Colloid Polym Sci 291:1863–1870. doi:10.1007/s00396-013-2917-x

Fortelný I, Jůza J (2014) Flow-induced coalescence in polydisperse systems. Macromol Mater Eng 299:1213–1219. doi:10.1002/mame.201400050

Cristini V, Guido S, Alfani A, Blawzdziewicz J, Loewenberg M (2003) Drop breakup and fragment size distribution in shear flow. J Rheol 47:1283–1298. doi:10.1122/1.1603240

Tokita N (1977) Analysis of morphology formation in elastomer blends. Rubber Chem Technol 50:292–300. doi:10.5254/1.3535144

Favis BD, Willis JM (1990) Phase size/composition dependence in immiscible blends. Experimental and theoretical considerations. J Polym Sci Part B Polym Phys 28:2259–2269. doi:10.1002/polb.1990.090281208

Favis BD, Chalifoux JP (1988) Influence of composition on the morphology of polypropylene polycarbonate blends. Polymer 29:1761–1767. doi:10.1016/0032-3861(88)90388-6

Everaert V, Aerts L, Groeninckx G (1999) Phase morphology development in immiscible PP/(PS/PPE) blends: influence of the melt-viscosity ratio and blend composition. Polymer 40:6627–6644. doi:10.1016/S0032-3861(99)00048-8

Li YY, Yan D, Ma GQ, Yuan XB, Sheng J (2010) Application of Mie light scattering to the morphological development of polypropylene/polystyrene blends. I. Method for the determination of Mie scattering pages. J Appl Polym Sci 116:1933–1939. doi:10.1002/app.31074

Bhadane PA, Tsou AH, Cheng J, Favis BD (2008) Morphology development and interfacial erosion in reactive polymer blending. Macromolecules 41:7549–7559. doi:10.1021/ma801390s

Yin L, Yin J, Shi D, Luan S (2009) Effects of SEBS-g-BTAI on the morphology, structure and mechanical properties of PA6/SEBS blends. Eur Polym J 45:1554–1560. doi:10.1016/j.eurpolymj.2009.01.022

Zhu L, Song N, Xu X (2009) Real space and wave-number space studies of the phase structure and morphology of iPP/PEOc blends using scanning electron microscopy. Macromol Mater Eng 294:516–524. doi:10.1002/mame.200900068

Zhang Z, Qiao J (1991) Quantitative prediction of particle size of dispersed phase in elastomer-plastic blends. Polym Eng Sci 31:1553–1557. doi:10.1002/pen.760312109

Thomas S, Groeninckx G (1999) Nylon 6/ethylene propylene rubber (EPM) blends: phase morphology development during processing and comparison with literature data. J Appl Polym Sci 71:1405–1429. doi:10.1002/(SICI)1097-4628(19990228)71:9<1405:AID-APP6>3.0.CO;2-E

Lin B, Sundararaj U (2004) Visualization of poly(ether imide) and polycarbonate blending in an internal mixer. J Appl Polym Sci 92:1165–1175

Oommen S, Zachariah R, Thomas S, Groeninckx G, Moldenaers P, Mewis J (2004) Melt rheology and morphology of uncompatibilized and in situ compatibilized nylon-6/ethylene propylene rubber blends. J Appl Polym Sci 92:252–264. doi:10.1002/app.13652

Xu X, Yan X, Zhu T, Zhang C, Sheng J (2007) Phase morphology development of polypropylene/ethylene-octene copolymer blends: effects of blend composition and processing conditions. Polym Bull 58:465–478. doi:10.1007/s00289-006-0678-0

Fortelný I, Dimzoski B, Michálková D, Mikešová J, Kaprálková L (2013) Dependence of the average size of particles formed during steady mixing on their concentration in immiscible polymer blends. J Macromol Sci Part B Phys 52:662–673. doi:10.1080/00222348.2012.720176

Bousmina M, Ait-Kadi A, Faisant JB (1999) Determination of shear rate and viscosity from batch mixer data. J Rheol 43:415–434. doi:10.1122/1.551044

Fortelný I, Dimzoski B, Michálková D (2012) Phase structure evolution during compression molding of compatibilized polymer blends. J Macromol Sci Part B Phys 51:2026–2033. doi:10.1080/00222348.2012.661668

Imre B, Pukánszky B (2013) Compatibilization in bio-based and biodegradable polymer blends. Eur Polym J 49:1215–1233. doi:10.1016/j.eurpolymj.2013.01.019

Dell’Erba R, Groeninckx G, Maglio G, Malinlonico M, Migliozzi A (2001) Immiscible polymer blends of semicrystalline biocompatible components: thermal properties and phase morphology analysis of PLLA/PCL blends. Polymer 42:7831–7840. doi:10.1016/S0032-3861(01)00269-5

Monticelli O, Calabrese M, Gardella L, Fina A, Gioffredi E (2014) Silsesquioxanes: novel compatibilizing agents for tuning the microstructure and properties of PLA/PCL immiscible blends. Eur Polym J 58:69–78. doi:10.1016/j.eurpolymj.2014.06.021

Gardella L, Calabrese M, Monticelli O (2014) PLA maleation: an easy and effective method to modify the properties of PLA/PCL immiscible blends. Colloid Polym Sci 292:2391–2398. doi:10.1007/s00396-014-3328-3

Bai H, Huang C, Xiu H, Gao Y, Zhang Q, Fu Q (2013) Toughening of poly(l-lactide) with poly(ε-caprolactone): combined effects of matrix crystallization and impact modifier particle size. Polymer 54:5257–5266. doi:10.1016/j.polymer.2013.07.051

Šlouf M, Kolařík J, Kotek J (2007) Rubber-toughened polypropylene/acrylonitrile-co-butadiene-co-styrene blends: morphology and mechanical properties. Polym Eng Sci 47(582):592. doi:10.1002/pen.20727

Zolotarevová E, Fejfárková Z, Entlicher G, Lapčíková M, Šlouf M, Pokorný D, Sosna A (2008) Can centrifugation affect the morphology of polyethylene wear debris? Wear 265:1914–1917. doi:10.1016/j.wear.2008.04.005

Šlouf M, Ostafińska A, Nevoralová M, Fortelný I (2015) Morphological analysis of polymer systems with broad particle size distribution. Polym Testing 42:8–16. doi:10.1016/j.polymertesting.2014.12.012

Macosko CW (1994) Rheology: principles, measurements, and applications. Wiley-VCH, New York

Palierne JF (1990) Linear rheology of viscoelastic emulsions with interfacial tension. Rheol Acta 29:204–214. doi:10.1007/BF01331356

Tucker CL, Moldenaers P (2002) Microstructural evolution in polymer blends. Annu Rev Fluid Mech 34:177–210. doi:10.1146/annurev.fluid.34.082301.144051

Harrats C, Mekhilef N (2006) Cocontinuous phase morphologies: predictions, generation, and practical application. In: Harrats C, Thomas S, Groeninckx G (eds) Micro- and nanostructured multiphase polymer blends systems. Taylor and Francis, Boca Raton, pp 91–132

Pötschke P, Paul DR (2003) Formation of co-continuous structures in melt-mixed immiscible polymer blends. J Macromol Sci Part C Polym Rev C43:87–141. doi:10.1081/MC-120018022

Underwood EE (1970) Quantitative stereology. Addison-Wesley, Reading, p 91

deBruijn RA (1989) Deformation and break-up of drops in simple shear flows. Disertation, Eindhoven University of Technology, The Netherlands

Majesté JC, Santamaría A (2011) Macro, micro and nanostructured morphologies of multiphase polymer systems. In: Boudenne A, Ibos L, Candau Y, Thomas S (eds) Handbook of multiphase polymer systems, vol 1. Wiley, Chichester, pp 311–357

Utracki LA (2011) Rheology of polymer blends. In: Isayev AI (ed) Encyclopedia of polymer blends, vol 2. Wiley-VCH, Weinheim, pp 27–107

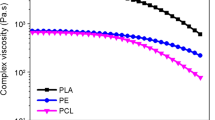

Noroozi N, Schafer LL, Hatzikiriakos SG (2012) Thermorheological properties of poly(ε-caprolactone)/polylactide blends. Polym Eng Sci 52:2348–2359. doi:10.1002/pen.23186

Wu D, Zhang Y, Yuan L, Zhang M, Zhou W (2010) Viscoelastic interfacial properties of compatibilized poly((ε-caprolactone)/polylactide blends. J Polym Sci Part B Polym Phys 48:756–765. doi:10.1002/polb.21952

Ghodgaonkar PG, Sundararaj U (1996) Prediction of dispersed phase drop diameter in polymer blends: the effect of elasticity. Polym Eng Sci 36:1656–1665. doi:10.1002/pen.10562

Van Oene HJ (1972) Modes of dispersion of viscoelastic fluids in flow. J Colloid Interface Sci 40:448–467. doi:10.1016/0021-9797(72)90355-4

Laun HM (1986) Prediction of elastic strains of polymer melts in shear and elongation. J Rheol 30:459–502. doi:10.1122/1.549855

Dimzoski B, Fortelný I, Šlouf M, Sikora A, Michálková D (2013) Morphology evolution during cooling of quiescent immiscible polymer blends: matrix crystallization effect on the dispersed phase coalescence. Polym Bull 70:263–275. doi:10.1007/s00289-012-0848-1

Fortelný I, Jůza J, Dimzoski B (2012) Coalescence in quiescent polymer blends with a high content of the dispersed phase. Eur Polym J 48:1230–1240. doi:10.1016/j.eurpolymj.2012.04.017

Acknowledgments

Financial support from the Grant Agency of the Czech Republic (Grants No. GA14-17921S and No. P106/11/1069) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Fortelný, I., Ostafińska, A., Michálková, D. et al. Phase structure evolution during mixing and processing of poly(lactic acid)/polycaprolactone (PLA/PCL) blends. Polym. Bull. 72, 2931–2947 (2015). https://doi.org/10.1007/s00289-015-1445-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-015-1445-x