Abstract

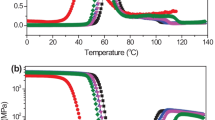

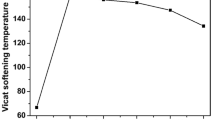

This study examines the rheological, mechanical and thermal behavior of Poly(lactic acid)/Poly(methyl methacrylate) (PLA/PMMA) blends and takes a look at the phase structure evolution during their melt processing. Semi-crystalline or amorphous PLA grades were combined with PMMA of different molecular weight to prepare the blends. The rheological properties and phase structure was first assessed using small-amplitude oscillatory shear experiments. The blends were injection molded into bars and characterized in terms of their tensile properties and of their dynamic mechanical behavior. Differential scanning calorimetry was also used to study the miscibility and crystallization behavior of prepared blends. Tensile properties of the blends nearly followed a linear mixing rule with no detrimental effect that could have been associated with an uncompatibilized interface. However, dynamic mechanical analysis and calorimetric experiments showed that some phase separation was present in the molded parts. Nevertheless, a single Tg was found if sufficient time was given in quiescent conditions to achieve miscibility. The Gordon-Taylor equation was used to assess the polymer interactions, suggesting that miscibility is the thermodynamically stable state. The ability of PLA to crystallize was strongly restricted by the presence of PMMA and little or no crystallinity development was possible in the blends with more than 30% of PMMA. Results showed an interesting potential of these blends from an application point of view, whether they are phase separated or not.

Similar content being viewed by others

References

Auras R, Harte B, Selke S (2004) An overview of Polylactides as packaging materials. Macromol Biosci 4(9):835–864. https://doi.org/10.1002/mabi.200400043

Flory PJ (1953) Principles of polymer chemistry. Cornell University Press, Ithaca

Anderson KS, Hillmyer MA (2004) The influence of block copolymer microstructure on the toughness of compatibilized polylactide/polyethylene blends. Polymer 45(26):8809–8823. https://doi.org/10.1016/j.polymer.2004.10.047

Choudhary P, Mohanty S, Nayak SK, Unnikrishnan L (2011) Poly(L-lactide)/polypropylene blends: evaluation of mechanical, thermal, and morphological characteristics. J Appl Polym Sci 121(6):3223–3237. https://doi.org/10.1002/app.33866

Sarazin P, Favis BD (2003) Morphology control in co-continuous poly (L-lactide)/polystyrene blends: a route towards highly structured and interconnected porosity in poly (L-lactide) materials. Biomacromolecules 4(6):1669–1679

Gajria AM, Davé V, Gross RA, McCarthy SP (1996) Miscibility and biodegradability of blends of poly(lactic acid) and poly(vinyl acetate). Polymer 37(3):437–444. https://doi.org/10.1016/0032-3861(96)82913-2

Huneault MA, Li H (2007) Morphology and properties of compatibilized polylactide/thermoplastic starch blends. Polymer 48(1):270–280. https://doi.org/10.1016/j.polymer.2006.11.023

Homklin R, Hongsriphan N (2013) Mechanical and thermal properties of PLA/PBS co-continuous blends adding nucleating agent. Energy Procedia 34:871–879. https://doi.org/10.1016/j.egypro.2013.06.824

Iannace S, Ambrosio L, Huang S, Nicolais L (1994) Poly (3-hydroxybutyrate)-co-(3-hydroxyvalerate)/poly-L-lactide blends: thermal and mechanical properties. J Appl Polym Sci 54(10):1525–1535

La Mantia FP, Botta L, Morreale M, Scaffaro R (2012) Effect of small amounts of poly(lactic acid) on the recycling of poly(ethylene terephthalate) bottles. Polym Degrad Stab 97(1):21–24. https://doi.org/10.1016/j.polymdegradstab.2011.10.017

McLauchlin AR, Ghita OR (2016) Studies on the thermal and mechanical behavior of PLA-PET blends. J Appl Polym Sci 133(43):n/a–n/a. https://doi.org/10.1002/app.44147

Hiljanen-Vainio M, Varpomaa P, Seppälä J, Törmälä P (1996) Modification of poly (L-lactides) by blending: mechanical and hydrolytic behavior. Macromol Chem Phys 197(4):1503–1523

Harada M, Iida K, Okamoto K, Hayashi H, Hirano K (2008) Reactive compatibilization of biodegradable poly(lactic acid)/poly(ε-caprolactone) blends with reactive processing agents. Polym Eng Sci 48(7):1359–1368. https://doi.org/10.1002/pen.21088

Yang J-M, Chen H-L, You J-W, Hwang JC (1997) Miscibility and crystallization of poly (L-lactide)/poly (ethylene glycol) and poly (L-lactide)/poly (ε-caprolactone) blends. Polym J 29(8):657–662

Sheth M, Kumar RA, Davé V, Gross RA, McCarthy SP (1997) Biodegradable polymer blends of poly(lactic acid) and poly(ethylene glycol). J Appl Polym Sci 66(8):1495–1505. https://doi.org/10.1002/(SICI)1097-4628(19971121)66:8<1495::AID-APP10>3.0.CO;2-3

Eguiburu JL, Iruin JJ, Fernandez-Berridi MJ, San Román J (1998) Blends of amorphous and crystalline polylactides with poly(methyl methacrylate) and poly(methyl acrylate): a miscibility study. Polymer 39(26):6891–6897. https://doi.org/10.1016/S0032-3861(98)00182-7

Zhang G, Zhang J, Wang S, Shen D (2003) Miscibility and phase structure of binary blends of polylactide and poly(methyl methacrylate). J Polym Sci B Polym Phys 41(1):23–30. https://doi.org/10.1002/polb.10353

Li S-H, Woo EM (2008) Effects of chain configuration on UCST behavior in blends of poly(L-lactic acid) with tactic poly(methyl methacrylate)s. J Polym Sci B Polym Phys 46(21):2355–2369. https://doi.org/10.1002/polb.21567

Li S-H, Woo EM (2008) Immiscibility–miscibility phase transitions in blends of poly(L-lactide) with poly(methyl methacrylate). Polym Int 57(11):1242–1251. https://doi.org/10.1002/pi.2469

Shirahase T, Komatsu Y, Tominaga Y, Asai S, Sumita M (2006) Miscibility and hydrolytic degradation in alkaline solution of poly(l-lactide) and poly(methyl methacrylate) blends. Polymer 47(13):4839–4844. https://doi.org/10.1016/j.polymer.2006.04.012

Le K-P, Lehman R, Remmert J, Vanness K, Ward PML, Idol JD (2006) Multiphase blends from poly(L-lactide) and poly(methyl mathacrylate). J Biomater Sci Polym Ed 17(1–2):121–137. https://doi.org/10.1163/156856206774879054

Anakabe J, Zaldua Huici AM, Eceiza A, Arbelaiz A (2015) Melt blending of polylactide and poly(methyl methacrylate): thermal and mechanical properties and phase morphology characterization. J Appl Polym Sci 132(42):n/a–n/a. https://doi.org/10.1002/app.42677

Samuel C, Raquez J-M, Dubois P (2013) PLLA/PMMA blends: a shear-induced miscibility with tunable morphologies and properties? Polymer 54(15):3931–3939. https://doi.org/10.1016/j.polymer.2013.05.021

Nishi T, Wang T (1975) Melting point depression and kinetic effects of cooling on crystallization in poly (vinylidene fluoride)-poly (methyl methacrylate) mixtures. Macromolecules 8(6):909–915

Canetti M, Cacciamani A, Bertini F (2014) Miscible blends of polylactide and poly(methyl methacrylate): morphology, structure, and thermal behavior. J Polym Sci B Polym Phys 52(17):1168–1177. https://doi.org/10.1002/polb.23544

Fischer EW, Sterzel HJ, Wegner G (1973) Investigation of the structure of solution grown crystals of lactide copolymers by means of chemical reactions. Kolloid-Zeitschrift und Zeitschrift für Polymere 251(11):980–990. https://doi.org/10.1007/bf01498927

Roovers J, Toporowski PM (1992) Rheological study of miscible blends of 1,4-polybutadiene and 1,2-polybutadiene (63% 1,2). Macromolecules 25(3):1096–1102. https://doi.org/10.1021/ma00029a014

RunMing L, Wei Y, ChiXing Z (2007) Phase inversion and viscoelastic properties of phase-separated polymer blends. Polym Bull 59(4):545–554. https://doi.org/10.1007/s00289-007-0794-5

Schnell M, Ziegler V, Wolf BA (2008) Evolution of viscosities and morphology for the two-phase system polyethylene oxide/poly(dimethylsiloxane). Rheol Acta 47(4):469–476. https://doi.org/10.1007/s00397-007-0240-5

Liu C, Wang J, He J (2002) Rheological and thermal properties of m-LLDPE blends with m-HDPE and LDPE. Polymer 43(13):3811–3818. https://doi.org/10.1016/S0032-3861(02)00201-X

Chopra D, Kontopoulou M, Vlassopoulos D, Hatzikiriakos GS (2002) Effect of maleic anhydride content on the rheology and phase behavior of poly(styrene-co -maleic anhydride)/ poly(methyl methacrylate) blends. Rheol Acta 41(1):10–24. https://doi.org/10.1007/s003970200001

Sarkhel G, Banerjee A, Bhattacharya P (2006) Rheological and mechanical properties of LDPE/HDPE blends. Polym Plast Technol Eng 45(6):713–718. https://doi.org/10.1080/03602550600609663

Lodge TP, McLeish TCB (2000) Self-concentrations and effective glass transition temperatures in polymer blends. Macromolecules 33(14):5278–5284. https://doi.org/10.1021/ma9921706

Gordon M, Taylor JS (1952) Ideal copolymers and the second-order transitions of synthetic rubbers. i. Non-crystalline copolymers. J Appl Chem 2(9):493–500. https://doi.org/10.1002/jctb.5010020901

Jalali A, Huneault MA, Elkoun S (2016) Effect of thermal history on nucleation and crystallization of poly(lactic acid). J Mater Sci 51(16):7768–7779. https://doi.org/10.1007/s10853-016-0059-5

Saeidlou S, Huneault MA, Li H, Sammut P, Park CB (2012) Evidence of a dual network/spherulitic crystalline morphology in PLA stereocomplexes. Polymer 53(25):5816–5824. https://doi.org/10.1016/j.polymer.2012.10.030

Acknowledgements

The authors would like to acknowledge the financial contribution of the Fond de recherche nature et technologie (FRQNT) of the province of Québec, Canada.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gonzalez-Garzon, M., Shahbikian, S. & Huneault, M.A. Properties and phase structure of melt-processed PLA/PMMA blends. J Polym Res 25, 58 (2018). https://doi.org/10.1007/s10965-018-1438-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-018-1438-1