Abstract

Single cell oils (SCO) can be a source of nutritionally valuable fatty acids and raw material in biodiesel production. Among the oleaginous yeasts, those which additionally generate carotenoid pigments are beneficially distinguished. Rhodotorula and Sporobolomyces strains were screened for the ability to grow and produce intracellular lipids in medium containing pure glycerol. In this paper, we verified that glycerol is unfavorable carbon source for a strain of S. salmonicolor and a good source of carbon for the growth and increases lipids content in the biomass of examined Rhodotorula yeast compared to glucose. The best volumetric efficiency of lipids biosynthesis (4.73 g L−1) in the medium with glycerol showed R. glutinis var. rubescens LOCKR13. In all investigated strains, oleic acid had the highest proportion of the total fatty acids. Nutritionally beneficial features were demonstrated by R. mucilaginosa, strain ATCC 66034 containing docosapentaenoic acid and reaching a high lipids biosynthesis efficiency (3.24 g L−1). Compared to glucose after incubation of R. aurantiaca, R. glutinis, R. gracilis and R. mucilaginosa strains with glycerol, the higher PUFA content per unit volume of medium was observed.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The microbial lipids, known as single cell oils (SCO), may provide a source of nutritionally valuable fatty acids and crude oils may also be the raw material in biodiesel production [20, 39, 44, 49]. These fats are effectively synthesized by many oleaginous microorganisms, i.e., those which cells contain over 25 % lipids [15]. Compared to oilseed crops, the production of SCO is fast, does not take up cultivation areas and does not depend on geographic location, weather conditions, seasons of the year and irrigation. The yeasts are desirable that have low nutritional requirements and show a rapid growth rate. Oleaginous yeasts belong to Cryptococcus, Lipomyces, Yarrowia, Trichosporon as well as Rhodotorula and Rhodosporidium [5, 34, 36].

About 80 % of intracellular fat of the yeasts is present in a form of triacylglycerols (TAG), and the rest are monoacylglycerols, diacylglycerols, sterols, phospholipids, glycolipids and free fatty acids [15, 35]. Lipids accumulation in these eukaryotes occurs in lipid bodies [18], and their production begins at the end of exponential growth phase and runs most intensively in the stationary phase [16]. When the substrates are hydrophobic compounds (vegetable oils, waste fats, n-alkanes) and intracellular fat accumulation is observed simultaneously with cells growth, the lipid synthesis is called ex novo. In turn, during lipid synthesis de novo, the substrates may include glucose, lactose and maltose [35]. Assurance of optimum C:N ratio is crucial in de novo synthesis, since quick nitrogen depletion guarantees lipid biosynthesis [1]. Under nitrogen limitation conditions, the cellular AMP level is lowered; consequently, mitochondrial citrate accumulates and permeates to the cytosol, where it serves as substrate to form acetyl-CoA [52]. Acetyl-CoA with malonyl-CoA is the precursors in lipids synthesis. However, under nitrogen limitation conditions, slow rate of cells proliferation results in low yield of biomass. The profile of fatty acids produced by the yeasts depends on many factors, but primarily upon the species, medium composition and culture conditions.

The barrier in the industrial SCO production is relatively low yield per unit volume of the medium. Strategies to enhance lipids productivity mainly include selection of producer strain, optimization temperature and oxygenation conditions, as well as genetic engineering, metabolic engineering toward intracellular lipids enrichment with polyunsaturated fatty acids (PUFA). The culture with high cell density but with lower lipids content in the biomass (% CDW) can improve volumetric efficiency better than the low biomass yield containing large amounts of lipids. The cost-effectiveness of the process is significantly determined by the cost of substrate. It is estimated that one ton of microbial fat production requires about 5 t of carbon substrate [40]. Therefore, the aim is to apply cheap sources of assimilable carbon, often the side products of various industry branches, e.g., molasses, hydrolyzed starch, whey. The glycerol fraction derived from biodiesel production containing 50 % glycerol can also be used in the production of SCO [50].

Among the oleaginous yeasts, those which additionally generate carotenoid pigments are beneficially distinguished. Rhodotorula and Rhodosporidium genera are able to synthesize β-carotene, torulene and torularhodin in various proportions [27, 42]. Carotenoids are an important class of compounds applied in food, fodder, cosmetics industry as well as in medicine and pharmacy. They play a role of vitamin A precursors and exhibit antioxidant, and probably also anticancer and immune system supporting properties in fungal and bacterial infections [22]. Carotenoids have the features of the pigment, e.g., β-carotene acts as a component of fodders for laying hens and fish in order to achieve better color of egg yolks and meat [41]. The species belonging to the yeast genus Rhodotorula belong to the family Sporidiobolaceae, order Sporidiales, class Urediniomycetes, division Basidiomycota in the kingdom of Fungi [24]. The genus includes about 50 species [6]. They are mostly mesophilic organisms, with optimal growth temperature of 20–40 °C; however, some of them also develop well under cooling conditions. Sporobolomyces is another genus, which species produce β-carotene, γ-carotene, and torulene and torularhodin [7]. The representatives of this genus are mainly observed on the surfaces of leaves and flowers, and they create so-called phyllosphere, where they acquire the nutrients from plant secretions [48]. Species of Sporobolomyces do not ferment sugars [24], and their optimum growth temperature is 25–30 °C.

The main aim to our research was to select a yeast strain producer of lipids based on medium containing pure glycerol. The following goals of the study were pursued: (1) determination of the effect of pure glycerol on the growth of Rhodotorula and Sporobolomyces yeast; (2) the impact assessment of pure glycerol on the lipid biosynthesis of the yeast; and (3) determination of the pure glycerol effect used as a sole carbon source on the fatty acid composition in yeast strains. One of the tested strains has previously been identified as R. rubra, which according to [24] is synonymous to R. mucilaginosa which causes confusion and does not allow a strict interpretation and comparison with the previous literature data. For this reason, we decided also to characterize all yeast strains using ITS restriction analysis.

Although waste glycerol (from biodiesel production) is desirable for the profitability of SCO production, it was decided to use pure glycerol at this stage of research.

Materials and methods

Yeast strains

The yeast strain Rhodotorula mucilaginosa ATCC 66034 was obtained from the American Type Culture Collection (USA), Rhodotorula glutinis var. rubescens LOCKR13, Rhodotorula aurantiaca LOCKR17, Rhodotorula minuta LOCKR19 and Sporobolomyces salmonicolor LOCK53 were obtained from the Technical University of Lodz (Poland) and Rhodotorula glutinis RhIX, Rhodotorula gracilis RhVII and Rhodotorula rubra RhVIII were obtained from the University of Life Sciences in Lublin (Poland). Biological material was stored on YPD slants at a temperature of 6–8 °C.

Yeast identification

DNA isolation

DNA isolation was performed according to the method described by Bzducha-Wróbel [8]. After 24 h yeast culturing in YPD medium (containing 20 g L−1 of peptone, 20 g L−1 of glucose and 10 g L−1 of yeast extract) at pH 5.6, yeast biomass was centrifuged (716×g/4 °C/10 min). Then, it was rinsed twice with sterile deionized water and suspended in lysis buffer (1 mM EDTA; 10 mM Tris–HCl, pH 8.0; 100 mM NaCl; 2 % Triton X-100; 1 % SDS) and then gently vortexed. The precipitate was incubated at a temperature of 37 °C for 1 h. The next stage was an addition of 200 μL of TE buffer (10 mM Tris–HCl, pH 8.0; 1 mM EDTA). Then, 200 μL of phenol: chloroform: isoamyl alcohol mixture at a ratio of 25: 24: 1 (pH 8.0) was added, and the whole was vortexed for 60 s. The upper phase, obtained by samples centrifuging (4472×g/4 °C/10 min), was transferred to new sterile Eppendorf tubes, and 1 mL of 96 % ethanol was added. The precipitate was centrifuged (8765×g/10 min/temp. 4 °C), and the precipitate was washed with ice-cold 70 % ethanol, dried and then suspended in 50 μL of sterile water.

DNA amplification

The process of DNA amplification was carried out according to the procedure provided by Fietto et al. [16]. The following primers were used in the experiment: ITS1 (5′ CGG GAT CCG TAG GTG AAC CTG CGG 3′) and ITS4 (5′ CGG GAT CCT CCG CTT ATT GAT ATG C 3′) at the concentrations of 20 pmol dm−3. 1.5 mM dm−3 of MgCl2, 0.25 mmol dm−3 of dNTP, 0.5 U of Taq polymerase (Fermentas, Lithuania) were added to template DNA of a concentration of 300 ng μL−1 (5 μL). An amplification reaction was performed in a Mastercycler gradient thermocycler (Eppendorf company) using a program with the following parameters: temp. 94 °C–5 min, then 34 cycles: 94 °C–45 s, 60 °C–1 min, 72 °C–2 min and 72 °C–5 min. PCR products were separated in 2 % (w/v) agarose gel (Sigma) in 1× TAE buffer. Molecular weight marker Gene Ruler 100-bp DNA Ladder Plus by Fermentas was applied in order to determine the size of the bands obtained.

Restriction cutting

Two restriction enzymes: HinfI and HaeIII (Fermentas, Lithuania), were used for the digestion of amplified DNA fragments. The reaction mixture contained 10 μL of PCR product, 1 μL of yellow or green buffer, depending on the enzyme employed, and 1 U of restriction enzyme (HinfI or HaeIII). The digestion was performed for 1 h at temperature of 37 °C. The digestion products were separated by electrophoresis in 2 % agarose gel (Sigma) and analyzed under UV light.

Media and culture conditions

The experimental cultivations of yeast strains were performed in control YPD medium and in a model YPGly medium containing 20 g L−1 of peptone, 50 g L−1 of glycerol and 10 g L−1 of yeast extract (pH 5.6). Also YPGly medium solidified with agar was used in the experiment. All media were sterilized in autoclave at a temperature of 121 °C for 20 min. Yeast inocula were grown in YPD medium of pH 5.6 for 24 h at 28 °C. Thereafter, the cultures were centrifuged (2012×g/4 °C/10 min, Eppendorf 5810R Centrifuge), and obtained biomass was rinsed twice with sterile saline solution and then suspended in saline solution. YPD agar plates were inoculated using a loop (diameter 2 cm), while microcells of honeycomb plates and culture media in the flasks in amount of 10 % v/v. During the culturing in Bioscreen C device, the complete filling of the cells was 300 μL of the medium. The cultures were grown under constant shaking, and every 15 min OD measurements were performed. Suitable maximum growth rates (μ max) and generation time were determined after growth curves preparation. The appearance of colonies was observed in the case of cultures on agar media.

Model cultures were conducted in flasks of a total volume of 500 mL, and biomass was grown for 72 h in a shaker of plane-turning operation mode (200 cycles/min). All cultures were conducted in triplicate at 28 °C.

Analytical methods

Biomass yield

Biomass concentration was determined gravimetrically. A volume of 10 mL of the fermented medium was centrifuged (2012×g/4 °C/10 min); then, the centrifuged biomass was rinsed twice with sterile distilled water and dried at 80 °C to constant weight. Biomass yield was expressed in grams of dry yeast per L of cultivation medium (g d.w. L−1 medium). The biomass concentration at the beginning of cultivation was about 0.4 g d.w. L−1 medium for each strain.

Determination of glycerol content in medium

Determination of glycerol content in the medium was performed using the method proposed by Milchert et al. [28], involving oxidizing activity of meta-periodic acid to hydroxyl groups in glycerol.

Lipid analysis

The presence of fats in the cells was examined using the method of staining with Sudan Black, which was observed under immersion objective (Microscope Opta-Tech MB300) and the photographs were taken (Opta-Tech camera and Program OptaView 7 version 3.1.7). Determination of fats content in yeast biomass was carried out—after their prior centrifugation (2012×g/4 °C/10 min) and drying to constant weight—according to method of Bligh and Dyer modified by Zhang [51], involving lipids extraction using chloroform and methanol. Fats content was provided as % CDW.

Relative composition of fatty acids

Determination of fatty acids methyl esters was conducted using the technique of gas chromatography coupled with flame ionization detector (GC-FID TRACE 1300, Thermo Scientific) after prior acids methylation to methyl esters. Methylation of the lipid phase dissolved in hexane, and obtained after prior fat extraction from yeast biomass with chloroform: methanol mixture, was carried out using potassium methoxide (37 °C/12 h). The hexane layer was collected and subjected to chromatographic separation using Rtx-2330 column (60 m × 0.25 mm × 0.2 μm). The samples were injected at a temperature of 250 °C (split 1:10). The following gradient of chromatograph oven temperatures was applied: 50 °C (3 min), 3 °C/min temperature increase to 250 °C (5 min). The separation was conducted with steady flow of carrier gas through the capillary column (1.6 cm3/min). The applied temperature of FID detector was 260 °C. The identification of methyl esters was carried out on the basis of retention times of standards present in the mixture GLC 461 Nu-Chek Prep., Inc., USA.

Calculation of the specific yield coefficient and volumetric productivities

The weights of dry biomass, lipids and consumed glycerol were used to calculate biomass/glycerol (Y X/S) lipid/glycerol (Y L/S) and lipid/biomass yield (Y L/X) coefficients, expressed as g g−1. The volumetric productivities of biomass (Q x) and lipids (Q L) were calculated by dividing their concentrations with the corresponding culture time. Volumetric lipids efficiency was also calculated and mean lipids were produced by 1 L of medium.

Statistical analysis of the results

All values are means of three separate experiments. The obtained results were subjected to a statistical analysis using the Statistica version 10 program (StatSoft Polska Sp. z o.o., Krakow, Poland). An analysis with the ANOVA method (Tukey’s test) was carried out at the α = 0.05 level of significance.

Results and discussion

The genetic characterization of yeast collection strains

The reason of genetic characterization of all strains was that according to Kurtzman and Fell [24] R. rubra strain name is a synonym with R. mucilaginosa. It does not allow a reliable interpretation and comparison with the literature data.

Application of ITS1 and ITS4 primers in DNA fragments amplification of Rhodotorula and Sporobolomyces yeasts causes an intensification of PCR product of about 630–660 bp [17]. The molecular weights of PCR products for all the yeast strains were about 630 bp (Fig. 1). Similar results were published by Arroyo-López et al. [4] where the obtained amplification products of a mass of about 640 bp for Rhodotorula glutinis strain. Guillamón et al. [21] on Rhodotorula minuta strain demonstrated amplification product size of 660 bp. In turn, Stringini et al. [45] demonstrated that amplification product for R. mucilaginosa strain amounted to 640 bp. Also Esteve-Zarzoso et al. [17] using the same primers for different Rhodotorula strains obtained PCR products with similar weight from 610 to 675 bp. In the case of S. salmonicolor yeast, amplicon weight was 600 bp.

DNA analysis of R. minuta, R. aurantiaca and R. rubra strains digested with HinfI enzyme revealed the presence of two fragments of the size of about 400 and 220 bp (Fig. 2) which is similar to Esteve-Zarzoso et al. [17] results. In turn, three DNA fragments of sizes 280, 250 and 130 bp were obtained for S. salmonicolor strain, which was similar to the results obtained for Sporidiobolus salmonicolor (300, 250 and 130 bp) [17] that represent the teleomorphic of Sporobolomyces [24]. Digestion of DNA of R. glutinis, R. mucilaginosa, R. gracilis, R. glutinis var. rubescens strains allowed to obtain three bands with weights of 340, 225 and 75 bp, which was consistent with the data published by Arroyo-López et al. [4]. Different results were obtained by Guillamón et al. [21] for R. glutinis strain, where DNA analysis revealed the presence of only two bands with weights of 170 and 150 bp.

The occurrence of two fragments of sizes 430 and 210 bp was observed as a result of digestion of DNA fragments of R. gracilis, R. glutinis, R. mucilaginosa and R. glutinis var. rubescens yeast strains with HaeIII restriction enzyme (Fig. 3). Two DNA fragments of a size of about 400 and 210 bp were also observed in the case of R. minuta, R. rubra and R. aurantiaca strains. The results obtained confirmed earlier presented results [4, 21]. Digestion of DNA for S. salmonicolor strain demonstrated the presence of three faint bands of sizes of about 410, 135 and 100 bp. The results are similar to early presented [17] where three DNA fragments of sizes of 410, 140 and 95 bp were obtained. The formation of such restriction patterns for individual Rhodotorula strains is probably a result of large similarity in the genome of the examined yeasts.

PCR analysis with ITS1 and ITS4 primers can be used to distinguish the yeast of Rhodotorula and Sporobolomyces genus, and no difference to the identifications provided by the culture collections was found. The application of selected enzymes resulted in restriction patterns obtaining 400 and 200 bp (HinfI), 400 and 210 bp (HaeIII) for R. rubra strain, 340, 225 and 75 bp (HinfI), and 430 and 210 bp (HaeIII) for R. mucilaginosa strain. Clearly we indicate that the R. rubra strain used in the studies differs from R. mucilaginosa ATCC 66034 and belongs to different species.

Fatty acids profile after culturing in medium with glucose

Lipids content in yeast biomass obtained after culturing in medium with glucose was determined in the range from 5.36 to 9.50 % CDW, wherein the largest content was observed in the biomass of R. gracilis, R. mucilaginosa and S. salmonicolor.

All examined yeast strains demonstrated a large share of C18 acids, among which oleic acid (C18:1) was predominant (Table 1). The highest share of this acid (54.6 %) was found in R. glutinis fats, while the lowest in R. glutinis var. rubescens—more than 34 %. In the case of the latter strain, the content of linoleic acid (C18:2, cis-9, cis-12) was over 23 %, which accounted for the largest share in fatty acid composition of all examined strains. A similar share of C18:1, C18:2 and C18:3 in R. glutinis fat was reported by Vieira et al. [46]. The highest share of γ-linoleic acid (C18:3 n-6), on the level of 3.1 %, was found for R. aurantiaca strain. Moreover, this strain showed the highest content of eicosanoic acid (C20:0), reaching nearly 30 %. The absence of C18:3 in the lipid fraction of R. minuta biomass confirms the results obtained by Vieira et al. [46]. Intracellular fat of R. aurantiaca was characterized by a lower share of linoleic acid and higher share of γ-linoleic acid compared to the composition of intracellular lipids of R. aurantiaca CBS 317 strain examined by Perrier et al. [37].

The presence of unsaturated C20:4 was only noted in the case of R. minuta and R mucilaginosa (0.7 %) which is consistent with a report of Perrier et al. [37]. It should be concluded in general, that the content of very long-chain fatty acids (C:19–25) was low, except the share of eicosanoic acid (C20), from about 10 to nearly 30 %, depending on the strain. The presence of docosapentaenoic acid (DPA, C22:5), which is a precursor to docosahexaenoic acid (DHA, C22:6) [9] was observed for R. mucilaginosa strain. Similar content of particular fatty acids in the cells of Rhodotorula mucilaginosa strain isolated from food was observed by Aloklah et al. [3]. However, in that case, the lipids contained more C18:1 (over 55 %) and C18:3 (over 4.6 %). Similarly, a higher share of C18:3 in lipids of R. mucilaginosa was noted by Ahmad et al. [2]. In the lipids of the same species, Kataray and Domnez [23] determined only 6.5 % of linoleic acid among all PUFA.

Observed fatty acid composition of S. salmonicolor corresponds to S. ruberrium [13] in the range of the share of C16:0, C22:0 and C24:0. However, the share of C18:1 and C18:2 in fat of the examined S. salmonicolor strain was definitely much higher.

The highest total share of PUFA (25.5 %) was noted for R. glutinis var. rubescens. The highest share of monounsaturated fatty acids MUFA was demonstrated for R. glutinis strain (56.1 %), with concurrently the lowest content of saturated acids (only 32 %).

Yeasts growth in medium with glycerol

All examined yeast strains demonstrated the ability to grow on media with glycerol. The morphology of yeast colonies on YPGly agar medium did not differ from those on YPD medium. The smallest and least-stained colonies were characterized S. salmonicolor (Fig. 4).

The cultures carried out in liquid YPGly medium in Bioscreen C device and in the flasks were characterized by a classic course of growth curves for periodical cultures, during which particular phases were highlighted: adaptation, logarithmic growth acceleration, delayed growth and stationary. The fastest growth (Table 2) was demonstrated for the cultures of R. rubra and R. mucilaginosa yeasts (0.163 and 0.144 h−1). They also reached the highest biomass yield, which may result from their ability to rapid glycerol utilization. After 72 h of culturing, the consumption of carbon source was 69.4 % in the case of R. rubra and 87.8 % in the case of R. mucilaginosa. The maximum specific growth rate (µ max) in case of others strains was approximately 0.1 h−1 except for S. salmonicolor (0.043 h−1). In the case of S. salmonicolor, the generation time was the longest and was over 16 h, while biomass yield after 72 h culture in the flasks was only about 1.3 g d.w. L−1, which was correlated with low glycerol consumption reaching about 10 %.

Lipids biosynthesis by yeasts in medium with glycerol

The observations of preparations fixed with Sudan Black B were conducted during examined yeast culturing. The staining visible in blue highlighted the presence of lipid droplets in the cells. Sample photographs are presented in Fig. 5.

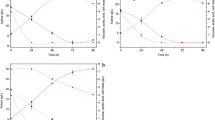

The highest content of lipids after culturing in medium with glycerol was noted in biomass of R. glutinis var. rubescens, R. gracilis, R. minuta and R. aurantiaca (Fig. 6). This proves lipogenic ability of these strains. After 2 days of culturing, the cells of R. glutinis var. rubescens accumulated the highest amount of fats (30 % CDW). The highest increase in lipids content in the biomass between the second and third day of cultivation was observed for R. mucilaginosa (from 5.5 to over 10 % CDW) and R minuta (from 19.5 to over 30 % CDW).

The value of volumetric efficiency of intracellular lipids biosynthesis is affected by the ability of lipids synthesis and growth of biomass yield, which in turn is a function of ability of carbon source utilization. Therefore, although the lipid glycerol coefficient (Y L/S) was the highest for R. minuta (Table 2), the lipids efficiency calculated for 1 L of the medium during the culturing was low (1.82 g L−1). The reason for that was the low biomass yield. This is also suggested by the lowest maximum growth rate (μ max) compared to other strains.

The best volumetric lipids efficiency was noted for R. glutinis var. rubescens strain (4.73 g L−1). The lower Y L/S, compared to the values reached by other strains, suggests the need to extend the culturing time which should improve glycerol utilization by the cells and increase the yield of lipids synthesis. R. mucilaginosa strain reached the highest biomass yield and utilized 89 % of the glycerol pool. Volumetric productivity of lipids by this strain was satisfactory, as indicated by the parameter Q L = 0.044 g L−1 h−1, although the lipids content in biomass was slightly over 10 %.

The R. gracilis and R. aurantiaca strains are efficient oleaginous yeast since they produced about 3 g of lipids in 1 L up to 72 h. Similar intracellular lipids content (about 22 %) in R. aurantiaca biomass after 96-h culture in medium with technical glycerol was observed by Petrik et al. [38]. The biomass (dry weight) of examined in this study R. glutinis contained 9.1 % triacylglycerols and 1.36 g. of lipids was produced by 1 L of medium Similarly, a low lipids efficiency (<2 g L−1) for R. glutinis strain in the medium with pure glycerol was observed by Yen et al. [50]. According to the reports of Petrik et al. [38] who examined R. rubra and determined nearly 15 % lipids during the 96-h culture in the medium with glycerol, R. rubra was characterized by a low (7.5 %) lipids content and therefore does not belong to efficient SCO producers.

All Rhodotorula strains accumulated more lipids during the culturing with glycerol compared to glucose. The essential feature of oleaginous organisms is the ability to accumulate citric acid, which is a substrate for ATP-dependent lyase (a key enzyme in lipids synthesis) providing acetyl-CoA for fatty acids synthesis [39, 52]. The use of glycerol as the sole carbon source increases the level of citric acid [31] and consequently increases lipids biosynthesis.

In turn, glycerol appeared to be an unfavorable carbon source for the growth and synthesis of lipids by S. salmonicolor strain. This strain biomass yield and fat content were the lowest among the examined strains, and therefore, fatty acid profile of this strain was not determined. The results differ significantly from the published by Petrik et al. [38], where biomass of S. salmonicolor strain after 96 h efficiently utilizing technical glycerol contained almost 15 % triacylglycerols. The differences can be explained by variable ability of S. salmonicolor strains to glycerol assimilation [24].

Pure glycerol was used as a carbon source in order to assess growth and lipid production in the Rhodotorula and Sporobolomyces sp. without possible interference of contaminants. However, using a pure form of glycerol as a feedstock for SCO production would be cost prohibitive for larger-scale production. During the biodiesel production process, glycerol is the primary by-product. It can be undoubtedly be used as a low-cost carbon source for lipid fermentation. The composition of the waste glycerol depends on many factors including the type of catalysis and the conditions of trans-esterification reaction. Waste glycerol contains in its composition methanol, mono- and diglyceride, free fatty acids and soap [10]. These substrates may affect the growth and lipids synthesis by yeast. However, no negative effect on growth was observed for Rhodotorula strain when metabolizing biodiesel-derived glycerol, even when using a higher concentration of waste glycerol [29]. Regarding the oleaginous yeast Yarrowia lipolytica, biomass density was practically unaffected when cultivated on nitrogen-limited media with crude glycerol utilized as substrate [32, 33, 36]. The ability of R. toruloides to produce more biomass on biodiesel-derived glycerol over pure glycerol was also observed. Oleic acid present in the medium, as a part of waste glycerol, probably acted as a surfactant and aid nutritional uptake of cells and improved the levels of biomass produced. Likewise, crude glycerol as a co-substrate together with stearin had, as a consequence, the production of SCO with a higher degree of unsaturation [32, 36].

Fatty acids profile of yeasts after culturing in medium with glycerol

After culturing in medium with glycerol all examined yeast demonstrated a large share of C18 acids, among which oleic acid (C18:1) was predominant. Evidences in the last years have showed the effects of oleic acid in human health and disease. Food rich in oleic acid (olive oil) is supposed to present modulatory effects in a wide physiological function. Some authors suggest a beneficial effect on cancer, autoimmune and inflammatory diseases [43].

Depending on the strain, the share of arachidic acid (C20:0) after culturing in YPGly medium was lower compared to the biomass lipids obtained from YPD and ranged from 2.8 to 9.7 % of total fatty acids (data not shown). At the same time, the content of palmitic acid and overall share of C16 acids increased for almost all strains, except R. glutinis and R. rubra. The share of behenic acid (C22:0) significantly increased in case of both R. glutinis strains. Particularly linoleic acid (C18:2, cis-9, cis-12) content increased significantly after culturing of R. aurantiaca, R. glutinis, R. gracilis and R. mucilaginosa yeasts in medium with glycerol and was 19.1, 15.3, 19 and 17.3 %, respectively. Conjugated linoleic acid (CLA) is a group of positional and geometrical isomers of linoleic acid (C18:2, cis-9, cis-12), an essential fatty acid for human and animals. It has become a subject of interest as a supplement for human nutrition because of its biological activities. The capacity of CLA to reduce the body fat levels as well as its benefic actions on glycemic profile, atherosclerosis and cancer has already been proved in experimental models [25, 30]. It has been considered an anti-obesity agent and can be useful in the weight reduction process [11]. Linoleic acid has also become increasingly popular in the cosmetics industry because of its beneficial anti-inflammatory, acne reductive and moisture retentive properties on the skin [12, 14, 26]. The principal natural sources of CLA in the human diet are meat and dairy products from ruminant animals (such as milk, butter, yogurt and cheese). From this point of view, the SCO from Rhodotorula yeast can be a potential source of CLA to vegan diet. Rhodotorula lipid can be also considered as an interesting material for biodiesel production. The important technological advantage for the fuel production is good fuel properties at low temperatures, which can be provided by polyunsaturated fatty acid methyl esters [47]. The use of glycerol (relative to glucose) has significantly improved the CLA content in R. aurantiaca, R. glutinis, R. gracilis and R. mucilaginosa yeasts. These strains should be further evaluated in future studies investigating different feeding strategies to enhance lipid and linoleic acid production.

After incubation with glycerol, the presence of docosapentaenoic acid (DPA, C22:5) was observed only for R. mucilaginosa strain. Its content remained unchanged compared to glucose. DPA is a precursor to nutritionally beneficial docosahexaenoic acid (DHA, C22:6).

Except the discussed cases, composition of fatty acids in lipids derived from biomass of examined strains after culturing with glycerol did not change significantly compared to that after culturing in medium with glucose.

Compared to glucose as a carbon source, significantly higher PUFA content per 1 L medium containing glycerol was determined after R. aurantiaca, R. glutinis var. rubescens and R. gracilis culturing (Table 3). MUFA content increased for most strains (except R. glutinis), as well as SFA (except R. mucilaginosa and R. glutinis). However, it is worth noting that the contribution of individual fatty acids has not changed irrespective of the carbon source (data not shown). The reason of an increase in particular fatty acids groups content per unit volume of the medium is improved efficiency of fats biosynthesis in the medium with glycerol compared to glucose.

Conclusions

The results of PCR analysis confirmed the affiliation of the examined yeast strains to Rhodotorula and Sporobolomyces genus. R. rubra strain RhVIII differ from R. mucilaginosa ATCC 66034, indicating that R. rubra and R. mucilaginosa are not synonyms.

Analysis of fatty acid composition demonstrated that the examined strains were characterized by the highest share of C18:1 (oleic acid), irrespective of using glucose or glycerol as a carbon source.

Glycerol at a concentration of 5 % is assimilable carbon source for the yeasts of Rhodotorula genus. The fastest growth was demonstrated for the cultures of R. rubra and R. mucilaginosa strains. Glycerol appeared to be an unprofitable carbon source for S. salmonicolor strain.

The application of glycerol in the medium resulted in an increase in intracellular lipids content in the biomass. The best abilities for intracellular lipids biosynthesis in medium with glycerol were noted for R. glutinis var. rubescens LOCKR13 strain, since the volumetric efficiency of biosynthesis (4.73 g L−1) was significantly the largest among the other strains. R. mucilaginosa ATCC 66034 strain which lipids contained DPA exhibited nutritionally valuable qualities. Moreover, with low content of intracellular lipids, the strain reached a high volumetric yield (3.14 g L−1). Compared to glucose, glycerol increased the PUFA content per unit volume of medium after incubation of R. aurantiaca, R. glutinis, R. gracilis and R. mucilaginosa strains.

The study confirmed the possibility of application of pure glycerol to the SCO synthesis by yeast from the Rhodotorula genera. R. glutinis var. rubescens LOCKR13 and R. mucilaginosa ATCC 66034 exhibited high lipid production potential and should be further evaluated in future studies investigating lipid production. Using of waste glycerol for SCO production by these strains is currently under investigation.

References

Ageitos JM, Vallejo JP, Veiga-Crespo P, Villa TG (2011) Oily yeast as oleaginous cell factories. Appl Microbiol Biotechnol 90:1219–1227

Ahmad FB, Zhang Z, Doherty WOS, O’Hara IM (2015) A multi-criteria analysis approach for ranking and selection of microorganisms for the production of oils for biodiesel production. Biores Technol 190:264–273

Aloklah B, Alhajali A, Yaziji S (2014) Identification of some yeasts by fatty acid profiles. Pol J Microbiol 63(4):467–472

Arroyo-López FN, Durán-Quintana MC, Ruiz-Barba JL, Querol A, Garrido- Fernández A (2006) Use of molecular methods for the identification of yeast associated with table olives. Food Microbiol 23:791–796

Beopoulos A, Nicaud JM (2012) Yeast: a new oil producer? OCL 19:22–28

Biswas S, Yokoyama K, Nishimura K, Miyaji M (2001) Molecular phylogenetics of the genus Rhodotorula and related basidiomycetous yeast inferred from the mitochondrial cytochrome b gene. Int J Sys Evol Microbiol 51:1191–1199

Buzzini P, Vaughan-Martini A (2006) Yeast biodiversity and biotechnology. In: Rosa C A, Peter G (eds) Biodiversity and ecophysiology of yeasts. Springer, Berlin, p 537–539, 545

Bzducha-Wróbel A, Kieliszek M, Błażejak S (2013) Chemical composition of the cell wall of probiotic and brewer’s yeast in response to cultivation medium with glycerol as a carbon source. Eur Food Res Technol 237:489–499

Certik M, Shimizu S (1999) Biosynthesis and regulation of microbial polyunsaturated fatty acid production. J Biosci Bioeng 87(1):1–14

Chatzifragkou A, Papanikolaou S (2012) Effect of impurities in biodiesel-derived waste glycerol on the performance and feasibility of biotechnological processes. Appl Microbiol Biotechnol 95:13–27

Churruca I, Fernandez-Quintela A, Portillo MP (2009) Conjugated linoleic acid isomers: differences in metabolism and biological effects. BioFactors 35:105–111

Darmstadt GL, Mao-Qiang M, Chi E, Saha SK, Ziboh VA, Black RE, Santosham M, Elias PM (2002) Impact of tropical oils on the skin barrier: possible implications for neonatal health in developing countries. Acta Paediatr 91(5):546–554

Davoli P, Mierau V, Weber RWS (2004) Carotenoids and fatty acids in red yeast Sporobolomyces rosues and Rhodotorula glutinis. Appl Biochem Microb 40:392–397 translated from Prikladnaya Biokhimiya i Mikrobiologiya 40(4):460–465

Diezel WE, Schulz E, Skanks M, Heise H (1993) Plant oils: topical application and anti-inflammatory effects (croton oil test). Dermatol Monatsschrift 179:173

Donot F, Fontana A, Baccou JC, Strub C, Schorr-Galindo S (2014) Single cell oils (SCOs) from oleaginous yeasts and moulds: production and genetic. Biomass Bioen 68:135–150

Enshaeieh M, Abdoli A, Nahvi I (2013) Medium optimization for biotechnological production of single cell oil using Yarrowia lipolytica M7 and Candida sp. J Cell Mol Res 5:17–23

Esteve-Zarzoso B, Belloch C, Uruburu F, Querol A (1999) Identification of yeast by RFLP analysis of the 5.8S rRNA gene and the two ribosomal internal transcribed spacers. Int J Sys Bacteriol 49:329–337

Fickers P, Benetti PH, Wachè Y, Marty A, Mauersberger S, Smit MS, Nicaud JM (2005) Hydrophobic substrate utilization by the yeast Yarrowia lipolytica and its potential applications. FEMS Yeast Res 5:527–543

Fietto JL, Araujo RS, Valadao FN, Fietto LG, Brandao RL, Neves MJ, Gomes FC, Nicoli JR, Castro IM (2004) Molecular and physiological comparisons between Saccharomyces cerevisiae and Saccharomyces boulardii. Can J Microbiol 50:615–621

Galafassi S, Cucchetti D, Pizza F, Franzosi G, Bianchi D, Compagno C (2012) Lipid production for second generation biodiesel by the oleaginous yeast Rhodotorula graminis. Biores Technol 111:398–403

Guillamón JM, Sabate´ J, Barrio E, Cano J, Querol A (1998) Rapid identification of wine yeasts species based on RFLP analysis of the ribosomal internal transcribed spacer (ITS) region. Arch Microbiol 169:387–392

Hernández-Almanza A, Montanez JC, Aguilar-González MA, Martínez-Ávila C, Rodríguez-Herrera R, Aguilar CN (2014) Rhodotorula glutinis as source of pigments and metabolites for food industry. Food Biosci 5:64–72

Karatay SE, Dönmez G (2010) Improving the lipid accumulation properties of the yeast cells for biodiesel production using molasses. Biores Technol 101:7988–7990

Kurtzman CP, Fell JW (eds) (1998) The yeast, a taxonomic study. Amsterdam, Elsevier, p 698, 822, 828

Lehnen TE, da Silva MR, Comacho A, Marcadenti A, Lehnen AM (2015) A review on effects of conjugated linoleic fatty acid (CLA) upon body composition and energetic metabolism. J Int Soc Sports Nutr 12:36–47

Letawe C, Boone M, Pierard GE (1998) Digital image analysis of the effect of topically applied linoleic acid on acne microcomedones. Clin Exp Dermat 23(2):56–58

Malisorn C, Suntornsuk W (2009) Improved β-carotene production of Rhodotorula glutinis in fermented radish brine by continuous cultivation. Biochem Eng J 43:27–32

Milchert E, Goc W, Lewandowski G, Myszkowski J (1995) Dehydrochlorination of glicerol dichlorohydrin to epichlorohydrin. Chem Pap 49(3):133–136

Munch G, Sestric R, Sparling R, Levin DB, Cicek N (2015) Lipid production in the under-characterized oleaginous yeasts, Rhodosporidium babjevae and Rhodosporidium diobovatum, from biodiesel-derived waste glycerol. Bioresour Technol 185:49–55

Nagpal R, Yadav H, Puniya AK, Singh K, Jain S, Marotta F (2002) Conjugated linoleic acid: sources, synthesis and potential health benefits—an overview. Curr Top Nutraceutical Res 5(2/3):55–66

Pan L-X, Yang D-F, Shao L, Li W, Chen G-G, Liang Z-Q (2009) Isolation of the oleaginous yeast from the soil and studies of their lipid-producing capacities. Food Technol Biotechnol 47:215–220

Papanikolaou S, Aggelis G (2002) Lipid production by Yarrowia lipolytica growing on industrial glycerol in a single-stage continuous culture. Bioresour Technol 82:43–49

Papanikolaou S, Aggelis G (2009) Biotechnological valorization of biodiesel derived glycerol waste through production of single cell oil and citric acid by Yarrowia lipolytica. Lipid Technol 21:83–87

Papanikolaou S, Aggelis G (2010) Yarrowia lipolytica: a model organism used for the production of tailor-made lipids. Eur J Lipid Sci Technol 112:639–654

Papanikolaou S, Aggelis G (2011) Lipids of oleaginous yeasts. Part I; Biochemistry of single cell oil production. Eur J Lipid Sci Technol 113:1031–1051

Papanikolaou S, Chevalot I, Komaitis M, Marc I, Aggelis G (2002) Single cell oil production by Yarrowia lipolytica growing on an industrial derivative of animal fat in batch cultures. Appl Microbiol Biotechnol 58:308–312

Perrier V, Dubreucq E, Galzy P (1995) Fatty acid and carotenoid composition of Rhodotorula strains. Arch Microbiol 164:173–179

Petrik S, Marova I, Haronikova A, Kostovova I, Breierova E (2013) Production of biomass, carotenoid and other lipid metabolites by several red yeast strains cultivated on waste glycerol from biofuel production—a comparative screening study. Ann Microbiol 63:1537–1551

Ratledge C (2004) Fatty acid biosynthesis in microorganisms being used for single cell oil production. Biochimie 86:807–815

Ratledge C, Cohen Z (2008) Microbial and algal oils: do they have a future for biodiesel or as commodity oils? Lipid Technol 20:155–160

Roadjanakamolson M, Suntornsuk W (2010) Production of β-carotene-enriched rice bran using solid-state fermentation of Rhodotorula glutinis. J Microbiol Biotechnol 20(3):525–531

Saenge C, Cheirsilp B, Suksaroge TT, Bourtoom T (2011) Potential use of oleaginous red yeast Rhodotorula glutinis for the bioconversion of crude glycerol from biodiesel plant to lipids and carotenoids. Process Biochem 46:210–218

Sales-Campos H, Souza PR, Peghini BC, da Silva JS, Cardoso CR (2013) An overview of the modulatory effects of oleic acid in health and disease. Mini Rev Med Chem 13(2):201–210

Sitepu IR, Garay LA, Sestric R, Levin D, Block DE, German JB, Boundy-Mills KL (2014) Oleaginous yeast for biodiesel: current and future trends in biology and production. Biotechnol Adv 32:1336–1360

Stringini M, Comitini F, Taccari M, Ciani M (2008) Yeast diversity in crop-growing environments in Cameroon. Int J Food Microbiol 127:184–189

Vieira JPF, Ienczak JL, Rossell CEV, Pradella JGC, Franco TT (2014) Microbial lipid production: screening with yeast grown on Brazilian molasses. Biotechnol Lett 36:2433–2442

Vincente G, Bautista LF, Gutierrez FJ, Rodriguez R, Martinez V, Rosa A et al (2010) Direct transformation of fungal biomass from submerged cultures into biodiesel. Energy Fuels 24:3173–3178

Wang QM, Bai FY (2004) Four new yeast species of the genus Sporobolomyces from plant leaves. FEMS Yeast Res 4:579–586

Xue F, Miao J, Zhang X, Luo H, Tan T (2008) Studies on lipid production by Rhodotorula glutinis fermentation using monosodium glutamate wastewater as culture medium. Bioresour Technol 99:5923–5927

Yen H-W, Yang Y-Ch, Yu Y-H (2012) Using crude glycerol and thin stillage for the production of microbial lipids through the cultivation of Rhodotorula glutinis. J Biosci Bioeng 114(4):453–456

Zhang G, French WT, Hernandez R, Alley E (2011) Effect of furfural and acetic acid on grown and lipid production from glucose and xylose by Rhodotorula glutinis. Biomass Bioeng 35:734–740

Zhu Z, Zhang S, Liu H, Shen H, Lin X, Yang F, Zhou YJ, Jin G, Ye M, Zou H, Zhao ZK (2012) A multi-omic map of the lipid-producing yeast Rhosporidium toruloides. Nature Comm 3:1112

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declare that they have no conflict of interest.

Compliance with ethics requirements

This article does not contain any studies with human or animal subjects.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Gientka, I., Gadaszewska, M., Błażejak, S. et al. Evaluation of lipid biosynthesis ability by Rhodotorula and Sporobolomyces strains in medium with glycerol. Eur Food Res Technol 243, 275–286 (2017). https://doi.org/10.1007/s00217-016-2742-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-016-2742-9