Abstract

The structure of cell wall of yeasts (genus Saccharomyces) is one of the factors that determine their health-promoting properties connected to the presence of β-glucans and mannoprotein. The aim of the study was to determine the influence of glycerol as a carbon source on structural polymers of cell wall (β-glucan and mannoprotein) of probiotic yeasts Saccharomyces cerevisiae var. boulardii and brewer’s yeasts S. cerevisiae R9. Significant increase of the percentage of polysaccharide content in the cell wall dry weight of S. cerevisiae R9 brewer’s yeasts was noted (in the range of 10–20 %) after cultivation in medium containing glycerol at a concentration of 2–5 % and pH 4.0. The highest content of carbohydrates in probiotic yeasts’ cell wall (58 %) was observed after cultivation in medium containing 3 % of glycerol and pH 5.0. The cell wall of probiotic yeasts was characterized by higher content of mannoprotein comparing with cell wall preparation of brewer’s yeasts S. cerevisiae R9 composed mainly of β-glucans. After cultivation in mediums with 2 and 3 % of glycerol, the cell of brewer’s yeasts contained the highest amount of β(1,3/1,6)-glucan in dry weight of the cell wall (about 36 %). Glycerol at a concentration of 3 and 5 % also intensified mannoprotein biosynthesis in cell wall of S. cerevisiae R9, approximating their content to those noted in the cells of probiotic yeasts (about 29 % (w/w) of dry weight of the cell wall) after cultivation in a medium of pH 5.0 containing 3 % of glycerol.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Strains of yeast species Saccharomyces cerevisiae var. boulardii are included in the group of probiotic fungi. This strain exhibits a significant health-promoting activity involving inter alia pathogen binding and prevention of their adhesion to the intestinal epithelium, inhibition of toxin activity of pathogenic bacteria, or binding of these substances to cell wall components, prevention of diarrhea after antibiotherapy, as well as immunostimulation and anti-inflammatory activity [28, 53].

Saccharomyces cerevisiae var. boulardii yeasts were initially treated as a separate species of Saccharomyces genus (S. boulardii). However, genetic examinations based on an analysis of ITS1-5.8S sequence of rDNA, ITS2 region, and D1/D2 domain of 26S rRNA gene did not confirm the differences between S. boulardii yeasts and S. cerevisiae strains, and therefore, the first ones were classified as S. cerevisiae subsp. [52, 53]. This allowed for the formulation of the hypothesis that other strains of S. cerevisiae sp. may also demonstrate biotherapeutic effect. Results of the latest study by Jawhara et al. [16] confirm this line of thought. The authors screened a range of S. cerevisiae sp. toward an anti-inflammatory activity, and prevention of alimentary tract colonization in mice by Candida albicans pathogenic yeasts demonstrated similar therapeutic effect of S. cerevisiae Sc1-1 to those of probiotic strain S. cerevisiae var. boulardii. The authors of this study [16] connect probiotic activity of both strains to the presence of β-glucans in the cell wall.

The cell wall structure of Saccharomyces genus is one of the factors conditioning their health-promoting properties [7]. Yeast cell wall is composed of a complex of polysaccharides connected in a covalent manner, which include: α-mannan soluble in water and alkali, present in connection with proteins (mannoprotein), alkali-soluble β-glucan, and alkali-insoluble β-glucan bonded with chitin [19]. According to the latest study of Kopecká [27] on solubilization and reaggregation of yeasts cell wall polysaccharides, there are 3 types of yeast β-glucan: alkali-insoluble branched β(1,3)-glucan, acid-soluble branched β(1,6)-glucan, and alkali-soluble branched β(1,3)-glucan. Mannoprotein constitute about 20–50 % of d.w. of cell wall of S. cerevisiae, while β-glucan represents about 30–60 % of the cell wall dry weight [4, 19, 20, 24, 29, 39, 41]. β(1,3)-glucan, which linear structure is moderately branched via β(1,6)-linked glucose residue, dominates in the wall of S. cerevisiae yeasts. The contribution of this polymer in total glucan content reaches 65–90 % [4, 20, 24]. β(1,3)-glucan molecules were found to consists of about 1.500 glucose monomers. This polymer chains form a single- or triple-helix structure stabilized by inter-chain hydrogen bonds [17, 27]. β(1,6)-glucan is a low-molecular weight polymer, consisting on average 130–150 glucose moieties and strongly branched via β(1,3)-linked monomers. This water- and acid-soluble polymer constitutes about 10–20 % of yeast cell wall glucan [4, 24]. Chitin constitutes only 1–2 % of the walls of yeasts of Saccharomyces genus. Content of particular fraction of polysaccharides and mannoprotein, degree of particles polymerization, and their chemical structure are individual features of each strain depending on growth conditions and time of cultivation [2, 23, 31].

Polysaccharides and mannoprotein obtained from yeast cell walls demonstrate a range of bioactive properties in humans and animals. This is connected to an interaction of these polymers with pattern recognition receptors (PRRs) present on the surface of cells of immunological system (Toll-like receptors, mannose receptors, lectin receptors, complement receptors CR3). They recognize β-glucans and mannoprotein as pathogen-associated molecular patterns (PAMPs) [31, 45]. Significance of polysaccharides of cell wall in yeasts in stimulation of immunological response, antibacterial activity as well as probiotic one with respect to beneficial microflora of alimentary tract is emphasized [6, 9, 13, 26, 37, 40, 47, 51, 55]. Polymers of yeasts cell wall exhibit an ability to adsorb harmful chemical substances, for example, mycotoxins, they lower the level of cholesterol and triglycerides in blood, act in anti-mutagenic, anticancerous, antioxidative way, and protect against UV radiations [17, 29, 41, 45, 54]. According to other authors [55], β-glucan of yeast origin stimulates collagen biosynthesis which is a significant component in wound-healing process.

Due to their hydrocolloidal properties, β-glucans and mannoprotein have technological applications [9]. They can be used as emulsifiers, gelling substances, water- and oil-binding substances, and as prebiotics [9, 30].

Aguilar-Uscanga and François [2] confirmed that β-glucans and mannan content in cell wall of unicellular fungi is strongly connected to growth conditions. Biosynthesis of polysaccharides of yeasts wall is influenced inter alia by the kind of carbon and nitrogen source, pH of an environment, temperature, degree of medium oxygenation, as well as the phase of cell growth, and cultivation parameters [2].

Macromolecular structure of polymers isolated from cell walls of various yeasts may be characterized by various degree of polymerization and branching. Parameters such as molecular weight, degree of branching, primary structure, as well as charge of the polymers determine chemical and physical properties (e.g., solubility) of β-glucans and mannoprotein and are involved in the biological activity [3, 37]. Therefore, practical utilization of structural elements of yeasts cell walls depends on the species and even strain of the fungi as well as method of isolation and preparation.

The aim of this study was to determine the influence of glycerol as a carbon source on structural polymers of cell wall (β-glucan and mannoprotein) of probiotic yeasts S. cerevisiae var. boulardii and brewer’s yeasts S. cerevisiae R9. The yeasts were cultivated in model media (differentiated with regard to pH, type, and concentration of carbon source). Percentage of polysaccharides and mannoprotein in cell wall preparations obtained from these yeasts were determined after fractionation of yeasts cell walls. This investigation is one stage of the research on optimization of yeasts cultivation conditions toward intensification of biosynthesis of cell wall structure polymers.

Materials and methods

Microorganisms

Two yeasts strains were investigated: S. cerevisiae R9 (brewer’s yeasts) derived from the collection of pure cultures of the Department of Biotechnology and Microbiology of Warsaw University of Life Sciences-SGGW, Poland, and probiotic strain S. cerevisiae var. boulardii isolated from Enterol 250® probiotic preparation. Used strains were maintained in a laboratory on YPD agar medium at 6 °C.

Yeast identification

DNA isolation

In order to confirm an affiliation of the strain of S. cerevisiae var. boulardii yeasts isolated from probiotic preparation to S. cerevisiae sp., DNA obtained from reference strains of S. cerevisiae var. boulardii from Polish Academy of Science, S. cerevisiae ATCC 2366 and S. cerevisiae strain R9, was used.

After 24-h cultivation of yeasts in YPD medium (50 mL, pH 5.0), a volume of 1.5 mL of fermentation broth was centrifuged in Eppendorf type test tubes (4,000 rpm/4 °C/10 min), rinsed twice with sterile demineralised water, suspended in lysis buffer (1 mM EDTA; 10 mM Tris–HCl, pH 8.0; 100 mM NaCl; 2 % Triton X-100; 1 % SDS), and vortexed gently followed by incubation at 37 °C for 1 h. The concentration of yeasts inoculum (1 ml) was 6 × 108 cfu/ml.

The next stage was an addition of 200 μl of TE buffer (10 mM Tris–HCl, pH 8.0; 1 mM EDTA). Thereafter, 200 μl of phenol/chloroform/isoamyl alcohol mixture (volume ratio of 25:24:1, pH 8.0) was added and vortexed for 60 s. Supernatant obtained after centrifugation (10,000 rpm/4 °C/10 min) was transferred to sterile Eppendorf test tubes and 1 ml of 96 % ethanol was added and centrifuged (14,000 rpm/4 °C/10 min). The precipitate obtained was rinsed with 70 % ethanol and then was suspended in 50 μl of sterile water.

DNA amplification

The process of DNA amplification was conducted according to the procedure provided by Fietto et al. [10]. ITS1 (5′ CGG GAT CCG TAG GTG AAC CTG CGG 3′) and ITS4 primers (5′ CGG GAT CCT CCG CTT ATT GAT ATG C 3′) were used in the experiment at a concentration of 20 pmol each. MgCl2 (1.5 mM/l), 0.25 mmol/l dNTP, 0.5 U Taq polymerase (Fermentas, Lithuania) were added to the matrix DNA of a concentration of 300 ng/μl (5 μl). Amplification reaction was performed in Mastercycler gradient thermocycler (Eppendorf) according to the following program: Initial denaturation. 94 °C—5 min, and then 34 cycles: 94 °C—45 s, 60 °C—1 min, 72 °C—2 min, and 72 °C—5 min. The PCR products were separated in 1.5 % (w/v) agarose gel (Sigma) in 1 × TAE buffer. Gene Ruler 100-bp DNA Ladder Plus molecular mass marker (Fermentas, Lithuania) was used to determine the size of obtained bands.

Mediums and growth conditions

The experimental cultivations of S. cerevisiae var. boulardii and S. cerevisiae strain R9 yeasts were performed in control YPD medium containing 20 g/L of peptone, 20 g/L of glucose and 10 g/L of yeast extract, and in a model medium where glucose was replaced with glycerol in the amount of 2, 3, and 5 % (w/v). All mediums were prepared in three pH variants, that is, 4.0, 5.0, and 7.0. Yeast inocula were grown in YPD medium of pH 5.0 for 20 h at 28 °C. Thereafter, the cultures were centrifuged (5,000 rpm/21 °C/10 min), obtained yeasts biomass was rinsed twice with sterile distilled water, and then suspended in 80 cm3 of sterile water. Yeast cultivations were started by an addition of 10 ml of yeasts inoculum to the mediums (90 cm3). Biomass was grown for 24 h at 28 °C in a shaker of plane-turning operation mode (200 cycles/min). All cultivations were performed in triplicate.

Cell wall isolation

The preparations of cell walls of S. cerevisiae var. boulardii and S. cerevisiae R9 yeasts from the experimental cultivations were obtained via 24-h cell autolysis at a temperature of 55 °C and pH 5.0 [51]. Autolyzed cells were centrifuged (11,000 rpm/4 °C/15 min) and rinsed five times with sterile deionized water mixing intensively on a vortex in order to wash out cytosol components. It was assumed that centrifuged precipitates contained fragments of yeasts cell walls, which were dried at the next stage (80 °C/24 h). The content of total carbohydrates, β-glucans, and mannoprotein was determined in the obtained cell wall preparations.

Determination of mannoprotein and β-glucan in yeast cell wall preparations

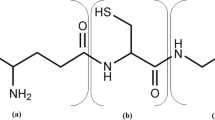

The obtained yeast cell wall preparations were subjected to fractionation on particular structural polysaccharides, that is, β(1,3)-glucan, β(1,6)-glucan, and mannoprotein (Fig. 1, fractions determined no. 1–6). The first stage of this procedure was the separation of alkali-soluble polymers (mannoprotein and β(1,3)/(1,6)-glucan) and alkali-insoluble polysaccharides [β(1,3)- and β(1,6)-glucan connected to chitin]. For this purpose, cell walls (50 mg) were extracted three times in alkaline conditions using 5 ml of 3 % NaOH [34] at 75 °C. Alkali-soluble glucans were separated from the supernatant obtained after alkaline extraction (14,000 rpm/15 min) using neutralization with acetic acid [11, 36]. Mannoprotein precipitation was prepared according to modified procedure of Magnelli et al. [36]. The alkali-soluble/acid-soluble fraction of alkaline extract of yeast cell wall, obtained after acetic acid neutralization, was treated with 2 volumes of ethanol (instead of methanol) and left at 4 °C for 24 h. Precipitate (contained mannan as mannoprotein) was separated by centrifugation (14,000 rpm/15 min).

Scheme of fractionation of yeast cell wall [5]

Fractions of alkali-insoluble polymers were subjected to hydrolysis with Zymolyase 20T enzymatic preparation (MP Biomedicals LLC) [36, 42]. For this purpose, the precipitate after alkaline hydrolysis was neutralized by rinsing twice with TRIS–HCl buffer of pH 7.4 (0.1 M and then 0.01 M buffer). Enzymatic hydrolysis was conducted at 37 °C for 24 h using enzyme solution of a concentration of 5 mg/mL prepared in 0.01 M TRIS–HCl buffer (pH 7.4) containing 5 mM mercaptoethanol. Thereafter, the precipitate was centrifuged (14,000 rpm/15 min) and supernatant was subjected to 24-h dialysis (Sigma-Aldrich: dialysis tubing, height retention seamless cellulose tubing, MWCO 12400, 99.99 % retention) in the presence of deionized water. The aim of this procedure was to separate β(1,6)-glucan from hydrolyzed β(1,3)-glucan.

The confirmation of the β(1,3)-glucan, β(1,6)-glucan, and mannoprotein presence in fractions no. 1–6 (Fig. 1) was based on the literature data [36] where structural identification and quantitative analysis of each S. cerevisiae cell wall fractions were presented. The content of β(1,3)-glucan in alkali-insoluble fraction was expressed from the difference of carbohydrates content in fraction 2 and a sum of β(1,6)-glucan content (fractions 5 and 6). In case of fraction 5, it was assumed in the calculations that it does not contain chitin but only β(1,6)-glucan [42]. It was also assumed that fractions 3 and 4 are not polluted by mannoprotein and β-glucan, respectively.

The obtained results, for their comparison, were presented as recalculated per 100 % of extraction yield in alkaline conditions.

Analytical methods

Biomass yield

Biomass concentration was determined gravimetrically. At the end of cultivation (24 h) in control mediums and model ones, a volume of 10 ml of the fermented medium was centrifuged (11,000 rpm/21 °C/10 min), the centrifuged biomass was rinsed twice with sterile distilled water and dried 24 h at 80 °C. Biomass yield was expressed in grams of dry yeast per liter of cultivation medium (g d.w./L medium). The biomass concentration at the beginning of cultivation was about 0.4 g d.w./L medium for each strain.

Acidic hydrolysis and analysis of reducing sugars

The content of total carbohydrates in yeast cell wall was determined directly in cell wall preparations. For this purpose, acidic hydrolysis of cell wall polymers was conducted using 72 % H2SO4 (100 °C/4 h), following a 3-h incubation of the samples at room temperature [8]. The content of reducing carbohydrates (as glucose) was analyzed using colorimetric method (λ = 540 nm) with 3,5-dinitrosalicylic acid [36]. The content of polysaccharide fractions obtained via alkali extraction, enzymatic hydrolysis, and dialysis (Fig. 1, fractions determined no. 1–6) was also expressed as recalculated on reducing carbohydrates content, after previous acidic hydrolysis.

Statistical analysis

The obtained results were subjected to statistical analysis using STATISTICA version 10 software. One-factor analysis of variance (ANOVA, Tukey’s HSD test) and analysis of correlation were conducted. The tests were performed at a significance level of α = 0.05. The average results were presented in tables and expressed as mean ± standard deviation (SD).

Results and discussion

The waste biomass of brewer’s yeasts is a main source of β-glucans and mannoprotein obtained on an industrial scale [9, 12, 56]. These polymers may also be a final product of biotechnological processes performed with a contribution of other strains of Saccharomyces genus or other yeast species, including genetically improved ones [37]. The possibility to alter the content of structural polymers of yeast cell wall in response to cultivation condition supported the application of probiotic S. cerevisiae var. boulardii strain in this study. Determination of changes in the structure of probiotic yeasts cell wall as a consequence of growth conditions was compared with changes occurring in the structure of brewer’s yeasts cell wall.

Yeast identification

The analysis of DNA amplification products was conducted with ITS1 and ITS4 primers to confirm an affiliation of the strain isolated from probiotic preparation to S. cerevisiae sp. [1, 10, 38]. Application of ITS1 and ITS4 primers in DNA fragments amplification of S. cerevisiae yeasts causes an intensification of PCR product of about 840 bp. DNA derived from reference strains of S. cerevisiae ATCC 2366, S. cerevisiae var. boulardii from Polish Academy of Sciences and S. cerevisiae strain R9 were used in the analysis. The electrophoretic separation of PCR products in a gel is presented in Fig. 2. The obtained PCR products were characterized by a molecular mass of approximately 860 bp. These results confirmed an affiliation of isolated probiotic strain to S. cerevisiae sp. Arlorio et al. [1], using ITS1 and ITS4 primers, obtained amplification products of about 800 bp for S. cerevisiae baker’s strain while Mirhendi et al. [38], using the same primers for S. cerevisiae AJ544-253 strain, noticed PCR products at a level of about 850 bp.

Yeasts biomass yield in experimental cultivations

An increase in biodiesel production generates considerable amounts of by-products during this process, especially glycerol, what stimulate a search for new solutions of its utilization [32]. In this study, the possibility of glycerol application in yeasts cultivation to obtain biomass of an increased content of polysaccharides and mannoprotein in cell wall was tested. The yield of yeasts biomass obtained at this condition is important as a potential source of β-glucans and mannoprotein. Results of this study may be a basis for obtaining bioactive β-glucans and mannoprotein preparations or elaboration of probiotic culture of increased content of cell wall structure polymers. The experimental data point that not only polymers isolated from cell wall of yeasts of Saccharomyces genus demonstrate health-promoting activity, but also the whole cells of these fungi [3, 16, 54].

The analysis of yeast biomass yield of examined strain after cultivation at experimental conditions, differentiated with regard to pH (4.0, 5.0, 7.0), kind of carbon source in the cultivation media (glucose or glycerol), and its concentration (2, 3, or 5 % w/v), was conducted for 24 h of yeasts cultivation.

It was noticed that the factor determining the possibility of growth of investigated S. cerevisiae strains in the media containing glycerol was this compound concentration in a medium and pH of the cultivation. Each of the strains demonstrated individual requirements in this range (Table 1).

The best conditions for the growth of brewer’s yeasts S. cerevisiae R9 were stated at YPD medium, irrespective of the accepted level of pH, and at the media containing 3 % of glycerol and initial pH 4.0. In these cultivations, the biomass yield of the discussed species did not differ significantly and was in the range of 5–6 g d.w./L (Table 1). Brewer’s yeasts were able to utilize glycerol as a carbon and energy source only in mediums of pH 4.0. S. cerevisiae R9 strain did not exhibit any growth in media containing 2, 3, and 5 % glycerol, when initial pH was established at a level of 5.0 and 7.0.

Saccharomyces cerevisiae var. boulardii yeasts were not able to grow in the medium containing 2, 3, and 5 % glycerol when pH was 7.0. In the mediums containing glycerol at concentrations of 2, 3, and 5 % at pH 4.0 and 5.0, the determined yield did not differ significantly from those obtained in the cultivation of composition optimal for yeasts growth (YPD medium).

The yeasts demonstrate a growth in pH range of 4.5–6.5; however, almost all are able to grow in more alkaline or more basic environment [15]. As may be concluded from the experiments conducted in mediums in which glucose was a carbon source, the examined strains of S. cerevisiae R9 and S. cerevisiae var. boulardii yeasts grew irrespective of pH (i.e., 4.0, 5.0, or 7.0). In case of media containing glycerol, the examined yeast strains did not exhibit a growth at pH 7.0. Such a correlation may be explained by the specificity of glycerol transport inside the cells. It was believed initially that glycerol, due to its lipophilic nature, is transported through cytoplasmic membranes of the cells of S. cerevisiae yeasts only via simple diffusion. Composition of membrane lipids may however affect the rate of passive transport. Microorganisms may synthesize the proteins which facilitate the rate of glycerol transport through bilayered lipid membrane [49]. It was noted that in the case of yeasts of Saccharomyces genus, glycerol is subjected to an active transport via symporter coupled H+ ions due to the activity of carbohydrates transporting protein (Stl1p) encoded by the gene STL1 [21]. Its expression is regulated by the kind of carbon source in a medium. Glycerol transport in the cells of S. cerevisiae occurs in an active way only during cultivation in the medium containing carbon source not subjected to fermentation (e.g., glycerol). This transport is inhibited by the presence of glucose [21]. Alkaline environment, applied in the present study, probably prevented an occurrence of glycerol symporter coupled with H+ ions, which is essential for the binding of this carbon source with Stl1p protein.

Summarizing, glycerol may be a carbon source in the cultivation of the yeasts of Saccharomyces genus; however, possibility of its utilization is an individual feature of each strain depending on environmental pH and concentration of carbon source in cultivation medium.

Portion of mannoprotein and β-glucan in yeast cell wall preparations

Preparations of cell wall of S. cerevisiae R9 and S. cerevisiae var. boulardii yeasts were prepared via autolysis of yeasts cells. Autolysis is a common procedure used in obtaining yeast cell wall preparations, from which β-glucans and mannoprotein are isolated [16, 20, 35, 48, 50, 51, 56].

The examined strains of Saccharomyces genus were characterized by varying total carbohydrate content in dry weight of cell wall. Total carbohydrates in the preparations of cell wall of S. cerevisiae var. boulardii yeasts, after cultivation in optimal growth conditions (YPD medium of pH 5.0), constituted about 53 % of the examined organelle (Table 2), while in S. cerevisiae R9 this value was about 41 % (Table 3). The results obtained in the present study find a confirmation in the data published in the literature considering the content of carbohydrate in S. cerevisiae cell wall preparations [41, 48, 50, 51]. However, variations of polysaccharides can be caused by different strains, cultivation time, and parameters.

On the basis of obtained results, it can be concluded that the cultivation of S. cerevisiae R9 and S. cerevisiae var. boulardii yeasts in mediums varying in terms of pH, kind of carbon source in media, and its concentration induced changes in structural polysaccharides content in the examined organelle.

Saccharomyces cerevisiae R9 yeasts synthesized significantly higher amount of cell wall polysaccharides after cultivation in mediums of pH 4.0 containing 2, 3, and 5 % of glycerol (Table 2). When compared to cell wall preparations from YPD medium of pH 5.0, it had a higher content of about 16–22 g per 100 g d.w. of the cell wall. Increased biosynthesis of cell wall components by S. cerevisiae R9 yeasts would have been a response toward stress conditions in the growth environment.

In the case of S. cerevisiae var. boulardii strain, the cell wall contained significantly lower amount of polysaccharides after cultivation in YPD medium of pH 4.0 and in media containing 5 % of glycerol (pH 5.0) comparing with cell walls obtained from YPD pH 5.0 (Table 3). It was decreased about 13 and 10 % adequately. In other cases, the differences appeared to be not significant.

The obtained results indicate that despite an affiliation to one S. cerevisiae sp., the response of probiotic and brewer’s yeasts on the presence of glycerol and changes in growth environment pH was differentiated in terms of the content of synthesized cell wall polysaccharides. S. cerevisiae R9 strain increased the content of wall polysaccharides after cultivation in all mediums of pH 4.0 containing glycerol. Such unequivocal tendency was not observed in the case of S. cerevisiae var. boulardii strain. This confirms the need of optimization of conditions of wall polysaccharides biosynthesis individually for each strain. Glycerol application as carbon and energy source for the growth of yeasts Saccharomyces genus, including probiotic yeasts, may contribute to an increase in the content of wall polymers, which would make these yeast biomass a more efficient source of biologically active polysaccharides. In addition, the health-promoting activity of the strain itself, connected to the presence of β-glucans and mannoprotein, may be subjected to changes which should be verified in further stages of the research.

The investigated yeast cell wall preparations were subjected to fractionation in alkali and acid condition to separate particular structural polysaccharides. The mechanism of this separation is based on weak acidic characteristic of β-glucans. These polysaccharides are week acids because numerous, very weak acidic hydroxyl groups are in their chain. During dissolution of β-glucan in alkali, the ionization of hydroxyl groups occurs. Dissolution of polysaccharides in alkali causes disruption of the hydrogen bonds between polymer chains and, as a consequence, disruption of the regular organization of β-glucan chains. After neutralization with acetic acid, the decrease in the ionization of OH groups and their electrostatic interactions leads to a conformational transition from regular helices or random coils to triple helices and then β-glucans precipitate [27]. At the same conditions, mannoprotein are still ionized, because of protonated nitrogen atoms in protein chains. β-glucans connected with chitin are not soluble in alkali. The confirmation of the β(1,3)-glucan, β(1,6)-glucan, and mannoprotein presence in fractions no. 1–6 (Fig. 1) was based on the literature data [36]. Magnelli et al. [36] performed structural identification and quantitative analysis of S. cerevisiae cell wall fractions obtained after polymer separation by 3 % NaOH, acetic acid neutralization of alkali-soluble polymer fraction, and alcohol precipitation of mannan from alkali-soluble acid-soluble fraction, as well as Zymolyase digestion of alkali-insoluble polymers. Cited authors [36] did not dialyzed the Zymolyase-solubilized fraction that is why they analyzed also β(1,3)-glucan in alkali-insoluble material directly. Zymolyase 20T is an enzymatic preparation containing β(1,3)-glucanase, protease, and mannanase activities but does not contain β(1,6)-glucanase activity. Therefore, after dialysis of Zymolyase-solubilized material, β(1,6)-glucan is collected [42, 43]. The aim of dialysis was to separate β(1,6)-glucan from hydrolyzed β(1,3)-glucan [42].

Quantitative determination of alkali-insoluble and alkali-soluble cell wall polymers confirmed the differences in the structure of cell wall of the examined yeasts. Cell wall of these yeasts contained mainly alkali-soluble polymers (mannoprotein and β-glucan). They constituted about 40 g/100 g d.w. of cell wall of S. cerevisiae var. boulardii yeasts after cultivation in YPD medium of pH 5.0 and containing 3 % of glycerol, respectively (Table 3). The lowest value of this fraction was noted in the wall of S. cerevisiae var. boulardii from YPD medium (pH 4.0) and in media of pH 5.0 with 5 % glycerol addition (Table 3). At the same time, the lowest amounts of carbohydrates in total were determined in these preparations. Lower content of alkali-insoluble fraction, which constituted of β(1,3)- and β(1,6)-glucan connected with chitin, was noted in the cell walls of probiotic yeasts, when compared to the cells of S. cerevisiae R9. The highest content of this fraction (about 16 % of d.w. of cell wall) was noted in the walls of yeasts from cultivation enriched with 2 and 3 % of glycerol (pH 5.0).

In the case of S. cerevisiae R9 strain, the highest amount of alkali-soluble polymers (app. 42 %) was obtained from cells cultivated in media containing 3 % of glycerol at pH 4.0 (Table 2). At the same cultivation condition, the cell wall of brewer’s yeasts characterized the highest content of alkali-insoluble fractions (about 20 % of d.w. of cell wall). It can be concluded that the cultivation of these yeasts in mediums with glycerol as carbon source contributed to an increase in the content of alkali-insoluble β(1,3)- and β(1,6)-glucans.

The proportion of soluble and insoluble fraction in yeast cell wall seems however to be dependent on the species and even strain of the yeasts what is supported by the literature data [11, 18, 20, 22, 39, 41, 48, 51].

Cell wall preparations obtained from S. cerevisiae R9 yeasts contained higher amount of β-glucans when compared to the walls of S. cerevisiae var. boulardii (Tables 2, 3). The highest content of β(1,3)/β(1,6)-glucans in cell wall of brewer’s yeasts was noted after cultivation in a medium containing 2 and 3 % of glycerol (pH 4), significantly more than in mediums containing glucose (table 2). Mentioned dependence was also noticed in the contribution of β-glucans in carbohydrates in total, which amounted to about 64 and 58 %, respectively (Table 4). In the medium containing 3 % of glycerol, the brewer’s yeasts intensified synthesis of β(1,6)-glucan (Table 2, 4). Research of Magnelli et al. [36] confirmed that β(1,6)-glucan is mainly present in alkali-insoluble fraction of S. cerevisiae cell wall. An analysis of all the results allowed to notice that the proportions of β(1,3)- and β-(1,6)-glucan depended on growth conditions. Aguilar-Uscanga and François [2] also noted difference in β(1,6)-glucan contribution in total content of β-glucans depending on the conditions of yeasts cultivation. The contribution of β(1,6)-glucan polymer in wall of the yeasts examined by mentioned authors was in the range of 10–20 %. This confirms an adaptation of cells to an environment and concurrently points different structure of discussed organelle in cells originating from various cultivations. Higher contribution of β(1,6)-glucan in the fraction of β-D-glucopyranose polymers proves higher degree of chains branching and may change three-dimensional structure of β(1,3)-glucans. These changes determine the difference in physical and chemical properties of β-glucans and are reflected in, for example, solubility. They may also modify bioactive properties of β-glucans [47] which requires further studies.

Statistical analysis of the obtained results demonstrated an existence of correlations between changes in β-(1,6)-glucan and mannoprotein content in wall of the examined yeasts from model cultivations. An increase in mannoprotein content in the preparations of examined yeast walls was correlated with an increasing content of β-(1,6)-glucan. Determined correlation coefficients were significant at p < 0.05 and amounted to r = 0.461 and r = 0.661, respectively, in the case of S. cerevisiae var. boulardii and in the case of brewer’s yeasts S. cerevisiae R9. The bonds between β(1,6)-glucan and mannoprotein play an essential role in the organization of cell wall structure of the yeasts [14]. The models of yeasts cell wall structure, presenting connections between polymers forming this structure, indicate a key role of β(1,6)-glucan in polymers binding. Its task is to participate in the formation of flexible cross-links between mannoprotein from abundant GPI-CWPS group (glycosyl–phosphatidylinositol-anchored membrane proteins) and non-reducing ends of three-dimensional network of β(1,3)-glucan [18, 46]. An increase in the content of cell wall proteins might thus initiate synthesis of β(1,6)-glucan, essential for mannoprotein incorporation to the network of β(1,3)-glucan. Kapteyn et al. [18] demonstrated than an increase in an amount of cross-links between proteins of yeasts cell wall and β(1,6)-glucan-chitin complex is a defense mechanism of the cell compensating a decrease in the content of β(1,3)-glucan in the cell wall.

In the cell wall of S. cerevisiae var. boulardii yeasts, the polymers of β(1,3)- and β(1,6)-glucan were noted in the highest amount after cultivation in mediums with 2 and 3 % of glycerol, like in the case of S. cerevisiae R9 strain (Table 3, 5). The lowest content of these glucose polymers was noted in wall preparations after cells cultivation in the presence of glucose (YPD pH 4.0 and 7.0). In the case of probiotic yeasts strain, glycerol addition to most of the cultivation mediums did not cause an significant increase in β-glucan contribution in a structure of the examined organelle.

Magnelli et al. [36] confirmed that the alkali-soluble/acid-soluble fraction of S. cerevisiae cell wall polymers is composed predominantly with mannan (as mannoprotein). The strain of probiotic yeasts was characterized by higher contribution of mannoprotein in cell wall when compared to brewer’s yeasts. Mannoprotein constituted about 27 % of d.w. of the cell walls of S. cerevisiae var. boulardii yeasts from cultivation in YPD medium of pH 5.0 (about 52 % of carbohydrates)—Tables 3, 5. The cell wall of S. cerevisiae R9 yeasts after cultivation in mentioned medium was composed of definitely lower mannoprotein content (about 15 % of d.w. of the cell wall). The highest amount of mannoprotein per 100 g d.w. of cell wall of probiotic yeasts (about 29 % of the cell wall) was noted in cells after incubation in medium containing 3 % of glycerol and pH 4.0, which constituted about 51 % of carbohydrates in total. The lowest amount of mannoprotein in cell wall dry weight was determined in the S. cerevisiae var. boulardii cells from YPD medium of pH 4. The cells of S. cerevisiae R9 yeasts obtained from all mediums with glycerol significantly increased the content of mannoprotein in the examined organelle. About 26 g of mannoprotein was noted in 100 g d.w. of the wall after cultivation in media with 3 and 5 % of glycerol, which constituted 42 and 46 % of structural carbohydrates of cell wall, respectively. Nguyen et al. [41] determined about 24 % mannoprotein in the cell wall of S. cerevisiae 1117 yeasts, while Fleet and Manners [11] noted about 30 % of mannoprotein in the wall of Saccharomyces yeast. Other authors pointed that mannoprotein constitute about 30–50 % of wall components of Saccharomyces yeasts [25, 33]. Thus, the obtained results are confirmed by the reference data.

Mannoprotein present in yeasts cell wall include structural proteins of the wall, adhesion molecules, invasins, hydrolytic enzymes, osmotic stress sensors, proteases, and iron-transporting proteins. Conditions of yeasts cultivation and growth phase of the cells have superior effect on the level of activation or transcription of yeasts wall proteins [19]. Some of mannoprotein present in yeasts cell wall are subject to more intense synthesis in stress conditions, while synthesis of others is subject to inhibition [19, 21, 44].

Summarizing the results of the conducted study confirm a possibility of an significant intensification of glucose polymers biosynthesis as well as mannoprotein in cell wall of Saccharomyces yeasts in mediums with glycerol as a carbon source. The process may be directed toward an increase in the content of β-glucans or mannoprotein in the yeast cell walls by an adjustment of the substrate concentration and environmental pH but the changes are strain specific.

Statements and conclusions

The results of PCR analysis confirmed an affiliation of yeasts isolated from probiotic preparation to S. cerevisiae sp.

Glycerol may be a source of carbon and energy in cultivations of yeasts of Saccharomyces genus oriented at an intensification of polysaccharides and mannoprotein forming this yeast cell wall.

The examined yeasts strains were characterized by varying content of β-glucans and mannoprotein in cell wall. Higher content of mannoprotein (between 45 and 52 % of total carbohydrates) was noted in the wall of probiotic yeasts, while brewer’s yeasts S. cerevisiae R9 were characterized by higher content of β-glucans in cell wall structure (about 53–64 % of total carbohydrates).

Cultivation mediums with glycerol as the carbon source contributed to modification of polymers content in cell wall of the examined yeast species. Response of the cells on cultivation conditions appeared to be, in this respect, an individual feature of each strain as well as depends on glycerol concentration and used environmental pH. In the case of S. cerevisiae R9 brewer’s yeasts strain, an increase in both β-glucans and mannoprotein content was observed, of about 10 g d.w./100 g d.w. of cell wall preparation on average.

The cells of S. cerevisiae R9 brewer’s yeasts were the best source of β-glucans after cultivation in mediums containing 2 and 3 % of glycerol at pH 4. Cell walls of these yeasts contained about 36 % of β(1,3)-/β(1,6)-glucan polymers in dry weight. Presence of glycerol at a concentration of 3 and 5 % intensified biosynthesis of mannoprotein in the cell wall, approaching their content (about 26 % d.w. of the cell wall) to those noted in the cells of probiotic yeasts (about 29 % g. d.w. of the wall) after cultivation in a medium of pH 5 containing 3 % of glycerol.

Further studies will be oriented toward an optimization of cultivation conditions for efficient biosynthesis of β-glucans and mannoprotein. A further aim will be to obtain preparations of mentioned polymers and determine their functional properties.

References

Arlorio M, Coïsson JD, Martelli A (1999) Eur Food Res Technol 209:185–191

Aguilar-Uscanga B, François JM (2003) Lett Appl Microbiol 37:268–274

Badia R, Zanello G, Chevaleyre C, Lizardo R, Meurens F, Martínez P, Brufau J, Salmon H (2012) Vet Res 43(4):1–11

Bowman SM, Free SJ (2006) Bioessays 28:799–808

Bzducha-Wróbel A, Błażejak S, Tkacz K (2012) Eur Food Res Technol 235:355–366

Chen J, Seviour R (2007) Mycol Res 111(6):635–652

Czerucka D, Piche T, Rampal P (2007) Aliment Pharmacol Ther 26:767–778

Dallies N, Fransçois J, Paquet V (1998) Yeast 14:1297–1306

Ferreira I, Pinho O, Vieira E, Tavarela JG (2010) Trends Food Sci Technol 21:77–84

Fietto JL, Araújo RS, Valadão FN, Fietto LG, Brandão RL, Neves MJ, Gomes FC, Nicoli JR, Castro IM (2004) Can J Microbiol 50(8):615–621

Fleet GH, Manners ADJ (1976) J Gen Microbiol 94(1):180–192

Freimund S, Sauter M, Käppeli O, Dutler H (2003) Carbohydr Polym 54:159–171

Ganner A, Stoiber C, Wieder D, Schtzmayr G (2010) J Microbiol Methods 83:168–174

Ha CH, Lim KH, Kim YT, Lim ST, Kim CW (2002) Appl Microbiol Biotechnol 58:370–377

Jalcin SK, Ozbas ZY (2008) Braz J Microbiol 39:325–332

Jawhara S, Habib K, Maggiotto F, Pignede G, Vandekerckove P, Maes E, Dubuquoy L, Fontaine T, Guerardel Y, Poulain D (2012) PLoS One 7(7):e40648

Jouany J-P, Yiannikouris A, Bertin G (2005) Arch Zootech 8:26–50

Kapteyn JC, Ram AFJ, Gross EM, Kollar R, Montijn RC, Van Den Ende H, Lllobell A, Cabib E, Klis FM (1997) J Bacteriol 179(20):6279–6284

Kapteyn JC, Van Den Ende H, Klis FM (1999) Biochim Biophys Acta 1426:373–383

Kath F, Kulicke WM (1999) Die Angewande Macromoleculare Chemie 268:59–68

Kayingo G, Martins A, Andrie R, Neves L, Lucas C, Wong B (2009) Microbiology 155:1547–1557

Kessler G, Nickerson WJ (1959) J Biol Chem 234(9):2281–2285

Kim KS, Yun HS (2006) Enzyme Microb Technol 39:496–500

Klis MF, Mol P, Hellingwerf K, Brul S (2002) FEMS Microbiol Rev 26:239–256

Klis FM, Boorsma A, De Groot PWJ (2006) Yeast 23:185–202

Kogan G, Kocher A (2007) Livest Sci 109:161–165

Kopecká M (2012) J. Electron Microsc. doi:10.1093/jmicro/dfs076

Krasowska A, Murzyn A, Dyjankiewicz A, Łukaszewicz M, Dziadkowiec D (2009) FEMS Yeast Res 9:1312–1321

Križková L, Ďuračková Z, Šandula J, Sasinková V, Krajčovič J (2001) Mutat Res 497:213–222

Kuncheva M, Pavlova K, Panchev I, Dobreva S (2007) Int J Cosmet Sci 29:377–384

Latgé J-P (2010) Cell Microbiol 12(7):863–872

Lipińska E, Błażejak S, Markowski K (2010) Acta Sci Pol Biotechnol 9(3):3–14

Lipke PN, Ovalle RJ (1998) Bacteriology 180:3735–3740

Liu XY, Wang Q, Ciu SW, Liu HZ (2008) Food Hydrocoll 22:239–247

Magnani M, Calliari CM, de Macedo FC, Mori MP, de Syllos Cólus IM, Castro-Gomez RJH (2009) Carbohydr Polym 78:658–665

Magnelli P, Cipollo JF, Abeijon C (2002) Anal Biochem 301:136–150

Mantovani A, Allavena P, Sica A, Balkwill F (2008) Nature 454:436–444

Mirhendi H, Diba K, Rezaei A, Jalalizand N, Hosseinpur L, Khodadadi H (2007) Iran J Publ Health 36(1):40–44

Montijn RC, Vink E, Müller WH, Verkleij AJ, van den Ende H, Henrissat B, Klis FM (1999) J Bacteriol 181(24):7414–7420

Montovani MS, Bellini MF, Angeli JPF, Oliveira RJ, Silva AF, Ribeiro LR (2008) Mutat Res 658:154–161

Nguyen TH, Fleet GH, Rogers PL (1998) Appl Microbiol Biotechnol 50:206–212

Orłowski J, Machula K, Janik A, Zdebska E, Palamarczyk G (2007) Yeast 24:239–252

Pérez P, Ribas JC (2004) Methods 33:245–251

Ram AFJ, Kapteyn JC, Montijn RC, Caro LHP, Douwes JE, Baginsky W, Mazur P, Van Den Ende H, Klis FM (1998) J Bacteriol 180(6):1418–1424

Ruszova E, Pavek S, Hajkowa V, Jandova S, Velebny V, Papezikova V, Kubala L (2008) Carbohydr Res 343:501–511

Smits G, Van den Ende H, Klis FM (2001) Microbiology 147:781–794

Soltanian S, Dhont J, Sorgeloos P, Bossier P (2007) Fish Shellfish Immunol 23:141–153

Suphantharika M, Khunrae P, Thanardkit P, Verduyn C (2003) Bioresour Technol 88:55–56

Sutherland FC, Lages F, Lucas C, Luyten K, Albertyn J, Hohmann S, Prior PA, Kilian SG (1997) J Bacteriol 179(24):7790–7795

Thammakiti S, Suphantharika M, Phaesuwan T, Verduyn C (2004) Int J Food Sci Technol 39:21–29

Thanardkit P, Khunrae P, Suphantharika M, Verduyn C (2002) World J Microbiol Biotechnol 18:527–539

Van der Kühle A, Jespersen L (2003) Syst Appl Microbiol 26:564–571

Vanhee LME, Goemé F, Nelis HJ, Coenye T (2010) J Appl Microbiol 109:1745–1752

Waszkiewicz-Robak B, Bartnikowska E (2009) J Anim Feed Sci 18:699–708

Wei D, Zhang L, Williams DL, Browder W (2002) Wound Repair Regen 10:161–168

Zechner-Krpan V, Petravić-Tominac V, Gospodarić I, Sajli L, Daković S, Filipović-Grčić J (2010) Food Technol Biotechnol 48(2):189–197

Conflict of interest

None.

Compliance with Ethics Requirements

This article does not contain any studies with human or animal subjects.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Bzducha-Wróbel, A., Kieliszek, M. & Błażejak, S. Chemical composition of the cell wall of probiotic and brewer’s yeast in response to cultivation medium with glycerol as a carbon source. Eur Food Res Technol 237, 489–499 (2013). https://doi.org/10.1007/s00217-013-2016-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00217-013-2016-8