Abstract

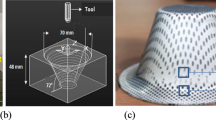

Incremental sheet forming (ISF) is recognized to have the capability to enhance the formability of metallic sheets in comparison to press working (PW), but there is insufficient knowledge regarding the physical mechanisms underlying this phenomenon. This paper examines the forming limits of Al 6061 and AISI 304 sheets in dieless incremental hole-flanging (IHF), which is an important supplement to conventional ISF. The effect of discontinuous deformation and strain-induced martensitic transformation in 304 steel on deformation is especially considered. It was found that the limiting forming ratios (LFRs) of all the blanks in IHF were improved compared to those in PW, and the LFRs of the 6061 blanks were improved more. In the uniaxial tensile tests under repeated loading–unloading, the elongation of the 6061 specimens slightly improved, while that of 304 steel obviously decreased with the application of cyclic loading. The results indicate that cyclic straining can contribute to the ductility of 6061 blanks in IHF. For the 304 blanks, the strain-induced martensitic transformation was found in all the processes, and the martensite content increases with the deformation amount and the frequency of cyclic loading. The TRIP (transformation-induced plasticity) effect of 304 sheets does not dominate in the tensile tests and IHF. Moreover, a special failure mode of the 304 blanks, the petaloid neck, which is prone to appear before fracturing in IHF, was addressed.

Similar content being viewed by others

References

Isik K, Silva MB, Tekkaya AE, Martins PAF (2014) Formability limits by fracture in sheet metal forming. J Mater Process Technol 214:1557–1565

McAnulty T, Jeswiet J, Doolan M (2017) Formability in single point incremental forming: a comparative analysis of the state of the art. CIRP J Manuf Sci Technol 16:43–54

Gatea S, Ou H, McCartney G (2016) Review on the influence of process parameters in incremental sheet forming. Int J Adv Manuf Technol 87:479–499

Duflou JR, Habraken A, Cao J, Malhotra R, Bambach M, Adams D, Vanhove H, Mohammadi A, Jeswiet J (2017) Single point incremental forming: state-of-the-art and prospects. Int J Mater Form 11:743–773. https://doi.org/10.1007/s12289-017-1387-y

Wen T, Yang C, Zhang S, Liu L (2015) Characterization of deformation behavior of thin-walled tubes during incremental forming: a study with selected examples. Int J Adv Manuf Technol 78:1769–1780

Wen T, Zhang S, Zheng J, Huang Q, Liu Q (2016) Bi-directional dieless incremental flanging of sheet metals using a bar tool with tapered shoulders. J Mater Process Technol 229:795–803

Cui Z, Gao L (2010) Studies on hole-flanging process using multistage incremental forming. CIRP J Manuf Sci Technol 2:124–128

Hussain G, Valaei H, Al-Ghamdi KA, Khan B (2016) Finite element and experimental analyses of cylindrical hole flanging in incremental forming. Trans Nonferrous Met Soc China 26:2419–2425

Borrego M, Morales-Palma D, Martínez-Donaire A, Centeno G, Vallellano C (2016) Experimental study of hole-flanging by single-stage incremental sheet forming. J Mater Process Technol 237:320–330

Cao T, Lu B, Ou H, Long H, Chen J (2016) Investigation on a new hole-flanging approach by incremental sheet forming through a featured tool. Int J Adv Manuf Technol 110:1–17

Cristino VA, Montanari L, Silva MB, Atkins AG, Martins PAF (2014) Fracture in hole-flanging produced by single point incremental forming. Int J Mech Sci 83:146–154

Silva MB, Teixeira P, Reis A, Martins PAF (2013) On the formability of hole-flanging by incremental sheet forming. Proceedings of the Institution of Mechanical Engineers, Proc IMechE Part L: J Mater Des App 227:91–99

Cristino VA, Silva MB, Wong PK, Tam LM, Martins PAF (2015) Hole-flanging of metals and polymers produced by single point incremental forming. Int J Mater Prod Technol 50:37–48

Montanari L, Cristino VA, Silva MB, Martins PAF (2013) A new approach for deformation history of material elements in hole-flanging produced by single point incremental forming. Int J Adv Manuf Technol 69:1175–1183

Starr TL, Rafi K, Stucker B, Scherzer CM (2012) Controlling phase composition in selective laser melted stainless steels, Proc of SFF Symposium: 439–446

Feaugas X, Gaudin C (2004) Ratchetting process in the stainless steel AISI 316L at 300 K: an experimental investigation. Int J Plast 20:643–662

Emmens WC, Boogaard AH (2009) An overview of stabilizing deformation mechanisms in incremental sheet forming. J Mater Process Technol 209:3688–3695

De AK, Murdock DC, Mataya MC, Speer JG, Matlock DK (2004) Quantitative measurement of deformation-induced martensite in 304 stainless steel by X-ray diffraction. Scr Mater 50:1445–1449

Okayasu M, Fukui H, Ohfuji H, Shiraishi T (2013) Strain-induced martensite formation in austenitic stainless steel. J Mater Sci 48:6157–6166

Xu Y, Zhang S, Song H, Cheng M, Zhang H (2011) The enhancement of transformation induced plasticity effect on austenitic stainless steels by cyclic tensile loading and unloading. Mater Lett 65:1545–1547

Funding

This project is supported by the National Natural Science Foundation of China (Grant No. 51575066).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, X., Wen, T., Hu, J. et al. Investigation of factors affecting the formability of metallic sheets in dieless incremental hole-flanging. Int J Adv Manuf Technol 103, 2609–2620 (2019). https://doi.org/10.1007/s00170-019-03459-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-019-03459-x