Abstract

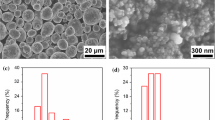

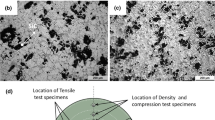

In this study, a silicon-carbide particulate (SiCp), reinforced aluminum alloy-based, metal-matrix composite was synthesized using disintegrated melt deposition. Microstructural characterization of the disintegrated melt deposition processed composite samples revealed the presence of columnar-equiaxed shaped grain structure, noninterconnected porosity associated with the reinforcing carbide particulates, improved interfacial integrity between the reinforcement and the aluminum alloy matrix coupled, and a near uniform distribution of the reinforcing SiC particulates in the alloy matrix. An examination of grain growth with the objective of delineating the effects of the silicon carbide particulates revealed a diminishing to minimal role of the reinforcing phase with an increase in temperature from 450 to 590 °C.

Similar content being viewed by others

References

A. Mortensen, J.A. Cornie, and M.C. Flemings, J. Met., 1988, p 12–15

P.S. Gilman, JOM, Vol 43 (No. 8), 1991, p 7

A.L. Geiger and J.A. Walker, JOM, Vol 43 (No. 8), 1991, p 8

A.P. Divecha, S.G. Fishman, and S.D. Karmarkar, J. Met., Vol 33, 1981, p 12

T.S. Srivatsan, R. Auradkar, and A. Prakash, Eng. Frac. Mech., Vol 40 (No. 2), 1991, p 277–296

S. Norose, T. Sasada, and M. Okabe, Proceedings of the 28th Japan Congress on Materials Research, 1985, p 231–240

D.L. Davidson, Eng. Frac. Mech., Vol 33 (No. 6), 1989, p 965–975

J.K. Shang and R.O. Ritchie, Metall. Trans. A, Vol 20, 1989, p 897

S. Suresh, Fatigue of Materials, Oxford University Press, 1991

T. Christman and S. Suresh, Mater. Sci. Eng., Vol 102, 1988, p 211–220

W.L. Phillips, Proceedings of the 1976 Conference on Composite Materials, B. Noton, Ed., Metallurgical Society of AIME, New York City, 1978, p 567

T.G. Nieh, Metall. Trans. A, Vol 15, 1984, p 139

G. Gould, Proceedings of the 3rd International Conference on Isostatic Pressing, London, Vol 1, 1986

T.S. Srivatsan and T.S. Sudarshan, Ed., Rapid Solidification Technology: An Engineering Guide, Technomic Publishing Co., Inc., 1991

W.H. Hunt, Jr., C.R. Cook, and R.R. Sawtell, “Cost Effective High Performance Powder Metallurgy Aluminum Matrix Composites for Automotive Applications,” SAE Technical Paper Series 910834, Warrendale, PA, Feb 1991

W.H. Hunt, Jr., “Cost Effective High Performance Aluminum Matrix Composites for Aerospace Applications,” International Conference on PM Aerospace Materials (Laussane, Switzerland), Nov 1991

T.S. Srivatsan, T.S. Sudarshan, and E.J. Lavernia, Prog. Mater. Sci., Vol 39 (No. 4/5), 1995, p 317–409

L.J. Broutman and R.H. Krock, Modern Composite Materials, Addison Wesley Publishing Co., New York City, 1969

P. Kelley, Composites, Vol 10, 1979, p 2

M.S. Zedalis, J.D. Bryant, P.S. Gilman, and S.K. Das, JOM, Part 1, Vol 43 (No. 8), 1991, p 29

S.H. Hong and K.H. Chung, Key Eng. Mater., Part 2, Vol 104–107, 1995, p 757

M. Gupta, C. Lane, and E.J. Lavernia, Scr. Metall. Mater., Vol 26, 1992, p 825

M. Gupta, T.S. Srivatsan, F.A. Mohamed, and E.J. Lavernia, J. Mater. Sci., Vol 28, 1993, p 2245

M. Gupta, J. Juarez-Islas, W.E. Frazier, F.A. Mohamed, and E.J. Lavernia, Metall. Trans. B., Vol 23, 1992, p 719

B. Chalmers, Principles of Solidification, John Wiley & Sons, Inc., 1964, p 253–297

Metallography and Microstructures, Vol 9, Metals Handbook, ASM International, 1986, p 632

L.N. Thanh and M. Suery, Scr. Metall., Vol 25, 1991, p 2781

M. Gupta and M.K. Surappa, Key Eng. Mater., Part 1, Vol 104–107, 1996, p 259

I.A. Ibrahim, F.A. Mohamed, and E.J. Lavernia, J. Mater. Sci., Vol 26, 1991, p 1137

M. Gupta, F.A. Mohamed, and E.J. Lavernia, Int. J. Rapid Solidif., Vol 6, 1991, p 247

M. Gupta, F. Mohamed, and E. Lavernia, Metall. Trans. A, Vol 23, 1991, p 831

R.J. Arsenault and N. Shi, Mater. Sci. Eng., Vol 81, 1986, p 175

P.A. Beck, J.C. Kremer, L.J. Demer, and M.L. Holzworth, Trans. Metal Soc. AIME, Vol 175, 1948, p 372

P.A. Beck, J. Appl. Phys., Vol 19, 1948, p 507

P.A. Beck, J. Towers, and W.O. Manley, Trans. Metall. Soc. AIME, Vol 175, 1951, p 634

R.L. Fullman, Metal Interfaces, American Society for Metals, 1952, p 179

P. Cotterill and P.R. Mould, Recrystallization and Grain Growth in Metals, Surrey University Press, 1976, p 275

M. Gupta, F. Mohamed, and E. Lavernia, Metall. Trans. A, Vol 23, 1992, p 845

X. Liang and E.J. Lavernia, Scr. Metall. Mater., Vol 25, 1991, p 1199

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Gupta, M., Srivatsan, T.S. Microstructure and grain growth behavior of an aluminum alloy metal matrix composite processed by disintegrated melt deposition. J. of Materi Eng and Perform 8, 473–478 (1999). https://doi.org/10.1361/105994999770346792

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1361/105994999770346792