Abstract.

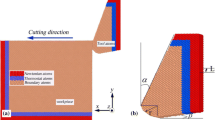

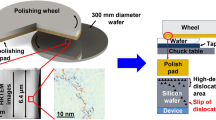

Molecular Dynamics (MD) simulations are carried out to study the thinning mechanism of silicon wafer containing through silicon via (TSV) at different loading conditions. The nano-metric grinding process is explained by lattice slip and distortion induced by tool extrusion. When the grinding depth is relatively low, amorphous silicon will appear on the surface of the silicon. The nano-twin defects appear on the subsurface of the workpiece as the grinding depth reaches 1.5nm. We compared the depth of the defect at the Si-SiO2 interface and inside the silicon. The results show that the nano-twins extend to the interface leading to a deeper damage. Between 40 and 100m/s, increasing the grinding speed can slightly reduce the depth of interface damage, while the defects inside the silicon are mainly affected by the grinding depth. Moreover, both normal and tangential force decrease with the increase of speed from 40 to 100m/s. The friction coefficient calculation results show that the larger the grinding depth, the larger the friction coefficient. Higher speeds reduce the friction coefficient of the diamond abrasive particles and the workpiece surface over the speed range from 40 to 100m/s. At last, the surface contact stress is calculated based on the actual contact surface. With the depth of 1.0nm, the contact stress is the largest, i.e. 11.99GPa.

Similar content being viewed by others

References

Gordon E. Moore, IEEE Solid-State Circ. Soc. Newslett. 11, 33 (2006)

H.L. John, Microelectron. Int. 28, 8 (2011)

R. Gassilloud, C. Ballif, P. Gasser, G. Buerki, J. Michler, Phys. Status Solidi (a) 202, 2858 (2005)

R. Chen, J. Luo, D. Guo, X. Lu, J. Appl. Phys. 104, 104907 (2008)

X. Han, Y. Hu, S. Yu, Appl. Phys. A 95, 899 (2009)

Z. Yang, Z. Lu, Y. Zhao, J. Appl. Phys. 106, 023537 (2009)

M.I. Baskes, M. Nastasi, J.G. Swadener, Phys. Rev. Lett. 89, 085503 (2002)

W.C. Nixon, J. R. Microsc. Soc. 83, 213 (1964)

D.B. Williams, C.B. Carter, The Transmission Electron Microscope, Transmission Electron Microscopy: A Textbook for Materials Science (Springer US, Boston, MA, 1996) pp. 3--17

W.C. Swope, H.C. Andersen, P.H. Berens, K.R. Wilson, J. Chem. Phys. 76, 637 (1982)

W.G. Hoover, B.H. Failor, B. Moran, A.J.C. Ladd, D.J. Evans, Phys. Rev. A 28, 1016 (1983)

D. Mulliah, S.D. Kenny, Roger Smith, C.F. Sanz-Navarro, Nanotechnology 15, 243 (2004)

R. Komanduri, N. Ch And Rasekaran, L.M. Raff, Philos. Mag. B 81, 1989 (2001)

I. Zarudi, L.C. Zhang, W.C.D. Cheong, T.X. Yu, Acta Mater. 53, 4795 (2005)

T. Yokosuka, H. Kurokawa, S. Takami, M. Kubo, A. Miyamoto, A. Imamura, Jpn. J. Appl. Phys. 41, 2410 (2002)

R. Chen, R. Jiang, H. Lei, M. Liang, Appl. Surf. Sci. 264, 148 (2013)

S. Plimpton, J. Comput. Phys. 117, 1 (1995)

I. Zarudi, W.C.D. Cheong, J. Zou, L.C. Zhang, Nanotechnology 15, 104 (2004)

J. Tersoff, Phys. Rev. B 39, 5566 (1989)

N.M. Putintsev, D.N. Putintsev, Dokl. Phys. Chem. 399, 278 (2004)

Y.S. Kim, K.H. Na, S.O. Choi, S.H. Yang, J. Mater. Process Tech. 155-156, 1847 (2004)

S. Alexander, Model Simul. Mater. Sci. 18, 015012 (2010)

E. Maras, O. Trushin, A. Stukowski, T. Ala-Nissila, H. Jónsson, Comput. Phys. Commun. 205, 13 (2016)

J.D. Honeycutt, H.C. Andersen, J. Phys. Chem. 91, 4950 (1987)

B. Wang, Z. Zhang, K. Chang, J. Cui, A. Rosenkranz, J. Yu, C. Lin, G. Chen, K. Zang, J. Luo, N. Jiang, D. Guo, Nano Lett. 18, 4611 (2018)

R.W.G. Wyckoff, Crystal Structures, Vol. 1, second edition (Interscience Publishers, New York, 1963) pp. 7--83

T. Fang, C. Weng, J. Chang, Mater. Sci. Eng.: A 357, 7 (2003)

W.C.D. Cheong, L.C. Zhang, Nanotechnology 11, 173 (2000)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

The EPJ Publishers remain neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Xu, Y., Wang, M., Zhu, F. et al. Study on subsurface damage of wafer silicon containing through silicon via in thinning. Eur. Phys. J. Plus 134, 234 (2019). https://doi.org/10.1140/epjp/i2019-12591-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epjp/i2019-12591-4