Abstract

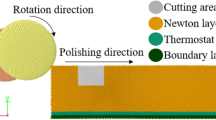

Chemical mechanical polishing (CMP) technology, being the mainstream technique of acquiring global planarization and nanometer level surface, has already become an attractive research item. In the case of CMP process, the indentation depth lies in the range of nanometer or sub-nanometer, huge hydrostatic pressure induced in the local deformation area which makes the material removal and surface generation process different from traditional manufacturing process. In order to investigate the physical essence of CMP technique, the authors carry out molecular dynamics (MD) analysis of chemical mechanical polishing of a silicon wafer. The simulation result shows that huge hydrostatic pressure is induced in the local area and leads to the silicon atom transform from the classical diamond structure (α silicon) to metal structure (β silicon). This important factor results in the ductile fracture of silicon and then in the acquisition of a super-smooth surface.

Similar content being viewed by others

References

F.W. Preston, The theory and design of plate glass polishing machine, J. Soc. Glass. Tech. 11(44), 214–256 (1927)

V.H. Nguyen, F.G. Shi, Modeling of the removal rate in chemical mechanical polishing, Proc. SPIE Int. Soc. Opt. Eng. 4181, 161–167 (2000)

G. Fu, A. Chandra, S. Guha , A plasticity-based model of material removal in chemical-mechanical polishing (CMP), IEEE Trans. Semicond. Manuf. 14(4), 406–417 (2001)

J.F. Luo, D.A. Dornfeld, Effects of abrasive size distribution in chemical mechanical planarization: modeling and verification, IEEE Trans. Semicond. Manuf. 16(3), 469–476 (2003)

S.R. Runnels, I. Kim, J. Schleuter , Modeling tool for chemical-mechanical polishing design and evaluation, IEEE Trans. Semicond. Manuf. 11(3), 501–510 (1998)

D.A. Litton, S.H. Garofalini, Modeling of hydrophilic wafer bonding by molecular dynamics simulations, J. Appl. Phys. 89(11), 6013–6023 (2001)

P.N. Blake, R.O. Scattergood, Ductile—regime machining of germanium and silicon, J. Am. Ceram. Soc. 73(4), 949–957 (1990)

J. Donohue, The Structures of Elements (Wiley, New York, 1974), pp. 262–266

D.R. Clark, M.C. Kroll, P.D. Kirchner , Amorphization and conductivity of silicon and germanium during indentation, Phys. Rev. Lett. 60, 2156–2160 (1988)

J.C. Morris, D.L. Callahan, J. Qulik , Origins of ductile regime in single point diamond turning of semiconductors, J. Am. Ceram. Soc. 78(8), 2015–2020 (1995)

K.D. Studip, W. Martin, S. Maddury , Pressure-induced amorphization and an amorphous–amorphous transition in densified porous silicon, Nature 414(29), 528–530 (2001)

D.A. Lucca, T.R. Oquin, Orthogonal ultraprecision machining of single crystal germanium, in ASPE Annual Meeting Proceedings, (1992), pp. 21–30

J.A. Harrison, C.T. White, R.J. Colton , Nanoscale investigation of indentation, adhesion and fracture of diamond (111) surfaces, Surf. Sci. 271(1–2), 57–67 (1992)

S. Shimada, N. Ikawa, T. Inamura , Brittle–ductile transition phenomena in microindentation and micromachining, CIRP Annu. 44(1), 523–526 (1995)

R. Rentsch, I. Inasaki, Molecular dynamics simulation for abrasive processes, CIRP Annu. 43(1), 327–330 (1994)

X.S. Han, S.Y. Yu, Molecular dynamics simulation of nanometric cutting process based on symplectic algorithm, Trans. CSME 41(4), 17–21 (2005)

X.S. Han, S.Y. Yu, Investigation of tool geometry in nanometric cutting by molecular dynamics simulation, J. Mater. Process. Technol. 129(1–3), 105–108 (2002)

X.S. Han, S.Y. Yu, Molecular dynamics simulation of nanometric grinding-the effect of crystal anisotropy on the quality of machined surface, Key Eng. Mater. 258–259, 361–365 (2004)

J. Tersoff, Modeling solid state chemistry: interatomic potential for multicomponent systems, Phys. Rev. B 39, 5566–5570 (1989)

P.M. Morse, Diatomic molecules according to the wave mechanics II vibrational levels, Phys. Rev. 34, 57–65 (1929)

W.C.D. Cheong, L.C. Zhang, Molecular dynamics simulation of phase transformations in silicon monocrystals due to nanoindentation, Key Eng. Mater. 11, 173–180 (2000)

J.M. Haile, Molecular Dynamics Simulation-Element Method (Wiley-Interscience, New York, 1997), pp. 332–339

T.G. Bifano, T.A. Dow, R.O. Scattergood, Ductile regime grinding: a new technology for machining brittle materials, J. Eng. Ind. 113, 184–189 (1991)

R.M. Tidwell, R.O. Scattergood, Diamond turning of brittle materials, PEC Ann. Rep. VIII, 153–159 (1990)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Han, X., Hu, Y. & Yu, S. Investigation of material removal mechanism of silicon wafer in the chemical mechanical polishing process using molecular dynamics simulation method. Appl. Phys. A 95, 899–905 (2009). https://doi.org/10.1007/s00339-009-5097-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00339-009-5097-2