Abstract

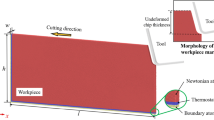

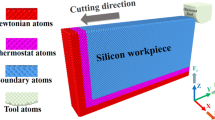

Molecular dynamics is employed to investigate the nanoscale cutting process of monocrystalline silicon with diamond tool. Materials removal behavior of workpiece through diamond cutting is studied. The effects of tool geometry on the deformation of material including rake angle, clearance angle and edge radius were carefully explored by analyzing the phase transformation, chips, hydrostatic stress, shear stress and workpiece deformation. The investigation shows that a positive rake angle tip, a larger clearance angle tip or a small edge radius tip would result in a smaller cutting force, a better subsurface and a larger chipping volume. Moreover, a bigger negative rake angle tip cutting has a larger hydrostatic stress and shear stress. However, a positive rake angle tip cutting has a larger average friction coefficient than a negative rake angle tip cutting, which means that negative rake angle tip cutting experiences a lower resistance rate. It is also found that a tip with positive rake angle or smaller edge radius will improve the smoothness of a ground surface. In addition, a bigger clearance angle tip cutting generates a lower temperature in workpiece.

Similar content being viewed by others

References

L.B. Kong, C.F. Cheung, X.Q. Jiang et al., Characterization of surface generation of optical microstructures using a pattern and feature parametric analysis method. Precis. Eng. 34, 755–766 (2010)

Y.Y. Ye, R. Biswas, J.R. Morris, A. Bastawros, A. Chandra, Molecular dynamics simulation of nanoscale machining of copper. Nanotechnology 14, 390 (2003)

I. Zarudi, T. Nguyen, L.C. Zhang, Effect of temperature and stress on plastic deformation in monocrystalline silicon induced by scratching. Appl. Phys. Lett. 86, 011922 (2005)

Y. Gogotsi, G. Zhou, S.S. Ku et al., Raman microspectroscopy analysis of pressure-induced metallization in scratching of silicon. Semicond. Sci. Technol. 16, 345 (2001)

Y.Q. Wu, H. Huang, J. Zou et al., Nanoscratch-induced deformation of single crystal silicon. J. Vac. Sci. Technol. B 27, 1374–1377 (2009)

R. Komanduri, N. Chandrasekaran, L.M. Raff, Effect of tool geometry in nanometric cutting: a molecular dynamics simulation approach. Wear 219, 84–97 (1998)

J.A. Patten, W. Gao, Extreme negative rake angle technique for single point diamond nano-cutting of silicon. Precis. Eng. 25, 165–167 (2001)

Q. Tang, F. Chen, MD simulation of phase transformations due to nanoscale cutting on silicon monocrystals with diamond tip. J. Phys. D Appl. Phys. 39, 3674 (2006)

H. Tanaka, S. Shimada, L. Anthony, Requirements for ductile-mode machining based on deformation analysis of mono-crystalline silicon by molecular dynamics simulation. CIRP Ann. Manuf. Technol. 56, 53–56 (2007)

M.B. Cai, X.P. Li, M. Rahman, Study of the temperature and stress in nanoscale ductile mode cutting of silicon using molecular dynamics simulation. J. Mater. Process. Technol. 192, 607–612 (2007)

F.Z. Fang, H. Wu, W. Zhou et al., A study on mechanism of nano-cutting single crystal silicon. J. Mater. Process. Technol. 184, 407–410 (2007)

J. Yan, H. Zhao, T. Kuriyagawa, Effects of tool edge radius on ductile machining of silicon: an investigation by FEM. Semicond. Sci. Technol. 24, 075018 (2009)

H. Zhao, C. Shi, P. Zhang et al., Research on the effects of machining-induced subsurface damages on mono-crystalline silicon via molecular dynamics simulation. Appl. Surf. Sci. 259, 66–71 (2012)

Y. Wang, J. Shi, C. Ji, A numerical study of residual stress induced in machined silicon surfaces by molecular dynamics simulation. Appl. Phys. A 115, 1263–1279 (2014)

R. Gassilloud, C. Ballif, P. Gasser et al., Deformation mechanisms of silicon during nanoscratching. Phys. Status Solidi A 202, 2858–2869 (2005)

B. Hendrickson, T.G. Kolda, Graph partitioning models for parallel computing. Parallel Comput. 26, 1519–1534 (2000)

A. Stukowski, Visualization and analysis of atomistic simulation data with OVITO–the Open Visualization Tool. Modell. Simul. Mater. Sci. Eng. 18, 015012 (2010)

C.S. Moura, L. Amaral, Molecular dynamics simulation of silicon nanostructures. Nucl. Instrum. Methods Phys. Res. Sect. B 228, 37–40 (2005)

J. Tersoff, New empirical model for the structural properties of silicon. Phys. Rev. Lett. 56, 632 (1986)

F.H. Stillinger, T.A. Weber, Computer simulation of local order in condensed phases of silicon. Phys. Rev. B 31, 5262 (1985)

J. Tersoff, Modeling solid-state chemistry: interatomic potentials for multicomponent systems. Phys. Rev. B 39, 5566 (1989)

M.B. Cai, X.P. Li, M. Rahman, Study of the mechanism of nanoscale ductile mode cutting of silicon using molecular dynamics simulation. Int. J. Mach. Tools Manuf. 47, 75–80 (2007)

L. Zhang, H. Zhao, Z. Ma et al., A study on phase transformation of monocrystalline silicon due to ultra-precision polishing by molecular dynamics simulation. AIP Adv. 2, 042116 (2012)

L. Zhang, H. Zhao, Y. Yang et al., Evaluation of repeated single-point diamond turning on the deformation behavior of monocrystalline silicon via molecular dynamic simulations. Appl. Phys. A 116, 141–150 (2014)

J.C. Rozzi, F.E. Pfefferkorn, F.P. Incropera et al., Transient, three-dimensional heat transfer model for the laser assisted machining of silicon nitride: I. Comparison of predictions with measured surface temperature histories. Int. J. Heat Mass Transf. 43, 1409–1424 (2000)

J.J. Zhang, T. Sun, Y.D. Yan et al., Molecular dynamics simulation of subsurface deformed layers in AFM-based nanometric cutting process. Appl. Surf. Sci. 254, 4774–4779 (2008)

P. Zhu, Y. Hu, T. Ma et al., Molecular dynamics study on friction due to ploughing and adhesion in nanometric scratching process. Tribol. Lett. 41, 41–46 (2011)

Z. Tong, Y. Liang, X. Jiang et al., An atomistic investigation on the mechanism of machining nanostructures when using single tip and multi-tip diamond tools. Appl. Surf. Sci. 290, 458–465 (2014)

S. Goel, X. Luo, A. Agrawal et al., Diamond machining of silicon: a review of advances in molecular dynamics simulation. Int. J. Mach. Tools Manuf. 88, 131–164 (2015)

D.E. Kim, S.I. Oh, Atomistic simulation of structural phase transformations in monocrystalline silicon induced by nanoindentation. Nanotechnology 17, 2259 (2006)

R.O. Piltz, J.R. Maclean, S.J. Clark et al., Structure and properties of silicon XII: a complex tetrahedrally bonded phase. Phys. Rev. B 52, 4072 (1995)

J. Crain, G.J. Ackland, J.R. Maclean et al., Reversible pressure-induced structural transitions between metastable phases of silicon. Phys. Rev. B 50, 13043 (1994)

H. Tanaka, S. Shimada, N. Ikawa, Brittle-ductile transition in monocrystalline silicon analysed by molecular dynamics simulation. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 218, 583–590 (2004)

S. Goel, X. Luo, R.L. Reuben, Wear mechanism of diamond tools against single crystal silicon in single point diamond turning process. Tribol. Int. 57, 272–281 (2013)

T. Vodenitcharova, L.C. Zhang, A new constitutive model for the phase transformations in mono-crystalline silicon. Int. J. Solids Struct. 41, 5411–5424 (2004)

M.B. Cai, X.P. Li, M. Rahman, Study of the mechanism of groove wear of the diamond tool in nanoscale ductile mode cutting of monocrystalline silicon. J. Manuf. Sci. Eng. 129, 281–286 (2007)

B. Shiari, R.E. Miller, D.D. Klug, Multiscale simulation of material removal processes at the nanoscale. J. Mech. Phys. Solids 55, 2384–2405 (2007)

L. Xiong, Y. Chen, Coarse-grained simulations of single-crystal silicon. Modell. Simul. Mater. Sci. Eng. 17, 035002 (2009)

M.C. Gupta, A.L. Ruoff, Static compression of silicon in the [100] and in the [111] directions. J. Appl. Phys. 51, 1072–1075 (1980)

D.R. Clarke, M.C. Kroll, P.D. Kirchner et al., Amorphization and conductivity of silicon and germanium induced by indentation. Phys. Rev. Lett. 60, 2156 (1988)

P.A. Romero, G. Anciaux, A. Molinari et al., Insights into the thermo-mechanics of orthogonal nanometric machining. Comput. Mater. Sci. 72, 116–126 (2013)

C. Shet, X. Deng, Finite element analysis of the orthogonal metal cutting process. J. Mater. Process. Technol. 105, 95–109 (2000)

X.S. Han, B. Lin, S.Y. Yu et al., Investigation of tool geometry in nanometric cutting by molecular dynamics simulation. J. Mater. Process. Technol. 129, 105–108 (2002)

G.L.W. Cross, Silicon nanoparticles: Isolation leads to change. Nat. Nanotechnol. 6, 467–468 (2011)

H.W. Zhao, L. Zhang, P. Zhang et al., Influence of geometry in nanometric cutting single-crystal copper via MD simulation//advanced materials research. Adv Mater. Res. 421, 123–128 (2011)

J. Li, Q. Fang, L. Zhang et al., Subsurface damage mechanism of high speed grinding process in single crystal silicon revealed by atomistic simulations. Appl. Surf. Sci. 324, 464–474 (2015)

K. Mylvaganam, L.C. Zhang, Nanotwinning in monocrystalline silicon upon nanoscratching. Scr. Mater. 65, 214–216 (2011)

X. Jing, S. Maiti, G. Subhash, A new analytical model for estimation of scratch-induced damage in brittle solids. J. Am. Ceram. Soc. 90, 885–892 (2007)

H.G. Wobker, H.K. Tonshoff, High-efficiency grinding of structural ceramics. NIST Spec. Publ. 847, 171 (1993)

Acknowledgments

The authors would like to appreciate the support from the National Science and Technology Major Project of the Ministry of Science and Technology of China (No. 2012ZX04003101).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Dai, H., Chen, G., Fang, Q. et al. The effect of tool geometry on subsurface damage and material removal in nanometric cutting single-crystal silicon by a molecular dynamics simulation. Appl. Phys. A 122, 804 (2016). https://doi.org/10.1007/s00339-016-0319-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00339-016-0319-x