Abstract

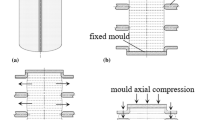

Gas tungsten arc (GTA) welding process is the best choice for joining Ti–6Al–4V (grade 5) material, with economical cost. To support the above aim, two simulation works are studied in this research. First work focuses on the simulation of GTA welding process. The second work focuses on the simulation of the tensile and cupping test. Initially, GTA welding parameters such as welding current (115–135 A) and welding speed (250–450 mm/min) are taken for conducting bead on plate (BoP) trials. From these BoP trails, bead profiles are measured to build a moving heat source model in COMSOL. The arc efficiency (η) is focused on this welding simulation. Using Abaqus software, tensile and cupping test analysis is performed to predict the fracture location and elongation. The bead profile at arc efficiency of 60% showed a better match with the experimental work. By implementing the temperature distribution analysis, the bright silver colour bead is achieved in experimental work. The butt joint showed comparable strength (95.9%) to the base metal; also the simulation error is not exceeded by 10%. The crack location predicted from the numerical study highly coincides with the experimental work for the cupping test.

Similar content being viewed by others

References

Yunlian, Q.; Ju, D.; Quan, H.; Liying, Z.: Electron beam welding, laser beam welding and gas tungsten arc welding of titanium sheet. Mater. Sci. Eng. A 280, 177–181 (2000). https://doi.org/10.1016/S0921-5093(99)00662-0

Boccarusso, L.; Arleo, G.; Astarita, A.; Bernardo, F.; De Fazio, P.; Durante, M.; Minutolo, F.M.; Sepe, R.; Squillace, A.: A new approach to study the influence of the weld bead morphology on the fatigue behaviour of Ti–6Al–4V laser beam-welded butt joints. Int. J. Adv. Manuf. Technol. 88, 75–88 (2017). https://doi.org/10.1007/s00170-016-8764-4

Li, J.; Guan, Q.; Shi, Y.; Guo, D.; Du, Y.; Sun, Y.: Studies on characteristics of temperature field during GTAW with a trailing heat sink for titanium sheet. J. Mater. Process. Technol. 147, 328–335 (2004). https://doi.org/10.1016/j.jmatprotec.2003.12.012

Cui, C.; Hu, B.M.; Zhao, L.; Liu, S.: Titanium alloy production technology, market prospects and industry development. Mater. Des. 32, 1684–1691 (2011). https://doi.org/10.1016/j.matdes.2010.09.011

Jamshidi Aval, H.; Farzadi, A.; Serajzadeh, S.; Kokabi, A.H.: Theoretical and experimental study of microstructures and weld pool geometry during GTAW of 304 stainless steel. Int. J. Adv. Manuf. Technol. 42, 1043–1051 (2009). https://doi.org/10.1007/s00170-008-1663-6

Cortés, R.; Barragán, E.R.; López, V.H.; Ambriz, R.R.; Jaramillo, D.: Mechanical properties of Inconel 718 welds performed by gas tungsten arc welding. Int. J. Adv. Manuf. Technol. 94, 3949–3961 (2018). https://doi.org/10.1007/s00170-017-1128-x

Li, X.; Xie, J.; Zhou, Y.: Effects of oxygen contamination in the argon shielding gas in laser welding of commercially pure titanium thin sheet. J. Mater. Sci. 40, 3437–3443 (2005). https://doi.org/10.1007/s10853-005-0447-8

Karpagaraj, A.; Siva Shanmugam, N.; Sankaranarayanasamy, K.: Some studies on mechanical properties and microstructural characterization of automated TIG welding of thin commercially pure titanium sheets. Mater. Sci. Eng. A 640, 180–189 (2015). https://doi.org/10.1016/j.msea.2015.05.056

Arunkumar, S.; Shrikrishna, A.K.; Paulraj, S.; Devakumaran, K.; Kumar, S.R.: Transient finite element simulation and microstructure evolution of Aa2219 weld joint using gas tungsten arc welding process. Adv. Sci. Technol. Res. J. 10, 64–73 (2016). https://doi.org/10.12913/22998624/64007

Karpagaraj, A.; Siva Shanmugam, N.; Sankaranarayanasamy, K.: Experimental investigations and numerical prediction on the effect of shielding area and post flow time in the GTAW of CP Ti sheets. Int. J. Adv. Manuf. Technol. 101, 2933–2945 (2019). https://doi.org/10.1007/s00170-018-3135-y

Karpagaraj, A.; Abhilash, N.; Siva Shanmugam, B., Suresha, S.; Vendan, A.: Studies on Spring back effect of TIG welded Ti–6Al–4V Sheets. In: Simulations for Design and Manufacturing. Sequence no 5, pp. 147–171. Springer, Singapore. https://doi.org/10.1007/978-981-10-8518-5_5 (2018)

García-Garino, C.; Gabaldón, F.; Goicolea, J.M.: Finite element simulation of the simple tension test in metals. Finite Elem. Anal. Des. 42, 1187–1197 (2006). https://doi.org/10.1016/j.finel.2006.05.004

Banerjee, A.; Dhar, S.; Acharyya, S.; Datta, D.; Nayak, N.: Determination of Johnson cook material and failure model constants and numerical modelling of Charpy impact test of armour steel. Mater. Sci. Eng. A 640, 200–209 (2015). https://doi.org/10.1016/j.msea.2015.05.073

Li, F.Q.; Mo, J.H.; Li, J.J.; Huang, L.; Zhou, H.Y.: Formability of Ti–6Al–4V titanium alloy sheet in magnetic pulse bulging. Mater. Des. 52, 337–344 (2013). https://doi.org/10.1016/j.matdes.2013.05.064

Winowiecka, J.; Wiȩckowski, W.; Zawadzki, M.: Evaluation of drawability of tailor-welded blanks made of titanium alloys Grade 2|| Grade 5. Comput. Mater. Sci. 77, 108–113 (2013). https://doi.org/10.1016/j.commatsci.2013.04.026

Goldak, J.; Chakravarti, A.; Bibby, M.: A new finite element model for welding heat sources. Metall. Trans. B 15, 299–305 (1984). https://doi.org/10.1007/BF02667333

Azar, A.S.; Ås, S.K.; Akselsen, O.M.: Determination of welding heat source parameters from actual bead shape. Comput. Mater. Sci. 54, 176–182 (2012). https://doi.org/10.1016/j.commatsci.2011.10.025

Yazdipour, A.; Ghaderi, M.R.: Optimization of weld bead geometry in GTAW of CP titanium using imperialist competitive algorithm. Int. J. Adv. Manuf. Technol. 72, 619–625 (2014). https://doi.org/10.1007/s00170-014-5682-1

Wang, X.: Three-dimensional vision applications in GTAW process modeling and control. Int. J. Adv. Manuf. Technol. 80, 1601–1611 (2015). https://doi.org/10.1007/s00170-015-7063-9

Sun, J.; Klassen, J.; Nitschke-Pagel, T.; Dilger, K.: Effects of heat source geometric parameters and arc efficiency on welding temperature field, residual stress, and distortion in thin-plate full-penetration welds. Int. J. Adv. Manuf. Technol. 99, 497–515 (2018). https://doi.org/10.1007/s00170-018-2516-6

Hussain, G.; Gao, L.; Zhang, Z.Y.: Formability evaluation of a pure titanium sheet in the cold incremental forming process. Int. J. Adv. Manuf. Technol. 37, 920–926 (2008). https://doi.org/10.1007/s00170-007-1043-7

Wang, J.; Li, L.; Zhou, P.; Wang, X.; Sun, S.: Improving formability of sheet metals in incremental forming by equal diameter spiral tool path. Int. J. Adv. Manuf. Technol. 101, 225–234 (2019). https://doi.org/10.1007/s00170-018-2911-z

Heidari, A.; Ghassemi, A.; Atrian, A.: A numerical and experimental investigation of temperature effects on the formability of AA6063 sheets using different ductile fracture criteria. Int. J. Adv. Manuf. Technol. 106, 2595–2611 (2020). https://doi.org/10.1007/s00170-019-04579-0

Wang, X.; Shi, J.: Validation of Johnson–Cook plasticity and damage model using impact experiment. Int. J. Impact Eng. 60, 67–75 (2013). https://doi.org/10.1016/j.ijimpeng.2013.04.010

Lesuer, D.: Experimental investigations of material models for Ti-6Al-4V Titanium and 2024-T3 Aluminum. U.S. Department of Transportation, Federal Aviation Administration. DOT/FAA/AR-00/25 (2000)

Jose, E.; Anto, T.: Analysis of tensile test of mild steel using finite element method. Int. J. Innov. Eng. Technol. 5, 247–251 (2015)

Haelsig, A.; Kusch, M.; Mayer, P.: New findings on the efficiency of gas shielded arc welding. Weld World 56, 98–104 (2012). https://doi.org/10.1007/BF03321400

Arul, S.; Sellamuthu, R.: Application of a simplified simulation method to the determination of arc efficiency of gas tungsten arc welding (GTAW) and experimental validation. Int. J. Comput. Mater. Sci. Surf. Eng. 4(3), 265–280 (2011)

Cantin, G.M.; Francis, J.A.: Arc power and efficiency in gas tungsten arc welding of aluminium. Sci. Technol. Weld. Join. 10(2), 200–210 (2005). https://doi.org/10.1179/174329305X37033

Nasiri, M.B.; Behzadinejad, M.; Latifi, H.; Martikainen, J.: Investigation on the influence of various welding parameters on the arc thermal efficiency of the GTAW process by calorimetric method. J. Mech. Sci. Technol. 28(8), 3255–3261 (2014). https://doi.org/10.1007/s12206-014-0736-8

Stenbacka, N.: On arc efficiency in gas tungsten arc welding. Soldag. Insp. 18(4), 380–390 (2013). https://doi.org/10.1590/S0104-92242013000400010

Balasubramanian, T.S.; Balakrishnan, M.; Balasubramanian, V.; Manickam, M.M.: Influence of welding processes on microstructure, tensile and impact properties of Ti–6Al–4V alloy joints. Trans. Nonferrous Met. Soc. 21(6), 1253–1262 (2011). https://doi.org/10.1016/S1003-6326(11)60850-9

Karpagaraj, A.; Shanmugam, N.S.; Sankaranarayanasamy, K.: Studies on mechanical behavior and microstructural analysis of tailor welded blanks of Ti–6Al–4V titanium alloy sheet. J. Mater. Res. 31(14), 2186–2196 (2016). https://doi.org/10.1557/jmr.2016.152

Caiazzo, F.; Curcio, F.; Daurelio, G.; Minutolo, F.M.C.: Ti6Al4V sheets lap and butt joints carried out by CO2 laser: mechanical and morphological characterization. J. Mater. Process. Technol. 149, 546–552 (2004). https://doi.org/10.1016/j.jmatprotec.2003.12.026

Giglio, M.; Manes, A.; Viganò, F.: Ductile fracture locus of Ti6Al4V titanium alloy. Int. J. Mech. Sci. 54, 121–135 (2012). https://doi.org/10.1016/j.ijmecsci.2011.10.003

Suresh, K.; Regalla, S.P.: Effect of mesh parameters in finite element simulation of single point incremental sheet forming process. Proc. Mater. Sci. 6, 376–382 (2014). https://doi.org/10.1016/j.mspro.2014.07.048

Panda, S.K.; Kumar, D.R.; Kumar, H.; Nath, A.K.: Characterization of tensile properties of tailor welded IF steel sheets and their formability in stretch forming. J. Mater. Process. Technol. 183(2–3), 321–332 (2007). https://doi.org/10.1016/j.jmatprotec.2006.10.035

Sorgente, D.; Palumbo, G.; Piccininni, A.; Guglielmi, P.; Tricarico, L.: Modelling the superplastic behaviour of the Ti6Al4V-ELI by means of a numerical/experimental approach. Int. J. Adv. Manuf. Technol. 90, 1–10 (2017). https://doi.org/10.1007/s00170-016-9235-7

Funding

Not applicable.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Karpagaraj, A., Rajesh Kumar, N., Sankaranarayanasamy, K. et al. Simulation and Experimental Studies on Arc Efficiency and Mechanical Characterization for GTA-Welded Ti–6Al–4V Sheets. Arab J Sci Eng 45, 9639–9650 (2020). https://doi.org/10.1007/s13369-020-04876-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13369-020-04876-x