Abstract

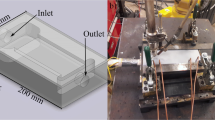

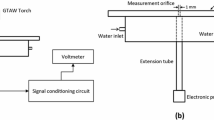

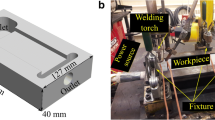

Arc efficiency of Gas Tungsten Arc Welding (GTAW) was determined by calorimetric method. A water-cooled anode calorimeter was designed and manufactured to measure the arc thermal efficiency, which was determined as a function of current, arc length, polarity and gas flow rate for GTAW of mild steel. With Direct Current Electrode Negative (DCEN) polarity and 5 mm arc length, a thermal efficiency of 67±4% was obtained, which was independent of the welding current. With Direct Current Electrode Positive (DCEP) polarity and 5 mm arc length, arc thermal efficiency was determined as 52±4%. The experimental data show that the arc efficiency decreases from 67% to 58% and 51% as the arc length increases from 5 mm to 11 and 17.5 mm, respectively. The experimental results also show that the arc efficiency is not significantly affected by the shielding gas flow rate.

Similar content being viewed by others

References

R. Komanduri and Z. B. Hou, Thermal analysis of the arc welding process: Part I. general solution, Metallurgical and Materials Transactions B, 31 (6) (2000) 1353–1370.

H. Y. Huang, Research on the activating flux gas tungsten arc welding and plasma arc welding for stainless steel, Metals and Materials International, 16 (5) (2010) 819–825.

V. Kamala and J. A. Goldak, Error due to two dimensional approximation in heat transfer analysis of welds, Welding Journal, 72 (9) (1993) 440–446.

E. Friedman, Thermomechanical analysis of the welding process using the finite element method, Journal of Pressure Vessel Technology, 97 (3) (1975) 206–213.

E. A. Bonifaz, Finite element analysis of heat flow in singlepass arc welds, Welding Journal, 79 (5) (2000) 121–125.

E. A. Bonifaz, Multiscale simulations in welds, Advances in Science and Engineering, 4 (2).(2012).C1–C5.

J. Goldak, A. Chakravarti and M. Bibby, A new finite element model for welding heat sources, Metallurgical Transactions B, 15 (2) (1984) 299–305.

V. Malin and F. Sciammarella, Controlling heat input by measuring net power, Welding Journal, 85 (7) (2006) 44–50.

G. M. D. Cantin and J. A. Francis, Arc power and efficiency in gas tungsten arc welding of aluminium, Science and Technolology of Welding & Joining, 10 (2) (2005) 200–210.

N. Pepe, S. Egerland, P. A. Colegrove, D. Yapp, A. Leonhartsberger and A. Scotti, Measuring the process efficiency of controlled gas metal arc welding processes, Science and Technolology of Welding & Joining, 16 (5) (2011) 412–417.

M. Jou, Experimental study and modeling of GTA welding process, Journal of Manufacturing Science and Engineering, 125 (4) (2003) 801–808.

N. S. Tsai and T. W. Eagar, Distribution of the heat and current fluxes in gas tungsten arcs, Metallurgical Transactions B, 16 (1985) 841–846.

C. S. Wu and J. Q. Gao, Analysis of the heat flux distribution at the anode of a TIG welding arc, Computational Materials Science, 24 (3) (2002) 323–327.

M. Ushio, D. Fan and M. Tanaka, Contribution of arc plasma radiation energy to electrodes, Transactions of the Japan Welding Research Institute, 22 (2) (1993) 201–207.

M. Tanaka, H. Terasaki, M. Ushio and J. J. Lowke, A unified numerical modeling of stationary tungsten inert gas welding process, Metallurgical and Materials Transactions A, 33 (7) (2002) 2043–2052.

W. H. Giedt, L. N. Tallerico and P. W. Fuerschbach, GTA welding efficiency: calorimetric and temperature field measurements, Welding Journal, 68 (1) (1989) 28–32.

P. W. Fuerschbach and G. A. Knorovsky, A study of melting efficiency in plasma arc and gas tungsten arc welding, Welding Journal, 70 (11) (1991) 287–297.

P. W. Fuerschbach and G. R. Eisler, Effect of laser spot weld energy and duration on melting and absorption, Science and Technology of Welding and Joining, 7 (4) (2002) 241–246.

R. R. Unocic and J. N. DuPont, Process efficiency measurements in the laser engineered net shaping (LENS) process, Metallurgical and Materials Transactions B, 35 (1) (2004) 143–152.

J. N. Dupont and A. R. Marder, Thermal efficiency of arc welding processes, Welding Journal, 74 (12) (1995) 406–416.

C. V. Goncalves, L. O. Vilarinho, A. Scotti and G. Guimaraes, Estimation of heat source and thermal efficiency in GTAW process by using inverse techniques, Journal of Materials Processing Technology, 172 (1) (2006) 42–51.

N. Christiansen, V. Davies and K. Gjermundsen, Distribution of temperatures in arc welding, British Welding Journal, 12 (2) (1965) 54–75.

S. Kou and Y. Le, Heat flow during the autogenous GTA welding of pipes, Metallurgical and Materials Transactions A, 15 (6) (1984) 1165–1171.

R. W. Niles and C. E. Jakson, Weld thermal efficiency of the GTAW process, Welding Journal, 54 (1) (1975) 25–32s.

S. Kou, Welding Metallurgy, Second Ed., John Wiley & Sons Inc., Hoboken, New Jersey, USA (2003).

T. W. Kerlin and R. L. Shepard, Industrial temperature measurement, Instrument Society of America, Philadelphia, USA (1982).

J. Hu and H. L. Tsai, Heat and mass transfer in gas metal arc welding. Part I: the arc, International Journal of Heat and Mass Transfer, 50 (5–6) (2007) 833–846.

J. F. Lancaster, The Physics of Welding, Pergamon Press, Oxford, UK (1986).

A. E. Guile, Studies of short electric arcs in transverse magnetic fields with application to arc welding, Welding in the World, 8 (1) (1970) 36–53.

K. Hiraoka, N. Sakuma and J. Zijp, Energy balance in argon-helium mixed gas tungsten (TIG) arcs. Study of characteristics of gas tungsten arc shielded by mixed gases (3rd report), Welding International, 12 (5) (1998) 372–379.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor Young Whan Park

Hamidreza Latifi received his M.Sc. degree in Mechanical Engineering from Lappeenranta University of Technology (LUT), Finland, in 2013. He is currently a Ph.D. candidate at the department of mechanical engineering and welding laboratory of Lappeenranta University of Technology. His research interests include materials science (composites and advanced ceramics) and welding technology (arc welding and adaptive welding).

Rights and permissions

About this article

Cite this article

Nasiri, M.B., Behzadinejad, M., Latifi, H. et al. Investigation on the influence of various welding parameters on the arc thermal efficiency of the GTAW process by calorimetric method. J Mech Sci Technol 28, 3255–3261 (2014). https://doi.org/10.1007/s12206-014-0736-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-014-0736-8