Abstract

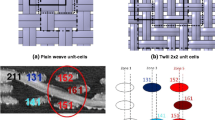

Different approaches used for the simulation of woven reinforcement forming are investigated. Especially several methods based on finite element approximation are presented. Some are based on continuous modelling, while others, called discrete or mesoscopic approaches, model the components of the fabric. A semi discrete finite element made of woven unit cells under biaxial tension and in-plane shear is detailed. In continuous approaches, the difficulty lies in the necessity to take the strong specificity of the fibrous material into account. The yarn directions must be strictly followed during the large strains of the fabric. This is the main goal of the non-orthogonal model and of the hypoelastic constitutive model based on the yarn rotation presented in this paper. In the case of discrete and semi-discrete approaches the directions of the yarns are “naturally” followed because the yarns are modeled. Explicitly, however, modeling each component at the mesoscopic scale can lead to high numerical cost.

Similar content being viewed by others

References

Mark C, Taylor HM (1956) The fitting of woven cloth to surfaces. J Text Inst 47:477–488

Van Der Ween F (1991) Algorithms for draping fabrics on doubly curved surfaces. Int J Numer Methods Eng 31:1414–1426

Long AC, Rudd CD (1994) A simulation of reinforcement deformation during the production of preform for liquid moulding processes. Proc Inst Mech Eng Part B J Eng Manuf 208:269–278

Cherouat A, Borouchaki H, Billoët JL (2005) Geometrical and mechanical draping of composite fabric. Eur J Comput Mech 14(6–7):693–708

Hsiao SW, Kikuchi N (1999) Numerical analysis and optimal design of composite thermoforming process. Comp Meth Appl Mech Eng 177:1–34

Spencer AJM (2000) Theory of fabric-reinforced viscous fluid. Compos Part A 31:1311–1321

Yu WR, Pourboghrat F, Chung K, Zamploni M, Kang TJ (2002) Non-orthogonal constitutive equation for woven fabric reinforced thermoplastic composites. Compos Part A 33:1095–1105

Xue P, Peng X, Cao J (2003) A non-orthogonal constitutive model for characterizing woven composites. Compos Part A 34:183–193

Peng X, Cao J (2005) A continuum mechanics-based non-orthogonal constitutive model for woven composite fabrics. Compos Part A 36:859–874

Hagège B, Boisse P, Billoët J-L (2005) Finite element analyses of knitted composite reinforcement at large strain. Eur J Comput Mech 14(6–7):767–776

Boisse P, Gasser A, Hagege B, Billoet JL (2005) Analysis of the mechanical behaviour of woven fibrous material using virtual tests at the unit cell level. Int J Mater Sci 40:5955–5962

Rogers TG (1989) Rheological characterisation of anisotropic materials. Composites 20:21–27

Ten Thije RHW, Akkerman R, Huetink J (2007) Large deformation simulation of anisotropic material using an updated Langrangian finite element method. Comput Methods Appl Mech Eng 196(33–34):3141–3150

Durville D (2002) Modélisation par éléments finis des propriétés mécaniques de structures textiles: de la fibre au tissu. Eur J Comput Mech 11(2–3–4):463–477

Sharma SB, Sutcliffe MPF (2004) A simplified finite element model for draping of woven material. Compos Part A 35:637–643

Pickett AK, Creech G, de Luca P (2005) Simplified and advanced simulation methods for prediction of fabric draping. Eur J Comput Mech 14(6–7):677–691

Duhovic M, Bhattacharyya D (2006) Simulating the deformation mechanisms of knitted fabric composites. Compos Part A 37–11:1897–1915

Ben Boubaker B, Haussy B, Ganghoffer JF (2007) Discrete models of woven structures. Macroscopic approach. Compos Part B 38:498–505

Boisse P, Zouari B, Gasser A (2005) A mesoscopic approach for the simulation of woven fibre composite forming. Compos Sci Technol 65:429–436

Boisse P, Zouari B, Daniel JL (2006) Importance of in-plane shear rigidity in finite element analyses of woven fabric composite performing. Compos Part A 37:2201–2212

Peng XQ, Cao J, Chen J, Xue P, Lussier DS, Liu L (2004) Experimental and numerical analysis on normalization of picture frame tests for composite materials. Compos Sci Tech 64:11–21

Jaumann G (1911) Geschlossenes system physikalischer und chemischer differentialgesetze. Sitzungsber Akad Wiss Wien 120:385–530

Dafalias YF (1983) Corotational rates for kinematic hardening at large plastic deformations. J Appl Mech 50:561–565

Crisfield MA (1991) Non-linear finite element analysis of solids and structures, II: Advanced topics. Wiley, New York

Green AE, Naghdi PM (1965) A general theory of an elastic–plastic continuum. Arch Ration Mech Anal 18:251–281

Dienes JK (1979) On the analysis of rotation and stress rate in deforming bodies. Acta Mech 32:217–232

Hagege B (2004) Simulation du comportement mécanique des milieux fibreux en grandes transformations: application aux renforts tricotés. Ph.D. Thesis, ENSAM Paris

Yu X, Ye L, Mai Y (2005) Spurious wrinkles in forming simulations of woven fabric. Int J Form Process 8/SI:141–155

ten Thije RHW, Akkerman R (2008) Solutions to intra-ply shear locking in finite element analyses of fibre reinforced materials, Compos Part A (in press)

Boisse P, Borr M, Buet K, Cherouat A (1997) Finite element simulation of textile composite forming including the biaxial fabric behaviour. Compos Part B 28:453–464

Buet-Gautier K, Boisse P (2001) Experimental analysis and modeling of biaxial mechanical behavior of woven composite reinforcements. Exp Mech 41(3):260–269

Lomov SV, Verpoest I (2006) Model of shear of woven fabric and parametric description of shear resistance of glass woven reinforcements. Compos Sci Technol 66:919–933

Launay J, Hivet G, Duong AV, Boisse P (2008) Experimental analysis of the influence of tensions on in plane shear. Compos Sci Technol 68:506–515

Badel P, Vidal-Sallé E, Boisse P (2007) Computational determination of in-plane shear mechanical behaviour of textile composite reinforcements. Comput Mater Sci 40(4):439–448

Hamila N, Boisse P (2007) A meso-macro three node finite element for draping of textile composite preforms. Appl Compos Mater 14:235–250

Numisheet’93 Numerical simulation of 3-D sheet metal forming processes—verification of simulation with experiments. Edited by Makinouchi A, Nakamachi E, Onate E, Wagoner RH, Japan (1993)

Dumont F (2003) Experimentations et modeles de comportement de renforts de composites tisses, Ph.D. Thesis, Paris VI University

Acknowledgements

The work reported here has been carried out in the scope of the project ITOOL (European Commission) and the National Science Foundation of US.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Boisse, P., Hamila, N., Helenon, F. et al. Different approaches for woven composite reinforcement forming simulation. Int J Mater Form 1, 21–29 (2008). https://doi.org/10.1007/s12289-008-0002-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12289-008-0002-7