Abstract

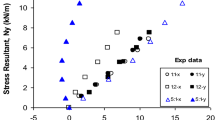

This paper presents experimental studies on the mechanical behavior of fiber fabrics using a biaxial tensile device based on two deformable parallelograms. The cross-shaped specimens are well adapted to fabrics because of their lack of shear stiffness. Tension versus deformation curves, for different strain ratios, are obtained in the case of composite woven reinforcements used in aeronautic applications. It is shown that the tensile behavior of the fabric is strongly nonlinear due to the weaving undulations and the yarn contraction, and that the phenomenon is clearly biaxial. A constitutive model is described and identified from the experimental data. The essential role played by the yarn crushing will be pointed out.

Similar content being viewed by others

References

Billoët, J.-L., Introduction aux matériaux composites à hautes performances, Tecknea (1993).

Gay, D., Matériaux composites, 4th ed., Hermès (1997).

Carronnier, D. and Gay, D., “Approche intégrée du RTM,” Revue des composites et des matériaux avancés,6,Hermès (1996).

Bickerton, S., Simacek, P., Guglielmi, S.E., andAdvani, S.G., “Investigation of Draping and Its Effects on the Mold Filling Process During Manufacturing of a Compound Curved Composite Part,”Composites: Part A,28A,801–816 (1997).

Li, H. andGutowski, T., “The Forming of Thermoset Composites,”Composite Sheet Forming, Composite Material Series,11,Elsevier,441–471 (1997).

Long, A.C., Blanchard, P.U., Rudd, C.D., andSmith, P., “The Development of an Integrated Process Model for Liquid Composite Moulding,”Composites: Part A,29A,847–854 (1998).

De Luca, P., Lefebure, P., Pickett, A.K., Vodermayer, A.M., and Werner, W., “The Numerical Simulation of Some Press Forming of Continuous Fiber Reinforced Thermoplastics,” Proceedings of the 28th International SAMPE Technical Conference, Seattle, WA (1996).

Astrom, B.T., “Thermoplastic Composite Sheet Forming: Materials and Manufacturing Techniques,”Composite Sheet Forming, Composite Material Series,11,Elsevier,27–73 (1997).

Wilks, C.E., Rudd, C.D., Long, A.C., and Johnson, C.F., “Rate Dependency During Processing of Glass/Thermoplastic Composites,” Proceedings of the 12th International Conference on Composite Materials (ICCM12), Paris, France (1999).

Bergsma, O.K. and Huisman, J., “Deep Drawing of Fabric Reinforced Thermoplastics,” Proceedings of the 2nd International Conference on Computer Aided Design in Composite Material Technology, Springer-Verlag, 323–333 (1988).

Van Der Ween, F., “Algorithms for Draping Fabrics on Doubly Curved Surfaces,”Int. J. Numeric. Meth. Eng.,31,1414–1426 (1991).

Long, A.C. andRudd, C.D., “A Simulation of Reinforcement Deformation During the Production of Preform for Liquid Moulding Processes,”Inst. Mech. Eng. J. Eng. Manufact.,208,269–278 (1994).

Boisse, P., Cherouat, A., Gelin, J.C., andSabhi, H., “Experimental Study and Finite Element Simulation of Glass Fiber Fabric Shaping Process,”Polymer Composites,16 (1),83–95 (1995).

Blanlot, R. and Billoet, J.L., “Simulation of the Shaping of Woven Fabrics,” Proceedings of ICCE/3, New Orleans, LA, 117–118 (1996).

Boisse, P., Borr, M., Buet, K., andCherouat, A., “Finite Element Simulation of Textile Composite Forming Including the Biaxial Fabric Behaviour,”Composites: Part B,28B,453–464 (1997).

Boisse, P., Daniel, J.L., Hivet, G., and Soulat, D., “A Simplified Explicit Approach for Simulations of Fibre Fabric Deformation During Manufacturing Preforms for R.T.M. Process,” Int. J. Forming Processes (2001).

Ishikawa, T. andChou, T., “Non-linear Behaviour of Woven Fabric Composites,”J. Composite Mat.,17,399–413 (1983).

Glaessgen, E.H., Pastore, C.M., Griffin, O.H., andBirger, A., “Geometrical and Finite Element Modeling of Textile Composites,”Composites: Part B,27B,43–50 (1996).

Lene, F., “Technique d'homogénéisation des composites à renforts tissés,”Mécanique Matériaux Electricité,433,24–28 (1990).

Paumelle, P., Hassim, A., andLene, F., “Les composites à renforts tissès: Calcul et étude paramétrée du comportement homogénéisé,”La Recherche Aérospatiale,1,1–12 (1990).

Ladevèze, P., Gasser, A., andAllix, O., “Damage Mechanisms Modeling for Ceramic Composites,”J. Eng. Mat. Tech.,116,331–336 (1994).

Kawabata, S., “Non-linear Mechanics of Woven and Knitted Materials,”Textile Structural Composites,3,ed. T.-W. Chou and F.K. Ko, Elsevier,67–116 (1989).

Realff, M.L., Boyce, M.C., andBacker, S., “A Micromechanical Approach to Modeling Tensile Behaviour of Woven Fabrics,”Use of Plastic and Plastic Composites: Materials and Mechanics Issues,46,285–293 (1993).

Sinoimeri, A. andDréan, J.-Y., “Mechanical Behaviour of the Plain Weave Structure Using Energy Methods: Fabric Uniaxial Extension,”Textile Res. J.,67,370–378 (1997).

Durville, D., “Modélisation du comportement mécanique des câbles métalliques,”Actes du 3rd colloque national en calcul des structures,1,Giens,139–144 (1997).

Boisse, P., Buet, K., Gasser, A., Hanklar, S., andLaunay, J., “Comportement mécanique biaxial des renforts composites tissés,”Mécanique Industrielle et Matériaux,50,140–144 (1997).

Boisse, P., Cherouat, A., Gelin, J.C., and Sabhi, H., “Fabrication de structures composites par le procédé R.T.M. simulation numérique de l'opération d'emboutissage,” Comptes rendus des 9th journées nationales sur les composites, Saint-Etienne, France, 95–104 (1994).

Cherouat, A., “Simulation numérique du préformage des tissus de fibres de verre par la méthode des E.F.,” Doctoral thesis, Université de Franche-Comté (1994).

Ferron, G., “Dispositif de traction biaxiale DAX2,” Documentation Techmetal, Mézières-Lès-Metz (1992).

Borr, M. and Boisse, P., “Détermination du comportement biaxial des tissue de fibres de verre: Mesure optique de la déformation,” Proceedings of Photomécanique95, Cachan, France, 187–194 (1995).

Kawabata, S., Niwa, M., andKawai, H., “The Finite Deformation Theory of Plain Weave Fabrics, Part 1,”J. Textile Inst.,64,21–83 (1973).

Buet-Gautier, K., “Analyse et simulation du comportement mécanique des renforts composites tissés,” Doctoral thesis, Université d'Orléans (1998).

Boisse, P., Buet-Gautier, K., Gasser, A., and Launay, J., “Mesomacro Mechanical Behaviour of Dry Fiber Fabrics,” 12th International Conference on Composites Materials, Paris, France (1999).

Gasser, A., Boisse, P., andHanklar, S., “Analysis of the Mechanical Behaviour of Dry Fabric Reinforcements: 3D Simulations Versus Biaxial Tests,”Comput. Mat. Sci.,17 (1),7–20 (2000).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Buet-Gautier, K., Boisse, P. Experimental analysis and modeling of biaxial mechanical behavior of woven composite reinforcements. Experimental Mechanics 41, 260–269 (2001). https://doi.org/10.1007/BF02323143

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF02323143