Abstract

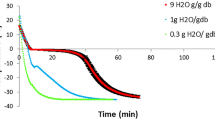

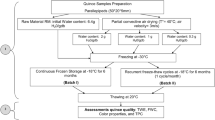

The present study deals with the dehydrofreezing of apples. Fresh samples (700 % db) and samples dehydrated up to different water contents (200, 100, and 30 % db) were frozen at high practical freezing rate (PFR+) and low practical freezing rate (PFR−). The effects of water content (W) and practical freezing rate (PFR) were investigated in terms of freezing characteristics: initial freezing temperature (IFT), practical freezing time (PFT), specific freezing time (SFT), thaw exudate water (TEW), and texture (maximum puncture force as index of firmness). Only high W samples (700 and 200 % db) had a significant impact of PFR in terms of PFT, SFT, and TEW. IFT decreased sharply with the decrease in the sample W. PFT greatly depended on PFR for fresh apples. PFT varied from 86 to 329 min for fresh apples at PFR+ and PFR−, respectively, whereas it was lower than 32 min for samples with W = 30 % db. SFT decreased, equally, with sample W decrease. The TEW of fresh frozen samples, during thawing, was approximately 12 g/100 g water for low PFR (PFR−), whereas it was lower than 3 g/100 g water for samples with W = 200 % db at the same PFR. Moreover, the impact of PFR on TEW was significant and very important for high W samples. Finally, the firmness increased when W decreased for both PFR+ and PFR−. Nevertheless, an insignificant impact of PFR on apple firmness was found. Thus, partial removal of water constitutes a promising solution to prevent the negative impacts of freezing on apple fruit firmness.

Similar content being viewed by others

Abbreviations

- IFT:

-

Initial freezing temperature °C

- F :

-

Maximum puncture force N

- PFR:

-

Practical freezing rate °C/min

- PFR+ :

-

High practical freezing rate °C/min

- PFR− :

-

Low practical freezing rate °C/min

- PFT:

-

Practical freezing time min

- SFT:

-

Specific freezing time min

- TEW:

-

Thaw exudate water g/100 g water

- W :

-

Water content (% db)

References

Agnelli, M. E., Marani, C. M., & Mascheroni, R. H. (2005). Modelling of heat and mass transfer during (osmo) dehydrofreezing of fruits. Journal of Food Engineering, 69(4), 415–424. doi:10.1016/j.jfoodeng.2004.08.034.

Ando, H., Kajiwara, K., Oshita, S., & Suzuki, T. (2012). The effect of osmotic dehydrofreezing on the role of the cell membrane in carrot texture softening after freeze-thawing. Journal of Food Engineering, 108(3), 473–479. doi:10.1016/j.jfoodeng.2011.08.013.

AOAC (1990). Association of official analytical chemists (15th edn). In 567 K. Helrich (Ed.). Arlington: Virginia 22201, USA.

Ben Ammar, J., Lanoisellé, J.-L., Lebovka, N., Van Hecke, E., & Vorobiev, E. (2010). Effect of a pulsed electric field and osmotic treatment on freezing of potato tissue. Food Biophysics, 5(3), 247–254. doi:10.1007/s11483-010-9167-y.

Ben Haj Said, L., Bellagha, S., & Allaf, K. (2015a). Optimization of instant controlled pressure drop (DIC)-assisted dehydrofreezing using mechanical texture measurements versus initial water content of apple. Food and Bioprocess Technology, 8(5), 1102–1112.

Ben Haj Said, L., Bellagha, S., & Allaf, K. (2015b). Measurements of texture, sorption isotherms and drying/rehydration kinetics of dehydrofrozen-textured apple. Journal of Food Engineering, 165, 22–33.

Biswal, R. N., Bozorgmehr, K., Tompkins, F. D., & Liu, X. (1991). Osmotic concentration of green beans prior to freezing. Journal of Food Science, 56(4), 1008–1012. doi:10.1111/j.1365-2621.1991.tb14628.x.

Blanda, G., Cerretani, L., Cardinali, A., Barbieri, S., Bendini, A., & Lercker, G. (2009). Osmotic dehydrofreezing of strawberries: polyphenolic content, volatile profile and consumer acceptance. LWT - Food Science and Technology, 42(1), 30–36. doi:10.1016/j.lwt.2008.07.002.

Bolin, H. R., & Huxsoll, C. C. (1993). Partial drying of cut pears to improve freeze/thaw texture. Journal of Food Science, 58(2), 357–360. doi:10.1111/j.1365-2621.1993.tb04274.x.

Bunger, A., Moyano, P., Vega, R., Guerrero, P., & Osorio, F. (2004). Osmotic dehydration and freezing as combined processes on apple preservation. Food Science and Technology International, 10(3), 163–170.

Chen, L., & Opara, U. L. (2013). Approaches to analysis and modeling texture in fresh and processed foods—a review. Journal of Food Engineering, 119(3), 497–507. doi:10.1016/j.jfoodeng.2013.06.028.

Chiralt, A., Martínez-Navarrete, N., Martínez-Monzó, J., Talens, P., Moraga, G., Ayala, A., et al. (2001). Changes in mechanical properties throughout osmotic processes: cryoprotectant effect. Journal of Food Engineering, 49(2–3), 129–135. doi:10.1016/S0260-8774(00)00203-X.

Delgado, A., & Rubiolo, A. (2005). Microstructural changes in strawberry after freezing and thawing processes. LWT--Food Science and Technology, 38(2), 135–142.

Dermesonlouoglou, E. K., Giannakourou, M. C., & Taoukis, P. (2007). Stability of dehydrofrozen tomatoes pretreated with alternative osmotic solutes. Journal of Food Engineering, 78(1), 272–280. doi:10.1016/j.jfoodeng.2005.09.026.

Dermesonlouoglou, E. K., Pourgouri, S., & Taoukis, P. S. (2008). Kinetic study of the effect of the osmotic dehydration pre-treatment to the shelf life of frozen cucumber. Innovative Food Science & Emerging Technologies, 9(4), 542–549. doi:10.1016/j.ifset.2008.01.002.

Floury, J., Le Bail, A., & Pham, Q. T. (2008). A three-dimensional numerical simulation of the osmotic dehydration of mango and effect of freezing on the mass transfer rates. Journal of Food Engineering, 85(1), 1–11. doi:10.1016/j.jfoodeng.2007.06.011.

Forni, E., Sormani, A., Scalise, S., & Torreggiani, D. (1997). The influence of sugar composition on the colour stability of osmodehydrofrozen intermediate moisture apricots. Food Research International, 30(2), 87–94. doi:10.1016/S0963-9969(97)00038-0.

Giannakourou, M. C., & Taoukis, P. S. (2003). Stability of dehydrofrozen green peas pretreated with nonconventional osmotic agents. Journal of Food Science, 68(6), 2002–2010. doi:10.1111/j.1365-2621.2003.tb07009.x.

Goni, O., Munoz, M., Ruiz-Cabello, J., Escribano, M. I., & Merodio, C. (2007). Changes in water status of cherimoya fruit during ripening. Postharvest Biology and Technology, 45(1), 147–150.

Goula, A. M., & Lazarides, H. N. (2012). Modeling of mass and heat transfer during combined processes of osmotic dehydration and freezing (osmo-dehydro-freezing). Chemical Engineering Science, 82, 52–61. doi:10.1016/j.ces.2012.07.023.

Hsieh, R. C., Lerew, L. E., & Heldman, D. R. (1977). Prediction of freezing times for foods as influenced by product properties. Journal of Food Process Engineering, 1(2), 183–197. doi:10.1111/j.1745-4530.1977.tb00177.x.

Huang, L. L., Zhang, M., Wang, L.-P., Mujumdar, A. S., & Sun, D.-F. (2012). Influence of combination drying methods on composition, texture, aroma and microstructure of apple slices. LWT - Food Science and Technology, 47(1), 183–188. doi:10.1016/j.lwt.2011.12.009.

Ilicali, C., & Icier, F. (2010). Freezing time prediction for partially dried papaya puree with infinite cylinder geometry. Journal of Food Engineering, 100(4), 696–704. doi:10.1016/j.jfoodeng.2010.05.022.

James, C., Purnell, G., & James, S. (2014). A critical review of dehydrofreezing of fruits and vegetables. Food and Bioprocess Technology, 7(5), 1219–1234. doi:10.1007/s11947-014-1293-y.

Li, B., & Sun, D.-W. (2002). Novel methods for rapid freezing and thawing of foods—a review. Journal of Food Engineering, 54(3), 175–182. doi:10.1016/S0260-8774(01)00209-6.

Lowithun, N., & Charoenrein, S. (2009). Influence of osmodehydrofreezing with different sugars on the quality of frozen rambutan. International Journal of Food Science and Technology, 44(11), 2183–2188. doi:10.1111/j.1365-2621.2009.02058.x.

Maestrelli, A., Lo Scalzo, R., Lupi, D., Bertolo, G., & Torreggiani, D. (2001). Partial removal of water before freezing: cultivar and pre-treatments as quality factors of frozen muskmelon (Cucumis melo, cv reticulatus Naud.). Journal of Food Engineering, 49(2–3), 255–260. doi:10.1016/S0260-8774(00)00211-9.

Marani, C. M., Agnelli, M. E., & Mascheroni, R. H. (2007). Osmo-frozen fruits: mass transfer and quality evaluation. Journal of Food Engineering, 79(4), 1122–1130. doi:10.1016/j.jfoodeng.2006.03.022.

Moraga, G., MartÍNez-Navarrete, N., & Chiralt, A. (2006). Compositional changes of strawberry due to dehydration, cold storage and freezing-thawing processes. Journal of Food Processing and Preservation, 30(4), 458–474. doi:10.1111/j.1745-4549.2006.00079.x.

Neri, L., Hernando, I., Pérez-Munuera, I., Sacchetti, G., Mastrocola, D., & Pittia, P. (2014). Mechanical properties and microstructure of frozen carrots during storage as affected by blanching in water and sugar solutions. Food Chemistry, 144, 65–73. doi:10.1016/j.foodchem.2013.07.123.

Ohnishi, S., & Miyawaki, O. (2005). Osmotic dehydrofreezing for protection of rheological properties of agricultural products from freezing-injury. Food Science and Technology Research, 11(1), 52–58. doi:10.3136/fstr.11.52.

Pham, Q. T. (2014). Freezing time formulas for foods with low moisture content, low freezing point and for cryogenic freezing. Journal of Food Engineering, 127, 85–92.

Ramallo, L. A., & Mascheroni, R. H. (2010). Dehydrofreezing of pineapple. Journal of Food Engineering, 99(3), 269–275. doi:10.1016/j.jfoodeng.2010.02.026.

Rincon, A., & Kerr, W. L. (2010). Influence of osmotic dehydration, ripeness and frozen storage on physicochemical properties of mango. Journal of Food Processing and Preservation, 34(5), 887–903. doi:10.1111/j.1745-4549.2009.00404.x.

Robbers, M., Singh, R. P., & Cunha, L. M. (1997). Osmotic-convective dehydrofreezing process for drying kiwifruit. Journal of Food Science, 62(5), 1039–1042. doi:10.1111/j.1365-2621.1997.tb15033.x.

Sirijariyawat, A., & Charoenrein, S. (2012). Freezing characteristics and texture variation after freezing and thawing of four fruit types. Songklanakarin Journal of Science & Technology, 34(5).

Sobral, P., Telis, V., Habitante, A., & Sereno, A. (2001). Phase diagram for freeze-dried persimmon. Thermochimica Acta, 376(1), 83–89.

Sormani, A., Maffi, D., Bertolo, G., & Torreggiani, D. (1999). Textural and structural changes of dehydrofreeze-thawed strawberry slices: Effects of different dehydration pretreatments / Cambiostexturales y estructurales de rodajas de fresadeshidratadas y descongeladas: Efectos de diferentespretratamientos de deshidratación. Food Science and Technology International, 5(6), 479–485. doi:10.1177/108201329900500605.

Talens, P., Martínez-Navarrete, N., Fito, P., & Chiralt, A. (2002). Changes in optical and mechanical properties during osmodehydrofreezing of kiwi fruit. Innovative Food Science & Emerging Technologies, 3(2), 191–199. doi:10.1016/S1466-8564(02)00027-9.

Tregunno, N. B., & Goff, H. D. (1996). Osmodehydrofreezing of apples: structural and textural effects. Food Research International, 29(5–6), 471–479. doi:10.1016/S0963-9969(96)00056-7.

Uemura, T., & Tagawa, A. (2012). Effect of dehydration method on the physical properties of fresh-cut radish after freezing and after post-thaw rehydration in the dehydro-freezing technique. Nippon Shokuhin Kagaku KogakuKaishi, 59(3), 115–121. doi:10.3136/nskkk.59.115.

Vega-Gálvez, A., Ah-Hen, K., Chacana, M., Vergara, J., Martínez-Monzó, J., García-Segovia, P., et al. (2012). Effect of temperature and air velocity on drying kinetics, antioxidant capacity, total phenolic content, colour, texture and microstructure of apple (var. Granny Smith) slices. Food Chemistry, 132(1), 51–59. doi:10.1016/j.foodchem.2011.10.029.

Wu, L., Orikasa, T., Tokuyasu, K., Shiina, T., & Tagawa, A. (2009). Applicability of vacuum-dehydrofreezing technique for the long-term preservation of fresh-cut eggplant: effects of process conditions on the quality attributes of the samples. Journal of Food Engineering, 91(4), 560–565. doi:10.1016/j.jfoodeng.2008.10.021.

Wu, B., Pan, Z., Qu, W., Wang, B., Wang, J., & Ma, H. (2014). Effect of simultaneous infrared dry-blanching and dehydration on quality characteristics of carrot slices. LWT - Food Science and Technology, 57(1), 90–98. doi:10.1016/j.lwt.2013.11.035.

Xie, J., & Zhao, Y. (2004). Use of vacuum impregnation to develop high quality and nutritionally fortified frozen strawberries. Journal of Food Processing and Preservation, 28(2), 117–132.

Zhao, J. H., Hu, R., Xiao, H. W., Yang, Y., Liu, F., Gan, Z. L., & Ni, Y. Y. (2014). Osmotic dehydration pretreatment for improving the quality attributes of frozen mango: effects of different osmotic solutes and concentrations on the samples. International Journal of Food Science and Technology, 49, 960–968.

Zhao, J. H., Liu, F., Wen, X., Xiao, H. W., & Ni, Y. Y. (2015). State diagram for freeze-dried mango: freezing curve, glass transition line and maximal-freeze-concentration condition. Journal of Food Engineering, 157, 49–56.

Zhu, Y., Pan, Z., McHugh, T. H., & Barrett, D. M. (2010). Processing and quality characteristics of apple slices processed under simultaneous infrared dry-blanching and dehydration with intermittent heating. Journal of Food Engineering, 97(1), 8–16.

Acknowledgments

This research was supported by a scholarship from the Ministry of Higher Education and Scientific Research of Tunisia.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ben Haj Said, L., Bellagha, S. & Allaf, K. Dehydrofreezing of Apple Fruits: Freezing Profiles, Freezing Characteristics, and Texture Variation. Food Bioprocess Technol 9, 252–261 (2016). https://doi.org/10.1007/s11947-015-1619-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-015-1619-4