Abstract

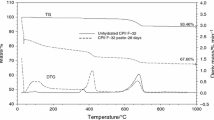

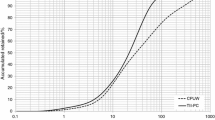

Although the literature presents intensive studies based on monitoring cement hydration in adiabatic and semi-adiabatic environments, such as non-conventional differential thermal analysis (NCDTA) systems, studies of cement hydration in controlled climatic chambers are very rare. Using three W/C ratios (0.5, 0.6 and 0.7) and three relative humidity conditions (60, 80 and 100%) at 25 °C, the authors analyzed in real time the evolution of cement hydration reaction during the first 24 h in an environmental-controlled chamber. The main objective of this paper is to present two new developed systems of NCDTA (NNCDTA) and non-conventional TG and to show, using high-strength sulfate-resistant Portland cement pastes in a controlled chamber as application examples, how the developed systems measure on real time the thermal effects and the mass changes that occur during hydration and carbonation reactions. The captured CO2 mass can be quantified as it occurs by carbonation curves. The results are in agreement with the mechanical and structural properties of the used pastes and with their TG/DTG data, after being processed by different operational conditions. Carbonation for 24 h alters significantly the cement hydrated paste composition, resulting in final poor mechanical resistance properties. However, carbonation for 1 h, in specific conditions, enhances them when compared to a non-carbonated reference paste, due to a final higher content of silica and alumina hydrated phases and to a lower mass ratio between that of their combined water and their total mass as well.

Similar content being viewed by others

Notes

Patent pending.

References

Ge Z, Wang K, Sandberg PJ, Ruiz JM. Characterization and performance prediction of cement-based materials using a simple isothermal calorimeter. J Adv Concr Technol. 2009;7(3):355–66.

Pang X, Bentz DP, Meyer C, Funkhouser GP, Darbe R. A comparison study of Portland cement hydration kinetics as measured by chemical shrinkage and isothermal calorimetry. Cem Concr Compos. 2013;39:23–32.

Garcia LI, Fernandez JA, Paloma A. Hydration kinetics in hydrid binders: early reaction stages. Cem Concr Compos. 2013;39:82–92.

Melchert MBM, Viana MM, Lemos MS, Dweck J, Büechler PM. Simultaneous solidification of two catalyst wastes and their effect on the early stages of cement hydration. J Therm Anal Calorim. 2011;105(2):625–33.

Chaipanich A, Nochaiya T. Thermal analysis and microstructure of Portland cement-fly ash-silica fume pastes. J Therm Anal Calorim. 2010;99(2):487–93.

Dweck J, Buchler PM, Coelho ACV, Cartledge FK. Hydration of a Portland cement blended with calcium carbonate. Thermochim Acta. 2000;346:105–13.

Gruyaert E, Robeyst N, De BN. Study of the hydration of Portland cement blended with blast-furnace slag by calorimetry and thermogravimetry. J Therm Anal Calorim. 2010;102(3):941–51.

Shao Y, Mirza MS, Wu X. CO2 sequestration using calcium-silicate concrete. Can J Civ Eng. 2006;33:776.

Shao Y, Monkman S, Boyd AJ. Recycling carbon dioxide into concrete: a feasibility study. Concrete sustainability conference. McGill University, Department of Civil Engineering, Canadá; 2010.

Shao Y, Zhou X, Monkman S. A new CO2 sequestration process via concrete products production. Montreal: Department of Civil Engineering, McGill University; 2006.

Neves Junior A, Dweck J, Toledo Filho RD, FairBairn EMR. CO2 sequestration by high initial strength Portland cement pastes. J Therm Anal Calorim. 2013;113:1577–84.

Neves Junior A, Dweck J, Toledo Filho RD, FairBairn EMR. A study of the carbonation profile of cement pastes by thermogravimetry and its effect on the compressive strength. J Therm Anal Calorim. 2013;116:69–79.

Rostami V, Shao Y, Boyd AJ. Microstructure of cement paste subject to early carbonation curing. Cem Concr Res. 2012;42(1):186–93.

Neves Junior A, Lemos MS, Dweck J, Toledo Filho RD, FairBairn EMR. Early stages hydration of high initial strength Portland cement—Part II—NCDTA and Vicat analysis. J Therm Anal Calorim. 2013;113:659–65.

Brazilian Association of Technical Standards. High initial strength Portland cement. NBR 5733. Rio de Janeiro. 1991.

Brazilian Association of Technical Standards. Moderate sulphate resistance Portland cement and moderate hydration heat (MRS) and high sulphate resistance NBR 5737. Rio de Janeiro. 1986.

Neves Junior A, Dweck J, Toledo Filho RD, FairBairn EMR. Early stages hydration of high initial strength Portland cement—Part I—thermogravimetric analysis on calcined mass basis. J Therm Anal Calorim. 2012;108:725–31.

ASTM Standard G 40-95. Standard terminology relating to wear and erosion. ASTM International.

TA Instruments—TGA 500 Thermogravimetric analyzer. 2013. http://www.egr.msu.edu/cmsc/equipment/ta-instruments-tga-500. Accessed 20 Oct 2015.

TA Instruments—Symultaneous Q600 TGA/DSC equipment. 2013. http://eqdb.nrf.ac.za/equipment/ta-instruments-sdt-q600-thermogravimetric-analyser-differential-scanning-calorimeter-tga. Accessed 20 Oct 2015.

Mettler Toledo—Symultaneous TGA/DSC1 analyzer. 2013. http://www.azom.com/equipament-detais.aspx?EquipID=642. Accessed 20 Oct 2015.

Neves Junior A, Dweck J, Toledo Filho RD, FairBairn EMR. The effects of the early carbonation curing on the mechanical and porosity properties of high initial strength Portland cement pastes. Constr Build Mater. 2015;77:448–54.

Acknowledgements

The authors acknowledge the experimental assistance of the Federal University of Rio de Janeiro, School of Chemistry, the Thermal Analysis and Civil Engineering Structure Laboratories and the financial support of the National Research Council (CNPq).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Neves Junior, A., Toledo Filho, R.D., Dweck, J. et al. A study of CO2 capture by high initial strength Portland cement pastes at early curing stages by new non-conventional thermogravimetry and non-conventional differential thermal analysis. J Therm Anal Calorim 129, 1341–1352 (2017). https://doi.org/10.1007/s10973-017-6326-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-017-6326-0