Abstract

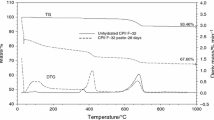

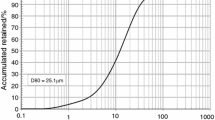

In a previous work, the authors have carbonated totally high initial strength and sulfate-resistant Portland cement pastes. In order to solve the mechanical problems caused by the intense carbonation that occurred during those experiments, new carbonation conditions were applied in this study. The obtained products were analyzed with respect to the carbonation reactions by thermogravimetry and compressive mechanical strength. Comparative analysis with reference pastes obtained without carbonation at the same age shows that CO2 capture increases with carbonation time. However, there is an optimum time, up to which the carbonation treatment does not affect the mechanical properties of the paste. Below this time, the lower is the carbonation time the higher is the increase of compressive strength, when compared to that of the reference pastes processed at same operating conditions without carbonation.

Similar content being viewed by others

References

Shao Y, Mirza MS, Wu X. CO2 sequestration using calcium–silicate concrete. Can J Civ Eng. 2006;33:776.

Shao Y, Zhou X, Monkman S. A new CO2 sequestration process via concrete products production. Montreal: Department of Civil Engineering, McGill University; 2006.

Shao Y, Monkman S, Wang S. Market analysis of CO2 sequestration in concrete building products. Second international conference on sustainable construction materials and technologies. Italy: Ancona; 2010. p. 28–30 June.

Shao Y, Monkman S, Boyd AJ. Recycling carbon dioxide into concrete: a feasibility study. Concrete sustainability conference. Canada: McGill University, Department of Civil Engineering; 2010.

Habert G, Roussel N. Study of two concrete mix-design strategies to reach carbon mitigation objectives. Cem Conc Comp. 2009;31:397–402.

Rostami V, Shao Y, Boyd AJ. Microstructure of cement paste subject to early carbonation curing. Cem Concr Res. 2012;42(1):186–93.

Li Y, Liu H, Wu S, Sun R, Lu C. Sulfation behavior of CaO from long-term carbonation/calcination cycles for CO2 capture at FBC temperatures. J Therm Anal Calorim. 2013;111:1335–43.

Tejeda AR, Pfeiffer H. α–γ Lithium borate phase transition produced during the CO2 chemisorption process. J Therm Anal Calorim. 2012;110:807–11.

Neves Junior A, Dweck J, Toledo Filho RD, FairBairn EMR. CO2 sequestration by high initial strength Portland cement pastes. J Therm Anal Calorim. 2013;113:1577–84.

Brazilian Association of Technical Standards. High initial strength Portland cement. NBR 5733. Rio de Janeiro. 1991.

Brazilian Association of Technical Standards. Moderate sulphate resistance Portland cement and moderate hydration heat (MRS) and high sulphate resistance NBR 5737. Rio de Janeiro. 1986.

Brazilian Association of Technical Standards. Concrete—compressive testing of cylindrical specimens. Rio de Janeiro. 1994.

Neves Junior A, Dweck J, Toledo Filho RD, FairBairn EMR. Early stages hydration of high initial strength Portland cement—Part I—thermogravimetric analysis on calcined mass basis. J Therm Anal Calorim. 2012;108:725–31.

Dweck J, Buchler PM, Coelho ACV. Hydration of a Portland cement blended with calcium carbonate. Therm Acta. 2000;346:105–13.

Dweck J, Cunha ALC, Pinto CA. Thermogravimetry on calcined mass basis—hydrated cement phases and pozzolanic activity quantitative analysis. J Therm Anal Calorim. 2009;97:85–9.

Dweck J, Silva PFF, Buchler PM, Cartledge FK. Study by thermogravimetry of the evolution of ettringite phase during type II Portland cement hydration. J Therm Anal Calorim. 2002;69:179–86.

Cong X, Kirkpatrick RJ. Effects of the temperature and relative humidity on the structure of C–S–H gel. Cem Concr Res. 1995;25(6):1237–45.

Acknowledgements

The authors acknowledge the experimental assistance of the Rio de Janeiro Federal University Chemical School Thermal Analysis and Civil Engineering Structure Laboratories and the financial support of the National Research Council (CNPq).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Neves Junior, A., Filho, R.D.T., Fairbairn, E.M.R. et al. A study of the carbonation profile of cement pastes by thermogravimetry and its effect on the compressive strength. J Therm Anal Calorim 116, 69–76 (2014). https://doi.org/10.1007/s10973-013-3556-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-013-3556-7