Abstract

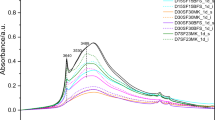

The hydration of ordinary Portland cement (OPC) blended with blast-furnace slag (BFS) is a complex process since both materials have their own reactions which are, however, influenced by each other. Moreover, the effect of the slag on the hydration process is still not entirely known and little research concerning the separation of both reactions can be found in the literature. Therefore, this article presents an investigation of the hydration process of mixes in which 0–85% of the OPC is replaced by BFS. At early ages, isothermal, semi-adiabatic and adiabatic calorimetric measurements were performed to determine the heat of hydration. At later ages, thermogravimetric (TG) analyses are more suitable to follow up the hydration by assessment of the bound water content w b. In addition, the microstructure development was visualized by backscattered electron (BSE) microscopy. Isothermal calorimetric test results show an enhancement of the cement hydration and an additional hydration peak in the presence of BFS, whilst (semi-)adiabatic calorimetric measurements clearly indicate a decreasing temperature rise with increasing BFS content. Based on the cumulative heat production curves, the OPC and BFS reactions were separated to determine the reaction degree Q(t)/Q ∞ (Q = cumulative heat production) of the cement, slag and total binder. Moreover, thermogravimetry also allowed to calculate the reaction degree by w b(t)/w b∞. The reaction degrees w b(t)/w b∞, Q(t)/Q ∞ and the hydration degrees determined by BSE-image analysis showed quite good correspondence.

Similar content being viewed by others

References

Mostafa NY, Brown PW. Heat of hydration of high reactive pozzolans in blended cements: isothermal conduction calorimetry. Thermochim Acta. 2005;435:162–7.

Shi C, Dau RL. Some factors affecting early hydration of alkali-slag cements. Cem Concr Res. 1999;26:439–47.

Zhou J, Ye G, Van Breugel K. Hydration of Portland cement blended with blast furnace slag at early age. In: Marchand J, Bissonnette B, Gagné R, Jolin M, Paradis F, editors. Second International Symposium on Advances in Concrete through Science and Engineering. Québec; 2006.

Wadsö L. Using isothermal (heat conduction) calorimetry to study the effect of mixing intensity on reaction rate of cement mortars. In: Beadoin JJ, Makar JM, Raki L, editors. 12th International Congress on the Chemistry of Cement. Montréal; 2007.

Evju C. Initial hydration of cementitious systems using a simple isothermal calorimeter and dynamic correction. J Therm Anal Calorim. 2003;71:829–40.

Schindler AK, Folliard KJ. Influence of supplementary cementing materials on the heat of hydration of concrete. In: Ninth Conference on Advances in Cement and Concrete. Colorado; 2003.

Bensted J. Some application of conduction calorimetry to cement hydration. Adv Cem Res. 1987;1:35–44.

Baert G. Physico-chemical interactions in Portland cement-(high volume) fly ash binders. Ghent: Ghent University. PhD; 2009.

Taylor H. Cement chemistry. 2nd ed. London: Thomas Telford Publishing; 1997.

Hewlett PC. Lea’s chemistry of cement and concrete. London: Elsevier; 1998.

Meinhard K, Lackner R. Multi-phase hydration model for prediction of hydration-heat release of blended cements. Cem Concr Res. 2008;38:794–802.

Song S, Sohn D, Jennings HM, Mason TO. Hydration of alkali-activated ground granulated blast-furnace slag. J Mater Sci. 2000;35:249–57.

Neville AM. Properties of concrete. Essex: Longmen; 1995.

De Schutter G, Taerwe L. General hydration model for Portland cement and blast furnace slag cement. Cem Concr Res. 1995;25:593–604.

Bougara A, Lynsdale C, Milestone NB. Reactivity and performance of blast-furnace slags of different origin. Cem Concr Compos. 2010;32:319–24.

Escalante-Garcia JI, Sharp JH. The chemical composition and microstructure of hydration products in blended cements. Cem Concr Compos. 2004;26:967–76.

Singh NB, Bhattacharjee KN, Shukla AK. Hydration of Portland blended cements. Cem Concr Res. 1995;25:1023–30.

Escalante-Garcia JI, Sharp JH. Effect of temperature on the hydration of the main clinker phases in Portland cements: Part II, blended cements. Cem Concr Res. 1998;28:1259–74.

Stark J, Möser B, Bellmann F. Nucleation and growth of C–S–H phases on mineral admixtures. In: Grosse CU, editor. Advances in construction materials. Berlin: Springer; 2007. p. 231–538.

D’Aloia L, Chanvillard G. Determining the “apparent” activation energy of concrete: Ea-numerical simulations of the heat of hydration of cement. Cem Concr Res. 2002;32:1277–89.

Pane I, Hansen W. Investigation of blended cement hydration by isothermal calorimetry and thermal analysis. Cem Concr Res. 2005;35:1155–64.

De Schutter G. Hydration and temperature development of concrete made with blast-furnace slag cement. Cem Concr Res. 1999;29:143–9.

Baert G, Hoste S, De Schutter G, De Belie N. Reactivity of fly ash in cement paste studied by means of thermogravimetry and isothermal calorimetry. J Therm Anal Calorim. 2008;94:485–92.

Robeyst N. Monitoring setting and microstructure development in fresh concrete with the ultrasonic through-transmission method. Ghent: Ghent University. PhD; 2009.

Copeland LE, Kantro DL. Chemistry of hydration of Portland cement. In: Symposium on the Chemistry of Cement. Washington: Cement and Concrete Association; 1960. p. 429.

Chen W. Hydration of slag cement—theory, modeling and application. Enschede: University of Twente. PhD; 2006.

Mills RH. Factors influencing cessation of hydration in water-cured cement pastes. In: Board HR, editor. Symposium on the Structure of Portland Cement Paste and Concrete. Washington, D.C.; 1966. p. 406.

Acknowledgements

As Research Assistants of the Research Foundation—Flanders (FWO-Vlaanderen), the authors Elke Gruyaert and Nicolas Robeyst want to thank the foundation for the financial support. Moreover, this study was supported in part by grant no. BOF/B/05928/01 from the Universtiy of Ghent (BOF—Bijzonder Onderzoeksfonds).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gruyaert, E., Robeyst, N. & De Belie, N. Study of the hydration of Portland cement blended with blast-furnace slag by calorimetry and thermogravimetry. J Therm Anal Calorim 102, 941–951 (2010). https://doi.org/10.1007/s10973-010-0841-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-010-0841-6