Abstract

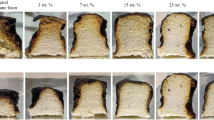

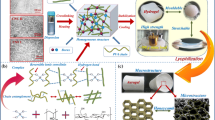

Nanotechnology applied to polymer foams is an emerging field, because even at low filler contents, different cellular morphologies can be obtained in the development of foams. Based on these premises, this work addresses the development of poly(ethylene-co-vinyl acetate)—EVA foams reinforced with two types of nanocellulose (a) short fibers (NC), and (b) long fibers (NCF). The foams were expanded in an autoclave with supercritical carbon dioxide (CO2). Different expansion conditions were evaluated, with variations of temperature and pressure. The main results indicate that the presence of the fibers significantly reduces the size of the cells and increase the number of cells per unit area. However, by increasing the NC content, nanocellulose fibers agglomeration is observed, resulting in the formation of a bimodal cellular structure.

Similar content being viewed by others

References

Trone JL (1996) Thermoplastics Foams. Ed. Publishing company, Sherwood

Eaves D (2004) Handbook of polymer Foams. Ed. Rapra Technology, UK

Li Q, Matuana LM (2003) Foam extrusion of high density polyethylene/wood-flour composites using chemical foaming agents. J Appl Polym Sci 88:3139–3150. doi:10.1002/app.12003

Bledzki AK, Faruk O (2006) Microcellular injection molded wood fiber PP composites: part I—effect of chemical foaming agent content on cell morphology and physico-mechanical properties. Cell. Plast. 41:63–76. doi:10.1177/0021955X06060945

Bledzki AK, Faruk O (2006) Injection Moulded microcellular wood fiber-polypropylene composites. Compos Part A-Appl. 37:1358–1367. doi:10.1016/j.compositesa.2005.08.010

Sauceau M, Nikitine C, Rodier E, Fages J (2007) Effect of supercritical carbon dioxide on polystyrene extrusion. J Supercrit Fluids 43:367–373. doi:10.1016/j.supflu.2007.05.014

Jacobs MA, Kemmere MF, Keurentjes JTF (2004) Foam processing of poly(ethylene-co-vinyl acetate) rubber using supercritical carbon dioxide. Polymer 45:7539–7547. doi:10.1016/j.polymer.2004.08.061

Rizvi GM, Park CB, Lin WS, Guo G, Iliev RP (2003) Expansion mechanism of plastic/wood-flour composites foams with moisture, dissolved gaseous volatiles and undissolved bubbles. Polym Eng Sci 43:1347–1360. doi:10.1002/pen.10115

Tsivintzelis I, Angelopoulou AG, Panayiotou C (2007) Foaming of polymers with supercritical CO2: an experimental and theoretical study. Polymer 48:5928–5939. doi:10.1016/j.polymer.2007.08.004

Mori T, Hayashi H, Okamoto M, Yamasaki S, Hayami H (2009) Foam processing of polyethylene ionomers with supercritical CO2. Compos Part A-Appl Sci 40:1708–1716. doi:10.1016/j.compositesa.2009.08.018

Zhu XH, Lee LY, Jackson JSH, Tong YW (2008) Characterization of porous poly(d, l-lactic-co-glycolic acid) sponges fabricated by supercritical CO2 gas-foaming method as a scaffold for three-dimensional growth of Hep3B cells. Biotechnol Bioeng 100:998–1009. doi:10.1002/bit.21824

Goren K, Chen L, Schadler LS, Ozisik R (2010) Influence of nanoparticle surface chemistry and size on supercritical carbon dioxide processed nanocomposite foam morphology. J Supercrit Fluids 51:420–427. doi:10.1016/j.supflu.2009.09.007

Ema Y, Ikeya M, Okamoto M (2006) Foam processing and cellular structure of polylactide-based nanocomposites. Polymer 47:5350–5359. doi:10.1016/j.polymer.2006.05.050

Antunes M, Gedler G, Velasco JI (2013) Multifunctional nanocomposite foams based on polypropylene with carbon nanofillers. J Cell Plast 49:259–279. doi:10.1177/0021955X13477433

Shan CW, Izwana MI, Ghazali MI (2012) Study of flexible polyurethane foams reinforced with coir fibres and tyre particles. Int J Appl Phys Math 2:123–130. doi:10.7763/IJAPM.2012.V2.67

Siqueira AS, Soares BG (2006) O efeito de EPDM modificado com Grupos Mercapto ou Tioacetato na Cinética de Vulcanização de Misturas de NR/EPDM. Polímeros 16:299–304. doi:10.1590/S0104-14282006000400009

Peng Y, Gardner DJ, Han Y (2012) Drying cellulose nanofibrils: in search of a suitable method. Cellulose 19:91–102. doi:10.1007/s10570-011-9630-z

Khalil HPSA, Davoudpour Y, Islam MdN, Mustapha A, Sudesh K, Dungani R, Jawaid M (2014) Production and modification of cellulose nanofibrillated using various mechanical processes: a review. Carbohydr Polym 99:649–665. doi:10.1016/j.carbpol.2013.08.069

Sauders RE, Pawlak JJ, Lee JM (2014) Properties of surface acetylated microfibrillated cellulose relative to intra- and inter-fibril bonding. Cellulose 21:1541–1552. doi:10.1007/s10570-014-0177-7

Park CB, Baldwin DF, Suh NP (1995) Effect of the pressure drop rate on cell nucleation in continuous processing of microcellular polymers. Polym Eng Sci 35:432–440. doi:10.1002/pen.760350509

Jones SF, Evans GM, Galvin KP (1999) Bubble nucleation from gas cavities—a review. Adv Colloid Interface 80:27–50. doi:10.1016/S0001-8686(98)00074-8

Leung SNS (2009) Mechanisms of cell nucleation, growth, and coarsening in plastics foaming: theory, simulation, and experiment. PhD Thesis. Department of Mechanical and Industrial Engineering, University of Toronto

Spence KL, Venditti RA, Rojas OJ, Habibi Y, Pawlak JJ (2011) The effect of chemical composition on microfibrillar cellulose films from wood pulps: water interactions and physical properties for packaging applications. Cellulose 18:1097–1111. doi:10.1007/s10570-010-9424-8

Kalia S, Boufi S, Celli A, Kango S (2014) Nanofibrillated cellulose: surface modification and potential applications. Colloid Polym Sci 292:5–31. doi:10.1007/s00396-013-3112-9

Petchwattana N, Sirijutaratana C (2011) Influences of particle sizes and contents of chemical blowing agents on foaming wood plastic composite prepared from poly(vinyl chloride) and rice hull. Mater Des 32:2844–2850. doi:10.1016/j.matdes.2010.12.044

Matuana LM, Faruk O, Diaz CA (2009) Cell morphology of extrusion foamed poly(lactic acid) using endothermic chemical foaming agent. Bioresour Technol 100:5947–5954. doi:10.1016/j.biortech.2009.06.063

Sefadi JS, Luyt AS (2012) Morphology and properties of EVA/empty fruit bunch composites. J Thermoplast Compos Mater 27:895–914. doi:10.1177/0892705711421806

Xu ZM, Jiang XL, Liu T, Hu GH, Zhao L, Zhu ZH, Yuan WK (2007) Foaming of polypropylene with supercritical carbon dioxide. J Supercrit Fluids 41:299–310. doi:10.1016/j.supflu.2006.09.007

Chen L, Wang X, Straff R, Blizard K (2002) Shear stress nucleation in microcellular foaming process. Polym Eng Sci 42:1151–1158. doi:10.1002/pen.11019

Duan Z, Ma J, Xue C, Deng F (2014) Effect of stearic acid/organic montmorillonite on EVA/SA/OMMT nanocomposite foams by melting blending. J Cell Plast 50:263–277. doi:10.1177/0021955X14525796

Han JH, Han CD (1990) Bubble nucleation in polymeric liquids. II. Theoretical considerations. J Polym Sci Part B 28:743–761. doi:10.1002/polb.1990.090280510

Acknowledgements

The authors would like to thank the National Council of Technological and Scientific Development (CNPq) and the Secretariat of Science, Innovation and Development of Rio Grande do Sul (SCT/RS) for the financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zimmermann, M.V.G., Zattera, A.J. & Santana, R.M.C. Nanocomposites foams of poly(ethylene-co-vinyl acetate) with short and long nanocellulose fibers and foaming with supercritical CO2 . Polym. Bull. 75, 1789–1807 (2018). https://doi.org/10.1007/s00289-017-2123-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00289-017-2123-y