Abstract

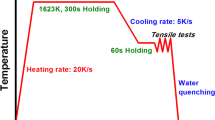

Accurate simulation of residual stress and deformation is necessary to optimize the design and lifetime of casting components. Therefore, the recovery and strain-rate dependence of the stress–strain curve have been incorporated into empirical constitutive equations to improve the thermal stress analysis accuracy. Nevertheless, these equations present several difficulties related to the determination of material constants and their physical bases. This study suggested an empirical elasto-plastic-creep constitutive equation incorporating these phenomena. To determine the material parameters used in this constitutive equation, this study investigated tensile test methods to obtain stress–strain curves that most closely resemble those during or immediately after casting for the Al-Si-Cu high-pressure die-casting alloy JIS ADC 12 (A383.0), which exhibits natural aging. Results show that solution heat treatment with subsequent cooling to the test temperature should be applied to obtain stress–strain curves used for the thermal stress analysis of high-pressure die casting process of this alloy. The yield stresses obtained using the conventional heating method were 50-64 pct higher than those of the method described above. Therefore, the conventional method is expected to overestimate the overestimation of the predicted residual stress in die castings. Evaluation of the developed equation revealed that it can represent alloy recovery and strain-rate dependence.

Similar content being viewed by others

References

A.G. Delgado, K.K. Bamoradian, and R.A. Miller: Die Casting Engineer, 2008, vol. 52, pp. 40-6.

M.M. Makhlouf, D. Apelian, and L. Wang: North American Die Casting Association Rosemonet, 1998, IL, pp. 9-16.

S. Dong, Y. Iwata, Y. Sugiyama, and H. Iwahori: Materials Transactions, 2010, vol. 51, pp. 371-76.

B. Magnin, L. Maenner, L. Katgerman, and S. Engler: Materials Science Forum, 1996, vol. 217-222, pp. 1209-15.

A.K. Miller: Ph.D. Dissertation, 1975, Stanford University.

E. Gustafsson, M. Hofwing, and N. Strömberg: Journal of Materials Processing Technology, 2009, vol. 209, pp. 4320-28.

P. Hofer, E. Kaschnitz, and P. Schumacher: JOM, 2014, vol. 66, pp. 1638-46.

Y. Motoyama, H. Takahashi, T. Okane, Y. Fukuda, and M. Yoshida: Metallurgical and Materials Transactions A, 2013, vol. 44, pp. 3261-70.

Y. Motoyama, D. Inukai, T. Okane, and M. Yoshida: Metallurgical and Materials Transactions A, 2014, vol. 45, pp. 2315-25.

J. Thorborg, J. Klinkhammer, and M. Heitzer: Materials Science and Engineering, 2012, vol. 33, 012050.

H.G. Ejær and A. Mo: Metallurgical and Materials Transactions B, 1990, vol. 21, pp. 1049-61.

J.-M. Drezet, O. Ludwig, C. Jacquerod, and E. Waz: International Journal of Cast Metals Research, 2007, vol. 20, pp. 163-70.

A. Alankar and M.A. Wells: Materials Science and Engineering A, 2010, vol. 527, pp. 7812-20.

W.M. van Haaften, B. Magnin, W.H. Kool, and L. Katgerman: Metallurgical and Materials Transactions A, 2002, vol. 33, pp. 1971-80.

H. Shiga, T. Sato, H. Kambe, Y. Motoyama, and M. Yoshida: Japan Patent Kokai 2015-132564 (20015.07.23).

M. Reich and O. Kessler: Journal of Physics: Conference Series, 2010, vol. 240, 1.

N. Chobaut, D. Carron, S. Arsène, P. Schloth, and J.-M. Drezet: Journal of Materials Processing Technology, 2015, vol. 222, PP. 373-80.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript submitted January 28, 2016.

Rights and permissions

About this article

Cite this article

Motoyama, Y., Shiga, H., Sato, T. et al. Elasto-Plastic-Creep Constitutive Equation of an Al-Si-Cu High-Pressure Die Casting Alloy for Thermal Stress Analysis. Metall Mater Trans A 47, 5598–5608 (2016). https://doi.org/10.1007/s11661-016-3734-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-016-3734-x