Abstract

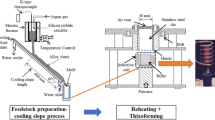

This paper investigated the microstructure and mechanical properties of a typical Al-6.2Si-3.4Cu-0.4 Mg cast alloy under four heat treatment processes and compared the non-proportional fatigue behavior of completely reversed stress cycles under circular and elliptical loading paths. The solution treatment significantly reduced the size and aspect ratio of the eutectic Si phase, achieved excellent and balanced mechanical properties, and yielded the highest non-proportional fatigue life, while the aging treatment mainly acted on the precipitation phases, especially the size of the needle-like Mg2Si phase. The cyclic deformation behavior indicated that the four heat-treated alloys exhibited two different stress responses and plastic damage forms. Surrounding alloys with these two damage forms, the fracture characteristics were analyzed and summarized. The differences between the two loading paths for the same heat-treated alloy were also discussed in terms of cyclic deformation behavior, crack propagation paths and fracture characteristics. The dislocation evolution revealed the development of plastic damage as the distance decreased from the fatigue section.

Similar content being viewed by others

References

M.S. Salleh, M.Z. Omar, J. Syarif, K.S. Alhawari, and M.N. Mohammed, Microstructure and Mechanical Properties of Thixoformed A319 Aluminium Alloy, Mater. Des., 2014, 64, p 142–152.

L. Wang, N. Limodin, A.E.I. Bartali, J.F. Witz, R. Seghir, J.Y. Buffiere, and E. Charkaluk, Influence of Pores on Crack Initiation in Monotonic Tensile and Cyclic Loadings in Lost Foam Casting A319 Alloy by using 3D in-situ Analysis, Mater. Sci. Eng. A, 2016, 673, p 362–372.

H.K. Govindaraju, T. Jayaraju, and P.R.S. Rao, Fatigue Crack Propagation Behaviour of Al-Zn-Ce Alloys, Fatigue Fract. Eng. Mater. Struct., 2011, 34(8), p 547–561.

C.J. Davidson, J.R. Griffiths, and A.S. Machin, The Effect of Solution Heat-Treatment Time on the Fatigue Properties of an Al-Si-Mg Casting Alloy, Fatigue Fract. Eng. Mater. Struct., 2002, 25(2), p 223–230.

C. Wei, G.L. Liu, H. Wan, Y.S. Li, and N.C. Si, Effect of Heat Treatment on Microstructure and Thermal Fatigue Properties of Al-Si-Cu-Mg Alloys, High Temp. Mater. Processes, 2018, 37(4), p 289–298.

B. Jiang, Z.S. Ji, H.Y. Xu, M.L. Hu, Y.B. Zhang, and S.Z. Wang, Transformation of Fe-rich Intermetallic Phases and Eutectic Si Morphology in Al–Si–Cu–Fe Cast Alloy with Solution Treatment, Mater. Res. Express, 2019, 6(6), p 066515.

E. Sjölander and S. Seifeddine, Artificial Ageing of Al–Si–Cu–Mg Casting Alloys, Mater. Sci. Eng. A, 2011, 528(24), p 7402–7409.

N.D. Alexopoulos and GSp. Pantelakis, Quality Evaluation of A357 Cast Aluminum Alloy Specimens Subjected to Different Artificial Aging Treatment, Mater. Des., 2004, 25(5), p 419–430.

S. Beroual, Z. Boumerzoug, P. Paillard, and Y. Borjon-Piron, Effects of Heat Treatment and Addition of Small Amounts of Cu and Mg on the Microstructure and Mechanical Properties of Al-Si-Cu and Al-Si-Mg Cast Alloys, J. Alloys Compd., 2019, 784, p 1026–1035.

G. Ran, J.E. Zhou, and Q.G. Wang, Precipitates and Tensile Fracture Mechanism in a Sand Cast A356 Aluminum Alloy, J. Mater. Process. Technol., 2008, 27(1–3), p 46–52.

M. Furui, T. Kitamura, T. Ishikawa, S. Ikeno, S. Saikawa, and N. Sakai, Evaluation of Age Hardening Behavior Using Composite Rule and Microstructure Observation in Al-Si-Mg Alloy Castings, Mater. Trans., 2011, 52(6), p 1163–1167.

M.G. Akhil, S. Preenu, S. Hari, and M. Ravi, Effect of Heat Treatment on the Mechanical Properties of Squeeze-Cast Al–5Si–3Cu Alloy for Automotive Applications, Trans. Indian Inst. Met., 2019, 72(5), p 1129–1132.

R.X. Li, R.D. Li, Y.H. Zhao, L.Z. He, C.X. Li, H.R. Guang, and Z.Q. Hu, Age-Hardening Behavior of Cast Al–Si Base Alloy, Mater. Lett., 2004, 58(15), p 2096–2101.

G. Atxaga, A. Pelayo, and A.M. Irisarri, Effect of Microstructure on Fatigue Behaviour of cast Al – 7Si – Mg Alloy, Mater. Sci. Technol., 2011, 17(4), p 446–450.

Y. Li, G.F. Xe, S.C. Liu, X.Y. Peng, Z.M. Yin, L. Wang, and X.P. Liang, Effect of Ageing Treatment on Fatigue Crack Growth of Die Forged Al-5.87Zn-2.07Mg-2.42Cu Alloy, Eng. Fract. Mech., 2019, 215, p 251–260.

D.D. Tian, X.S. Liu, G.Q. He, Y. Shen, S.Q. Lv, and Q.G., Wang, Low Cycle Fatigue Behavior of Casting A319 Alloy Under Two Different Aging Conditions Mater, Sci. Eng, 2016, 654(60), p 68.

L. Leng, Z.J. Zhang, Q.Q. Duan, P. Zhang, and Z.F. Zhang, Improving the Fatigue Strength of 7075 Alloy Through Aging, Mater. Sci. Eng., 2018, 738, p 24–30.

D. Skibicki and L. Pejkowski, The Relationship Between Additional Non-Proportional Hardening Coefficient and Fatigue Life, Int. J. Fatigue, 2019, 123, p 66–78.

T. Itoh, M. Sakane, and K. Ohsuga, Multiaxial Low Cycle Fatigue Life Under Non-Proportional Loading, Int. J. Pressure Vessels Piping, 2013, 110, p 50–56.

C.M. Sonsino and R. Franz, Multiaxial Fatigue Assessment for Automotive Safety Components of Cast Aluminium EN AC-42000 T6 (G-AlSi7Mg0.3 T6) Under Constant and Variable Amplitude Loading, Int. J. Fatigue, 2017, 100, p 489–501.

H. Nakamura, M. Takanashi, T. Itoh, M. Wu, and Y. Shimizu, Fatigue Crack Initiation and Growth Behavior of Ti–6Al–4V Under Non-Proportional Multiaxial Loading, Int. J. Fatigue, 2011, 33(7), p 842–848.

Z.Q. Zhou, X.S. Liu, G.Q. He, B. Ge, P.W. Le, J.Q. Pan, Z.A. Huang, J.Q. Li, and Q.G. Wang, A New Microstructure-Based Multiaxial Fatigue Life Prediction Model for A319 Casting Alloys, Fatigue Fract. Eng. Mater. Struct., 2021, 44(9), p 2429–2443.

V.D. Le, F. Morel, D. Bellett, N. Saintier, and P. Osmond, Multiaxial high cycle fatigue damage mechanisms associated with the different microstructural heterogeneities of cast aluminium alloys, Mater. Sci. Eng. A, 2016, 649, p 426–440.

X.Q. Ding, G.Q. He, and C.S. Chen, Study on the Dislocation Sub-Structures of Al-Mg-Si Alloys Fatigued Under Non-Proportional Loadings, J. Mater. Sci, 2010, 45(15), p 4046–4053.

X.S. Jiang, G.Q. He, B. Liu, Z.Y. Zhu, and W.H. Zhang, Fatigue Characteristics and Microcosmic Mechanism of Al-Si-Mg Alloys Under Multiaxial Proportional Loadings, Int. J. Miner. Metall. Mater, 2011, 18(4), p 437–443.

P.W. Le, X.S. Liu, G.Q. He, B. Ge, Z.Z. Weng, and Q.G. Wang, Effect of HIPing and Degassing on the Low Cycle Fatigue Behavior of A319 Cast Alloy, Mater. Res. Express, 2019, 6(10), p 106552.

E. Ogris, H. Lüchinger, and P.J. Uggowitzer, ilicon Spheroidization Treatment of Thixoformed Al-Si-Mg Alloys, Mater. Sci. Forum, 2002, 396–402(1), p 149–154.

S.W. Youn and C.G. Kang, Characterization of age-Hardening Behavior of Eutectic Surface on Rheo-Cast A356–T5 Alloy by Using Nano/Micro-indentation, Scratching and Atomic Force Microscopy, Mater. Chem. Phys., 2006, 100(1), p 117–123.

E. Sjölander and S. Seifeddine, The Heat Treatment of Al–Si–Cu–Mg Casting Alloys, J. Mater. Process. Technol., 2010, 210(10), p 1249–1259.

Y.J. Li, S. Brusethaug and A. Olsen, Influence of Cu on the Mechanical Properties and Precipitationbehavior of AlSi7Mg0. 5 alloy During Aging Treatment, Scr. Mater, 2006, 54(1), p 99–103.

H.J. Kang, H.S. Jang, S.H. Oh, P.H. Yoon, G.H. Lee, and J.Y. Park, Effects of Solution Treatment Temperature and Time on the Porosities and Mechanical Properties of Vacuum Die-Casted and T6 Heat-Treated Al–Si–Mg Alloy, Vac., 2021, 193, 110536.

T.A. Costa, M. Dias, L.G. Gomes, O.L. Rocha, and A. Garcia, Effect of Solution Time in T6 Heat Treatment on Microstructure and Hardness of a Directionally Solidified Al-Si-Cu Alloy, J. Alloys Compd., 2016, 683, p 485–494.

O. ElSebaie, A.M. Samuel, F.H. Samuel, and H.W. Doty, The Effects of Mischmetal, Cooling Rate and Heat Treatment on the Hardness of A319 1, A356 2 and A413 1 Al-Si Casting Alloys, Mater. Sci. Eng. A, 2008, 486(1–2), p 241–252.

F.H. Wang, J. Dong, Y.Y. Jiang, and W.J. Ding, Cyclic Deformation and Fatigue of Extruded Mg–Gd–Y Magnesium Alloy, Mater. Sci. Eng., 2013, 561, p 403–410.

M.A. Tschopp, G.J. Tucker, and D.L. McDowell, Atomistic Simulations of Tension–Compression Asymmetry in Dislocation Nucleation for Copper Grain Boundaries, Comput. Mater. Sci., 2008, 44, p 351–362.

H.W. Hoppel, Z.M. Zhou, H. Mughrabi, and R.Z. Valiev, Microstructural Study of the Parameters Governing Coarsening and Cyclic Softening in Fatigued Ultrafinegrained Copper, Philos. Mag. A, 2002, 82(9), p 1781–1794.

A. Plumtree and H.A. Abdel-Raouf, Cyclic Stress–Strain Response and Substructure, Int. J. Fatigue, 2001, 23, p 799–805.

H. Wang, H. Jing, L. Zhao, Y.D. Han, X. Lv, and L. Xu, Dislocation Structure Evolution in 304L Stainless Steel and Weld Joint During Cyclic Plastic Deformation, Mater. Sci. Eng. A, 2017, 690, p 16–31.

Y.B. Li, M.J. Yang, K. Li, C.D. Ma, T. Yang, J.C. Wang, and Q. Lu, In-Situ Study of Effects of Heat Treatments and Loading Methods on Fracture Behaviors of a Cast Al–Si Alloy, Mater. Today Commun., 2021, 28, 102680.

Y.X. Gao, J.Z. Yi, P.D. Lee, and T.C. Lindley, A Micro-Cell Model of the Effect of Microstructure and Defects on Fatigue Resistance in Cast Aluminum Alloys, Acta Mater., 2004, 52(12), p 5435–5449.

G.H. Zhang, J.X. Zhang, B.C. Li, and W. Cai, Double-Stage Hardening Behavior and Fracture Characteristics of a Heavily Alloyed Al–Si Piston Alloy During Low-Cycle Fatigue Loading, Mater. Sci. Eng. A, 2013, 561, p 26–33.

X. Chen, Q. Gao, and X.F. Sun, Low-Cycle Fatigue Under Non-Proportional Loading, Fatigue Fract. Eng. Mater. Struct., 1996, 19, p 839–854.

C. Laird, The Influence of Metallurgical Structure on the Mechanisms of Fatigue Crack Propagation, In: Fatigue Crack Propagation, 100 Barr Harbor Drive, PO Box C700, WestConshohocken, PA 19428–2959: ASTM International, 1967, p 131–168.

S.K. Shaha, F. Czerwinski, W. Kasprzak, J. Friedman, and D.L. Chen, Effect of Solidification Rate and Loading Mode on Deformation Behavior of Cast Al-Si-Cu-Mg Alloy with Additions of Transition Metals, Mater. Sci. Eng. A, 2015, 636, p 361–372.

S.M.A.K. Mohammed, D.J. Li, X.Q. Zeng, and D.L. Chen, Low-Cycle Fatigue Behavior of a Newly Developed Cast Aluminum Alloy for Automotive Applications, Fatigue Fract. Eng. Mater. Struct., 2019, 42, p 1912–1926.

T. Mayama, K. Sasaki, and M. Kuroda, Quantitative Evaluations for Strain Amplitude Dependent Organization of Dislocation Structures due to Cyclic Plasticity in Austenitic Stainless Steel 316L, Acta Mater., 2008, 56(12), p 2735–2743.

Z.Q. Zhou, X.S. Liu, G.Q. He, Y.P. Liao, Z.A. Huang, J.Q. Pan, J.Q. Li, and Q.G. Wang, A Comparison of Uniaxial and Multiaxial Non-proportional Fatigue Properties in Cast Al-Si-Cu-T6 Alloys Solidified at Two Cooling Rates: Fatigue Behavior, Fracture Characteristics and Dislocation Evolution, Mater. Character., 2022, 189, p 111957.

Acknowledgments

The authors would like to express their sincere thanks to General Motors Powertrain (No.1314) for the materials and financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhou, Z., Liu, X., Le, P. et al. Effect of Heat Treatment and Loading Path on Non-proportional Fatigue Behavior and Fracture Characteristics of an Al-Si Casting Alloy. J. of Materi Eng and Perform 32, 4325–4337 (2023). https://doi.org/10.1007/s11665-022-07400-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07400-4