Abstract

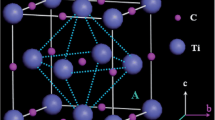

The application of monolithic/un-doped/single-phase ceramics has been limited due to their difficulty in sintering and low fracture toughness. Ceramic matrix composites have gained predominant attention in the past decades in comparison to monolithic/un-doped/single phase ceramics, this is as a result of the high fracture toughness, good wear resistance, and high hardness that they (ceramic matrix composite) possess. Also, the use of sintering additives in collaboration with the application of modern consolidation viz spark plasma sintering (SPS) has gained high prominence to nullify these challenges faced by ceramics. Although, previous review has highlighted the use of diverse techniques (hot press, hot isostatic, pressureless sintering, and SPS) on the consolidation of ceramics and its composites. Amidst all these techniques, SPS has stood to be an effective powder metallurgy route for achieving good microstructure and excellent mechanical properties. This review takes a research on the effects of nitrides based sintering additives on the microstructure, densification, and mechanical properties of titanium carbides ceramic matrix by SPS. The review finally concludes on the potential research importance on the types of sintering additives inclusion that should be in further research processes for improvement in material properties of titanium carbides.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Ahmadi, Z., Nayebi, B., Asl, M.S., Farahbakhsh, I., Balak, Z.: Densification improvement of spark plasma sintered TiB2-based composites with micron-, submicron-and nano-sized SiC particulates. Ceram. Int. 44, 11431–11437 (2018)

Ebrahimi, A., Esfahani, H., Fattah-alhosseini, A., Imantalab, O.: In-vitro electrochemical study of TiB/TiB2 composite coating on titanium in Ringer’s solution. J. Alloy. Compd. 765, 826–834 (2018)

Balcı, Ö., Ağaoğulları, D., Gökçe, H., Duman, I., Öveçoğlu, M.L.: Influence of TiB2 particle size on the microstructure and properties of Al matrix composites prepared via mechanical alloying and pressureless sintering. J. Alloy. Compd. 586, S78–S84 (2014)

Ji, W., Zhang, J., Wang, W., Wang, H., Zhang, F., Wang, Y., et al.: Fabrication and properties of TiB2-based cermets by spark plasma sintering with CoCrFeNiTiAl high-entropy alloy as sintering aid. J. Eur. Ceram. Soc. 35, 879–886 (2015)

Basu, B., Vleugels, J., Van der Biest, O.: Fretting wear behavior of TiB2-based materials against bearing steel under water and oil lubrication. Wear 250, 631–641 (2001)

Rabiezadeh, A., Ataie, A., Hadian, A.M.: Sintering of Al2O3–TiB2 nano-composite derived from milling assisted sol–gel method. Int. J. Refract. Metal Hard Mater. 33, 58–64 (2012)

Asl, M.S., Ahmadi, Z., Parvizi, S., Balak, Z., Farahbakhsh, I.: Contribution of SiC particle size and spark plasma sintering conditions on grain growth and hardness of TiB2 composites. Ceram. Int. 43, 13924–13931 (2017)

Namini, A.S., Gogani, S.N.S., Asl, M.S., Farhadi, K., Kakroudi, M.G., Mohammadzadeh, A.: Microstructural development and mechanical properties of hot pressed SiC reinforced TiB2 based composite. Int. J. Refract. Metal Hard Mater. 51, 169–179 (2015)

Fu, Z., Koc, R.: Pressureless sintering of TiB2 with low concentration of Co binder to achieve enhanced mechanical properties. Mater. Sci. Eng. A 721, 22–27 (2018)

Farahbakhsh, I., Ahmadi, Z., Asl, M.S.: Densification, microstructure and mechanical properties of hot pressed ZrB2–SiC ceramic doped with nano-sized carbon black. Ceram. Int. 43, 8411–8417 (2017)

Demirskyi, D., Borodianska, H., Sakka, Y., Vasylkiv, O.: Ultra-high elevated temperature strength of TiB2-based ceramics consolidated by spark plasma sintering. J. Eur. Ceram. Soc. 37, 393–397 (2017)

Lin, J., Yang, Y., Zhang, H., Wu, Z., Huang, Y.: Effect of sintering temperature on the mechanical properties and microstructure of carbon nanotubes toughened TiB2 ceramics densified by spark plasma sintering. Mater. Lett. 166, 280–283 (2016)

Germi, M.D., Mahaseni, Z.H., Ahmadi, Z., Asl, M.S.: Phase evolution during spark plasma sintering of novel Si3N4-doped TiB2–SiC composite. Mater. Charact. 145, 225–232 (2018)

Li, B.: Effect of ZrB2 and SiC addition on TiB2-based ceramic composites prepared by spark plasma sintering. Int. J. Refract. Metal Hard Mater. 46, 84–89 (2014)

Cymerman, K., Oleszak, D., Rosinski, M., Michalski, A.: Structure and mechanical properties of TiB2/TiC–Ni composites fabricated by pulse plasma sintering method. Adv. Powder Technol. 29, 1795–1803 (2018)

Black, J.T., Kohser, R.A.: DeGarmo’s Materials and Processes in Manufacturing. Wiley, Hoboken (2017)

Binner, J., Porter, M., Baker, B., Zou, J., Venkatachalam, V., Diaz, V.R., et al.: Selection, processing, properties and applications of ultra-high temperature ceramic matrix composites, UHTCMCs–a review. Int. Mater. Rev. 65, 389–444 (2019)

Xue, J.-X., Liu, J.-X., Zhang, G.-J., Zhang, H.-B., Liu, T., Zhou, X.-S., et al.: Improvement in mechanical/physical properties of TiC-based ceramics sintered at 1500 C for inert matrix fuels. Scripta Mater. 114, 5–8 (2016)

Asl, M.S., Namini, A.S., Motallebzadeh, A., Azadbeh, M.: Effects of sintering temperature on microstructure and mechanical properties of spark plasma sintered titanium. Mater. Chem. Phys. 203, 266–273 (2018)

Azizian-Kalandaragh, Y., Namini, A.S., Ahmadi, Z., Asl, M.S.: Reinforcing effects of SiC whiskers and carbon nanoparticles in spark plasma sintered ZrB2 matrix composites. Ceram. Int. 44, 19932–19938 (2018)

Oguntuyi, S.D.,Johnson, O.T., Shongwe, M.B.: Spark Plasma Sintering of Ceramic Matrix Composite of ZrB 2 and TiB 2: Microstructure, Densification, and Mechanical Properties—A Review, Metals and Materials International, pp. 1–14 (2020)

Sabahi Namini, A., Azadbeh, M., Shahedi Asl, M.: Effects of in-situ formed TiB whiskers on microstructure and mechanical properties of spark plasma sintered Ti–B4C and Ti–TiB2 composites. Scientia Iranica 25, 762–771 (2018)

Balak, Z., Asl, M.S., Azizieh, M., Kafashan, H., Hayati, R.: Effect of different additives and open porosity on fracture toughness of ZrB2–SiC-based composites prepared by SPS. Ceram. Int. 43, 2209–2220 (2017)

Nikzad, L., Licheri, R., Ebadzadeh, T., Orru, R., Cao, G.: Effect of ball milling on reactive spark plasma sintering of B4C–TiB2 composites. Ceram. Int. 38, 6469–6480 (2012)

Wang, L., Jiang, W., Chen, L.: Rapidly sintering nanosized SiC particle reinforced TiC composites by the spark plasma sintering (SPS) technique. J. Mater. Sci. 39, 4515–4519 (2004)

Song, G.-M., Guo, Y.-K., Zhou, Y., Li, Q.: Preparation and mechanical properties of carbon fiber reinforced-TiC matrix composites. J. Mater. Sci. Lett. 20, 2157–2160 (2001)

Sribalaji, M., Mukherjee, B., Bakshi, S.R., Arunkumar, P., Babu, K.S., Keshri, A.K.: In-situ formed graphene nanoribbon induced toughening and thermal shock resistance of spark plasma sintered carbon nanotube reinforced titanium carbide composite. Compos. Part B Eng. 123, 227–240 (2017)

Chae, K.W., Niihara, K., Kim, D.Y.: Improvements in the mechanical properties of TiC by the dispersion of fine SiC particles. J. Mater. Sci. Lett. 14, 1332–1334 (1995)

Locci, A.M., Orru, R., Cao, G., Munir, Z.A.: Effect of ball milling on simultaneous spark plasma synthesis and densification of TiC–TiB2 composites. Mater. Sci. Eng. A 434, 23–29 (2006)

Cheng, L., Xie, Z., Liu, G.: Spark plasma sintering of TiC ceramic with tungsten carbide as a sintering additive. J. Eur. Ceram. Soc. 33, 2971–2977 (2013)

Fattahi, M., Babapoor, A., Delbari, S.A., Ahmadi, Z., Namini, A.S., Asl, M.S.: Strengthening of TiC ceramics sintered by spark plasma via nano-graphite addition. Ceram. Int. 46, 12400–12408 (2020)

Fattahi, M., Delbari, S.A., Babapoor, A., Namini, A.S., Mohammadi, M., Asl, M.S.: Triplet carbide composites of TiC, WC, and SiC. Ceram. Int. 46, 9070–9078 (2020)

Chen, J., Li, W., Jiang, W.: Characterization of sintered TiC–SiC composites. Ceram. Int. 35, 3125–3129 (2009)

Nie, J., Wu, Y., Li, P., Li, H., Liu, X.: Morphological evolution of TiC from octahedron to cube induced by elemental nickel. CrystEngComm 14, 2213–2221 (2012)

Liu, N., Chao, S., Huang, X.: Effects of TiC/TiN addition on the microstructure and mechanical properties of ultra-fine grade Ti (C, N)–Ni cermets. J. Eur. Ceram. Soc. 26, 3861–3870 (2006)

Russias, J., Cardinal, S., Aguni, Y., Fantozzi, G., Bienvenu, K., Fontaine, J.: Influence of titanium nitride addition on the microstructure and mechanical properties of TiC-based cermets. Int. J. Refract. Metal Hard Mater. 23, 358–362 (2005)

Pazhouhanfar, Y., Namini, A.S., Delbari, S.A., Nguyen, T.P., Van Le, Q., Shaddel, S., et al.: Microstructural and mechanical characterization of spark plasma sintered TiC ceramics with TiN additive. Ceram. Int. 46, 18924–18932 (2020)

Babapoor, A., Asl, M.S., Ahmadi, Z., Namini, A.S.: Effects of spark plasma sintering temperature on densification, hardness and thermal conductivity of titanium carbide. Ceram. Int. 44, 14541–14546 (2018)

Jiang, C.C., Goto, T., Hirai, T.: Microhardness of non-stoichiometric TiCx, plates prepared by chemical vapour deposition. J. Less Common Metals 163, 339–346 (1990)

Zhang, Z., Geng, C., Ke, Y., Li, C., Jiao, X., Zhao, Y., et al.: Processing and mechanical properties of nonstoichiometric TiCx (0.3 ≤ x ≤ 0.5). Ceram. Int. 44, 18996–19001 (2018)

Shaddel, S., Namini, A.S., Pazhouhanfar, Y., Delbari, S.A., Fattahi, M., Asl, M.S.: A microstructural approach to the chemical reactions during the spark plasma sintering of novel TiC–BN ceramics. Ceram. Int. 46, 15982–15990 (2020)

Fattahi, M., Pazhouhanfar, Y., Delbari, S.A., Shaddel, S., Namini, A.S., Asl, M.S.: Strengthening of novel TiC–AlN ceramic with in-situ synthesized Ti3Al intermetallic compound. Ceram. Int. 46, 14105–14113 (2020)

Yonenaga, I.: Hardness of bulk single-crystal GaN and AlN. Mater. Res. Soc. Internet J. Nitride Semiconductor Res. 7, 1–4 (2002)

Chen, B., Xiong, H., Sun, B., Tang, S., Du, B., Li, N.: Microstructures and mechanical properties of Ti3Al/Ni-based superalloy joints arc welded with Ti–Nb and Ti–Ni–Nb filler alloys. Prog. Nat. Sci. Mater. Int. 24, 313–320 (2014)

Asl, M.S., Ahmadi, Z., Namini, A.S., Babapoor, A., Motallebzadeh, A.: Spark plasma sintering of TiC–SiCw ceramics. Ceram. Int. 45, 19808–19821 (2019)

Teber, A., Schoenstein, F., Têtard, F., Abdellaoui, M., Jouini, N.: Effect of SPS process sintering on the microstructure and mechanical properties of nanocrystalline TiC for tools application. Int. J. Refract. Metal Hard Mater. 30, 64–70 (2012)

Acknowledgments

Appreciation goes to all the author for their contributions to the success of this review.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2021 The Author(s), under exclusive license to Springer Nature Singapore Pte Ltd.

About this paper

Cite this paper

Oguntuyi, S.D., Johnson, O., Shongwe, M.B. (2021). Spark Plasma Sintering of Ceramic Matrix Composite of TiC: Microstructure, Densification, and Mechanical Properties: A Review. In: Awang, M., Emamian, S.S. (eds) Advances in Material Science and Engineering. Lecture Notes in Mechanical Engineering. Springer, Singapore. https://doi.org/10.1007/978-981-16-3641-7_13

Download citation

DOI: https://doi.org/10.1007/978-981-16-3641-7_13

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-16-3640-0

Online ISBN: 978-981-16-3641-7

eBook Packages: EngineeringEngineering (R0)