Abstract

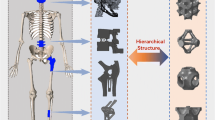

Biomaterials are essential to medical device production, play a critical role in health care and affect the quality and longevity of human life. The ever-increasing demand for the use of medical devices and implants offering improved function and ease of life makes the development of new biomaterials a challenging task. The design and development of biomaterials are quite a complicated procedure, which involves the manipulation of composition and structure to combine multiple mechanical and biological properties, sometimes even conflicting, in the desired biomaterial, simultaneously. The use of computational techniques can help in the evaluation of designed materials without the need to make any physical object and spend too much money, and more importantly reduce the risks to the development efforts. This chapter overviews the design of orthopaedic biomaterials for total hip and knee replacements, and bone scaffolds. The computational methods involved in their design scenarios are presented, and some efficient tools are introduced to aid in the development of more reliable and optimal biomaterials.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Similar content being viewed by others

References

Banerjee S et al (2014) Emerging technologies in arthroplasty: additive manufacturing. J Knee Surg 27(3):185–191

Huang Y et al (2015) Additive manufacturing: current state, future potential, gaps and needs, and recommendations. J Manuf Sci Eng 137(1):014001

Kanouté P et al (2009) Multiscale methods for composites: a review. Arch Comput Methods Eng 16(1):31–75

Boccaccio A et al (2018) A computational approach to the design of scaffolds for bone tissue engineering. Advances in bionanomaterials. Springer, Berlin, pp 111–117

Kohn J (2004) New approaches to biomaterials design. Nat Mater 3(11):745–747

Nygren M et al (2009) Dual-sided joint implant having a wear resistant surface and a bioactive surface. In: International application published under the patent cooperation treaty (PCT), W.I.P. Organization, Editor. Google Patents, US

Bahraminasab M et al (2012) Aseptic loosening of femoral components—a review of current and future trends in materials used. Mater Des 42:459–470

Melvin JS et al (2014) Early failures in total hip arthroplasty—a changing paradigm. J Arthroplasty 29(6):1285–1288

Brown NM et al (2015) Extensor mechanism allograft reconstruction for extensor mechanism failure following total knee arthroplasty. J Bone Joint Surg 97(4):279–283

Morrey MC (2015) Revision total knee arthroplasty: management of periprosthetic femur fracture around total knee arthroplasty. Complex primary and revision total knee arthroplasty. Springer, Berlin, pp 129–142

Nishii T et al (2015) Fluctuation of cup orientation during press-fit insertion: a possible cause of malpositioning. J Arthroplasty 30(10):1847–1851

Liddle AD, Rodríguez-Merchán EC (2015) Periprosthetic fractures. Total knee arthroplasty. Springer, Berlin, pp 219–227

Jiranek WA et al (2015) Surgical treatment of prosthetic joint infections of the hip and knee: changing paradigms? J Arthroplasty 30(6):912–918

Bahraminasab M et al (2013) Aseptic loosening of femoral components-materials engineering and design considerations. Mater Des 44:155–163

Katz JN et al (2012) Twelve-year risk of revision after primary total hip replacement in the US Medicare population. J Bone Joint Surg 94(20):1825–1832

Marius N et al (2015) Biomaterials view on the complications associated with hip resurfacing arthroplasty. In: Advanced materials research, vol 1114

Oshkour A et al (2015) Mechanical and physical behaviour of newly developed functionally graded materials and composites of stainless steel 316L with calcium silicate and hydroxyapatite. J Mech Behav Biomed Mater 49:321–331

Doni Z et al (2015) Tribocorrosion behaviour of hot pressed CoCrMo—HAP biocomposites. Tribol Int 91:221–227

Dehaghani MT, Ahmadian M, Beni BH (2015) Fabrication and characterization of porous Co–Cr–Mo/58S bioglass nano-composite by using NH 4 HCO 3 as space-holder. Mater Des 88:406–413

Patel AK, Balani K (2015) Dispersion fraction enhances cellular growth of carbon nanotube and aluminum oxide reinforced ultrahigh molecular weight polyethylene biocomposites. Mat Sci Eng C 46:504–513

Bahraminasab M et al (2013) Material tailoring of the femoral component in a total knee replacement to reduce the problem of aseptic loosening. Mater Des 52:441–451

Enab TA, Bondok NE (2013) Material selection in the design of the tibia tray component of cemented artificial knee using finite element method. Mater Des 44:454–460

Hedia H et al (2014) A new design of cemented stem using functionally graded materials (FGM). Bio-med Mater Eng 24(3):1575–1588

Mehboob H, Chang S-H (2015) Optimal design of a functionally graded biodegradable composite bone plate by using the Taguchi method and finite element analysis. Compos Struct 119:166–173

Gupta A, Talha M (2015) Recent development in modeling and analysis of functionally graded materials and structures. Progr Aerosp Sci 79:1–14

Oshkour A et al (2015) Parametric study of radial functionally graded femoral prostheses with different geometries. Meccanica 1–22

Oshkour AA et al (2013) Finite element analysis on longitudinal and radial functionally graded femoral prosthesis. Int J Numer Methods Biomed Eng 29(12):1412–1427

Oshkour AA et al (2015) Effect of geometrical parameters on the performance of longitudinal functionally graded femoral prostheses. Artif Organs 39(2):156–164

Taylor M, Barrett DS, Deffenbaugh D (2012) Influence of loading and activity on the primary stability of cementless tibial trays. J Orthop Res 30(9):1362–1368

Willing R, Kim IY (2009) Three dimensional shape optimization of total knee replacements for reduced wear. Struct Multi Optim 38(4):405–414

Abdelgaied A et al (2011) Computational wear prediction of artificial knee joints based on a new wear law and formulation. J Biomech 44(6):1108–1116

Mattei L, Di Puccio F, Ciulli E (2013) A comparative study of wear laws for soft-on-hard hip implants using a mathematical wear model. Tribol Int 63:66–77

Netter J et al (2015) Prediction of wear in crosslinked polyethylene unicompartmental knee arthroplasty. Lubricants 3(2):381–393

Jahan A, Bahraminasab M (2015) Multicriteria decision analysis in improving quality of design in femoral component of knee prostheses: influence of interface geometry and material. In: Advances in materials science and engineering

Bahraminasab M et al (2014) Multi-objective design optimization of functionally graded material for the femoral component of a total knee replacement. Mater Des 53:159–173

Bahraminasab M et al (2014) On the influence of shape and material used for the femoral component pegs in knee prostheses for reducing the problem of aseptic loosening. Mater Des 55:416–428

Van Lenthe GH et al (2002) Stemmed femoral knee prostheses: effects of prosthetic design and fixation on bone loss. Acta Orthop 73(6):630–637

Completo A et al (2009) Relationship of design features of stemmed tibial knee prosthesis with stress shielding and end-of-stem pain. Mater Des 30(4):1391–1397

Taylor M, Prendergast PJ (2015) Four decades of finite element analysis of orthopaedic devices: where are we now and what are the opportunities? J Biomech 48(5):767–778

Rezaei F et al (2015) Carbon/PEEK composite materials as an alternative for stainless steel/titanium hip prosthesis: a finite element study. Australas Phys Eng Sci Med 1–12

Gillies RM et al (2007) Adaptive bone remodelling of all polyethylene unicompartmental tibial bearings. ANZ J Surg 77(1–2):69–72

Andersen MR, Petersen MM (2015) Adaptive bone remodeling of the femoral bone after tumor resection arthroplasty with an uncemented proximally hydroxyapatite-coated stem. J Clin Densitometry 19(2):202–207

Pérez M et al (2014) Bone remodeling in the resurfaced femoral head: Effect of cement mantle thickness and interface characteristics. Med Eng Phys 36(2):185–195

Mukherjee K, Gupta S (2015) Bone ingrowth around porous-coated acetabular implant: a three-dimensional finite element study using mechanoregulatory algorithm. Biomech Model Mechanobiol 1–15

Waide V et al (2004) Modelling the fibrous tissue layer in cemented hip replacements: experimental and finite element methods. J Biomech 37(1):13–26

Puthumanapully PK, Browne M (2011) Tissue differentiation around a short stemmed metaphyseal loading implant employing a modified mechanoregulatory algorithm: a finite element study. J Orthop Res 29(5):787–794

Miramini S et al (2015) Computational simulation of the early stage of bone healing under different configurations of locking compression plates. Comput Methods Biomech Biomed Eng 18(8):900–913

Miramini S et al (2015) The relationship between interfragmentary movement and cell differentiation in early fracture healing under locking plate fixation. Australas Phys Eng Sci Med 1–11

Stolk J et al (2002) Finite element and experimental models of cemented hip joint reconstructions can produce similar bone and cement strains in pre-clinical tests. J Biomech 35(4):499–510

Coultrup OJ et al (2010) Computational assessment of the effect of polyethylene wear rate, mantle thickness, and porosity on the mechanical failure of the acetabular cement mantle. J Orthop Res 28(5):565–570

Bouziane M et al (2015) Analysis of the behaviour of cracks emanating from bone inclusion and ordinary cracks in the cement mantle of total hip prosthesis. J Braz Soc Mech Sci Eng 37(1):11–19

Caouette C et al (2015) Influence of the stem fixation scenario on load transfer in a hip resurfacing arthroplasty with a biomimetic stem. J Mech Behav Biomed Mater 45:90–100

Van de Groes S, de Waal-Malefijt M, Verdonschot N (2014) Probability of mechanical loosening of the femoral component in high flexion total knee arthroplasty can be reduced by rather simple surgical techniques. Knee 21(1):209–215

Abdelgaied A et al (2014) The effect of insert conformity and material on total knee replacement wear. Proc Inst Mech Eng Part H J Eng Med 228(1):98–106

Gao L, Dowson D, Hewson RW (2015) Predictive wear modeling of the articulating metal-on-metal hip replacements. J Biomed Mater Res Part B Appl Biomater 105(3):497–506

Bellucci D et al (2011) A new generation of scaffolds for bone tissue engineering. In: Advances in science and technology. Trans Tech Publ

Sanz-Herrera J, García-Aznar J, Doblaré M (2009) On scaffold designing for bone regeneration: a computational multiscale approach. Acta Biomater 5(1):219–229

Hollister SJ et al (2005) Engineering craniofacial scaffolds. Orthod Craniofac Res 8(3):162–173

Hollister SJ (2005) Porous scaffold design for tissue engineering. Nat Mater 4(7):518–524

Kelly DJ, Prendergast PJ (2006) Prediction of the optimal mechanical properties for a scaffold used in osteochondral defect repair. Tissue Eng 12(9):2509–2519

Hutmacher DW, Sittinger M, Risbud MV (2004) Scaffold-based tissue engineering: rationale for computer-aided design and solid free-form fabrication systems. Trends Biotechnol 22(7):354–362

Chu T-MG et al (2002) Mechanical and in vivo performance of hydroxyapatite implants with controlled architectures. Biomaterials 23(5):1283–1293

Hollister SJ et al (2000) An image-based approach for designing and manufacturing craniofacial scaffolds. Int J Oral Maxillofac Surg 29(1):67–71

Feinberg SE et al (2001) Image-based biomimetic approach to reconstruction of the temporomandibular joint. Cells Tissues Organs 169(3):309–321

Dallago M et al (2018) Fatigue and biological properties of Ti-6Al-4V ELI cellular structures with variously arranged cubic cells made by selective laser melting. J Mech Behav Biomed Mater 78:381–394

Sengers BG et al (2007) Computational modelling of cell spreading and tissue regeneration in porous scaffolds. Biomaterials 28(10):1926–1940

Sanchez-Palencia E, Zaoui A (1987) Homogenization techniques for composite media. In: Homogenization techniques for composite media

Beaupré G, Orr T, Carter D (1990) An approach for time-dependent bone modeling and remodeling—theoretical development. J Orthop Res 8(5):651–661

Van Lenthe G, De Waal Malefijt M, Huiskes R (1997) Stress shielding after total knee replacement may cause bone resorption in the distal femur. J Bone Joint Surg Br 79(1):117–122

Adachi T et al (2006) Framework for optimal design of porous scaffold microstructure by computational simulation of bone regeneration. Biomaterials 27(21):3964–3972

Sanz-Herrera J, Garcia-Aznar J, Doblare M (2008) A mathematical model for bone tissue regeneration inside a specific type of scaffold. Biomech Model Mechanobiol 7(5):355–366

Hollister SJ, Maddox R, Taboas JM (2002) Optimal design and fabrication of scaffolds to mimic tissue properties and satisfy biological constraints. Biomaterials 23(20):4095–4103

Adachi T et al (2001) Trabecular surface remodeling simulation for cancellous bone using microstructural voxel finite element models. J Biomech Eng 123(5):403–409

Sanz-Herrera J, García-Aznar J, Doblaré M (2008) Micro–macro numerical modelling of bone regeneration in tissue engineering. Comput Methods Appl Mech Eng 197(33):3092–3107

Chen Y, Zhou S, Li Q (2011) Microstructure design of biodegradable scaffold and its effect on tissue regeneration. Biomaterials 32(22):5003–5014

Kuehmann C, Olson G (2009) Computational materials design and engineering. Mater Sci Technol 25(4):472–478

Thapa N, Prayson M, Goswami T (2015) Case studies in engineering failure analysis

Santiago A et al (2015) Design of an impulsion prosthetic system for prosthetic foot. In: VI Latin American congress on biomedical engineering CLAIB 2014, Paraná, Argentina 29, 30 and 31 Oct 2014. Springer

Jahan A, Edwards KL, Bahraminasab M (2016) Multi-criteria decision analysis for supporting the selection of engineering materials in product design. Butterworth-Heinemann, Boston

Alaimo G et al (2017) Multi-objective optimization of nitinol stent design. Med Eng Phys 47:13–24

Aherwar A, Singh A, Patnaik A (2016) Study on mechanical and wear characterization of novel Co30Cr4Mo biomedical alloy with added nickel under dry and wet sliding conditions using Taguchi approach. Proc Inst Mech Eng Part L J Mater Des Appl. https://doi.org/10.1177/1464420716638112

Curtarolo S et al (2013) The high-throughput highway to computational materials design. Nat Mater 12(3):191–201

Author information

Authors and Affiliations

Corresponding author

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2019 Springer Nature Singapore Pte Ltd.

About this chapter

Cite this chapter

Bahraminasab, M., Edwards, K.L. (2019). Computational Tailoring of Orthopaedic Biomaterials: Design Principles and Aiding Tools. In: Bains, P., Sidhu, S., Bahraminasab, M., Prakash, C. (eds) Biomaterials in Orthopaedics and Bone Regeneration . Materials Horizons: From Nature to Nanomaterials. Springer, Singapore. https://doi.org/10.1007/978-981-13-9977-0_2

Download citation

DOI: https://doi.org/10.1007/978-981-13-9977-0_2

Published:

Publisher Name: Springer, Singapore

Print ISBN: 978-981-13-9976-3

Online ISBN: 978-981-13-9977-0

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)