Abstract

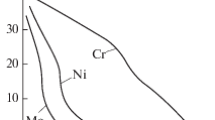

The results of numerical experiments that reveal a correlation between the thermal load and microstresses in ceramics upon wearing the tools are considered. Particular features of the deformation processes in the ceramics surface layer at temperatures T = 1100–1200°C, at which cutters equipped with the inserts from nitride ceramics pass over to an unstable operation regime, have been defined. Based on the established regularities, a series of the innovative ceramic tools is produced.

Similar content being viewed by others

References

Kuzin, V.V., Grigor’ev, S.N., and Volosova, M.Yu., Heat factor role in friction mechanisms of ceramic tools. Part I. Macrolevel, Trenie Iznos, 2014, vol. 35, pp. 628–637; J. Fric. Wear, 2014, vol. 35, no. 6 (in press).

Pronikov, A.S., Nadezhnost’ Mashin (Reliability of Machines), Moscow: Mashinostroenie, 1978.

Kelina, I.Yu., Ershova, N.I., Dorbinskaya, V.A., Plyasunkova, L.A., Microstructure and properties of composition ceramic materials on the Si3N4 base, Ogneupory i tekhnicheskaya keramika, 1998, no. 1, pp. 23–26.

Kuzin, V.V., Effective use of high density ceramic for manufacture of cutting and working tools, Refractor. Industr. Ceram., 2010, vol. 51, pp. 421–426.

Volosova, M.A., Technology of production of cutting plates from high durability ceramics with many-functional coatings for high-effective treatment of welded bearing steels, Perspekt. Mater., 2014, no. 6, pp. 64–74.

Xiaobin Cui, Jun Zhao, Yonghui Zhou, and Guangming Zheng, Damage mechanics analysis of failure mechanisms for ceramic cutting tools in intermittent turning, Eur. J. Mech.-A/Solids, 2013, vol. 37, pp. 139–149.

Kuzin, V. and Grigoriev, S., Method of investigation of the stress-strain state of surface layer of machine elements from a sintered nonuniform material, Appl. Mech. Mater., 2014, vol. 486, pp. 32–35.

Grigor’ev, S.N., Myachenkov, V.I., and Kuzin, V.V., Automated thermal-strength calculations of ceramic cutting plates, Russ. Eng. Res., 2011, vol. 31, pp. 1060–1066.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © V.V. Kuzin, S.N. Grigoriev, M.Yu. Fedorov, 2015, published in Trenie i Iznos, 2015, Vol. 36, No. 1, pp. 50–55.

About this article

Cite this article

Kuzin, V.V., Grigoriev, S.N. & Fedorov, M.Y. Role of the thermal factor in the wear mechanism of ceramic tools. Part 2: Microlevel. J. Frict. Wear 36, 40–44 (2015). https://doi.org/10.3103/S1068366615010079

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068366615010079