A developed procedure is used to evaluate the reliability of cutters fitted with replaceable multifaceted plates of oxide VO13, oxide-carbide VOK71, and nitride RKS22ceramics during turning hardened steel 35KhGSA (44 – 48 HRC). The high efficiency of the set of operational characteristics formed and established wear criteria is demonstrated.

Similar content being viewed by others

References

V. K. Starkov, Cutting. Control of Stability and Quality in Automated Manufacture [in Russian], Mashinostronenie, Moscow (1989).

S. N. Grigor’ev, M. V. Kokhomskii, and A. R. Maslov, Tool Equipment of NMC Machines [in Russian], Mashinostronenie, Moscow (2006).

V. A. Sinopal’nikov and S. N. Grigor’ev, Reliability and Appraisal of Production Systems [in Russian], Vysshaya Shkola, Moscow (2003).

V. V. Kuzin, S. I. Dos’ko, V. F. Popov, et al., “Tooling for high-speed cutting,” Russian Engineering Research, 25(9), 20 – 25 (2005).

S. N. Grigor’ev,M. P. Kozochkin, F. S. Sabirov, et al., Technical appraisal of machine equipment for automated manufacture,” Kontrol’. Diagnostika, No. 8, 48 – 54 (2011).

Xiaobin Cui, Feng Jiao, Pingmei Ming, et al., “Reliability analysis of ceramic cutting tools in continuous and interrupted hard turning,” Ceram. Internat., 43, 10109 – 10122 (2017).

V. V. Kuzin, “Study of high-speed cutting with ceramic tools,” Russian Engineering Research, 24(3), 40 – 46 (2004).

A. A. Vereschaka, A. D. Batako, A. A. Krapostin, et al., “Improvement in reliability of ceramic cutting tool using a damping system and nano-structured multi-layered composite coatings,” Procedia CIRP, 63, 563 – 568 (2017).

V. V. Kuzin, “Effective use of high density ceramic for manufacture of cutting and working tools,” Refract. Indust. Ceram., 51(6), 421 – 426 (2010).

J. Vigneau, P. Bordel, and R. Geslot, “Reliability of ceramic cutting tools,” CIRP Annals, 37, 101 – 104 (1988).

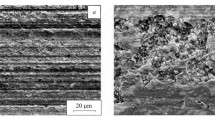

V. V. Kuzin, V. N. Anikin, S. Yu. Fedorov, and M. Yu. Fedorov, “Wear and failure of ceramic cutting plates,” Russian Engineering Research, 30(11), 1116 – 1123 (2010).

P. G. Katsev, Statistical methods of Studying a Cutting Tool [in Russian], Mashinostroenie, Moscow (19974).

V. V. Kuzin, S. N. Grigor’ev, M. Yu. Fedorov, and S. Yu. Fedorov, “Performance of channel cutters with ceramic plates in machining quenched steel,” Russian Engineering Research, 33(1), 24 – 28 (2013).

V. V. Kuzin, S. N. Grigoriev, and M. A. Volosova, “The role of the thermal factor in the wear mechanism of ceramic tools. Part 1. Macrolevel,” J. Friction and Wear, 35(6), 505 – 510 (2014).

V. V. Kuzin, S. N. Grigoriev, and M. Yu. Fedorov, “Role of the thermal factor in the wear mechanism of ceramic tools. Part 2. Microlevel,” J. Friction and Wear, 36(1), 40 – 44 (2015).

Work was carried out with financial support of the RF Ministry of Education and Science within the scope of fulfilling a state assignment in the sphere of scientific activity, project No. 9.1372.2017/4.6.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 7, pp. 66 – 70, July, 2018.

Rights and permissions

About this article

Cite this article

Kuzin, V.V., Grigor’ev, S.N. & Fedorov, S.Y. Evaluation of Ceramic Tool Reliability with a Limited Number of Tests Based on Established Wear Criteria. Refract Ind Ceram 59, 386–390 (2018). https://doi.org/10.1007/s11148-018-0241-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-018-0241-1