Abstract

Additive manufacturing (or 3D printing) is an evolving technology that shows great potential as a sustainable method for fabricating gas separation membranes for carbon capture applications. Compared to other gas separation techniques or membranes fabricated by conventional formative methods, the use of 3D-printed membranes is more advantageous because of their simplicity, higher energy efficiency, practicality, flexible and tailorable designs, and high separation efficiency. Although polymeric, cementitious, and gel-based materials have been exploited for the development and fabrication of robust and highly efficient CO2-capturing membranes, these materials require further innovation to become fit and suitable as feedstock for 3D printers. In this work, we review several and potential membrane materials used for capturing CO2 and discuss their corresponding separation mechanisms and fabrication via 3D printing. We also summarize the challenges and limitations in using 3D-printed membranes and provide perspectives towards high-performance membrane fabrication and future industrial applications.

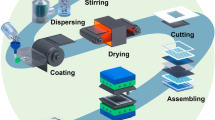

Graphic abstract

Reproduced from Ref. 24 with permission from Elsevier.

Reproduced from Ref. 92 with permission from Elsevier.

Reproduced from Ref. 104 with permission from Elsevier.

Similar content being viewed by others

References

US Environmental Protection Agency, Indicators and concentrations and their impacts on human, https://www.epa.gov/report-environment/greenhouse-gases#:~:text=Major greenhouse gases include carbon,warming associated with human activities. Accessed 8 Mar 2021

M. Fischedick, J. Roy, A. Abdel-Aziz, A. Acquaye, J. Allwood, J.-P. Ceron, Y. Geng, H. Kheshgi, A. Lanza, D. Perczyk, L. Price, E. Santalla, C. Sheinbaum, K. Tanaka, Chapter V. Industry. In: Climate Change 2014: Mitigation of Climate Change. Contri-bution of Working Group III to the Fifth Assessment Report of the Intergovernmental Panel on Climate Change (Cambridge University Press, New York, 2014)

D.S. Pisupati, Products of combustion. https://www.e-education.psu.edu/egee102/node/1951. Accessed 15 Mar 2021

Global Carbon Project: Data supplement to the Global Carbon Budget 2020 (Version 1.0). https://www.icos-cp.eu/science-and-impact/global-carbon-budget/2020. Accessed 15 Mar 2021

M.M. Muñoz-Boado, E.B. Caldona, Gypsum-reinforced zeolite composite for particulate matter reduction from vehicular emissions. J. Environ. Chem. Eng. 5, 2631 (2017)

J.Z. Duran, E.B. Caldona, Design of an activated carbon equipped-cyclone separator and its performance on particulate matter removal. Part. Sci. Technol. 38, 694 (2020)

R.G. Prinn, J. Reilly, M. Sarofim, C. Wang, B. Felzer, Effects of air pollution control on climate (2005), p. 1–14

K. Halada, K. Ijima, K. Yagi, Estimation of the emissions of CO2, SOx, and NOx of steel alloys. J. Mater. Res. 13, 2514 (1987)

G. Xu, F. Liang, Y. Yang, Y. Hu, K. Zhang, W. Liu, An improved CO2 separation and purification system based on cryogenic separation and distillation theory. Energies 7, 3484 (2014)

D.Y.C. Leung, G. Caramanna, M.M. Maroto-Valer, An overview of current status of carbon dioxide capture and storage technologies. Renew. Sustain. Energy Rev. 39, 426 (2014)

Z.Y. Yeo, T.L. Chew, P.W. Zhu, A.R. Mohamed, S.P. Chai, Conventional processes and membrane technology for carbon dioxide removal from natural gas: a review. J. Nat. Gas Chem. 21, 282 (2012)

L. Baxter, A. Baxter, S. Burt, Cryogenic CO2 capture as a cost-effective CO2 capture process (2009)

M. Songolzadeh, M. Soleimani, M. Takht Ravanchi, R. Songolzadeh, Carbon dioxide separation from flue gases: a technological review emphasizing reduction in greenhouse gas emissions. Sci. World J. (2014). https://doi.org/10.1155/2014/828131

J. Mustafa, M. Farhan, M. Hussain, CO2 separation from flue gases using different types of membranes. J. Membr. Sci. Technol. 6 (2016)

C.A. Scholes, G.W. Stevens, S.E. Kentish, Membrane gas separation applications in natural gas processing. Fuel 96, 15 (2012)

T.C. Merkel, H. Lin, X. Wei, R. Baker, Power plant post-combustion carbon dioxide capture: An opportunity for membranes. J. Membr. Sci. 359, 126 (2010)

A.D. Ebner, J.A. Ritter, State-of-the-art adsorption and membrane separation processes for carbon dioxide production from carbon dioxide emitting industries. Sep. Sci. Technol. 44, 1273 (2009)

Y. Alqaheem, A. Alomair, M. Vinoba, A. Pérez, Polymeric gas-separation membranes for petroleum refining. Int. J. Polym. Sci. 2017, 1 (2017)

Y. Han, W.S.W. Ho, Recent advances in polymeric membranes for CO2 capture. Chin. J. Chem. Eng. 26, 2238 (2018)

S. Li, Z. Wang, C. Zhang, M. Wang, F. Yuan, J. Wang, S. Wang, Interfacially polymerized thin film composite membranes containing ethylene oxide groups for CO2 separation. J. Membr. Sci. 436, 121 (2013)

C.E. Powell, G.G. Qiao, Polymeric CO2/N2 gas separation membranes for the capture of carbon dioxide from power plant flue gases. J. Membr. Sci. 279, 1 (2006)

M.A. Aroon, A.F. Ismail, Performance studies of mixed matrix membranes for gas separation: a review. Sep. Purif. Technol. 75, 229 (2010)

Y. Wu, D. Zhao, S. Chen, J. Ren, K. Hua, H. Li, M. Deng, The effect of structure change from polymeric membrane to gel membrane on CO2 separation performance. Sep. Purif. Technol. 261, (2021)

Y.F. Lin, C.R. Syu, K.W. Huang, K.Y.A. Lin, Synthesis of silica aerogel membranes using low-cost silicate precursors for carbon dioxide capture. Chem. Phys. Lett. 726, 13 (2019)

L. Keshavarz, M.R. Ghaani, J.M.D. MacElroy, N.J. English, A comprehensive review on the application of aerogels in CO2-adsorption: materials and characterisation. Chem. Eng. J. 412, 128604 (2021)

H. Thakkar, S. Lawson, A.A. Rownaghi, F. Rezaei, Development of 3D-printed polymer-zeolite composite monoliths for gas separation. Chem. Eng. J. 348, 109 (2018)

Z. Dong, H. Cui, H. Zhang, F. Wang, X. Zhan, M. Wegener, P.A. Levkin, F. Mayer, B. Nestler, Polymerization-induced phase separation. Nat. Commun. 12, 1 (2021)

K. Hunger, N. Schmeling, H.B.T. Jeazet, C. Janiak, Investigation of cross-linked and additive containing polymer materials for membranes with improved performance in pervaporation and gas separation. Membranes 2, 727 (2012)

I. Hossain, A.Z. Al Munsur, T.H. Kim, A facile synthesis of (PIM-polyimide)-(6FDA-durene-polyimide) copolymer as novel polymer membranes for CO2 separation. Membranes (2019). https://doi.org/10.3390/membranes9090113

A.C. de Leon, I.G.M. da Silva, K.D. Pangilinan, Q. Chen, E.B. Caldona, R.C. Advincula, High performance polymers for oil and gas applications. React. Funct. Polym. (2021). https://doi.org/10.1016/j.reactfunctpolym.2021.104878

A.M. Bazzanella, S. Luhr, S. Schiebahn, L. Zhao, Ullmann’s Encyclopedia of Industrial Chemistry. Heterogeneous Catalysis and Solid Catalysts 1. Fundamentals (2014)

J.G. Vitillo, B. Smit, L. Gagliardi, Introduction: carbon capture and separation. Chem. Rev. 117, 9521 (2017)

G. Ji, M. Zhao, Membrane Separation Technology in Carbon Capture. IntechOpen. 59 (2017)

A. Ismail, A. Mustafa, T.D. Kusworo, H. Hasbullah, Understanding the solution-diffusion mechanism in gas separation membrane for engineering students (2005)

D.E. Gottschlich, D.L. Roberts, J.D. Way, A theoretical comparison of facilitated transport and solution-diffusion membrane modules for gas separation. Gas Sep. Purif. 2, 65 (1988)

L.M. Robeson, The upper bound revisited. J. Membr. Sci. 320, 390 (2008)

L.M. Robeson, Correlation of separation factor versus permeability for polymeric membranes. J. Membr. Sci. 62, 165 (1991)

R. Rea, M.G. De Angelis, M.G. Baschetti, Models for facilitated transport membranes: a review. Membranes 9, 1 (2019)

Z.X. Low, Y.T. Chua, B.M. Ray, D. Mattia, I.S. Metcalfe, D.A. Patterson, Perspective on 3D printing of separation membranes and comparison to related unconventional fabrication techniques. J. Membr. Sci. 523, 596 (2017)

L. Zhao, Y. Chen, B. Wang, C. Sun, S. Chakraborty, K. Ramasubramanian, P.K. Dutta, W.S.W. Ho, Multilayer polymer/zeolite Y composite membrane structure for CO2 capture from flue gas. J. Membr. Sci. 498, 1 (2016)

J.H. Meldon, P. Stroeve, V.E. Gregoire, Facilitated transport of carbon monoxide: a review. Chem. Eng. Commun. 16, 263 (1982)

Y. Han, Facilitated transport membranes for carbon capture from flue gas and H2 purification. https://etd.ohiolink.edu/apexprod/rws_etd/send_file/send?accession=osu1543333780761185&disposition=inline. Accessed 28 Feb 2021

R.P. Singh, K.A. Berchtold, Precombustion Carbon Capture (Elsevier, Amsterdam, 2015), pp. 177–206

M. Olaru, I. Bordianu, B.C. Simionescu, Polymers in membrane science. https://www.researchgate.net/profile/Gheorghe_Nechifor/publication/314257931_9_BCS-PPI/data/58be3c5ba6fdcc2d14eb58c3/9-BCS-PPI.pdf. Accessed 9 Mar 2021

R. Pandey, Photopolymers in 3D printing applications (2014)

M. Raouf, R. Abedini, M. Omidkhah, E. Nezhadmoghadam, A favored CO2 separation over light gases using mixed matrix membrane comprising polysulfone/polyethylene glycol and graphene hydroxyl nanoparticles. Process Saf. Environ. Prot. 133, 394 (2020)

S.C. Ligon, R. Liska, J. Stampfl, M. Gurr, R. Mülhaupt, Polymers for 3D printing and customized additive manufacturing. Chem. Rev. 117, 10212 (2017)

J. Lee, J. An, C.K. Chua, Fundamentals and applications of 3D printing for novel materials. Appl. Mater. Today 7, 120 (2017)

Z. Dai, V. Ottesen, J. Deng, R.M.L. Helberg, L. Deng, A brief review of nanocellulose based hybrid. Fibers 1 (2019)

J. Lee, W. See, J. An, C. Kai, C.Y. Tang, A.G. Fane, T. Haur, The potential to enhance membrane module design with 3D printing technology. J. Memb. Sci. 499, 480 (2016)

E.B. Caldona, D.W. Smith, D.O. Wipf, Protective action of semi-fluorinated perfluorocyclobutyl polymer coatings against corrosion of mild steel. J. Mater. Sci. 55, 1796 (2020)

E.B. Caldona, E.I. Borrego, K.E. Shelar, K.M. Mukeba, D.W. Smith Jr., Ring-forming polymerization toward perfluorocyclobutyl and ortho-diynylarene-derived materials: from synthesis to practical applications. Materials 14, 1486 (2021)

C. Staudt-Bickel, J.W. Koros, Improvement of CO2/CH4 separation characteristics of polyimides by chemical crosslinking. J. Membr. Sci. 155, 145 (1999)

C. Klumpen, M. Breunig, T. Homburg, N. Stock, J. Senker, Microporous organic polyimides for CO2 and H2O capture and separation from CH4 and N2 mixtures: interplay between porosity and chemical function. Chem. Mater. 28, 5461 (2016)

A. Georgiev, D. Dimov, E. Spassova, J. Assa, P. Dineff, G. Danev, Chemical and physical properties of polyimides: biomedical and engineering applications. In: High Performance Polymers—Polyimides Based—From Chemistry to Applications (2012)

X.Y. Chen, N. Tien-Binh, S. Kaliaguine, D. Rodrigue, Polyimide membranes for gas separation: synthesis, processing and properties (2016), pp. 1–71

X.Y. Chen, S. Kaliaguine, D. Rodrigue, Polymer hollow fiber membranes for gas separation: a comparison between three commercial resins. AIP Conference Proceedings 2139 (2019)

H. Yao, N. Zhang, N. Song, K. Shen, P. Huo, S. Zhu, Y. Zhang, S. Guan, Microporous polyimide networks constructed through a two-step polymerization approach, and their carbon dioxide adsorption performance. Polym. Chem. 8, 1298 (2017)

D.L. Dunson, Synthesis and characterization of thermosetting polyimide oligomers for microelectronics packaging, Ph.D. Dissertation, Virginia Polytechnic Institute and State University (2000)

Z. Gao, Y. Wang, H. Wu, Y. Ren, Z. Guo, X. Liang, Y. Wu, Y. Liu, Z. Jiang, Surface functionalization of polymers of intrinsic microporosity (PIMs) membrane by polyphenol for efficient CO2 separation. Green Chem. Eng. (2020). https://doi.org/10.1016/j.gce.2020.12.003

A. Arabi Shamsabadi, M. Rezakazemi, F. Seidi, H. Riazi, T. Aminabhavi, M. Soroush, Next generation polymers of intrinsic microporosity with tunable moieties for ultrahigh permeation and precise molecular CO2 separation. Prog. Energy Combust. Sci. 84, (2021)

Z. Wang, Q. Shen, J. Liang, Y. Zhang, J. Jin, Adamantane-grafted polymer of intrinsic microporosity with finely tuned interchain spacing for improved CO2 separation performance. Sep. Purif. Technol. 233, 116008 (2020)

N.B. Mckeown, The synthesis of polymers of intrinsic microporosity (PIMs). Sci. China Chem. 60, 1023 (2017)

J. Song, N. Du, Y. Dai, G.P. Robertson, M.D. Guiver, S. Thomas, I. Pinnau, Linear high molecular weight ladder polymers by optimized polycondensation of tetrahydroxytetramethylspirobisindane. Macromolecules 41, 1 (2021)

A. Fuoco, Polymeric gas separation membranes. J. Membr. Sci. Technol. 8, 8 (2018)

S. Saqib, S. Rafiq, N. Muhammad, A.L. Khan, A. Mukhtar, N.B. Mellon, Z. Man, M.H. Nawaz, F. Jamil, N.M. Ahmad, Perylene based novel mixed matrix membranes with enhanced selective pure and mixed gases (CO2, CH4, and N2) separation. J. Nat. Gas Sci. Eng. 73, 103072 (2020)

R.D. Noble, Perspectives on mixed matrix membranes. J. Membr. Sci. 378, 393 (2011)

D. Nguyen, M. Murialdo, K. Hornbostel, S. Pang, C. Ye, W. Smith, S. Baker, W. Bourcier, J. Knipe, R. Aines, J. Stolaroff, 3D printed polymer composites for CO2 capture. Ind. Eng. Chem. Res. 58, 22015 (2019)

D. Venturi, L. Ansaloni, M.G. Baschetti, Nanocellulose based facilitated transport membranes for CO2 separation. Chem. Eng. Trans. 47, 349 (2016)

X.F. Zhang, T. Hou, J. Chen, Y. Feng, B. Li, X. Gu, M. He, J. Yao, Facilitated transport of CO2 through the transparent and flexible cellulose membrane promoted by fixed-site carrier. ACS Appl. Mater. Interfaces. 10, 24930 (2018)

W. Zhang, M. Gaggl, G.J.G. Gluth, F. Behrendt, Gas separation using porous cement membrane. J. Environ. Sci. 26, 140 (2014)

Z. Weiqi, Experimental investigation on gas separation using porous membranes, der Technischen Universität Berlin. https://d-nb.info/1013350804/34 (2011)

A.H. Shafie, Gas separation membranes using cementitious-zeolite composite. https://era.library.ualberta.ca/items/0b5543c3-503a-4562-90c9-12e45c09e7a4/download/6103e4bb-d433-4011-b5f5-8ba69f40996e. Accessed 28 Feb 2021

M.G. Plaza, S. Martínez, F. Rubiera, CO2 capture, use, and storage in the cement industry: state of the art and expectations. Energies 13, 5692 (2020)

C.A. Scholes, M.T. Ho, A.A. Aguiar, D.E. Wiley, G.W. Stevens, S.E. Kentish, Membrane gas separation processes for CO2 capture from cement kiln flue gas. Int. J. Greenh. Gas Control. 24, 78 (2014)

R. Castro-muñoz, V. Martin-gil, M.Z. Ahmad, Matrimid ® 5218 in preparation of membranes for gas separation: current state-of-the-art. Chem. Eng. Commun. 205, 161 (2018)

S. Geng, J. Wei, S. Jonasson, J. Hedlund, K. Oksman, Multifunctional carbon aerogels with hierarchical anisotropic structure derived from lignin and cellulose nanofibers for CO2 capture and energy storage. ACS Appl. Mater. Interfaces. 12, 7432 (2020)

J.E. Amonette, J. Matyáš, Functionalized silica aerogels for gas-phase purification, sensing, and catalysis: a review. Microporous Mesoporous Mater. 250, 100 (2017)

M. Zeeshan, K. Yalcin, F.E. Sarac Oztuna, U. Unal, S. Keskin, A. Uzun, A new class of porous materials for efficient CO2 separation: ionic liquid/graphene aerogel composites. Carbon 171, 79–87 (2021)

D. Zhang, Y. Lin, W. Wang, Y. Li, G. Wu, Mechanically strong polyimide aerogels cross-linked with dopamine-functionalized carbon nanotubes for oil absorption. Appl. Surf. Sci. 543, 148833 (2021)

A. Bagheri, J. Jin, Photopolymerization in 3D printing. ACS Appl. Polym. Mater. 1, 593 (2019)

S. Wickramasinghe, T. Do, P. Tran, FDM-based 3D printing of polymer and associated composite: a review on mechanical properties. Polymers (2020). https://doi.org/10.3390/polym12071529

H.T. Afarani, W. Carroll, E.J. Garboczi, J.J. Biernacki, Designing 3D printable cementitious materials with gel-forming polymers. Constr. Build. Mater. 268, (2021)

R.V. Pazhamannil, P. Govindan, Current state and future scope of additive manufacturing technologies via vat photopolymerization. Mater. Today Proc. (2021). https://doi.org/10.1016/j.matpr.2020.11.225

N.U. Barambu, M.R. Bilad, Y. Wibisono, J. Jaafar, T.M.I. Mahlia, A.L. Khan, Membrane surface patterning as a fouling mitigation strategy in liquid filtration: a review. Polymers 11, 1 (2019)

M. Gillono, I. Roppolo, F. Frascella, L. Scaltrito, C.F. Pirri, A. Chiappone, CO2 permeability control in 3D printed light responsive structures. Appl. Mater. Today 18, 100470 (2020)

S.Y. Chin, V. Dikshit, B.M. Priyadarshini, Y. Zhang, Powder-based 3D printing for the fabrication of device with micro and mesoscale features. Micromachines 11, 29 (2020)

C. Cai, W.S. Tey, J. Chen, W. Zhu, X. Liu, T. Liu, L. Zhao, K. Zhou, Comparative study on 3D printing of polyamide 12 by selective laser sintering and multi jet fusion. J. Mater. Process. Technol. 288, 116882 (2021)

S. Yuan, Advanced membrane synthesis methods: exploration of 3D printed membranes for oil/water separation and development of novel polymers for organic solvent nanofiltration—KU Leuven. https://limo.libis.be/primo-explore/fulldisplay?docid=LIRIAS2327124&context=L&vid=KULeuven&search_scope=ALL_CONTENT&tab=all_content_tab&lang=nl_BE (2018)

A. Mostafaei, A.M. Elliott, J.E. Barnes, F. Li, W. Tan, C.L. Cramer, P. Nandwana, M. Chmielus, Binder jet 3D printing—process parameters, materials, properties, and challenges. Prog. Mater Sci. (2020). https://doi.org/10.1016/j.pmatsci.2020.100707

M. Shirinia, M. Abdollahi, M. Omidkhah, Simultaneous enhancement of CO2 permeability and CO2/CH4 and CO2/N2 selectivity via incorporating dense, rubbery and CO2-philic vinyl acetate- based copolymers into poly(ethylene oxide-b-amide 6) membranes. React. Funct. Polym. 154, 104673 (2020)

F.P.W. Melchels, J. Feijen, D.W. Grijpma, Biomaterials a review on stereolithography and its applications in biomedical engineering. Biomaterials 31, 6121 (2010)

H. Zhang, K. Xue, C. Cheng, D. Gao, H. Chen, Study on the performance of CO2 capture from flue gas with ceramic membrane contactor. Sep. Purif. Technol. (2021). https://doi.org/10.1016/j.seppur.2021.118521

M. Zhang, L. Deng, D. Xiang, B. Cao, S. Hosseini, P. Li, Approaches to suppress CO2-induced plasticization of polyimide membranes in gas. Processes 7, 51 (2019)

A.M.W. Hillock, W.J. Koros, Cross-linkable polyimide membrane for natural gas purification and carbon dioxide plasticization reduction. Macromolecules 40, 583 (2007)

J.D. Wind, C. Staudt-bickel, D.R. Paul, W.J. Koros, The effects of crosslinking chemistry on CO2 plasticization of polyimide gas separation membranes. Ind. Eng. Chem. Res. 41, 6139 (2002)

Q. Chen, L. Han, J. Ren, L. Rong, P. Cao, R.C. Advincula, 4D printing via an unconventional fused deposition modeling route to high-performance thermosets. ACS Appl. Mater. Interfaces. 12, 50052 (2020)

X. He, A review of material development in the field of carbon capture and the application of membrane-based processes in power plants and energy-intensive industries. Energy Sustain. Soc. (2018). https://doi.org/10.1186/s13705-018-0177-9

S.D. Bazhenov, I.L. Borisov, D.S. Bakhtin, A.N. Rybakova, V.S. Khotimskiy, S.P. Molchanov, V.V. Volkov, High-permeance crosslinked PTMSP thin-film composite membranes as supports for CO2 selective layer formation. Green Energy Environ. 1, 235 (2016)

J. Lee, W.S. Tan, J. An, C. Kai, C.Y. Tang, A.G. Fane, The potential to enhance membrane module design with 3D printing technology. J. Membr. Sci. (2015)

L.D. Tijing, J.R.C. Dizon, I. Ibrahim, A.R.N. Nisay, H.K. Shon, R.C. Advincula, 3D printing for membrane separation, desalination and water treatment. Appl. Mater. Today. 18, 100486 (2020)

S. Jasveer, X. Jianbin, Comparison of different types of 3D printing technologies. Int. J. Sci. Res. Publ. 8, 1 (2018)

M. Spoerk, C. Holzer, J. Gonzalez-gutierrez, Material extrusion-based additive manufacturing of polypropylene: a review on how to improve dimensional inaccuracy and warpage. J. Appl. Polym. Sci. 137, 48545 (2019)

D.J. Whyte, R. Rajkhowa, B. Allardyce, A.Z. Kouzani, A review on the challenges of 3D printing of organic powders. Bioprinting 16, (2019)

M. Walker, S. Humphries, 3D printing: applications in evolution and ecology. Ecol. Evol. 9, 4289 (2019)

Acknowledgments

The authors (DBG) would like to thank the Department of Science and Technology- Engineering Research and Development for Technology (DOST-ERDT) for the financial support. Work (or Part of this work) was conducted by ORNL’s Center for Nanophase Materials Sciences by RCA, which is a US Department of Energy Office of Science User Facility.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Rigoberto C. Advincula was an editor of this journal during the review and decision stage. For the MRS Communications policy on review and publication of manuscripts authored by editors, please refer to http://www.mrs.org/editor-manuscripts/.

Rights and permissions

About this article

Cite this article

Gutierrez, D.B., Caldona, E.B., Espiritu, R.D. et al. The potential of additively manufactured membranes for selective separation and capture of CO2. MRS Communications 11, 391–401 (2021). https://doi.org/10.1557/s43579-021-00062-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/s43579-021-00062-8