Abstract

This study examines perfluorocyclobutyl (PFCB) aromatic ether polymers and demonstrates, for the first time, their potential as corrosion-resistant coatings. PFCB polymers are a distinct class of semi-fluorinated polymers that are based on thermal cyclopolymerization of aromatic trifluorovinyl ethers. They combine the flexibility and thermal stability of aromatic ethers with strong fluorocarbon linkages. Electrochemical impedance spectroscopy and potentiodynamic scans reveal that PFCB coatings display protective barrier properties against corrosion attack nearly equal to that of polyvinylidene fluoride (PVDF) coatings. The PFCBs also show excellent adhesion to metal surfaces and nonstick properties comparable to that of PVDF. Combined with their high thermal resistance, PFCBs may lead to new corrosion-resistant coatings in marine, oil and gas, and other applications.

Similar content being viewed by others

References

Javaherdashti R (2000) How corrosion affects industry and life. AntiCorros Methods Mater 47:30–34

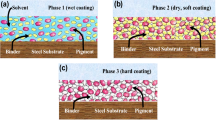

Forsgren A, Knudsen OØ (2017) Corrosion control through organic coatings. CRC Press, Boca Raton

Jones FN, Nichols ME, Pappas SP (2017) Organic coatings: science and technology. Wiley, New York

Van der Wel G, Adan O (1999) Moisture in organic coatings—a review. Prog Org Coat 37:1–14

Grundmeier G, Schmidt W, Stratmann M (2000) Corrosion protection by organic coatings: electrochemical mechanism and novel methods of investigation. Electrochim Acta 45:2515–2533

Caldona EB, De Leon ACC, Thomas PG et al (2017) Superhydrophobic rubber-modified polybenzoxazine/SiO2 nanocomposite coating with anticorrosion, anti-ice, and superoleophilicity properties. Ind Eng Chem Res 56:1485–1497

Caldona EB, Al Christopher C, Mangadlao JD et al (2018) On the enhanced corrosion resistance of elastomer-modified polybenzoxazine/graphene oxide nanocomposite coatings. React Funct Polym 123:10–19

Sørensen PA, Kiil S, Dam-Johansen K, Weinell CE (2009) Anticorrosive coatings: a review. J Coat Technol Res 6:135–176

Caldona EB, Al Christopher C, Pajarito BB, Advincula RC (2017) Novel anti-corrosion coatings from rubber-modified polybenzoxazine-based polyaniline composites. Appl Surf Sci 422:162–171

Siepmann F, Siepmann J, Walther M et al (2008) Polymer blends for controlled release coatings. J Control Release 125:1–15

Caldona EB, De Leon ACC, Pajarito BB, Advincula RC (2017) A review on rubber-enhanced polymeric materials. Polym Rev 57:311–338

Mittal V (2013) Polymer nanocomposite coatings. CRC Press, Boca Raton

Weiss KD (1997) Paint and coatings: a mature industry in transition. Prog Polym Sci 22:203–245

Bellucci F, Nicodemo L (1993) Water transport in organic coatings. Corrosion 49:235–247

Sangaj NS, Malshe V (2004) Permeability of polymers in protective organic coatings. Prog Org Coat 50:28–39

Thomas NL (1991) The barrier properties of paint coatings. Prog Org Coat 19:101–121

Mittal KL (1995) Adhesion measurement of films and coatings. VSP, Rancho Cordova

Awaja F, Gilbert M, Kelly G et al (2009) Adhesion of polymers. Prog Polym Sci 34:948–968

Keck S (1969) Mechanical alteration of the paint film. Stud Conserv 14:9–30

Bacon RC, Smith JJ, Rugg FM (1948) Electrolytic resistance in evaluating protective merit of coatings on metals. Ind Eng Chem 40:161–167

Leidheiser H Jr (1982) Corrosion of painted metals—a review. Corrosion 38:374–383

Bethencourt M, Botana F, Cano M et al (2004) Lifetime prediction of waterborne acrylic paints with the AC–DC–AC method. Prog Org Coat 49:275–281

Yang X, Vang C, Tallman D et al (2001) Weathering degradation of a polyurethane coating. Polym Degrad Stab 74:341–351

Malshe V, Waghoo G (2004) Weathering study of epoxy paints. Prog Org Coat 51:267–272

Knop A, Pilato LA (2013) Phenolic resins: chemistry, applications and performance. Springer, Berlin

Vecellio M (2000) Opportunities and developments in fluoropolymeric coatings. Prog Org Coat 40:225–242

Takayanagi T, Yamabe M (2000) Progress of fluoropolymers on coating applications: development of mineral spirit soluble polymer and aqueous dispersion. Prog Org Coat 40:185–190

Teng H (2012) Overview of the development of the fluoropolymer industry. Appl Sci 2:496–512

Iezzi RA (1997) Fluoropolymer coatings for architectural applications. Mod Fluoropolym 14:271–299

Scheirs J (1997) Structure/property considerations for fluoropolymers and fluoroelastomers to avoid in-service failure. Wiley, Chichester

He Y, Walsh D, Shi C (2015) Fluoropolymer composite coating for condensing heat exchangers: characterization of the mechanical, tribological and thermal properties. Appl Therm Eng 91:387–398

Forsythe J, Hill D (2000) The radiation chemistry of fluoropolymers. Prog Polym Sci 25:101–136

Tannenbaum HP (2004) Fluoropolymer non-stick coatings. US Patent 6,761,964, July 2004

Munekata S (1988) Fluoropolymers as coating material. Prog Org Coat 16:113–134

Yang MK, French RH, Tokarsky EW (2008) Optical properties of Teflon® AF amorphous fluoropolymers. J MicroNanolithogr MEMS MOEMS 7:033010

Chambers LD, Stokes KR, Walsh FC, Wood RJ (2006) Modern approaches to marine antifouling coatings. Surf Coat Technol 201:3642–3652

Graham P, Stone M, Thorpe A et al (2000) Fluoropolymers with very low surface energy characteristics. J Fluor Chem 104:29–36

Banks RE, Smart BE, Tatlow J (2013) Organofluorine chemistry: principles and commercial applications. Springer, Berlin

Biswas S, Vijayan K (1992) Friction and wear of PTFE—a review. Wear 158:193–211

Leivo E, Wilenius T, Kinos T et al (2004) Properties of thermally sprayed fluoropolymer PVDF, ECTFE, PFA and FEP coatings. Prog Org Coat 49:69–73

Sidebottom MA, Pitenis AA, Junk CP et al (2016) Ultralow wear Perfluoroalkoxy (PFA) and alumina composites. Wear 362:179–185

Smith DW, Iacono ST, Iyer SS (2014) Handbook of fluoropolymer science and technology. Wiley, New York

Millet G, Kosmala J (2000) Fluorine-containing polymers, polychlorotrifluoroethylene. Kirk-Othmer Encycl Chem Technol 11:393–396

Gregorio R, Capitao R (2000) Morphology and phase transition of high melt temperature crystallized poly (vinylidene fluoride). J Mater Sci 35:299–306. https://doi.org/10.1023/A:1004737000016

Nalwa HS (1991) Recent developments in ferroelectric polymers. J Macromol Sci Part C Polym Rev 31:341–432

Babb DA, Clement KS, Richey WF, Ezzell BR (1991) Perfluorocyclobutane ring-containing polymers. US Patent 5,037,917, February 2008

Smith DW Jr, Babb DA, Shah HV et al (2000) Perfluorocyclobutane (PFCB) polyaryl ethers: versatile coatings materials. J Fluor Chem 104:109–117

Babb DA, Ezzell BR, Clement KS et al (1993) Perfluorocyclobutane aromatic ether polymers. J Polym Sci Part Polym Chem 31:3465–3477

Kennedy AP, Babb DA, Bremmer JN, Pasztor JRAJ (1995) Perfluorocyclobutane aromatic ether polymers. II. Thermal/oxidative stability and decomposition of a thermoset polymer. J Polym Sci Part Polym Chem 33:1859–1865

Smith D, Babb D (1996) Perfluorocyclobutane aromatic polyethers. Synthesis and characterization of new siloxane-containing fluoropolymers. Macromolecules 29:852–860

Gavrin A, Nebo J, Rice N, et al (2004) Perfluorocyclobutane (PFCB) Polyaryl ethers for space-based applications. In: Kleiman J, Tagawa M, Kimoto Y (eds) Protection of materials and structures from space environment. Springer, Dordrecht, Netherlands, pp 491–501

Salimi A, Yousefi A (2003) Analysis method: FTIR studies of β-phase crystal formation in stretched PVDF films. Polym Test 22:699–704

Beele W, Marijnissen G, van Lieshout A (1999) The evolution of thermal barrier coatings—status and upcoming solutions for today’s key issues. Surf Coat Technol 120–121:61–67

Duvall DS (1981) Processing technology for advanced metallic and ceramic turbine airfoil coatings. In: Proceedings of the 2nd conference on advanced materials for alternative-fuel-capable heat engines, 24–28 August 1981. EPRI RD-2369-SR, Electric Power Research Institute, pp 6-102–6-117

Tallal J, Gordon M, Berton K et al (2006) AFM characterization of anti-sticking layers used in nanoimprint. Microelectron Eng 83:851–854

Brewis D, Dahm RH (2006) Adhesion to fluoropolymers. iSmithers Rapra Publishing, Shawbury

Mathieson I, Brewis D, Sutherland I, Cayless R (1994) Pretreatments of fluoropolymers. J Adhes 46:49–56

Martins P, Costa C, Benelmekki M et al (2013) Interface characterization and thermal degradation of ferrite/poly (vinylidene fluoride) multiferroic nanocomposites. J Mater Sci 48:2681–2689. https://doi.org/10.1007/s10853-012-7063-1

Nikravesh B, Ramezanzadeh B, Sarabi A, Kasiriha S (2011) Evaluation of the corrosion resistance of an epoxy-polyamide coating containing different ratios of micaceous iron oxide/Al pigments. Corros Sci 53:1592–1603

Liu S, Gu L, Zhao H et al (2016) Corrosion resistance of graphene-reinforced waterborne epoxy coatings. J Mater Sci Technol 32:425–431

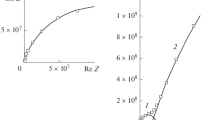

Bonora P, Deflorian F, Fedrizzi L (1996) Electrochemical impedance spectroscopy as a tool for investigating underpaint corrosion. Electrochim Acta 41:1073–1082

Amirudin A, Thieny D (1995) Application of electrochemical impedance spectroscopy to study the degradation of polymer-coated metals. Prog Org Coat 26:1–28

González JE, Mirza-Rosca J (1999) Study of the corrosion behavior of titanium and some of its alloys for biomedical and dental implant applications. J Electroanal Chem 471:109–115

Rammelt U, Köhler S, Reinhard G (2008) EIS characterization of the inhibition of mild steel corrosion with carboxylates in neutral aqueous solution. Electrochim Acta 53:6968–6972

Scully JR (1989) Electrochemical impedance of organic-coated steel: correlation of impedance parameters with long-term coating deterioration. J Electrochem Soc 136:979–990

Hirayama R, Haruyama S (1991) Electrochemical impedance for degraded coated steel having pores. Corrosion 47:952–958

Deflorian F, Fedrizzi L, Rossi S, Bonora P (1999) Organic coating capacitance measurement by EIS: ideal and actual trends. Electrochim Acta 44:4243–4249

Hsu C, Mansfeld F (2001) Concerning the conversion of the constant phase element parameter Y0 into a capacitance. Corrosion 57:747–748

Stern M, Geary AL (1957) Electrochemical polarization I. A theoretical analysis of the shape of polarization curves. J Electrochem Soc 104:56–63

Ramezanzadeh B, Niroumandrad S, Ahmadi A et al (2016) Enhancement of barrier and corrosion protection performance of an epoxy coating through wet transfer of amino functionalized graphene oxide. Corros Sci 103:283–304

Walter G (1986) A review of impedance plot methods used for corrosion performance analysis of painted metals. Corros Sci 26:681–703

Gray LG, Appleman BR (2003) EIS: electrochemical impedance spectroscopy. J Prot Coat Linings 20:66–74

Wessling B (1994) Passivation of metals by coating with polyaniline: corrosion potential shift and morphological changes. Adv Mater 6:226–228

Stojilovic N (2012) Why can’t we see hydrogen in X-ray photoelectron spectroscopy? J Chem Educ 89:1331–1332

Tran ND, Dutta NK, Choudhury NR (2006) Weatherability and wear resistance characteristics of plasma fluoropolymer coatings deposited on an elastomer substrate. Polym Degrad Stab 91:1052–1063

Touzin M, Chevallier P, Lewis F et al (2008) Study on the stability of plasma-polymerized fluorocarbon ultra-thin coatings on stainless steel in water. Surf Coat Technol 202:4884–4891

Delimi A, Galopin E, Coffinier Y et al (2011) Investigation of the corrosion behavior of carbon steel coated with fluoropolymer thin films. Surf Coat Technol 205:4011–4017

Acknowledgements

The authors acknowledge support from Mississippi State University, Department of Chemistry and Marvin B. Dow Advanced Composites Institute.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

This work is dedicated to Prof. Charles U. Pittman, Jr. on the occasion of his 80th birthday.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Caldona, E.B., Smith, D.W. & Wipf, D.O. Protective action of semi-fluorinated perfluorocyclobutyl polymer coatings against corrosion of mild steel. J Mater Sci 55, 1796–1812 (2020). https://doi.org/10.1007/s10853-019-04025-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-04025-2