Abstract

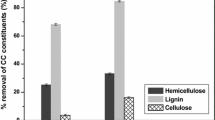

Optimizing process conditions and parameters such as ammonia loading, moisture content of biomass, temperature, and residence time is necessary for maximum effectiveness of the ammonia fiber explosion process. Approximate optimal pretreatment conditions for corn stover were found to be temperature of 90°C, ammonia: dry corn stover mass ratio of 1∶1, moisture content of corn stover of 60% (dry weight basis), and residence time (holding at target temperature), of 5 min. Approximately 98% of the theoretical glucose yield was obtained during enzymatic hydrolysis of the optimal treated corn stover using 60 filter paper units (FPU) of cellulase enzyme/g of glucan (equal to 22 FPU/g of dry corn stover). The ethanol yield from this sample was increased up to 2.2 times over that of untreated sample. Lowering enzyme loading to 15 and 7.5 FPU/g of glucan did not significantly affect the glucose yield compared with 60 FPU, and any differences between effects at different enzyme levels decreased as the treatment temperature increased.

Similar content being viewed by others

References

Hall, D. O. (1979), Solar Energy, 22, 307–328.

Wyman, C. E. (1999), Annu. Rev. Energy Environ. 24, 189–226.

Wyman, C. E. (1995), in Enzymatic Degradation of Insoluble Carbohydrates, ACS Symposium Series 618, Saddler, J. N. and Penner, M. H., eds., American Chemical Society, Washington, DC, pp. 272–290.

Walter, A. (2000), in Industrial Uses of Biomass Energy, Rosillo-Calle, F., Bajay, S. V., and Rothman, H., eds., Taylor & Francis, London, New York, pp. 200–253.

Lamptey, J., Moo-Young, M., and Robinson, C. W. (1986), in Biotechnology and Renewable Energy, Moo-Young, M. and Laptey, J., eds. Elsevier Applied Science, London, UK, pp. 46–56.

Holtzapple, M. T., Jun, J., Ashok, G., Patibandla, S. L., and Dale, B. E. (1991), Appl. Biochem. Biotechnol. 28/29, 59–74.

Wang, P. Y., Bolker, H. I., and Pruves, C. B. (1967), Tappi 50 (3), 123–124.

O'Conner, J. I. (1972), Tappi 55 (3), 353–358.

Moniruzzaman, M., Dale, B. E., Hespell, R. B., and Bothast, R. J. (1997), Appl. Biochem. Biotechnol. 67, 113–126.

Dale, B. E., Henk, L. L., and Shiang, M. (1985), Dev. Ind. Microbiol. 26, 223–233.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Teymouri, F., Laureano-Pérez, L., Alizadeh, H. et al. Ammonia fiber explosion treatment of corn stover. Appl Biochem Biotechnol 115, 951–963 (2004). https://doi.org/10.1385/ABAB:115:1-3:0951

Issue Date:

DOI: https://doi.org/10.1385/ABAB:115:1-3:0951