Abstract

In this whitepaper, the Manufacturing Technical Committee of the Product Quality Research Institute provides information on the common, best practices in use today in the development of high-quality chemistry, manufacturing and controls documentation. Important topics reviewed include International Conference on Harmonization, in vitro–in vivo correlation considerations, quality-by-design approaches, process analytical technologies and current scale-up, and process control and validation practices. It is the hope and intent that this whitepaper will engender expanded dialog on this important subject by the pharmaceutical industry and its regulatory bodies.

Similar content being viewed by others

INTRODUCTION

In 1991–1992, three scientific organizations—the American Association of Pharmaceutical Scientists, the Food & Drug Association (FDA), and the United States Pharmacopeia (USP)—collaborated to organize two workshops to explore the Scale-Up and Post-approval Change (SUPAC) principles for (1) immediate-release oral solid dosage forms (1991) and (2) oral extended-release dosage forms (1992). Proceedings from both workshops were published in 1993 (1,2) and have been used as guidance to the industry and regulatory bodies. The proceedings of both workshops discussed and defined the impact of (1) formulation or compositional changes, (2) process variable changes, (3) process scale changes, and (4) process site changes on the finished quality parameters of these products. Each area of change was further divided to reflect a hierarchy of “significance” and hence aided in establishing post-approval change filing documentation. In the case of the extended-release dosage forms, the potential need for the conduct of one or more pivotal bioavailability/bioequivalence (BA/BE) studies was recognized and, as a result, included a recommended decision tree to determine when a BE study would be needed to prove equivalence.

Although these documents continue to have utility in supporting post-approval changes, it has been recognized that there have been many improvements implemented in the scale-up and control of both immediate-release and extended-release oral solid dosage forms in the last two decades. It is the goal of the authors of this whitepaper to provide a concise updating of important development principles currently available to those in the industry involved in the development of such products. Accordingly, this whitepaper will present comprehensive chemistry, manufacturing, and controls (CMC) information to those involved in the development and review of oral solid dosage form dossiers. It is our hope that the added information will lead to improved process for post-approval changes. While much of this information is available in official guidance documents, for example, International Conference on Harmonization (ICH) and quality-by-design (QbD) documents, it is a goal of this whitepaper to bring all of the independent pieces into a unified document to facilitate improved understanding and implementation.

This whitepaper, sponsored by the Product Quality Research Institute, is a result of that thinking and is designed to engender additional discussion and commentary from experts within the industry, academia, and worldwide regulatory bodies. Although the document retains the spirit of the original workshop reports, it encourages the inclusion of new tools for the development, testing, and control of oral solid dosage forms. The use of tools and approaches such as process analytical technologies (PATs), QbD, in vitro–in vivo correlation (IVIVC), and more thorough excipient characterization should improve the robustness of the finished products and minimize or prevent unintended drift in the quality of the affected commercial drug products.

It should be noted that these best practices, as outlined in this paper, are only applicable to QbD-based applications. They cannot be used for legacy or mature products which were not developed using the new systematic and life cycle approaches. The principles of QbD are mainly in use in Canada, Europe, Japan, and the USA, but are gaining recognition in other countries as well.

REVIEW OF THE 1993 ORAL SOLID DOSAGE FORM WORKSHOP REPORT FINDINGS

We begin our oral solid whitepaper with a brief review of the salient findings of the 1993 publications.

Compositional Variables

In 1993, it was recognized that oral solid dosage forms contained both “noncritical” and “critical” components and that it was the job of the formulating scientist to establish (with data) which excipients fell into each category. Furthermore, it was recognized that for noncritical excipients, for both immediate- and extended-release (ER) products, “certain compositional adjustments (to formulations) were determined to be acceptable, without further justification” (2). The report also noted that “there is, however, an additional consideration for extended-release dosage forms: the inclusion of a critical release component(s) which enables the extended release of active ingredients. Thus, for extended-release dosage forms, consideration must be given as to whether the component is critical or not critical to drug release” (2). The passage of time has certainly confirmed the validity of these statements.

The authors have undertaken within this whitepaper to include a review of the current tools in place that allow pharmaceutical scientists and regulators to evaluate whether a change is critical or not critical.

Using tools in place today such as QbD approaches that explore and understand the relationships between target product parameters and end product quality attributes, our contributors believe that more robust products will result. We also feel that the use of the current improved statistical design packages when combined with QbD approaches can afford substantial information about the allowable range of both minor excipients/components and those that are critical to product performance. In addition, the use of these approaches when combined with improved testing techniques associated with PAT and enhanced finished product testing such as in vitro release can and should be used to facilitate review and approval of post-approval CMC submissions involving compositional variables. Each of these techniques will be discussed fully in subsequent sections of this whitepaper.

Process Variables

Since 1993, substantial progress has been made by the pharmaceutical industry in the development of robust manufacturing processes. Techniques such as PAT are becoming more common in process control of manufacturing operations and in continual feedback and feed-forward loops that adjust manufacturing operations, thereby providing a more consistent end product. In parallel, improvements to end product testing results, including enhanced statistical tools, have further increased the ability of companies to manufacture more consistent products and to monitor and control variation. Today’s pharmaceutical scientist also has greatly improved statistical design tools with which to proactively develop and test formulation and manufacturing process parameters. Our collaborators have elaborated on these control strategies in several sections of this whitepaper.

In Vitro Tests

In vitro testing was common in 1993 and was regarded as “a basic quality control tool used along with stability data to control scale-up and post-approval changes” (1). In this whitepaper, we review modernization of those techniques and the testing equipment used to monitor in vitro drug release, with an end goal of facilitating the development of IVIVCs that can be used to expedite post-approval changes.

In Vitro/In Vivo Correlation

The 1993 Workshop Report on extended-release dosage forms stated that “in order to utilize an IVIVC, the adequacy of the in vitro method to act as a surrogate for in vivo testing must be demonstrated” (2). In the two decades that have followed, a number of IVIVCs have been developed. The current state-of-the- art approaches to IVIVC development are reviewed within this whitepaper in order to encourage further development of this important tool.

In addition to providing a brief review of all of the major tools in place today that are useful to the pharmaceutical scientist involved in the development of immediate- and extended-release oral solid dosage forms, our whitepaper contributors have included brief commentary on what they see as developing trends that could bring new exciting tools to bear on these issues in the next 3–5 years.

CURRENT PRINCIPLES THAT AFFECT IR AND MR PRODUCT DEVELOPMENT

Introduction and Current State

The Federal Food, Drug, and Cosmetic Act and the Code of Federal Regulations (Section 314.70(a)(2)) state that the applicant holds the final responsibility for determining the effects of a change on the drug product as it relates to the product’s safety and efficacy before distributing the drug product made with a manufacturing change. When the safety aspect of the product is brought into question as a result of a change, a prior approval supplement is called for, irrespective of the suggested filing category for that change. Other than for minor editorial changes such as spelling corrections or reformatting batch records, etc., the applicant must notify the FDA about each change that is made beyond the range that is allowed for that change in the approved application (Section 314.70(a)(1)).

A Supplement or Annual Report must include a list of all changes contained in the document. The list must describe each change in sufficient detail so that the agency can make an objective assessment on the appropriateness of the reporting category used. For supplements, the list must be provided in the cover letter (Section 314.70(a)(6)); for annual reports, the list should be included in the Summary Section (Section 314.81(b)(2)(i)). Each change must be described in complete detail inside the document.

Available post-approval regulatory documents in the USA cover a range of topics, but are more focused on drug product and changes associated with drug product manufacture. There are some regulatory guidance documents in the USA that cover drug substance changes, but are fairly limited in scope. A few FDA guidance documents issued were specific to drug substance, e.g., Bulk Active Compound Post-approval Change (BACPAC) 1, but have since been withdrawn. Thus, there is a pressing need for active pharmaceutical ingredient (API)-focused guidance documents for post-approval changes in the USA.

Changes to the drug substance control strategy may be subject to post-approval change requirements, as stipulated in FDA guidance documents. For example, changes to the drug substance manufacturing process require the submission of a prior approval supplement as defined under computer-assisted NDA (CANDA) requirements, unless the change is covered by an approved design space in the New Drug Application (NDA).

The availability of ICH Q7 and Q11 guidance documents has relieved the current gap in a limited way. However, post-approval changes and submissions pathways to handle those changes are quite regional in nature, and these guidance documents do not address that issue. Several guidance documents have been issued by non-US regulatory agencies [e.g., EC communication on variations (3) and Health Canada guidance on post-notice of compliance (NOC) changes (4)] that offer valuable insight into the regulatory pathways (ex-US) to submitting post-approval changes.

ICH Initiatives (Q8, Q9, Q10, Q11)

The FDA’s Critical Path Initiative (5) triggered the development of new quality paradigms in the pharmaceutical industry, including the concept of QbD. The FDA’s ultimate goal was to transform its CMC review practices into a science and risk-based pharmaceutical quality assessment system which could potentially lead to an increase in the number of successful new applications and a reduction in the number of post-approval supplements.

Specifically, the FDA’s objectives were to:

-

Encourage early adoption of new technological advances by the pharmaceutical industry

-

Facilitate industry application of modern quality management techniques, including implementation of quality systems approaches, to all aspects of pharmaceutical production and quality assurance

-

Encourage implementation of risk-based approaches that focus both industry and the agency attention on critical areas

-

Ensure regulatory review and inspection policies are based on state-of-the-art pharmaceutical science

-

Enhance consistency and coordination of the FDA’s drug quality regulatory programs, in part, by integrating enhanced quality systems approaches into the agency’s business processes and regulatory policies concerning review and inspection activities

These objectives are reflected in the ICH’s Q8, Q9, and Q10 guidance documents.

Any discussion on QbD necessitates defining pharmaceutical quality, which is rather subjective. ICH defines drug quality as the ability of a product to satisfy stated needs, including identity, strength, and purity, without undesired side effects (6).

Historically, the relationship of product quality to product attributes has not been well defined or understood. As a consequence, the FDA has ensured product quality via tight specifications based on the observed properties of clinical and/or technical batches and by limiting the changes that can be made within manufacturing processes (7).

In considering post-approval changes to an approved NDA or abbreviated New Drug Application (ANDA), current guidelines do not readily allow for the consideration of risk-based and science-based approaches for regulatory decision making. The guidelines were not developed based on a thorough understanding of the manufacturing process, prior knowledge and experience from similar types of products, and overall quality in determining whether a submission is required. Current guidelines recommend manufacturers to assess the effects of manufacturing changes on identity, strength, quality, purity, and potency of a drug as they relate to the safety or effectiveness of a product.

This rather prescriptive approach has contributed to pharmaceutical companies being reluctant to change their manufacturing processes and equipment from time to time from a continuous improvement perspective. The current SUPAC Guidance for Immediate- and Modified-Release solid oral dosage forms permits manufacturers to determine the submission requirements and category based on a predefined algorithm of information and data.

The introduction of the ICH Quality Guidelines, Q8 (R2), Q9, and Q10, and Q11 are intended to help develop a science- and risk-based approach to quality and, at the same time, encourage continuous improvement as part of a product’s life cycle through an effective pharmaceutical quality control system.

Furthermore, the FDA’s Manual of Policies and Procedures (MAPP), specifically MAPP5016.1, outlines and clarifies how the CMC reviewers in the Office of New Drug Quality Assessment in the Office of Pharmaceutical Science should apply the guidance recommendations to the review of regulatory submissions (8).

Since the ICH Guidance documents have been reviewed extensively elsewhere, they are assumed to be part of the working knowledge of our readers and will not be reiterated within this whitepaper other than to list their main topic areas, namely,

-

ICH Q8 (R2)—Pharmaceutical Development (9)

-

ICH Q9—Quality Risk Management (10)

-

ICH Q10—Pharmaceutical Quality System (11)

-

ICH Q11—Development and Manufacture of Drug Substances (Chemical Entities and Biological/Biological Entities) (12)

The concept of design space for pharmaceutical manufacture was suggested in the Guidance for Industry—PAT—A Framework for Innovative Pharmaceutical Development, Manufacturing and Quality Assurance (13). The definition of design space was provided in ICH Q8 (R2) as a multidimensional combination and interaction of input variables such as material attributes and process parameters that have been demonstrated to provide assurances of quality. Working within such a design space should not be considered a change. The identification of the material attributes and critical process parameters is important in describing the boundary of a design space.

Movement outside a design space is generally considered a change which would normally initiate a regulatory post-approval change process. Using the principles in ICH Q9, the level of risk when assessing a change scenario requires sufficient information and detail on how the risks were identified, characterized, and evaluated to clearly convey a full understanding of the decision-making process and the impact of any subsequent decision in a given product or process change. Combining these risk principles to assess control, communicate, and review quality risks, with prior knowledge and understanding, it should be possible under the principles of a robust quality system as outlined in Q10 to determine, using sound scientific knowledge and judgment, the potential impact on patient safety and efficacy.

This should provide opportunities for determining the appropriate regulatory approach to a given product or process change and still meet the requirements as outlined in the 21 CFR 314.70 which outlines current requirements for changes to an approved NDA or ANDA (Prior Approval Supplement, CBE/CBE-30 or Annual Report) (14).

FDA Guidance

Changes to an Approved NDA or ANDA

An FDA-issued guidance (15,16) makes recommendations for post-approval changes in components and composition, manufacturing sites, manufacturing process, specifications, container closure system and labeling, as well as multiple related changes. This guidance does not provide recommendations on specific information required to assess the effect of changes to identity, strength, purity, or potency of a drug product. In general, it discusses three types of changes: major changes which have a substantial potential to have an adverse effect on product quality attributes of identity, strength, quality, purity, or potency as they relate to the safety and efficacy of a drug product; moderate changes which have a moderate potential to affect product quality attributes; and minor changes which would have a minimal potential to adversely impact product quality attributes.

CMC Post-approval Manufacturing Changes Reportable in Annual Reports

In an attempt to reduce the number of manufacturing supplements in recent years, in connection with FDA’s Pharmaceutical Product Quality Initiative, and incorporating a risk-based approach to the CMC review process, a list of post-approval manufacturing changes (16) that can be reported in an Annual Report was developed. This listing includes changes to components and compositions, manufacturing sites and processes, along with specifications, container closure systems, and miscellaneous changes.

Canada, Europe, Japan, and the Rest of the World’s Countries

While the SUPAC Guidance is specifically considered a US-only guidance, it is viewed favorably by some other regulatory authorities, and aspects of it are incorporated as part of their country-specific post-approval change regulatory requirements.

As many companies develop products with a global perspective, there are other guidance documents that may be considered when making post-authorization changes to approved immediate- and modified-release products.

Canada

NOC Changes—Quality Guidance Appendix 1 for Human Pharmaceuticals, Canada Ministry of Heath, Health Products and Food Branch

This guidance, implemented 17 October 2011 (4), outlines the categorization of post-approval changes and makes recommendations for supporting documentation based on the level of risk. This revised document simplifies the process for submitting post-authorization changes in manufacturing and chemistry which require Health Canada approval. This revision eliminates level II (Notifiable Change) and moves higher-risk submissions to level I while moving lower-risk changes to level III. The intent of this revision was to provide greater clarity for filing requirements of supplements without affecting safety and efficacy.

The data requirements associated with the changes outlined in the PNOC-QD are based on (commensurate to) the level of existing knowledge and established assurance of quality of a product afforded by an NOC and, in many cases, also by market manufacturing experience.

Where there are differences between Health Canada data requirements to support pre- and post-NOC changes, sponsors are expected to include information and data in their submission in accordance with pre-NOC guidance documents (17,18) rather than with the PNOC-QD.

European Medicines Agency

In the EU, amendments to an approved application are called variations. In 2003 (19), the Variations Guidance was amended; the intent was to simplify reporting procedures and, at the same time, provide the same regulatory framework for changes in both the mutual recognition and the centralized procedures.

There are three categories of post-approval variations (3). Type 1A variations are considered minor changes. Such changes are simply administrative in nature or other modifications which do not affect the quality, safety, or efficacy of the product. There are two subcategories of 1A variations, which have clearly defined document requirements and set of conditions for the change

Type 1A variations are “do and tell.” Generally, the IA variations can be submitted within 12 months of implementation. These 1A variations will be equivalent to the US annual reports. There is also a type IA(IN) variation where immediate notification is required upon implementation. This is similar to the US CBE.

Type 1B variations require notification of changes before implementation. Regulatory approval is expected within 30 days of submission for changes that are considered more scientifically minor in impact. Type 1B variations are given as examples rather than as set criteria and conditions. There is a 1B default classification for changes that are neither a 1A nor a type II variation. The idea behind type 1B changes is to create flexibility for industry, but with that flexibility come the challenges due to the lack of clearly defined requirements. Type 1B variations are essentially equivalent to the US CBE 30.

There is also an “unforeseen” variation approach for those variations that are not listed in either the guideline or the regulation and for which the type IB by default is uncertain or controversial and believed to be a lower category than a type II variation. The Ministry of Health may request the CMDh (Co-ordination Group for Mutual Recognition and Decentralised Procedures—Human) to provide a recommendation on the classification of the variation according to Article 5 of the regulation. Timings of this process can be equivalent to timings of a type II change, so one really needs to make sure there is a need to have a change classified.

Type II variations are for major changes not meeting the criteria for minor variations and line extensions. Type II variations are the severest category and will be prior approval change, similar to the US SNDA. The approval timing for a type II variation is typically 3–6 months.

In an attempt to further simply these variation classifications, the European Commission (EC) has proposed current amendments to the current regulations (20).

One difficulty in dealing with the EU is that there are a number of different marketing approvals that exist in Europe, i.e., centralized, decentralized, and national, and the administrative reporting burden varies with the different approval processes.

Japan

Japan revised its pharmaceutical Affairs Law in 2002 which amended its procedures for post-approval changes. Depending on the nature of the change, the requirements can be quite extensive, with a lengthy review time. Items noted as minor do not require pre-approval and can be submitted as notifications (21).

Quality By Design Principles

Importance of TPPs and QTPPs in Product Development

Proactive Identification and Definition of Desired Target Product Quality

A quality target product profile (QTPP) relates to the required quality of a drug product or drug substance that is necessary to deliver a desired therapeutic effect. When prepared proactively, the QTPP serves as a set of predefined objectives establishing product and process deliverables that will provide the greatest benefit for attaining the critical attributes that impact drug product quality. These predefined QTPPs evolve over time during drug development and may be modified to incorporate new knowledge, as is warranted by ongoing clinical studies; such as dose effect and toxicology data that are often conducted in parallel with a product’s developmental activities.

Clinical, Patient, Marketing Alignment

The QTPP comprised all the necessary attributes a product needs to deliver in order to meet its intended use. A product’s QTPP provides guidance for linking its process, formulation, and incoming materials with therapeutic patient outcomes. Examples of clinically relevant QTPPs include, but are not limited to, dosage form and biorelevant data, dosing regimen that achieves a predefined clinical result, pharmacokinetics (PK), bioequivalence, and established efficacy and safety profiles (9). In order to maximize ultimate product performance, other attributes of a drug product may also be considered, such as product identify (tablet size, shape, and color) and intended patient population.

QTPP and Risk Assessment

Once all of the components of a QTPP have been defined, a preliminary risk assessment should be completed before starting development activities. This allows for revision of the QTPP, if needed, and guides development activities prior to investment of major development resources. It is important to note that risk assessments should be updated as further knowledge is gained during development.

Importance of CQAs in Product Development

Align with QTPP

Once a product’s QTPP is defined, the appropriate formulation and process characteristics of the product can be developed around it. The attributes that assess the quality of the drug product or drug substance aligned with the QTPP are referred to as the critical quality attributes (CQAs). They link the product’s quality with its desired therapeutic performance. Similar to QTPPs, when CQAs are proactively identified, establishment of target process deliverables can be prepared and alignment with therapeutic targets achieved. Where QTPPs are derived based on desired clinical responses, CQAs are those characteristics that reflect the final process and product quality. For example, where bioavailability is an element of a product’s QTPP, dissolution may be its associated CQA. Although the CQAs are deemed product quality- and/or process-relevant, it is important to understand how they can potentially affect patient therapeutic outcomes when establishing ”acceptable” specification ranges. In this manner, the QTPP guides the selection of appropriate CQA specifications (or specification ranges) based on those critical attributes ultimately necessary for delivering the desired patient effect.

Changes made to the QTPP during development will necessitate corresponding changes to the product’s critical manufacturing attribute(s) (CMAs), critical process parameters (CPPs) and CQAs.

Process-Delivered Responses

The CQAs that define the drug product QTPP typically include assay, dissolution results, stability, impurity profile, microbial burden, and physical appearance. Presently, CQAs are similar to the drug product and drug substance release and stability specifications as they traditionally reflect the desired patient deliverables. However, CQAs are potentially influenced by multivariate parameters, which themselves may interact with other parameters or material attributes throughout the manufacturing process. Therefore, as the development process evolves, new knowledge may be uncovered that challenges earlier conclusions. This requires that CQAs are updated throughout the product development processes. An example is the possible shift of a CQA from dissolution to disintegration time (DT) for an immediate-release (IR) dosage form. As development proceeds and additional knowledge gained, it may become apparent that DT is a better quality surrogate than the traditional dissolution.

Correlation to CPPs

Process understanding through identification of potentially influential variables (such as process parameters, material attributes, drug substance quality, etc.) on CQAs is an integral aspect of the pharmaceutical development process. Those variables that have an impact (i.e., elicit a significant response) on a CQA(s) are deemed “critical.” When assessing criticality, it is helpful to have predetermined criteria for significance. For example, is a 3% impact on dissolution of an IR or modified-release (MR) product considered significant or can the impact be explained by the inherent variability of the analytical method? In-process attributes may be more challenging to define. Examples such as blend or granulation flowability (via Carr index or Hausner ratio), while easy to quantify, may be difficult to establish as a predetermined critical metric, especially if such attributes are not commonly monitored/studied and therefore no basis of comparison is available. It is important for the formulation scientist to evaluate how much variability in the associated attribute could elicit a response which can ultimately impact product quality. Understanding the main effects that critical process parameters, material attributes, and their mutual interactions have on a product’s defined CQA(s) is important in order to establish control of the CQAs and, ultimately, the final product quality (22).

Importance and Demonstration/Determination of CPPs and Resulting Design Space

Correlation and Alignment to Specific CQAs (Cause/Effect Relationship)

CQAs provide the link between critical formulation and process parameters with clinical product performance. Therefore, all critical sources of variability inherent in a formulation or process should be identified and understood and a rationale established on how they will be managed going forward.

Once an understanding of critical process parameters and material attributes is established for those variables that affect respective CQAs, deeper knowledge can be developed regarding the magnitude of effects. Ultimately, this helps establish the appropriate ranges of the multivariate design space. In order to attain this level of cause–effect understanding, one needs to establish a correlation of the CPP and/or CMA with its associated response on the design space. This becomes even more relevant when striving to attain real-time release testing (RTRT), where surrogates for therapeutic performance are correlated not only with analytical release tests but optimally to a specific process parameter(s) or material attribute(s) that impacts that analytical response. It is in these cases where mitigation of risk and optimal delivery of product performance can be delivered because the direct influence on quality can be measured. Additional information on RTRT can be found in subsequent sections of this paper.

Identifying Current Process Risk and Variability Using Systematic, Multivariate Design of Experiments and Cross-Discipline Team

The risks associated with a product, whether during development or commercial scale, are tied to the amount of incoming variability caused by materials and process conditions (i.e., parameters, equipment scale, means of operation, etc.). Distinguishing critical parameters from those variables whose impact is minimal or totally insubstantial is the essence of pharmaceutical development. Cross-functional teams composed of a wide array of disciplines (i.e., process development experts, formulators, statisticians, analysts, technicians, etc.) provide a varied perspective on the important formulation risks.

Traditionally, criticality evaluation has been performed by varying one condition at a time. Using this methodology, experiments are conducted by varying one parameter while keeping all others constant (fixed) and then assessing the response (impact). This manner at which variable performance is studied one factor at a time (OFAT) is not necessarily how parameters behave during routine production. The shortcoming of this methodology is that it fails to provide the experimenter with an understanding of interactions between variables. Oftentimes, these interactions go unnoticed and can result in synergistic affects when multiple variables are allowed to vary collectively, thereby resulting in a magnitude of effect that renders the initial parameter range suboptimal.

In contrast, the design of experiment (DoE) approach is designed to evaluate systematic variation of multiple factors (i.e., variables) within the context of one experimental design. DoEs can, thereby, be used to identify criticality of variables and ultimately create mathematical models of the process being examined aimed at predicting process performance (23).

Once a relationship between a CPP and CQA is demonstrated, the variable that demonstrated impact on a CQA should be further evaluated with the goal of understanding how much variability can be induced (i.e., how far the parameter range can be) in relation to other parameters as they collectively deliver acceptable product quality. Finding the technical edge of failure is not always necessary when evaluating criticality factors, especially when the range of the factor is unrealistically wide as it will likely not be employed in production. Therefore, when constructing a DoE, it is important to keep in mind the level of desired variability induced in order to learn as much as possible about a process within the given resource constraints.

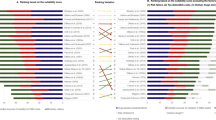

The complex relationship between formulation design factors, manufacturing unit operations, and their corresponding quality attributes is shown in Fig. 1. It is the responsibility of the development team to identify, and set control limits for, the attributes that are found to be critical to the quality of the product (22,23).

Assessment of Significance

Statistical significance results when the factors of a study cause an impact to the identified CQAs. It should be noted that although variables can have statistical significance, the practical significance must also be evaluated. If a sample size is large enough, variables will undoubtedly demonstrate statistical significance. The scientist must evaluate what practical meaning this effect has on CQAs.

One way of accessing practical significance is to evaluate the magnitude of effect the critical variable has on a given CQA. For example, if particle size distribution is statistically significant, it should only be deemed critical if the magnitude of the affect is large enough to be of practical concern. This is where establishing predetermined criteria for significance becomes valuable (as previously discussed).

Prior to the DoE and execution, the scientist should clearly define how much variability in particle size distribution is considered practically significant, in that the variability over this predetermined range would likely have an impact on drug product quality. While determination of statistical significance may be generated from statistical packages (i.e., SAS, JMP, MiniTab, etc.), practical significance determination should be made with the CQAs and patient effects in mind. While a variable may significantly impact an in-process attribute (i.e., particle size distribution, density, flow, etc.), the final CQAs may not necessarily be impacted. This is commonly seen with particle size distribution of granulation that may be impacted by variability in upstream conditions (i.e., granulator speed, time, etc.), but ultimately the overall manufacturing process (such as milling, blending operations) is robust enough to mitigate or eliminate these effects and no ultimate effect is demonstrated on final product quality.

Combining Input Variables and Process Parameters that Have Been Demonstrated to Provide Assurance of Quality

Prior knowledge, proactive team-based risk assessments, multivariate experiments, use of PATs (discussed in later subsection), and continual improvements are used to develop process understanding to a level necessary to establish a design space for a drug product or drug substance. The design space reflects the product understanding as a multivariate area where the impact on product quality is understood and controlled based on the variability of critical processing parameters and/or material attributes within a known range. A distinction between a design space and proven acceptable ranges (PARs) should be clearly made. PARs lack the capability to provide understanding of potential interactions among other parameters throughout the drug product manufacturing process. These interactions (either synergistic or antagonistic) can potentially affect a process and may not necessarily be determined if studied one at a time in a univariate manner.

Essentially, the manufacturing process runs in a multivariate environment (i.e., numerous factors are simultaneously in operation). Therefore, the parameters of that process should be studied in order to fully understand their effects on the design space.

Defining an Appropriate Control Strategy

Mitigating Risk Through Maintenance of CPPs and Adherence to Design Space to Ensure Product Quality

Once a process is developed and transferred to commercial scale, generally, the scope changes from inducing process variability in order to elicit an effect to monitoring the normal variability in the process and establishing/maintaining process control. Critical parameters that make up a design space should be controlled and continually monitored for trends and shifts that could occur over time in order to avoid significant deviation which could ultimately impact product CQAs. The design space is held within specifications via a control strategy, which is defined as “a planned set of controls, derived from current product and process understanding that ensures process performance and product quality” (9).

The establishment of a control strategy is necessary to ensure that the compliance of the drug product or drug substance processing parameters is delivered and that material attributes are consistently met and remain within their predefined settings. It is important to note that the control strategy should be developed specifically for the individual process that it monitors. A control strategy should include appropriate elements that will provide monitoring and/or controlling potential positioned at strategic junctures of a process where criticality has been demonstrated. Typically, a control strategy includes items such as additional in-process testing, use of PAT tools/probes, IT/software programs (i.e., feedback loops and automated recipes), well-defined batch records, specifications, etc. For example, if incoming raw material variability has been demonstrated to be critical to a CQA [i.e., disintegrant, particle size distribution (PSD) impact on dissolution], a supplier change could alter the incoming PSD characteristics that affect CQAs even though routine supplier sourcing evaluation is followed and specifications met. It is in this manner that true process monitoring is attained and, if performed far enough upstream, intervention possible.

Means of Constant Process Observation Using Technology and Science

Multivariate Data Analysis: As previously mentioned, criticality is determined by assessing the magnitude of impact a variable (parameter or material attribute) has on a response (CQA). Therefore, the relationship between the parameter and CQA needs to be understood. Multivariate data analysis (MVDA) is a form of statistics that helps to understand the relationships between variables, observations, and their relevance to each other (using principal component analysis, PCA) as well as relationships between variables and responses (using partial least squares, PLS). When coupled with process knowledge and criticality understanding, PLS and/or PCA models can be used to construct multivariate statistical process control (MSPC) charts in order to identify deviations from targeted behavior. MVDA uses established algorithms to create linear models comprising an approximation function and level of concomitant noise. MVDA models are designed to assess and ensure (in near real-time) that the progression of a batch is evolving within the defined design space during processing, thereby ultimately yielding material meeting predefined critical quality attributes. By this methodology, the process parameters are summarized by a few critical variables (“scores”) instead of a vast number of individual process parameters with limited significance.

Generally, these variables are defined by production of a series of target batches manufactured within normal operating range (NOR) parameters. NOR conditions are generally tighter than the encompassing design space and represent the day-to-day parameter settings where slight variability is allowed. Since the behavior of these batches is understood and even desired, target batches are normally used to build the reference model. Batches that were produced in other areas of the design space, generally at greater extremes, are either excluded from batch monitoring models or used to challenge the model for sensitivity. Consequently, batch quality can be depicted graphically and deviations of process variables from their expected range can be visualized online in real time, allowing for immediate attention and adjustment.

Process Analytical Technology

Process analytical technology (PAT) is defined as “a system for designing and controlling manufacturing through timely measurements (i.e. during processing) of critical quality and performance attributes for raw and in-process materials and also processes with the goal of ensuring final product quality”(13). PAT tools include spectrographic equipment such as near-infrared (NIR) and Raman, but can also include software enhancements that lead to a greater understanding of process execution. Some examples include power consumption, ΔT (difference in drying temperature used in wet granulation), and the MSPC models described above. The one element these examples of PAT have in common is their connection to the dynamic process data of a specific parameter and resulting data. These technologies allow for innovative development means by providing fundamental understanding of drug product processes.

Advances in technology have made available many tools that provide effective means for acquiring information to facilitate scientific understanding, continuous improvement and development of risk-managed pharmaceutical development, manufacture, and quality assurance. One of the most common PATs is the utilization of multivariate tools for design, data acquisition, and analysis: For example, design of experiments and multivariate data analysis seek to measure the interactions between multiple process variables simultaneously. Interactions between process variables are the most frequent attributable cause of process failures and are not typically detected, and thus a major pitfall of the univariate design. When used appropriately, multivariate tools enable the identification and evaluation of product and process variables that may be critical to product quality and performance. These tools may also identify potential failure modes and mechanisms and help quantify their effects on product quality. Therefore, PAT is part of an overall strategy of continuous improvement that enables continuous learning through data collection and analysis over the product life cycle.

PAT Process Controls, Controls Integration, and Information Management

Process Controls and Model-Based Systems: In today’s highly automated manufacturing environment, parametric controls are a critical component of the process control strategy and are fundamental to the process information and knowledge base.

Multiple components in pharmaceutical manufacturing machinery have elements of performance control, monitoring, and measurement; however, only the relevant control elements that are influential to CQAs are typically included as part of the process control strategy.

The evaluation of the equipment–product interaction is a key element of risk management analysis. Analyzing equipment–product interaction as part of the risk management tools allows for the determination of what is important to measure and control. ICH guideline Q9 provides risk analysis tools that can be used in the determination of the equipment–product interaction risk elements.

Typically, a pharmaceutical manufacturing process has equipment components that fit the need for the type of control design, either discrete, batch, continuous, or a combination of them. Figure 2 shows a diagram of the equipment train of a typical solids manufacturing process. Note that each piece of equipment in the figure includes a list of the equipment parametric control elements that are commonly agreed as process performance or safety controls. Filtering the quantum of parametric information into a critical parameter list requires the analysis of the equipment–process interaction with respect to available process knowledge and the criticality analysis on product quality. The criticality analysis of the process parametric space results in a failure mode hypothesis that needs empirical confirmation. The empirical confirmation of the failure modes often requires experimental evaluation, particularly in a new product or process design; otherwise, historical data or a combination of DOE and historical data shall lead to the definition of the critical process parameters.

Upon DOE execution, the hypothetical failure modes and their control definitions are either confirmed as critical or regarded as noncritical for the product CQAs. The conformance of the quality attributes satisfying the target product profile expectation may then be defined in a design space relevant to critical (equipment) process parameters (CPPs) that become part of the equipment control strategy.

The availability of a multivariate DOE-based process fingerprint shall be used in the establishment of process empirical models that relate relevant CPPs to the product CQAs. The initial goal for the use of the DOE data is to establish control loops, or limits of manual adjustments by equipment operators. In particular, when combined with CQA-surrogated process analytical technology (e.g., NIR, Raman, or fluorescent spectroscopy), the empirical model can become a process/product performance predictive model with real-time release capabilities that could enable dynamic control strategies. An expected subsequent improvement of the control strategy should include the analysis of process relationships to fundamental theoretical models that explain the observed process performance with mathematical accuracy (e.g., first principle and thermodynamic models, population balance models, mass balance models, diffusion models, etc.). The integration of the empirical data and the fundamental mathematical modeling along with the in-process analytical technology is a powerful tool that should become the ultimate goal of the control strategy when possible. This is particularly true when material quality attributes are well established and controlled and previous knowledge regarding model systems relevant to the pharmaceutical manufacturing process are considered.

Controls Integration and Information Management: The process control inputs, when defined relevant to the CQAs, are part of the PAT toolset and contain statistically significant predictive information that should be monitored and used as part of the control strategy. Univariate parametric information can be established as a first line of defense against process variation that could be detrimental to product performance. Charting techniques using statistically defined limits (e.g., run charts, moving average, moving range, or Shewhart control charts) can serve this purpose. Multivariate analysis of parametric data can also be important. Multiple regression analysis, PCA, and partial least squares or projections to latent structures (PLS) are tools available for multivariable data analysis. Charts of these data, either by score loading charts (PCA or PLS), residuals analysis, control or run charts of the product of the multivariable function, can provide adequate control monitoring for the multivariable relationship, allowing process parameter adjustment that is capable of restoring the process balance in case of drift conditions. Examples of processes that are multivariable in nature include wet granulation process, fluid bed granulation, fluid bed drying, roller compaction, compression process, film coating process, etc.

The equipment controls system SCADA (Supervisory Control and Data Acquisition) allows for data evaluation, calculation, and display using graphical tools that should be presented to the operator using a human–machine interface (HMI). This information provides a means of alerting the operator to deviations from the expected parametric performance. Upon an observed deviation, there should be in place deviation definitions and control policies (i.e., actions that should be taken to reestablish the desired process outcome) based on the defined CPPs and within the design space established via DOEs. The control strategy can be based on open loops, which require the operator to be trained and have the necessary skills to perform a process correction. On the other hand, a closed-loop control schema can be established to automate the response to the drift condition and to restore the process outcome independent of any operator action. The control action can be a feedback action upon the control, affecting the output of an upstream process step or equipment, or a feed-forward action, for which the measure of the output of the preceding step is used to define processing conditions of downstream process steps. Similarly, the analysis of intermediate material or final product property measurements using CQA-surrogated PAT (e.g., NIR, Raman, LIF, or other tests) should be considered in the control loop strategy, either as open or close loops. Under the scenario where the feedback or feed-forward control loop is based on an analytical surrogate in-process test, it is particularly important to ensure the adequacy of the measurement system, including sample presentation (e.g., sample size, probe location, accuracy, and reproducibility of measure), control loop response time, and define the targeted control strategy (trajectory tracking, midpoint correction, or drift correction).

Life Cycle Management Through Proactive Process Enhancement/Optimization

The established design space is required to be monitored throughout the life cycle of the product. For example, annual product reviews (APRs) are conducted on a yearly basis to assess the consistency of the quality production. Based on the new information generated during ongoing quality monitoring activities, any necessary improvements and changes needed to address trending and/or process optimization potential should be implemented as described in local quality systems concerning change management.

Annual product reviews are industry standards for assessing batch data over the yearly production activities. CQA data are evaluated for shifts as well as variability both over normal production as well as any post-process optimization implementation initiatives that may have taken place. Statistical assessment of data can provide a more representative account of CQA variability. Statistical measures of process quality capability, such as ANOVA, Cpk, and Ppk, assess variability around a mean and can therefore quantify the magnitude of variability of release data. DoE batches would not be used to calculate process capability because of the induced variability a DoE introduces to a process for the purpose of impact assessment. Cpk is designed to evaluate normal variability of a process (i.e., at set point or target conditions). Although CQA impact assessment provided by a DoE is beneficial from a CPP establishment perspective, the batch results should not be used for Cpk calculation because the inherent process variability cannot be assessed accurately. When none of the DoE parameters studied have an impact on a CQA, then all the DOE batches can be assessed collectively, as noncritical parameters. Hence, only the batches that were made with the same process conditions (i.e., target batches) are included in the Cpk calculation.

Another component of life cycle management is the utilization of continued process cerification (CPV) to proactively monitor routine production. The goal of continued process verification is to assure that the manufacturing process continuously remains within a predetermined state of control during routine commercial manufacture. Through CPV, unplanned deviations as well as trends in input variables, in-process control (IPC) results, and final product quality are detected and an assessment made regarding necessary improvements throughout the life cycle of the product.

A successful CPV program has systems in place which have the ability to proactively identify potential issues before they become critical. For example, statistically evaluating analytical release data which may be within specification but trending low or increasing in total variability can result in the avoidance of an ultimate failure if the cause of variability can be discovered and rectified prior to it reaching a significant magnitude.

Statistical process control techniques and data collection plans may also assist with the evaluation process as to the cause of variability. Statistical analysis of release and in-process data coupled with in-depth process knowledge obtained through risk assessment and criticality analysis can provide the means of identifying opportunities to optimize the current process and/or identify areas where enhanced detection mechanisms are needed to ultimately improve end product quality.

Use of PAT in Supporting Post-approval Changes to IR and MR Products

Quality risk management is a key part of PAT implementations by identifying potential quality concerns and implementing appropriate controls. The combination of risk management and PAT has allowed the ability not only to identify potential quality concerns but also implement ways to improve the likelihood of detection and/or control of the product/process. This section discusses PAT applications, how changes can be made to PAT applications, how they can be added or removed from processes, and how they can be used to support post-approval changes to an IR/MR product. Rather than identifying specific controls required, examples are provided and quality risk management is used to guide the appropriate requirements for changes.

R&D Requirements for a PAT Application In Order to Support Post-approval Changes: As part of product and process development, PAT methods can be used to support process understanding and facilitate scale-up and commercial site transfer. This information would be included in the filing as part of the process justification. The methods used for process understanding or design space development may not be validated or required for commercial manufacturing. Existence of these methods and reference to them in the filing may facilitate using the methods again for a site transfer, additional scale-up, or other post-approval changes. It is expected that PAT methods utilized in product/process development may support the post-approval change through inclusion of previous data and greater process understanding.

There are also scenarios where an online or at-line method is developed during development as a surrogate for a traditional high-performance liquid chromatography (HPLC) test. However, due to limited number of batches manufactured during development, the method would require additional updates before full commercial implementation. As defined by the PAT method maintenance strategy, after the product is approved and commercial manufacturing begins, data from commercial batches are used to update the PAT method and demonstrate its capability to support the commercial-scale process as intended. Assuming the defined outcomes are achieved with regard to predefined acceptance criteria, online/in-line might then become the primary commercial test method.

It is possible to have an in-process PAT method introduced to measure an attribute at an intermediate step and eliminate the need for the measurement of that attribute in the final product. In this case, it is not a direct substitution but is a way of testing for a product attribute at the appropriate manufacturing step and enables a feed-forward or feedback control loop that could assist with achieving consistent product quality by adjusting the appropriate process parameter(s). PAT measurements at intermediate steps reduce product risk because they allow for a process control and parameter adjustment to ensure the final product meets a predefined quality specification. Such a control scheme would also require sufficient commercial-scale data prior to full implementation. This may require, similar to what is mentioned above, completion of method development by the development team and method inclusion in the filed documentation.

For the two cases above, predefined acceptance criteria are needed prior to the filed submission and need to be agreed upon by all accountable organizations or departments. In addition, the methods proposed would be developed and validated through collaboration between the development and commercial organization. The expectation is that these methods would be consistent with the sponsor’s validation policy. In addition, discussion with the regulatory agency prior to the filed submission is recommended to insure alignment of expectations for the method validation, implementation, and maintenance.

Support of Changes from Previously Filed PAT: PAT methods are integral to continuous improvement and monitoring of a manufacturing process. It is expected that the PAT method will itself evolve and require continual improvement. As such, the quality system for the PAT method should include a procedure for updating the method with respect to increasing process understanding through greater process experience which captures variability associated with raw materials and non-product quality-related changes in the process. The requirements for updating the PAT method will vary depending upon the overall significance of the PAT method to the process control strategy and the assessed impact of the changes to method robustness. Simplified, the higher the criticality of the PAT method to a product CQA, the greater the expected level of detail for any changes to the PAT method. This criticality is best determined by reviewing established risk assessments. For example, a real-time release method, which is considered a direct substitute for a traditional laboratory release method, is a high-impact method, and changes to the method would be expected to capture the performance attributes critical to the CQA.

Complementary medium-impact methods (design space-related methods that are not sole indicators of product quality) and low-impact methods (for process understanding and development) would be expected to demonstrate performance attributes aligned to the intended use of the method.

Some level of expectation for PAT method evolution can be set at the development stage of the PAT method based on process and method development history. Ultimately, the PAT method maintenance strategy needs to be specified as part of the method’s quality system documentation at the site. A descriptive summary of the maintenance strategy should be included in filed documentation to align expectations for method evolution with agency guidance documents. In limited situations, where supported by a risk assessment, comparability protocols may be specified in filed documentation. Although, due to the complexity of comparability protocols, the preferred approach is to include the strategy for anticipated update(s) as part of the documented PAT method maintenance.

Post-approval of New PAT Applications: The continuous improvement and monitoring of a manufacturing process is likely to provide the opportunity to implement or improve PAT where it was previously not available or considered. The determination of the regulatory filing category should be based on the level of risk associated with the unit operation or attribute for which PAT is being utilized combined with the required filing category for associated changes. The following examples are provided to demonstrate the different degrees of risk and potential regulatory filing requirements.

-

Case 1

The current blending unit operation for a solid oral dosage form includes blending of ingredients for a set number of revolutions at a set speed. In order to increase process understanding and gain additional knowledge about the blending process, NIR monitoring is added to the blending process to better understand blend uniformity throughout the unit operation. There is no change to the manufacturing process as the blending unit operation process parameters remain unchanged. The addition of NIR either maintains or reduces the current risk level and would not require regulatory approval.

After gaining sufficient experience/data with NIR monitoring of the blending step, it is determined that controlling the completion of blending through NIR rather than a set number of revolutions ensures blend uniformity and a reduction in blending time. Therefore, it is desired to change the control of the blending step to utilize NIR. Additional continuous process verification would be added to ensure no change in the uniformity of dosage units CQA; therefore, the risk level is maintained or reduced. As a result of the change to the manufacturing process, the change would require regulatory approval (CBE/CBE30).

-

Case 2

The process of spraying drug substance onto a core tablet is currently monitored using HPLC to determine the end-point prediction of the spray coating process. In addition, assay testing is performed at release for the finished product. A NIR method is developed to monitor drug substance growth on the core tablet, allowing rapid analysis and monitoring for the completion of spray coating. The level of risk is reduced due to the increased monitoring through the coating end point, allowing for a more precise end point determination. The change to the process control would require regulatory approval (CBE/CBE 30). After sufficient data are obtained using NIR to determine end point through a PQS-approved continuous process plan, it is desired to use NIR to replace finished product assay testing. The risk level would be maintained or reduced, and the change to specifications would require regulatory approval through a CBE/CBE30.

In most situations, the implementation of PAT will result in either a reduction of risk or maintaining the current level, in which case prior approval (PAS) would not be required. This assessment is in line with the current Guidance for Industry Changes to an Approved NDA or ANDA (edition date, April 2004), which states “A change in methods or controls that provides increased assurance that the drug substance or drug product will have the characteristics of identity, strength, quality, purity, or potency that it purports or is represented to possess” be submitted as Changes Being Effected (CBE). The data requirements for the CBE should include submission of the PAT methodology and its validation. In addition, batch data demonstrating that the product manufactured with the new or improved controls continues to meet the existing specifications should be provided. The need for stability data should be dependent upon the degree of change to the process and the potential the change has to impact the stability profile of the product.

Removal of PAT Based on Practical and Scientific Considerations: PAT developed and implemented during product development stage serves as a key driver (or component) for rationalization of the manufacturing processes, knowledge-based production, and enhanced assurance of product quality after product approval (or launch). Following knowledge accumulation during commercial production, PAT may be removed or reduced under certain circumstances based on consideration of extent of product and process understanding, nature and role of the PAT, complexity of the product and process, availability, and life cycle cost of instrumentation. For instance, the following scenarios may prompt evaluation of possibly removing or replacing (or downsizing) PAT for commercial production:

-

When statistical process control demonstrates that removal of the PAT does not result in a decrease in process capability.

-

Change of manufacturing site where PAT transfer may be challenging due to instrument availability, need for equipment retrofit, method transfer, and cost.

-

For products or processes that are controlled using a multimodal PAT, reduction of modality (e.g., to a single sensor) has been proven to provide sufficient (or equivalent) process control. In general, reduction, replacement, or removal of PAT is feasible (or can be considered) for a production operation that is fully under control, and

-

demonstrates robustness of the manufacturing processes and an understanding of the interplays between the process involved and raw material properties, scale, and type of equipment, etc.

-

shows consistent correlation between parameters of in-line or online analytical systems (e.g., NIR) and a non-PAT in-process control (e.g., number of revolution of a blending operation) within its design space.

-

When removing PAT, caution should be exercised for a complex manufacturing process and/or drug product, such as modified-release or amorphous solid dispersions, or where the replacement process control is purely empirical in nature (e.g., a combination of mixing time and liquid volume for determining the end point of a wet granulation process). Risk assessments should be revisited and updated to justify any reductions, replacements, or removal of PAT.

Use of PAT in Supporting Post-approval Changes to IR and MR Products: The principles for the SUPAC QbD approach are based on product-specific risk assessment of changes which may impact approved design spaces within the framework of the approved control strategy to ensure consistent product quality and performance. The changes and requirements are less prescriptive compared to the SUPAC IR/MR approach, although they require a detailed and documented understanding of the formulation and process with a focus on continuous learning and improvement. These general principles for application of the QbD approach include no requirements for regulatory notification for changes within approved design spaces. Under this latter scenario, all documentation to support the proposed changes would be managed through the PQS and be available for submission or review when requested. This documentation includes: changes to batch records, risk assessments with technical justifications to support process qualification testing, extended dissolution/bioequivalence requirements, stability and continuous verification plans. Use of the proposed QbD approach incorporating specific PAT in the control strategy is illustrated by several examples in Table I below for comparison to the traditional SUPAC IR/MR approach. The examples are general in nature, but specific scenarios under the general cases were developed in order to further demonstrate the QbD principles.

Table I provides a comparison of the current SUPAC IR/MR requirements and the proposed requirements that result when an IR or MR product has been developed using QbD. Included in the table are the following SUPAC change control concepts:

-

Types of changes

-

Risk evaluation

-

Filing documentation

-

Manufacturing documentation

-

Application of compendial release documentation

-

Stability documentation

-

Dissolution documentation

-

In vivo bioequivalence documentation

The following examples provide further detail on the information found in Table I.

-

Example 1

SUPAC IR Level 1—Batch size change <10× biobatch (final blend size)

-

Current SUPAC Requirements: Annual notification with updated batch records, one lot on long-term stability; release via compendial/application specifications

-

Proposed QbD Approach: No notification if within approved blending design spaces or uniformity is controlled with in-line NIR; documentation managed internally through PQS, including documented risk assessment and justification for stability, extended testing beyond release, and continuous process verification plan

-

Rationale: No stability requirement since no expected change to stability indicating CQA; plan to monitor stability indicating CQA (moisture) and content uniformity using NIR (if applicable). No additional dissolution testing required based on risk assessment. Default to SUPAC requirements if no adequate technical justification can be developed, for example, no stability indicating CQA can be documented in risk assessment

-

-

Example 2

SUPAC IR Level 2—Batch size change >10× biobatch (final blend size)

-

Current SUPAC Requirements: Changes being effected supplement with updated batch records; one batch with 3 months’ accelerated stability data and one batch on long-term stability; multipoint dissolution profile comparison in the application/compendial medium versus pre-change/reference lot

-

Proposed QbD Approach: No notification if within approved blending design spaces or uniformity is controlled with scale-independent approach such as in-line NIR; documentation managed internally through PQS, including documented risk assessment and justification for stability, extended testing beyond release, and continuous process verification plan

-

Rationale: No stability requirement since no expected change to stability indicating CQA; plan to monitor stability indicating CQA (e.g., moisture) and content uniformity using NIR. No additional dissolution testing required above release with approved clinically relevant dissolution method and specifications or if process remains within the blending design space. Default to SUPAC requirements if no adequate technical justification can be developed, for example, no approved blending design spaces or scale-independent control strategy can be documented in risk assessment

-

-

Example 3

SUPAC IR Level 2—Change in granulation process, e.g., change in roller compaction roll pressure set point outside of filed/validated range

-

Current SUPAC Requirements: Changes being effected supplement with updated batch records; one batch on long-term stability; multipoint dissolution profile comparison in the application/compendial medium versus pre-change/reference lot

-

Proposed QbD Approach: No notification if within approved roller compaction design spaces or if ribbon attributes controlled within approved in-process controls, for example, using a validated and approved at-line or online ribbon density PAT measurement technique, e.g., NIR or GeoPyc; SUPAC documentation managed internally through PQS, including documented risk assessment and justification for stability, extended testing beyond release, and continuous process verification plan

-

Rationale: No stability requirement since no expected change to stability indicating CQAs or technical justification of no stability impact with change in ribbon density within design space; plan to monitor downstream controls (e.g., tablet hardness and weight uniformity) and ribbon density within design space in addition to the continuous process verification plan for monitoring CQAs. No additional dissolution testing required above release with approved clinically relevant dissolution method and specifications or if process remains within the roller compaction design space. Default to SUPAC requirements if no adequate technical justification can be developed, e.g., outside of approved roller compaction design spaces or no ribbon attribute-based control can be documented in risk assessment

-

-

Example 4

SUPAC MR Level 2—Change in coating quantity of rate controlling excipient (ER membrane coating) between 5% and 10% (w/w) of the tablet mass

-

Current SUPAC Requirements: Prior approval supplement (all information including accelerated stability data) and updated executed batch records; stability for non-narrow therapeutic range drugs: one batch with 3 months’ accelerated stability data reported in prior approval supplement and long-term stability data of first production batch reported in annual report; extended-release dissolution requirement: in addition to application compendial release requirements, multipoint dissolution profiles should be obtained in three other media, for example, in water, 0.1 N HCl, and USP buffer media at pH 4.5 and 6.8 for the changed drug product and the biobatch or marketed batch (unchanged drug product) using appropriate statistical comparison, e.g., f 2 similarity

-

Current QbD Approach: No notification if change is within membrane quantity design spaces or if quantity is controlled within approved in-process controls using a validated and approved at-line or online PAT measurement technique, for example, NIR, Raman spectroscopic techniques; documentation managed internally through PQS, including documented risk assessment and justification for stability, extended testing beyond release, and continuous process verification plan

-

Rationale: No stability requirement since no expected change to stability indicating CQA or technical justification of no stability impact with changes in coating quantity within the approved design space; plan to monitor critical coating parameters and film thickness/quantity within design space in addition to the continuous process verification plan for monitoring CQAs. No additional dissolution testing required above release with approved clinically relevant dissolution method and specifications or if process remains within the coating quantity design space. Default to SUPAC requirements if no adequate technical justification can be developed, for example, outside of approved coating quantity design spaces or insufficient coating quantity in-process control with clinically relevant dissolution assessment that can be documented in risk assessment

-

-

Example 5

SUPAC MR Level 3—Change in site of manufacture

-

Current SUPAC Requirements: Prior approval supplement (all information including accelerated stability data) and updated executed batch records; stability with significant body of information not available: three batches with 3 months’ accelerated stability data reported in prior approval supplement and long-term stability data of first three production batches reported in annual report; extended-release dissolution requirement: in addition to application compendial release requirements, multipoint dissolution profile for the changed drug product and the biobatch or marketed batch (unchanged drug product) using appropriate statistical comparison, e.g., f 2 similarity. Bioequivalence documentation: a single-dose bioequivalence study. The bioequivalence study may be waived in the presence of an established IVIVC.

-

Proposed QbD Approach: Notify via Changes Being Effected Supplement (CBE-30) with no changes to approved design spaces and control strategy compared to the original approved site; documentation managed internally through PQS, including documented risk assessment and justification for stability, extended testing beyond release, and continuous process verification plan. Emphasis should be on demonstrating equivalent quality and performance in the supplement through direct confirmation of design spaces at the new site, with additional emphasis on demonstrating equivalent in-process controls and attributes from the approved in-process tests using the at-line or in-line PAT tests (if applicable).

-

Rationale: Consider the change in location of an extended-release coating process to another site. All design spaces were confirmed at the new site without changes to the approved control strategy. From the risk assessment, it was determined that there was no stability CQAs for the drug product that could be monitored or which could be predicted. Therefore, the first three process qualification lots are put on accelerated stability and 3-month data included in the supplement. However, it was demonstrated that control of the controlled-release membrane was found to be equivalent via the approved in-process PAT methods for the controlled-release attribute, film thickness, which was previously shown in development to be clinically relevant and which correlated with dissolution. Consequently, there were no demonstrated changes to the rate-controlling step and, therefore, no bioequivalence study is required. No additional dissolution testing required above release with approved clinically relevant dissolution method and specifications or if process remains within all design spaces. The continuous verification plan would monitor CQAs as well as any in-process controls for the rate-controlling step. Default to SUPAC requirements if all design spaces cannot be confirmed without changes to the approved control strategy from the original site.

-

Improvement in the Control and Characterization of APIs (Analysis and Recommendations Based on Post-approval Change Guidance Documents)

Evolution of Drug Substance Control Strategy

Before the introduction of QbD concepts to pharmaceutical manufacturing, the approach to quality control was to test the drug substance to certain predetermined standards. Product quality was assured by ensuring conformance to current good manufacturing practices (GMPs) and end product testing. It needs to be noted that these principles still remain the cornerstone to the quality standards of today and continue to be valid.