Abstract

Background

Perindopril erbumine is a specific inhibitor of angiotensin-converting enzyme, indapamide is the one providing thiazide diuretic effect, and amlodipine besylate is a calcium antagonist which belongs to the dihydropyridines which helps to maintain the pressure of the blood in the patient having arterial hypertension. The literature survey discloses that only one method is available for the estimation of the combination in the quantitative analytical liquid chromatographic method. Moreover to this, the literature review also reveals that HPTLC, UV spectroscopy, and HPLC methods are available for the analysis of either of the two in combination. Hence, our area of interest is to develop and validate the RP-HPLC in order to quantify perindopril erbumine, indapamide, and amlodipine besylate simultaneously in bulk and formulation.

Result

Sensitive and accurate RP-HPLC method was developed for the simultaneous estimation of indapamide, perindopril erbumine, and amlodipine besylate in bulk and available as triplixam-marketed tablet dosage form which is a combination of these drugs. The Phenomenex C-18 column (250 mm × 4.6 mm, 5 μm) was used as a stationary phase, and acetonitrile: methanol: water (30:20:50, v/v/v) was found to be optimized mobile phase which was further adjusted to pH 3.0 by utilizing 1.0% orthophosphoric acid; the flow rate kept was 1 ml/min and experiments were performed using PDA detector. The common detection wavelength for all the three APIs was found to be 215.0 nm. The method was validated as per ICH Q2 (R1). The linearity range for amlodipine besylate was found to be 0.500–9.500 μg/ml; for perindopril erbumine was found to be 0.400–7.600 μg/ml, and for indapamide was found to be 0.125–2.375 μg/ml. The correlation coefficient was found to be more than 0.9975 for all three of them, whereas the mean percentage recovery was found to be 99.52–100.71%, 99.49–100.89%, and 99.90–100.78%, respectively.

Conclusion

The proposed RP-HPLC method is found to be accurate and robust enough to estimate the perindopril erbumine, indapamide, and amlodipine besylate simultaneously in bulk and available tablet dosage form of combination.

Similar content being viewed by others

Background

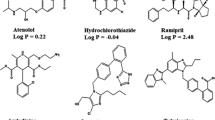

Perindopril erbumine, indapamide, and amlodipine besylate are three APIs generally used to treat hypertension. (2S,3aS,7aS)-1-[(2S)-2-[[(2S)-1-ethoxy-1-oxopentan-2-yl]amino]propanoyl]-2,3,3a,4,5,6,7,7a octahydroindole-2-carboxylicacid;2-methylpropan-2-amine is the chemical name of perindopril erbumine (PER) which is active component of an angiotensin-converting enzyme inhibitor (ACE-I). Apart from this, the other diseased conditions which can be cured using this are heart attacks, strokes, and kidney problem [1].

The chemical name of indapamide (IND) is 4-chloro-N-(2-methyl-2,3-dihydroindol-1-yl)-3-sulfamoylbenzamide. It belongs to the thiazide diuretics class and generally used for the treatment of salt and fluid retention associated with congestive heart failure or edema from pregnancy and also found to be the oral antihypertensive drug [2].

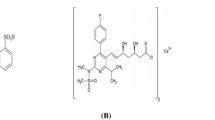

The chemical name of amlodipine besylate (AML) is 3-O-ethyl 5-O-methyl 2-(2-aminoethoxymethyl)-4-(2-chlorophenyl)-6-methyl-1,4-dihydropyridine- 3,5dicarboxylate;benzenesulfonic acid which is a well-known antihypertensive drug which belongs to calcium channel blockers [3]. The structures of all three chemical moieties, i.e., APIs are shown in Fig. 1.

The main purpose of this composition of three drugs is to regulate blood pressure in the patient suffering from arterial hypertension. The intake of this as once in a day is generally administered for better treatment [1,2,3].

The literature survey showed that only one method for the estimation of these drugs in combination is available by the quantitative analytical liquid chromatographic method [4]. Apart from this, HPLC, HPTLC, and UV spectrophotometric techniques were only reported for the determination of these APIs either alone or in dual combinations [5,6,7,8,9,10,11,12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27]. Moreover, this one HPTLC method was also found to quantify and estimate PER, IND, and AML simultaneously in bulk as well as a pharmaceutical formulation which is a tablet dosage form [28].

The RP-HPLC method has a distinct advantage over the HPTLC method in terms of sensitivity, resolution, and economic and is compatible with a wide range of detectors [29].

The present work includes the developed and validated RP-HPLC method as per ICH Q2 (R1) for the simultaneous analysis of PER, IND, and AML in bulk as well as pharmaceutical dosage form [29].

Methods

Materials

PER, IND, and AML were procured from the reputed pharmaceutical industry, Gujarat, India. Solvents and reagent like methanol (HPLC grade)—SRL Chemicals Pvt. Ltd., Ahmedabad, India; ACN (AR grade)—Astron chemicals Pvt Ltd., Ahmedabad, India; and 1.0% ortho-phosphoric acid (OPA) (AR grade)—Astron chemicals, Ahmedabad, India, were purchased. Triplixam tablet (Serdia Pharmaceutical Ltd.) was used having label claim: Each tablet contains perindopril erbumine 4 mg, indapamide 1.25, and amlodipine besylate 5 mg.

Instrument

Analytical balance making a model of Mettler Toledo electronic balance (ME204, Mettler Toledo Group, Mumbai, India) was used. HPLC System of Waters HPLC system consisted of a binary pump (model Waters 515 HPLC pump), loop injector, and PDA detector (Waters 2998) were connected with empower - version 2 software. Phenomenex C-18 column (250 mm × 4.6 mm, 5.0 μ) was used as a stationary phase for the better separation compound.

Chromatographic conditions

The Phenomenex C-18 column (250 mm × 4.6 mm, 5.0 μ) equilibrated with mobile phase acetonitrile: methanol: water (30:20:50, v/v/v) was further adjusted to pH 3.0 with the help of 1.0% ortho-phosphoric acid. The flow rate was kept to be 1 ml/min, eluents were supervised using a PDA detector at 215.0 nm with the fixed volume of injection that was 20 μl, and the stop time optimized was 11 min.

Preparation of standard stock solution

Weight accurately PER (4.0 mg), IND (1.25 mg), and AML (5.0 mg) and transferred to three different 10 ml volumetric flasks containing a minute amount of methanol (5.0 ml). Volumes were to be adjusted up to the mark with methanol to yield the strength of solution containing 400 μg/ml of PER, 125 μg/ml of IND, and 500 μg/ml of AML. Pipette out 1.0 ml from each of the above solutions and mix into 10 ml volumetric flask, make up to the mark with the mobile phase. The working standard solutions of 40 μg/ml of PER, 12.5 μg/ml of IND, and 50 μg/ml of AML were prepared.

Validation of the developed RP-HPLC method

Validation of the proposed developed RP-HPLC method was performed according to ICH Q2 (R1) for the accuracy, precision, robustness, and various other typical parameters.

Linearity and range

Appropriate aliquots of PER, IND, and AML working standard solution of 7 different concentration was taken in different 10-ml volumetric flasks and diluted up to the mark with a mobile phase to obtain a final concentration of 0.40, 1.60, 2.80, 4.00, 5.20, 6.40, and 7.60 μg/ml of PER; 0.125, 0.500, 0.875, 1.25, 1.625, 2.0, and 2.375 μg/ml of IND; and 0.50, 2.00, 3.50, 5.00, 6.50, 8.00, and 9.50 μg/ml of AML. The solution was injected using a 20-μl fixed loop system and the chromatogram was recorded. The calibration curve constructed by plotting the average peak area against concentrations and regression equation was computed (n = 5).

Precision

Intraday and interday as intermediate precision were performed as a part of precision. Working standard solutions of 40 μg/ml of PER, 12.5 μg/ml of IND, and 50 μg/ml of AML were prepared and analyzed as a part of the precision study. Intraday precision was performed for the solutions of PER, IND, and AML mixture at 3 levels covering respectively of lower (0.400, 0.125, 0.500 μg/ml), medium (4.0, 1.25, 5.0 μg/ml), and higher (7.60, 2.75, 9.50 μg/ml) concentration of the calibration curve analyzed three times on the same day. Interday precision was determined by analyzing the sample solution of PER, IND, and AML mixture at three levels covering lower, medium, and higher concentration periods for three different days. Mean and %RSD values were calculated by using the obtained peak area.

The repeatability was studied by injecting six times of the middle concentration of the calibration range and estimating the area of each injection and determines the %RSD.

Accuracy

The accuracy of the method was determined by calculating the recovery of PER, IND, and AML by the method of standard addition. The known amount of PER, IND, and AML at three levels of 80, 100, and 120% were spiked to prequantified sample solution, and the amount of 2.24, 2.80, and 3.36 μg/ml of PER; 0.70, 0.88, and 1.05 μg/ml of IND; and 2.80, 3.50, and 4.20 μg/ml of AML was added to prequantified sample solution. By putting the values of area to the calibration curve, the percentage (%) recoveries of PER, IND, and AML were estimated and regression analysis was carried out.

Detection limit and quantitation limit

The lowest concentration of drug which can be reliably detected and differentiate from the background is known as a limit of detection (LOD) and which can be quantified at the lowest concentration is known as LOQ, i.e., the limit of quantification. LOD and LOQ were calculated using the following equation as per ICH guidelines.

LOD = 3.3 × σ/SD

LOQ = 10 × σ/SD

where σ is the standard deviation of y-intercept of the regression line and S is the slope of the calibration curve.

Specificity

The specificity studies have been carried out by spiking commonly used excipients into a preweighed quantity of active pharmaceutical ingredients. The chromatogram was recorded for the appropriate dilution.

Robustness

Robustness of the method was studied by providing deliberate changes in the experimenting condition like mobile phase, temperature, and wavelength and flow rate. The mean and %RSD of peak retention time was calculated.

Solution stability

The stock standard solutions of the mixture were stored at normal room temperature for 48 h and were estimated using RP–HPLC at a specific time interval of 0, 8, 24, 36, and 48 h. The standard stock solution of 40 μg/ml of PER, 12.5 μg/ml of IND, and 50 μg/ml of AML was prepared. From the above, the stock solution withdrawn was 1.0 ml and was transferred into another 10.0 ml volumetric flask and make up the volume up to the mark with a mobile phase to obtain the final concentration 4.0 μg/ml for PER, 1.25 μg/ml for IND, and 5.0 μg/ml for AML and used for the solution stability studies. The solution stability study of the solution was studied by applying and analyzing it three times in the middle concentration of the calibration range.

System suitability

A system suitability test was an integral part of the process development to verify that the system is appropriate for the analysis of PER, IND, and AML to be carried out. The system suitability test for the proposed chromatographic system was performed following the validation run. Six replicate injections of a standard and one injection of a sample were made and evaluated the efficiency of the system by verification of different parameters like Rt, resolution, asymmetric factor, and theoretical plate.

Analysis of marketed formulations

Finely powdered and accurately weighted twenty tablets were prepared by using a mortar pestle. The powder equivalent to 4.0 mg of PER, 1.25 mg of IND, and 5.0 mg of AML was accurately weighed and transferred to a 10-ml volumetric flask containing minute ml (5.0 ml) of methanol and flask was sonicated for 5.0 min. The solution was filtered into using the Whatman filter paper (No. 42), the residues were washed twice with a few ml of methanol, and both filtrate and washing were combined in the same volumetric flask. The volume was adjusted to the mark with the methanol. From the above solution, pipetted out 1.0 ml of aliquots was transferred into another 10 ml volumetric flask and the volume was made up to the mark with methanol to obtain the concentration of stock solutions 40 μg/ml of PER, 12.5 μg/ml of IND, and 50 μg/ml AML. 1.0 ml above stock solution was pipetted out into another 10 ml volumetric flask and make up the volume up to the mark with a mobile phase to obtain a final concentration 4.0 μg/ml of PER, 1.25 μg/ml of IND, and 5.0 μg/ml of AML, respectively. 100 μl Hamilton syringe was used to inject the middle concentration of the calibration range of these solutions, and all the three drugs were simultaneously estimated by the proposed chromatographic method. The percentage (%) amount of PER, IND, and AML was noted by using the regression equation.

Result

Mobile phase optimization

The objective of the method development was to obtain well-resolved chromatographic peaks of APIs; PER, IND, and AML. Various compositions and different proportions of solvents comprising buffer, methanol, water, and ACN were tried as a mobile phase. The mobile phases like methanol to water (70:30, v/v) was used but it has a poor resolution of peaks observed of active drugs; acetonitrile to water (70:30, v/v) was tried where PER peak merged with void volume peak and AML showed tailing; acetonitrile to water (35:65, v/v) pH 4.0 adjusted using 1.0% ortho-phosphoric acid was tried in which PER and AML were eluted at similar retention time; by using a mobile phase acetonitrile to methanol to water (45:20:35, v/v/v), AML and PER have a good symmetric peak but the resolution is very poor because both drugs are eluted on the same retention time; by using mobile phase composition acetonitrile to methanol to water (20:20:60, v/v/v) pH 3.0 adjusted with 1.0% OPA, peak splitting and reduction in peak height are observed for PER and peak broadening is observed for IND. The well resolved, sharp, and symmetrical peaks peak for PER, IND, and AML (10 μg/ml) are observed with mobile phase acetonitrile to methanol to water (30:20:50, v/v/v) at pH 3.0 adjusted with 1.0% ortho-phosphoric acid where the working standard solution was diluted with a mobile phase. The flow rate was maintained at 1.0 ml/min. All three active pharmaceutical ingredients show an appreciable absorbance at a common wavelength 215.0 nm λmax (Fig. 2). The elution time of PER, AML, and IND with optimum retention time was found to be 3.5 ± 0.2, 7.1 ± 0.2, and 9.6 ± 0.3 min at a common wavelength λmax 215.0 nm, respectively (Fig. 3).

Method validation

Linearity and range

A linear response was found to be within the concentration range of 0.400–7.60 μg/ml for PER, 0.125–2.375 μg/ml for IND, and 0.500–9.50 μg/ml for AML (n = 5) along with respected peak area. Figure 4 represents an overlay chromatogram of PER, IND, and AML at 215.0 nm and shows a common absorbance wavelength by the proposed RP–HPLC method. Table 1 is representing the data of the regression analysis of the calibration curve.

Precision

The intraday and interday precision study has been carried out. The percentage (%) RSD values were less than 2%, confirming the precision of the method. Injection repeatability precision studied was perform by injecting and analyzing the sample with a concentration of 4.0 μg/ml for PER, 1.25 μg/ml for IND, and 5.0 μg/ml for AML six times, and the percentage (%) RSD was found to be less than 2.0%, which was confirmed the instrumental specifications.

Accuracy

The accuracy study of the proposed method was determined by calculating recoveries of PER, IND, and AML, where a known amount of standard was spiked into a pre-analyzed sample solution. Table 2 is representing the data of the accuracy study, and the percentage (%) recovery values were found to be more than 98%.

Limit of detection and limit of quantification

By using the proposed experimental conditions, the lowest detectable amount of drug (LOD) was found to be 0.065, 0.019, and 0.055, and also, the lowest quantifiable amount of drug (LOQ) was found to be 0.198, 0.056, and 0.168 for PER, IND, and AML, respectively.

Specificity

There was no interference of other elements present in the commercial formulation which is confirming the specificity of the proposed method.

Robustness

The robustness studies were performed by introducing little deliberate changes in proposed chromatographic condition parameters like change in detection wavelength, change in temperature, change in mobile phase ratio, and change in flow rate. The retention time and percentage (%) RSD value were measured for each condition. The percentage (%) RSD value was found to be less than 2.0%, which indicates that the method is robust. The results of the robustness of the proposed RP–HPLC method are shown in Table 3.

Solution stability

The solution stability study expressed that PER, IND, and AML solutions were found to be stable for 48 h at ambient temperature and humidity. The percentage amount of the drugs was calculated which was greater than 98%.

System suitability

The system suitability study was performing for evaluation parameters like the resolution, theoretical plate, capacity factor, and asymmetric factor.

Table 4 is representing the summary of validation parameters by the proposed RP–LC method.

Analysis of marketed formulation

The proposed method is applied for the quantification of PER, IND, and AML in their pharmaceutical dosage form. The percentage (%) amounts of drugs were found to be more than 98%. Figure 5 was represented by the overlay chromatogram of the standard and marketed formulation, and the data of the assay of marketed formulation were shown in Table 5.

Discussion (https://www.pharmatutor.org/articles/high-performance-thin-layer-chromatography-hptlc-instrumentation-overview)

The proposed studies include the development of the RP–HPLC method for estimation of PER, IND, and AML simultaneously in bulk and marketed formulation. The RP–HPLC method was developed, and the separation was carried out on stationary phase Phenomenex C18 column (250 mm × 4.6mm, 5 μm) through isocratic elution using acetonitrile to methanol to water (30:20:50, v/v/v) pH 3.0 adjusted with 1.0% ortho-phosphoric acid as a mobile phase at a flow rate of 1 ml/min, and all three drugs are monitored on 215.0 nm. The linearity for PER, IND, and AML was found to be 0.400–7.60 μg/ml, 0.125–2.375 μg/ml, and 0.500–9.50 μg/ml, respectively. Table 2 is representing the accuracy data, and the percentage of the recoveries for PER, IND, and AML were found to be 99.53–100.71%, 99.49–100.89%, and 99.90–100.78%, respectively. The specificity was carried out to check the interference of excipients used in the synthetic mixture, and the developed method was found to be specific. Table 3 represented the data of the robustness of the proposed developed analytical method which is used to measure its ability to remain unaffected by a small, but a deliberate change of the proposed method chromatographic conditions. It was estimated by small changes in the chromatographic conditions like change in detection wavelength (± 1 nm), change in flow rate (± 0.1 ml), mobile phase ratio, and temperature of working (± 5 °C) provided with deliberate changes. The described minor changes did not affect the symmetry of peak and retention time (Rt) of PER, IND, and AML which confirm the reliability of the method. The percentage amounts of drugs were found more than 98% for the assay of a synthetic mixture which specifies that the method provides accurate and precise results.

Conclusion

RP–HPLC method has been developed for the estimation of PER, IND, and AML simultaneously in bulk and its pharmaceutical dosage form. The %RSD value was found for the validation parameter that indicates the preciseness of the proposed method and is applicable for routine analysis for the quantitative determination of PER, IND, and AML in bulk and its pharmaceutical dosage form using the proposed RP–HPLC method. The statistical analysis of data indicates that the method is reproducible, selective, accurate, and robust.

Availability of data and materials

All data and material are available upon request.

Abbreviations

- HPLC:

-

High-performance liquid chromatography

- RP–HPLC:

-

Reverse-phase high-performance liquid chromatography

- HBP:

-

High blood pressure

- PER:

-

Perindopril erbumine

- IND:

-

Indapamide

- AML:

-

Amlodipine besylate

- OPA:

-

Orthophosphoric acid

- LOQ:

-

Limit of quantitation

- LOD:

-

Limit of detection

- %RSD:

-

Relative standard deviation

- Rt:

-

Retention time

References

https://pubchem.ncbi.nlm.nih.gov/compound/Perindopril-erbumine. Accessed 20 July 2019

https://pubchem.ncbi.nlm.nih.gov/compound/Indapamide. Accessed 20 July 2019

https://pubchem.ncbi.nlm.nih.gov/compound/Amlodipine%20besilate. Accessed 20 July 2019

Ramzia I, Bagary EL (2017) A validated HPLC method for simultaneous determination of Perindopril Arginine, Amlodipine, and Indapamide: application in bulk and in different pharmaceutical dosage forms. J AOAC Int 100:992–999

Saravanan G (2014) Development and validation of RP-HPLC method for simultaneous analysis of Perindopril and Indapamide in bulk and combined pharmaceutical dosage form. Asian J Res Chem 7:182–186

Dewani MG (2010) Development and validation of stability indicating HPTLC method for determination of Perindoripil Erbumine. Int Res J Pharm 1:428–435

Patel DB (2012) Simultaneous estimation of Amlodipine Besylate and Indapamide in a pharmaceutical formulation by a high performance liquid chromatographic (RP-HPLC) method. Sci Pharm 80:581–590

Erk N (2001) Comparison of spectrophotometric and HPLC method for the determination Perindopril and Indapamide in pharmaceutical formulations. J Pharm Biomed Anal 26:43–52

Jain PS, Badreshiya PR, Chalikwar SS, Todarwal AA (2010) Validation of a dissolution method with RP-HPLC analysis for Perindopril Erbumine and Indapamide combination tablet. J AOAC Int 93:108–115

Tiwar R (2012) Multicriteria optimization methodology in development of HPLC method for simultaneous estimation of Indapamide and Perindopril in bulk drug and its combined dosage form. Asian J Pharm Clin Res 2:50–53

Gandhi SV (2014) Development and validation of stability indicating RP-HPLC method for determination of Indapamide and Amlodipine Besylate. Indian J Pharm Educ Res 48:48–54

Raj MV (2012) Development and validation of RP-HPLC method for simultaneous estimation of Amlodipine Besylate and Indapamide in tablet dosage form. Int J Pharm Sci Res 3:3146–3150

Shah RN, Gandhi DB, Patel MM (2012) RP-HPLC method for simultaneous estimation of Amlodipine Besylate and Indapamide in tablet dosage form. Asian J Res Chem 5:633–636

Desai AK (2012) HPTLC method for the simultaneous estimation of Amlodipine Besylate and Indapamide in tablet formulation. Asian J Res Chem 5:510–514

Prajapati J (2011) Analytical method development and validation of Amlodipine Besylate and Perindopril Erbumine in combine dosage form by RP-HPLC. Int J Pharm Res 3:801–808

Gumustas M (2013) A validated stability-indicating RP-LC method for the simultaneous determination of Amlodipine and Perindopril in tablet dosage form and their stress degradation behavior under ICH-recommended stress conditions. J AOAC Int 96:751–757

Rajua VB, Rao AR (2011) Simultaneous estimation of Perindopril and Amlodipine in combined dosage form by RP-HPLC method. Int J Chem Sci 9:1290–1298

Nekkala K (2014) Method development and validation of stability indicating RP-HPLC method for simultaneous estimation of Perindopril Erbumine and Amlodipine Besylate in bulk and its pharmaceutical formulations. Ame J Alzhi Dise Deme 4:672–685

Patel BK (2016) Analytical method development and validation for simultaneous estimation of Amlodipine Besylate and Perindopril Arginine in combined pharmaceutical dosage form. Pharm Biol Eval 3:120–128

Zaazaa HE, Abbas SS, Essam HM, Mohammed G (2013) Validated chromatographic methods for determination of Perindopril and Amlodipine in pharmaceutical formulation in the presence of their degradation products. Bard Chrom Sci 51:533–543

Chitlange SS, Mohammed I, Sakarkar DM (2008) RP-HPLC method for simultaneous estimation of Amlodipine and Metoprolol in tablet formulation. Asian J Pharm 12:232–234

Muhammad A, Akhtar T (2014) Simultaneous estimation of Rosuvastatin and Amlodipine in pharmaceutical formulations using stability indicating HPLC method. Br J Pharm Sci 50:629–638

Moon HW, Mehmood YA, Hyung KC (2014) Evaluation of stability and simultaneous determination of Fimasartan and amlodipine by a HPLC method in combination tablets. Asian J Pharm Sci 9:123–128

Barman RK (2007) Simultaneous high performance liquid chromatographic determination of Atenolol and Amlodipine in pharmaceutical dosage form. Pak J Pharm Sci 20:274–279

Shimooka K, Sawada Y, Tatematsu H (1989) Analysis of Amlodipine in serum by a sensitive high-performance liquid chromatographic method with aerometric detection. J Pharm Biomed Anal 7:1267–1272

Safeer K, Anbarasi B, Senthilkumar N (2010) Analytical method development and validation of Amlodipine and Hydrochlorothiazide in combined dosage form by RP-HPLC. Int J Chem Tech Res 4:21–25

Kansara DA, Chhalotiya UK, Kachhiya HM et al (2020) Simultaneous estimation of amlodipine besylate, Rosuvastatin calcium and Fimasartan potassium trihydrate combination used in the treatment of hypertension using LC method. SN Appl Sci 2:948. https://doi.org/10.1007/s42452-020-2758-4

Patel K, Chhalotiya U, Kacchiya H, Patel J, Shah D, Nagda D (2020) Simultaneous quantification of Perindopril erbumine, Indapamide and Amlodipine besylate in newer combination of antihypertensive drugs in pharmaceutical dosage form by thin layer chromatography method. Sep Sci plus 3:1–10. https://doi.org/10.1002/sscp.202000010

ICH (2005) Validation of analytical procedures: methodology (Q2R1). International Conference on Harmonization, Food and Drug Administration, USA

Acknowledgements

All authors are very thankful to the Indukaka Ipcowala College of Pharmacy, New Vallabh Vidyanagar, and SICART, Vallabh Vidyanagar, for providing necessary facilities to carry out the research work.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

All authors associated with this research work declared that there is no conflict of interest for publication of work. All authors have read and approved the manuscript. The contribution of each authors are mentioned below: KP: He is a post graduate student and the above work has been carried out by him as dissertation work. UC: He is a mentor of KP and under his noble guidance proposed method has been developed and validated as per ICH guideline. He is also giving training for ease of operation sophisticated reverse-phase liquid chromatography instrument and involved in interpretation of data. HK: She is a co-mentor of KP and under her noble guidance student can understand the concept of mobile phase selection and how to optimize chromatographic conditions. She is also involved in interpretation of data. JP: Through his good relationship with the pharmaceutical industry, we have received all active pharmaceutical ingredients and he is having sound technical knowledge Waters HPLC software system.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable

Consent for publication

Not applicable

Competing interests

No competing interests to declare.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Patel, K.P., Chhalotiya, U.K., Kachhiya, H.M. et al. A new RP–HPLC method for simultaneous quantification of perindopril erbumine, indapamide, and amlodipine besylate in bulk and pharmaceutical dosage form. Futur J Pharm Sci 6, 80 (2020). https://doi.org/10.1186/s43094-020-00092-4

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s43094-020-00092-4