Abstract

Background

Outer membrane vesicles (OMVs) are nanoparticles released by Gram-negative bacteria and can be used as vaccines. Often, detergents are used to promote release of OMVs and to remove the toxic lipopolysaccharides. Lipopolysaccharides can be detoxified by genetic modification such that vesicles spontaneously produced by bacteria can be directly used as vaccines. The use of spontaneous OMVs has the advantage that no separate extraction step is required in the purification process. However, the productivity of spontaneous OMVs by bacteria at optimal growth conditions is low. One of many methods for increasing OMV formation is to reduce the linkage of the outer membrane to the peptidoglycan layer by knocking out the rmpM gene. A previous study showed that for Neisseria meningitidis this resulted in release of more OMVs. Furthermore, cysteine depletion was found to trigger OMV release and at the same time cause reduced growth and oxidative stress responses. Here we study the effect of growth rate and oxidative stress on OMV release.

Results

First, we identified using chemostat and accelerostat cultures of N. meningitidis that increasing the growth rate from 0.03 to 0.18 h−1 has a limited effect on OMV productivity. Thus, we hypothesized that oxidative stress is the trigger for OMV release and that oxidative stress can be introduced directly by increasing the dissolved oxygen tension of bacterial cultures. Slowly increasing oxygen concentrations in a N. meningitidis changestat showed that an increase from 30 to 150% air saturation improved OMV productivity four-fold. Batch cultures controlled at 100% air saturation increased OMV productivity three-fold over batch cultures controlled at 30% air saturation.

Conclusion

Increased dissolved oxygen tension induces the release of outer membrane vesicles in N. meningitidis cultures. Since oxygen concentration is a well-controlled process parameter of bacterial cultures, this trigger can be applied as a convenient process parameter to induce OMV release in bacterial cultures. Improved productivity of OMVs not only improves the production costs of OMVs as vaccines, it also facilitates the use of OMVs as adjuvants, enzyme carriers, or cell-specific drug delivery vehicles.

Similar content being viewed by others

Background

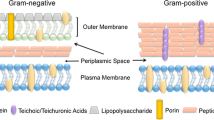

Outer membrane vesicles (OMVs) are naturally produced by Gram-negative bacteria and play a role in pathogenesis, cell-to-cell communication and stress responses [1]. OMVs are spherical nanoparticles that consist of a phospholipid bilayer with proteins and lipopolysaccharides (LPS) [1]. The lumen of the vesicle contains DNA and periplasmic components of the bacterium [2, 3]. Membrane vesicle formation has been shown recently in Gram-positive bacteria and archaea as well [4, 5].

OMVs are highly similar to the outer membrane of the bacteria, are non-replicating, and characteristically are full of pathogen associated molecular patterns. With this they fulfill major criteria for vaccine design and have been successfully used as such [6, 7]. These vaccines have been produced by extraction of vesicles from the bacterial outer membrane using detergents. In this way, vesicles are artificially formed and the amount of toxic LPS could be reduced [8, 9]. However, extraction of vesicles is disadvantageous since the proteome of extracted OMVs (eOMVs) shows a lowered amount of possible immunogenic proteins over spontaneously released OMVs (sOMVs) [10, 11]. Furthermore, extraction methods are not required anymore for LPS removal since the introduction of genetically modified low toxicity LPS [12, 13], which forms the basis for the use of spontaneously released OMV. Thus, the use of spontaneous released vesicles simplifies the purification of OMVs since it obsoletes the extraction step in the down-stream processing of the vaccine product [10, 11]. Sera from mice immunized with spontaneous OMVs show immunity against a broader range of serotypes than mice immunized with detergent extracted OMVs [14]. Furthermore, omission of detergent also preserves vesicle integrity, yielding a more uniform vaccine product.

Feasible sOMV production has not been straightforward since sOMV productivity at optimal growth conditions is low. Despite the research on OMV biogenesis over the past 4 decades, the exact mechanism triggering the release of OMVs by a bacterium remains unknown. Because the composition of OMVs differs from the outer membrane of the bacteria, it is generally thought that the release of vesicles is not a random process [15]. Biogenesis of OMVs has been described by several models although it remains unclear whether a shared mechanism exists [16]. OMV biogenesis is hypothesized to be based on peptidoglycan fragments accumulation in the periplasm, less anchoring of the outer membrane to the peptidoglycan layer, or O-antigen charge repulsion. These models are reviewed in [17] and [2]. Recently, Roier et al. suggested a novel mechanism based on phospholipid accumulation that is conserved among Gram-negative bacteria [18]. The proposed phospholipid transporter VacJ/Yrb ATP-binding cassette was shown to be involved in OMV production and could be part of regulated OMV release. Increasing the OMV production by Neisseria meningitidis is possible by deleting the rmpM gene, the product of which anchors the outer membrane to the peptidoglycan layer [14]. Reducing the linkage between the outer membrane and the peptidoglycan layer results in so-called blebbing mutants of bacteria that show increased release of OMVs in the supernatant. This was found not only for N. meningitidis, but also for E. coli [19].

External triggers for OMV release could be a convenient way to enhance production in bioreactor cultures. Van de Waterbeemd et al. showed that cysteine depletion can be used as a trigger to stimulate the release of vesicles in N. meningitidis cultures [20]. Simultaneously with cysteine depletion, the growth rate is reduced and oxidative stress responses were observed in the transcriptome of the bacterium. It is unknown whether cysteine directly triggers OMV formation or works indirectly through a reduction in growth rate and/or increase in oxidative stress. Furthermore, increased release of vesicles under hydrogen peroxide addition has been shown [20]. The method of hydrogen peroxide addition, however, is not feasible for scalable production processes of OMV since local hydrogen peroxide addition to a bacterial culture will result in significant cell death and lysis. In this study we hypothesize that extracellular oxidative stress is directly induced by high concentrations of dissolved oxygen, which is one of the controlled parameters in bioreactor cultivations. The dissolved oxygen tension is typically kept low, to minimize the stress from hyperoxia and to prevent oxygen inhibition [21]. Especially for a facultative anaerobic pathogen it is obvious to design the cultivation with low oxygen concentration [22]. For example, N. meningitidis cultivation for both the vaccine concepts HexaMen and NonaMen has been designed with levels of 30% air saturation [23, 24].

The aim of this study is to obtain more insight in the role of growth rate and oxidative stress in the release of OMVs. The first section of this paper will examine whether a decrease in growth rate can trigger OMV release by using accelerostat experiments. Next, oxidative stress is introduced in continuous cultures by increasing the dissolved oxygen tension. Lastly, increasing the dissolved oxygen concentration is tested on batch cultures.

Results

Neisseria meningitidis sOMV release at reduced growth rate

The increased productivity of OMVs during the stationary phase of a batch cultivation [20] raised the question what the direct influence of the growth rate on the sOMV release was. Here we assessed the influence of growth rate on sOMV release in three chemostat cultures in steady state at different dilution rates, and in an accelerostat, by slowly increasing the dilution rate of a chemostat culture of N. meningitidis. The slow change in dilution rate (aD) should keep the culture in steady state in this approach [25]. In this accelerostat an acceleration rate (aD) of 0.0055 h−2 was used (Fig. 1b). The carbon dioxide evolution rate (CER) and the optical density increased simultaneously with the dilution rate (Fig. 1a). In the accelerostat, OMVs were produced during the whole culture and were also similar in size and protein composition throughout the culture (Fig. 1c, d). The specific sOMV production was constant throughout the culture with the growth rate ranging from 0.03 to 0.18 h−1 (Fig. 1b). Chemostat cultures at three different growth rates showed comparable productivity to the accelerostat at a growth rate of 0.18 h−1, while the two lower growth rates show a minor increase in OMV productivity. From these results, we conclude that reducing the growth rate from 0.18 to 0.03 h−1 is not an important trigger for sOMV release.

Influence of the growth rate on OMV release in a N. meningitidis accelerostat. a The optical density (black squares) and the carbon dioxide evolution rate of the accelerostat culture (grey line). b The increase of the dilution rate (black line, aD of 0.0055 h−2), the actual measured dilution rate (diamonds). c The resulting specific OMV productivity (mg of total protein (TP) per liter culture of OD590 per hour ) at different dilution rates for the accelerostat (solid circles) and chemostats (open circles). Vesicles were purified from the accelerostat at different dilution rates and the size of the purified OMVs is shown in d. Error bars represent the standard deviation of the measurement. The protein composition of the OMVs is analyzed by SDS-PAGE (e). Lane 1 contains a molecular weight marker and lane 2–8 contain sOMVs purified at increasing dilution rates

Influence of oxidative stress in a dissolved oxygen tension changestat

The effect of increased oxygen concentration on bacterial growth and OMV release was assessed with a changestat approach. The dissolved oxygen tension of a chemostat culture is linearly increased at a rate (1%/h) that should be sufficient low to maintain a steady state culture (Fig. 2a). N. meningitidis is capable of growth up to 150% air saturation without significant impact on the carbon dioxide evolution rate (Fig. 2b). The release of sOMVs is linearly linked to the concentration of oxygen in the culture broth (Fig. 2c). sOMV production can be increased by a factor 4 at high oxygen concentration, while preserving growth of the bacteria. Between dissolved oxygen concentrations of 150% and 220% air saturation, bacterial growth is affected, illustrated by the declined carbon dioxide production rate and lower biomass concentration (Fig. 2b). Production of OMVs at these levels is not preferred.

The influence of increased dissolved oxygen tension on growth and OMV productivity. a The control of the dissolved oxygen concentration in the changestat, where the dissolved oxygen tension was increased by 1% per hour. The effect of the elevated oxygen concentration on the growth is shown in b. The carbon dioxide evolution rate (grey) and bacterial biomass density (black squares) is similar for oxygen concentrations up to 150% air saturation. c The specific productivity of sOMVs as a function of DO for three replicate cultures. The results for replicate 1 as shown in a, b are representative for the two other replicates

Next, the changestat was repeated until a dissolved oxygen concentration of 150% after which the setpoint was maintained constant at this value. The culture showed a steady state productivity at a similar level as at the corresponding oxygen concentration during the changestat (Fig. 3a), confirming that the accelerating factor of the changestat was sufficiently low to keep the culture in steady state. Last, a third changestat culture was done where after reaching a dissolved oxygen concentration of 150% the setpoint was returned to the starting value of 30%. The specific productivity returned to the level at the start of the changestats indicating that the changestat culture did not induce changes to the bacteria (Fig. 3b). Furthermore, the increased oxygen concentrations also showed to trigger sOMV release in an E. coli dissolved oxygen changestat (Additional file 1: Figure S1). In summary, it is shown that increased oxygen tension triggers OMV formation.

Verification of the dissolved oxygen changestat cultures. One replicate of the N. meningitidis dissolved oxygen changestat was maintained at 150% air saturation upon reaching this value (a). The specific sOMV productivity remained at 7 × 1010 sOMVs/L culture OD590 per hour , confirming the measurements in the changestats. Another replicate was returned to a steady state at 30% air saturation (b). During 5 dilutions, wash out of the OMVs produced at increased oxygen concentrations during the changestat was observed, resulting in a steady with similar productivity (1.6 × 1010 sOMVs/L culture OD590 per hour ) to the beginning of the changestat (1.7 × 1010 sOMVs/L culture OD590 per hour)

Improved productivity of batch cultures at increased oxygen concentrations

The high dissolved oxygen concentration was applied to a N. meningitidis batch cultivation to assess the feasibility of increased sOMV production. A dissolved oxygen tension of 100% air saturation was used since this value showed increased OMV release while maintaining similar growth characteristics as at 30% air saturation in the changestat (Fig. 2b). Bacteria were grown in chemically defined medium that results in sOMV release from the onset of the stationary phase. The bacterial growth profile was similar for the batch cultures at 30% and 100% air saturation, showing the capability of N. meningitidis to deal with higher oxygen concentrations (Fig. 4a). The higher oxygen concentration triggered an increased release of vesicles resulting in a three-fold higher productivity at the end of the culture compared to the standard level of 30% (Fig. 4b). The size of OMVs remains constant throughout the culture and is similar between the two oxygen concentrations (Fig. 4c). High dissolved oxygen levels are therefore a convenient method for increasing sOMV production in batch cultures.

High dissolved oxygen tension induces OMV release in N. meningitidis batch cultures. Growth curves of N. meningitidis batch cultures controlled at 30% (open symbols) and 100% air saturation (solid symbols) show similar growth (a). The increased oxygen concentration showed to induce a higher level of vesicle release (b). Graphs are the overlay of two replicate cultures to practically allow for sufficient data points covering 24 h. The first replicate consists of data points at 0 h to 12 h cultivation and at 24 h cultivation, and the second replicate at 0 h and 15 h to 22 h. c The mode size of sOMV particles as measured by NTA in the supernatants from a N. meningitidis batch cultivation at two dissolved oxygen concentrations (30% air saturation and 100% air saturation)

Discussion

In this study, we investigated reduced growth rate and oxidative stress as triggers to induce sOMV formation in N. meningitidis. In the accelerostat experiment, the growth rate increases linearly with the CER up to a growth rate of 0.18 h−1. At higher dilution rates, a reduction in CER was observed and the experiment was stopped. The maximum specific growth rate of N. meningitidis on this medium is 0.5 h−1 [14] and wash-out is thus not expected at this dilution rate. A change in limiting substrate could explain the results at growth rates over 0.18 h−1. All chemostats showed depletion of the carbon sources glucose and glutamate and the cultures were likely carbon limited. A lowered bacterial density was observed at reduced bacterial growth rates, that could be explained by the increased energy requirement for maintenance. The biomass yield on substrate (Yxs) and the maintenance coefficient (ms) were 0.43 gbiomass.g −1glucose and 0.08 gglucose.g −1biomass h−1, calculated using the maintenance model of Pirt [26]. These values were in line to the values of aerobic glucose limited chemostat cultures reported by Baart et al. (0.44 gbiomass.g −1glucose and 0.04 gglucose.g −1biomass h−1 for resp. Yxs and ms) [27]. For the chemostats there seems to be an increase in specific productivity when the growth rate is lowered, where the point at the lowest growth rate significantly deviates from the accelerostat measurement. Since the lowest growth rate is the starting point of the accelerostat, which is certainly in steady state, this difference is not due to a too high acceleration rate in the accelerostat. Together, this data shows that reducing the growth rate from 0.18 to 0.03 h−1 does not have a large effect on OMV productivity, although due to the contrasting results it is not clear if a minor increase in productivity is associated with lowered growth rates.

The effect of oxidative stress was assessed by changestat cultures with increasing dissolved oxygen tensions. N. meningitidis showed to be capable of handling dissolved oxygen concentrations of up to 220% air saturation. OMV productivity was increased fourfold in a changestat culture at oxygen concentrations elevated to 150% air saturation and threefold in a batch culture controlled at 100% air saturation in comparison to cultures at 30% air saturation. Applying increased dissolved oxygen tension on E. coli resulted in a similar increase in sOMV release. The production of sOMVs by oxidative stress could be triggered in the bioreactor by controlling the oxygen concentration in the culture broth, although the exact route of OMV induction remains to be elucidated. Oxidative stress triggers sOMV release on top of the known genetic mutations that increase OMV formation [14, 19, 28]. These mutations reduce the linkage between the outer membrane and the peptidoglycan layer. Here we show the effect of oxidative stress on a rmpM knockout strain of N. meningitidis and on a Tol-Pal mutant strain of E. coli. Oxidative stress may be a general mechanism to induce sOMV release. Applying increased oxygen concentrations on a batch culture showed enhanced release of OMVs of similar size to OMVs produced in a batch culture with sulfur depletion alone, which is an indication that oxidative stress is the underlying trigger in OMV release triggered by sulfur depletion. Moreover, Sabra et al. showed by electron micrographs that Pseudomonas aeruginosa seldom forms membrane vesicles under anoxic conditions (~ 0% of air saturation), while under extreme oxidative stress conditions (350% of air saturation) membrane vesicles were observed [29]. Biologically Neisseria spp. encounter oxidative stress upon oxidative bursts of phagocytes [30, 31]. Lappann et al. showed that OMVs of N. meningitidis serve as a decoy for the bacteria to circumvent binding of the bacteria to neutrophil extracellular traps (NETs) by binding of OMVs to the NETs [32]. The response of forming OMVs by the bacterium could thus enhance bacterial survival by avoiding phagocytosis and NET‐mediated killing. During infection, sOMV release probably contributes to disease progression and the severity of fulminant meningococcal sepsis [33, 34]. The biological role of OMVs in the interaction with phagocytes should gain more interest. Another explanation of OMV release under oxidative stress conditions would be that the OMVs alleviates stress of the bacterium. This method of stress release could be in the form of eliminating misfolded and unfolded proteins, as shown for Pseudomonas aeruginosa [35]. For E. coli, OMV formation has been shown advantageous to bacterial survival as response to periplasmic protein accumulation, and periplasmic peptidoglycan and LPS fragment accumulation was found to be associated with increased OMV release [36, 37]. Increased OMV release as response to increased oxidative stress could be advantageous to the bacterium in a similar manner.

During exponential growth in the batch culture, only minor OMV production is observed and high dissolved oxygen tension does not induce OMV release in this phase. A probable explanation is that N. meningitidis can handle the increased oxygen concentrations by their metabolism during unlimited growth. Production of oxidative stress is a characteristic of aerobic bacterial growth as components of the respiratory chain are oxidized [38]. Neisseria spp. are oxidase positive pathogens containing a mitochondrial like respiratory chain [39] and typically show high levels of respiration [40]. The N. meningitidis genome encodes multiple small c-type cytochromes and a single terminal cytochrome oxidase of the cbb3 type [41,42,43,44]. Li et al. hypothesized that the high respiratory capacity of Neisseria spp. and the excess capacity for oxygen reduction acts as defense against endogenous reactive oxygen species (ROS) [43]. SodA and MntC are the major effectors involved in the Neisseria spp. oxidative stress response [45, 46]. Upon cysteine depletion in batch cultures, high oxygen concentrations enhance the production of sOMVs. This increased release may be caused by a reduction in capacity of handling oxidative stress by the oxidative stress defense mechanisms due to cysteine limitation.

Our initial results show that OMV size was not affected although oxidative stress can cause damage to bacteria. In general, increased oxygen concentrations could affect bacterial growth and the production of biological compounds [47], as was observed in the changestat culture at concentrations over 150% air saturation. Neisseria spp. are adapted to ROS production, since reactive oxygen species accumulate as byproducts of the aerobic respiration [48, 49]. They thus contain several methods to handle ROS [42, 45]. The changestat experiments showed that increased oxygen concentrations can be controlled such that growth remains possible. Future work should ensure the quality of OMVs produced under oxidative stress remains consistent. Promising applications such as the additions and stabilization of enzymes on OMVs [50,51,52], the study of proteins in their native membrane environment [53], or the delivery of drugs packed in OMVs to specific cells [54] could also benefit from this production method.

Conclusion

In summary, this study shows that the dissolved oxygen tension of N. meningitidis cultivations could be used to stimulate OMV release by the introduction of oxidative stress. Increasing the dissolved oxygen concentration of batch cultures from 30 to 150% resulted in a factor 4 increased specific productivity. The dissolved oxygen tension is a well-controlled process parameter to induce outer membrane vesicle formation. With this approach, OMV production can be improved reducing the production costs of OMV-based vaccines and facilitating the use of OMVs for other applications.

Methods

Bacterial strains

A recombinant derivate of the Neisseria meningitidis serogroup B isolate H44/76 [55] was used in this study. The selected strain was a PorA lacking derivate of the H44/76 isolate [56]. This strain has a non-encapsulated phenotype due to the siaD knockout, lpxL1 deletion to attenuate LPS-toxicity, rmpM deletion to improve vesicle formation (unless indicated otherwise) and lgtB mutation to promote interactions with dendritic cells [14, 57]. This strain was stored in glycerol as working seedlots. All cultivations were performed in chemically defined growth medium [27].

For the cultivation with Escherichia coli strain JC8031 (TolRA) was used [58]. A shaker flask culture was started by adding 10 µL of frozen glycerol stock (− 80 °C) to 100 mL LB medium (Large Capsules: tryptone 10 g/L, yeast extract 5 g/L, NaCl 10 g/L, MP Biomedicals) and incubating the shaker flask at 37 °C for 16 h. Bioreactor cultivations were performed on LB medium without antifoam with a maximum stirrer speed of 600 RPM at 37 °C.

Bioreactor cultivations

Batch cultivations were performed in 5 L dished bottom Applikon bioreactors with an H/D ratio of 1.6 based on total volume. Cultivations were operated with 3 L working volume on a Pierre Guerin Trytoni controller. Temperature was controlled at 35 ± 0.5 °C and pH was controlled at pH 7.2 ± 0.05 using 1 M HCl and 1 M NaOH. Dissolved oxygen tension was controlled at 30% unless indicated otherwise. The membrane covered polarographic oxygen sensor (InPro 6850i, Mettler Toledo) was calibrated at 100% in air-saturated sterile growth medium of 35 °C. In the first phase of the cultivation, the dissolved oxygen tension is controlled by increasing the agitation rate (300–1000 RPM) followed by increasing the fraction of oxygen in the headspace aeration (1 L/min) by the addition of pure oxygen. The agitation rate of the 100% air saturation cultures was fixed at 1000 RPM directly after inoculation after which the oxygen tension was controlled by the addition of pure oxygen in the headspace. Samples were taken for optical density measurements and used for nutrient and sOMV measurements after sterile filtration (0.22 µm pore-size) and storage at 4 °C. Off-gas composition was analyzed by a Thermo Prima δb process mass spectrometer.

Chemostat cultivations

Continuous cultivations were performed in a similar setup as the batch cultivation setup. The working volume of the 5 L bioreactor was decreased from 3.0 to 2.0 L to reduce the feed medium required for the experiments. The vessel was equipped with a medium inlet and two outlet pipes, one submerged in the cultivation broth at the height of the stirrer and one directly at the liquid–gas interphase. The latter allowed the control of the working volume to be exactly 2.0 L at a fixed maximum stirrer speed, independent of foaming. The weight of the bioreactor, the feed medium and the pH titrant solutions was measured by balances and used for verification of the dilution rate. Samples were taken for optical density measurements and off-gas analysis was similar to the batch cultivation. The bioreactor was controlled with the same control loops as used in the batch cultivations. After 8 h of growth the feed and the bleed pumps were started to initiate a continuous culture. Steady state of the culture was assumed based on stable bacterial density values and stable carbon dioxide emission for at least 3 dilutions of the bioreactor volume.

Accelerostat and dissolved oxygen changestat cultivation

An accelerostat was started from a chemostat fermentation in steady state at D = 0.03 h−1, operated as described in the previous section, by increasing the dilution rate linearly with aD = 0.0055 h−2. The dilution rate was changed by increasing the medium inflow rate and equally increasing the broth outflow rate. From the culture broth, 50 mL samples were drawn to purify sOMVs. The samples were centrifuged at 4000×g for 30 min at 4 °C and the sterile filtered supernatants (Nalgene RapidFlow 0.2 µm pore-size PES filter unit) were concentrated on 100 kDa cut-off spin filters. The concentrated sOMVs were washed with 3% sucrose buffered by 10 mM TrisHCl (pH 7.4) to wash out contaminating proteins. Next, the diafiltrated sOMVs were centrifuged at 125.000×g for 2 h. The sOMV containing pellet was dissolved in 1 mL 10 mM TrisHCl (pH 7.4) with 3% sucrose.

The dissolved oxygen tension changestat was started from a chemostat culture. For this, a continuous culture in steady state with µ = 0.04 h−1 was obtained as described previously. During this steady state, the oxygen concentration was controlled at 30% air saturation, the starting point for the changestat. From the start of the changestat, the oxygen concentration was increased linearly with aDOT = 1.0%/h.

Escherichia coli JC8031 (TolRA) was used for the dissolved oxygen tension changestat of E. coli [58]. A shaker flask culture was started by adding 10 µL of frozen glycerol stock (− 80 °C) to 100 mL LB medium (Large Capsules: tryptone 10 g/L, yeast extract 5 g/L, NaCl 10 g/L, MP Biomedicals) and incubating the shaker flask at 37 °C for 16 h. Bioreactor cultivations were performed on LB medium without antifoam with a maximum stirrer speed of 600 RPM at 37 °C.

Quantification of sOMVs

Culture samples were sterile filtered (0.22 µm pore-size) before the sOMV were measured. sOMV concentration was measured with a phospholipid specific probe FM 4-64 (SynaptoRed C2, Biotium) by mixing 50 µL of 2- to 50-fold diluted samples with 50 µL of dye solution (0.05 mM FM 4-64). Fluorescence was measured directly after mixing this solution using a plate fluorometer (Synergy MX, Biotek ex480, em650). The concentration of sOMV in the culture supernatants was calculated from a calibration curve which was based on the responses of the standards (sOMV corresponding with 0–2.5 mg/L total protein). In the changestat experiments, nanoparticle tracking analysis [59] was used for sOMV quantification. Static measurements (10 captures of 30 s) were made on a NanoSight NS500 with 488 nm laser module and sCMOS camera, that was calibrated with the concentration upgrade [60]. Temperature was controlled at 25 °C and captures were analyzed with the NTA 3.2 software build 3.2.16. Automated flow measurements were made as described previously [61].

OMV size was assessed by dynamic light scattering in a Zetasizer Nano-ZS with Zetasizer 7.11 software (Malvern Instruments). Measurements were performed using a SOP that takes three measurements in backscatter mode, with auto measurement duration and “seek for optimal position” as positioning setting. The sample was assumed to be protein with a refractive index of 1.450 and 0.001 absorption, in water as dispersant with a viscosity of 0.8872 cP and refractive index of 1.330. Data was processed with the normal analysis model.

Sds-page

Purified OMVs were assessed for total protein content by the Lowry protein assay using Peterson’s modification. OMVs corresponding to 4 µg of protein were loaded on a precast polyacrylamide gel (Lonza) to perform SDS-gel electrophoresis. The gel was stained with InstantBlue protein stain (Expedeon).

Abbreviations

- OMV:

-

outer membrane vesicle

- sOMV:

-

spontaneously released OMV

- eOMV:

-

extracted OMV

- dOMV:

-

detergent extracted OMV

- LPS:

-

lipopolysaccharides

- D:

-

dilution rate

- a D :

-

acceleration rate of the dilution rate

- a DOT :

-

acceleration rate of the dissolved oxygen tension

- CER:

-

carbon dioxide evolution rate

- OUR:

-

oxygen uptake rate

- RQ:

-

respiratory quotient

- DO:

-

dissolved oxygen

- ROS:

-

reactive oxygen species

- TP:

-

total protein

- NTA:

-

nanoparticle tracking analysis

- NET:

-

neutrophil extracellular trap

- Ypx :

-

OMV yield per biomass

- Yxs :

-

biomass yield on substrate

- ms :

-

maintenance coefficient

- OD590 :

-

optical density at 590 nm

References

Kulp A, Kuehn MJ. Biological functions and biogenesis of secreted bacterial outer membrane vesicles. Annu Rev Microbiol. 2010;64:163–84.

Schwechheimer C, Kuehn MJ. Outer-membrane vesicles from Gram-negative bacteria: biogenesis and functions. Nat Rev Microbiol. 2015;13:605–19.

Dorward DW, Garon CF. DNA is packaged within membrane-derived vesicles of gram-negative but not gram-positive bacteria. Appl Environ Microbiol. 1990;56:1960–2.

Rivera J, Cordero RJ, Nakouzi AS, Frases S, Nicola A, Casadevall A. Bacillus anthracis produces membrane-derived vesicles containing biologically active toxins. Proc Natl Acad Sci USA. 2010;107:19002–7.

Ellen AF, Albers SV, Huibers W, Pitcher A, Hobel CF, Schwarz H, Folea M, Schouten S, Boekema EJ, Poolman B, Driessen AJ. Proteomic analysis of secreted membrane vesicles of archaeal Sulfolobus species reveals the presence of endosome sorting complex components. Extremophiles. 2009;13:67–79.

Holst J, Martin D, Arnold R, Huergo CC, Oster P, O’Hallahan J, Rosenqvist E. Properties and clinical performance of vaccines containing outer membrane vesicles from Neisseria meningitidis. Vaccine. 2009;27(Suppl 2):B3–12.

Gorringe AR, Pajon R. Bexsero: a multicomponent vaccine for prevention of meningococcal disease. Hum Vaccin Immunother. 2012;8:174–83.

Fredriksen JH, Rosenqvist E, Wedege E, Bryn K, Bjune G, Froholm LO, Lindbak AK, Mogster B, Namork E, Rye U, et al. Production, characterization and control of MenB-vaccine “Folkehelsa”: an outer membrane vesicle vaccine against group B meningococcal disease. NIPH Ann. 1991;14:67–79.

Zollinger WD, Mandrell RE, Griffiss JM, Altieri P, Berman S. Complex of meningococcal group B polysaccharide and type 2 outer membrane protein immunogenic in man. J Clin Invest. 1979;63:836–48.

Lappann M, Otto A, Becher D, Vogel U. Comparative proteome analysis of spontaneous outer membrane vesicles and purified outer membranes of Neisseria meningitidis. J Bacteriol. 2013;195:4425–35.

van de Waterbeemd B, Mommen GP, Pennings JL, Eppink MH, Wijffels RH, van der Pol LA, de Jong AP. Quantitative proteomics reveals distinct differences in the protein content of outer membrane vesicle vaccines. J Proteome Res. 2013;12:1898–908.

van der Ley P, Steeghs L, Hamstra HJ, ten Hove J, Zomer B, van Alphen L. Modification of lipid A biosynthesis in Neisseria meningitidis lpxL mutants: influence on lipopolysaccharide structure, toxicity, and adjuvant activity. Infect Immun. 2001;69:5981–90.

Zariri A, van der Ley P. Biosynthetically engineered lipopolysaccharide as vaccine adjuvant. Exp Rev Vaccines. 2015;14:861–76.

van de Waterbeemd B, Streefland M, van der Ley P, Zomer B, van Dijken H, Martens D, Wijffels R, van der Pol L. Improved OMV vaccine against Neisseria meningitidis using genetically engineered strains and a detergent-free purification process. Vaccine. 2010;28:4810–6.

Schwechheimer C, Sullivan CJ, Kuehn MJ. Envelope control of outer membrane vesicle production in Gram-negative bacteria. Biochemistry. 2013;52:3031–40.

Pathirana RD, Kaparakis-Liaskos M. Bacterial membrane vesicles: biogenesis, immune regulation and pathogenesis. Cell Microbiol. 2016;18:1518–24.

Haurat MF, Elhenawy W, Feldman MF. Prokaryotic membrane vesicles: new insights on biogenesis and biological roles. Biol Chem. 2015;396:95–109.

Roier S, Zingl FG, Cakar F, Durakovic S, Kohl P, Eichmann TO, Klug L, Gadermaier B, Weinzerl K, Prassl R, et al. A novel mechanism for the biogenesis of outer membrane vesicles in Gram-negative bacteria. Nat Commun. 2016;7:10515.

Bernadac A, Gavioli M, Lazzaroni JC, Raina S, Lloubes R. Escherichia coli tol-pal mutants form outer membrane vesicles. J Bacteriol. 1998;180:4872–8.

van de Waterbeemd B, Zomer G, van den Ijssel J, van Keulen L, Eppink MH, van der Ley P, van der Pol LA. Cysteine depletion causes oxidative stress and triggers outer membrane vesicle release by Neisseria meningitidis; implications for vaccine development. PLoS ONE. 2013;8:e54314.

Haugaard N. Cellular mechanisms of oxygen toxicity. Physiol Rev. 1968;48:311–73.

Hewitt CJ, Nebe-Von Caron G, Axelsson B, McFarlane CM, Nienow AW. Studies related to the scale-up of high-cell-density E. coli fed-batch fermentations using multiparameter flow cytometry: effect of a changing microenvironment with respect to glucose and dissolved oxygen concentration. Biotechnol Bioeng. 2000;70:381–90.

Claassen I, Meylis J, van der Ley P, Peeters C, Brons H, Robert J, Borsboom D, van der Ark A, van Straaten I, Roholl P, et al. Production, characterization and control of a Neisseria meningitidis hexavalent class 1 outer membrane protein containing vesicle vaccine. Vaccine. 1996;14:1001–8.

Baart GJ, de Jong G, Philippi M, van Riet K, van der Pol LA, Beuvery EC, Tramper J, Martens DE. Scale-up for bulk production of vaccine against meningococcal disease. Vaccine. 2007;25:6399–408.

Paalme T, Kahru A, Elken R, Vanatalu K, Tiisma K, Raivo V. The computer-controlled continuous culture of Escherichia coli with smooth change of dilution rate (A-stat). J Microbiol Methods. 1995;24:145–53.

Pirt SJ. Maintenance energy: a general model for energy-limited and energy-sufficient growth. Arch Microbiol. 1982;133:300–2.

Baart GJ, Zomer B, de Haan A, van der Pol LA, Beuvery EC, Tramper J, Martens DE. Modeling Neisseria meningitidis metabolism: from genome to metabolic fluxes. Genome Biol. 2007;8:R136.

Deatherage BL, Lara JC, Bergsbaken T, Rassoulian Barrett SL, Lara S, Cookson BT. Biogenesis of bacterial membrane vesicles. Mol Microbiol. 2009;72:1395–407.

Sabra W, Lunsdorf H, Zeng AP. Alterations in the formation of lipopolysaccharide and membrane vesicles on the surface of Pseudomonas aeruginosa PAO1 under oxygen stress conditions. Microbiology. 2003;149:2789–95.

Moslen MT. Reactive oxygen species in normal physiology, cell injury and phagocytosis. Adv Exp Med Biol. 1994;366:17–27.

Ng VH, Cox JS, Sousa AO, MacMicking JD, McKinney JD. Role of KatG catalase-peroxidase in mycobacterial pathogenesis: countering the phagocyte oxidative burst. Mol Microbiol. 2004;52:1291–302.

Lappann M, Danhof S, Guenther F, Olivares-Florez S, Mordhorst IL, Vogel U. In vitro resistance mechanisms of Neisseria meningitidis against neutrophil extracellular traps. Mol Microbiol. 2013;89:433–49.

van Deuren M, van der Ven-Jongekrijg J, Bartelink AK, van Dalen R, Sauerwein RW, van der Meer JW. Correlation between proinflammatory cytokines and antiinflammatory mediators and the severity of disease in meningococcal infections. J Infect Dis. 1995;172:433–9.

Brandtzaeg P, Kierulf P, Gaustad P, Skulberg A, Bruun JN, Halvorsen S, Sorensen E. Plasma endotoxin as a predictor of multiple organ failure and death in systemic meningococcal disease. J Infect Dis. 1989;159:195–204.

Baumgarten T, Sperling S, Seifert J, von Bergen M, Steiniger F, Wick LY, Heipieper HJ. Membrane vesicle formation as a multiple-stress response mechanism enhances Pseudomonas putida DOT-T1E cell surface hydrophobicity and biofilm formation. Appl Environ Microbiol. 2012;78:6217–24.

McBroom AJ, Kuehn MJ. Release of outer membrane vesicles by Gram-negative bacteria is a novel envelope stress response. Mol Microbiol. 2007;63:545–58.

Schwechheimer C, Kulp A, Kuehn MJ. Modulation of bacterial outer membrane vesicle production by envelope structure and content. BMC Microbiol. 2014;14:324.

Storz G, Imlay JA. Oxidative stress. Curr Opin Microbiol. 1999;2:188–94.

Bøvre K. Neisseriaceae prevot 1933. In: Krieg NR, Hold JG, editors. Bergey’s manual of systemic bacteriology, vol. 1. Baltimore: Williams and Wilkin; 1984.

Archibald FS, Duong MN. Superoxide dismutase and oxygen toxicity defenses in the genus Neisseria. Infect Immun. 1986;51:631–41.

Aspholm M, Aas FE, Harrison OB, Quinn D, Vik A, Viburiene R, Tonjum T, Moir J, Maiden MC, Koomey M. Structural alterations in a component of cytochrome c oxidase and molecular evolution of pathogenic Neisseria in humans. PLoS Pathog. 2010;6:e1001055.

Seib KL, Wu HJ, Kidd SP, Apicella MA, Jennings MP, McEwan AG. Defenses against oxidative stress in Neisseria gonorrhoeae: a system tailored for a challenging environment. Microbiol Mol Biol Rev. 2006;70:344–61.

Li Y, Hopper A, Overton T, Squire DJ, Cole J, Tovell N. Organization of the electron transfer chain to oxygen in the obligate human pathogen Neisseria gonorrhoeae: roles for cytochromes c4 and c5, but not cytochrome c2, in oxygen reduction. J Bacteriol. 2010;192:2395–406.

Deeudom M, Koomey M, Moir JW. Roles of c-type cytochromes in respiration in Neisseria meningitidis. Microbiology. 2008;154:2857–64.

Seib KL, Tseng HJ, McEwan AG, Apicella MA, Jennings MP. Defenses against oxidative stress in Neisseria gonorrhoeae and Neisseria meningitidis: distinctive systems for different lifestyles. J Infect Dis. 2004;190:136–47.

Tseng HJ, Srikhanta Y, McEwan AG, Jennings MP. Accumulation of manganese in Neisseria gonorrhoeae correlates with resistance to oxidative killing by superoxide anion and is independent of superoxide dismutase activity. Mol Microbiol. 2001;40:1175–86.

Baez A, Shiloach J. Effect of elevated oxygen concentration on bacteria, yeasts, and cells propagated for production of biological compounds. Microb Cell Fact. 2014;13:181.

Korshunov S, Imlay JA. Detection and quantification of superoxide formed within the periplasm of Escherichia coli. J Bacteriol. 2006;188:6326–34.

Imlay JA. Cellular defenses against superoxide and hydrogen peroxide. Annu Rev Biochem. 2008;77:755–76.

Alves NJ, Turner KB, Daniele MA, Oh E, Medintz IL, Walper SA. Bacterial nanobioreactors-directing enzyme packaging into bacterial outer membrane vesicles. ACS Appl Mater Interfaces. 2015;7:24963–72.

Su FH, Tabañag IDF, Wu CY, Tsai SL. Decorating outer membrane vesicles with organophosphorus hydrolase and cellulose binding domain for organophosphate pesticide degradation. Chem Eng J. 2017;308:1–7.

Alves NJ, Moore M, Johnson BJ, Dean SN, Turner KB, Medintz IL, Walper SA. Environmental decontamination of a chemical warfare simulant utilizing a membrane vesicle-encapsulated phosphotriesterase. ACS Appl Mater Interfaces. 2018;10:15712–9.

Thoma J, Manioglu S, Kalbermatter D, Bosshart PD, Fotiadis D, Müller DJ. Protein-enriched outer membrane vesicles as a native platform for outer membrane protein studies. Commun Biol. 2018;1:23.

Gujrati V, Kim S, Kim S-H, Min JJ, Choy HE, Kim SC, Jon S. Bioengineered bacterial outer membrane vesicles as cell-specific drug-delivery vehicles for cancer therapy. ACS Nano. 2014;8:1525–37.

Holten E. Serotypes of Neisseria meningitidis isolated from patients in Norway during the first six months of 1978. J Clin Microbiol. 1979;9:186–8.

Tommassen J, Vermeij P, Struyve M, Benz R, Poolman JT. Isolation of Neisseria meningitidis mutants deficient in class 1 (porA) and class 3 (porB) outer membrane proteins. Infect Immun. 1990;58:1355–9.

Steeghs L, van Vliet SJ, Uronen-Hansson H, van Mourik A, Engering A, Sanchez-Hernandez M, Klein N, Callard R, van Putten JP, van der Ley P, et al. Neisseria meningitidis expressing lgtB lipopolysaccharide targets DC-SIGN and modulates dendritic cell function. Cell Microbiol. 2006;8:316–25.

Espesset D, Corda Y, Cunningham K, Bénédetti H, Lloubès R, Lazdunski C, Géli V. The colicin A pore-forming domain fused to mitochondrial intermembrane space sorting signals can be functionally inserted into the Escherichia coli plasma membrane by a mechanism that bypasses the Tol proteins. Mol Microbiol. 1994;13:1121–31.

Malloy A, Carr B. Nano particle tracking analysis—the Halo™ system. Part Part Syst Charact. 2006;23:197–204.

MalvernInstruments: NanoSight NTA concentration measurement upgrade. In: TN1505152015.

Gerritzen MJH, Martens DE, Wijffels RH, Stork M. High throughput nanoparticle tracking analysis for monitoring outer membrane vesicle production. J Extracell Vesicles. 2017;6:1333883.

Authors’ contributions

MJHG, DEM, and MS designed the experiments. MJHG, LvK, JvdIJ performed the experiments. MJHG, DEM, and MS analyzed the data and MJHG wrote the manuscript. MJHG, RHWM, DEM, RHW and MS discussed the data. All authors read and approved the final manuscript.

Acknowledgements

The authors thank Leo van der Pol, Peter van der Ley, and Sven van der Kooi for constructive discussions. E. coli strain JC8031 was a kind gift of Roland Lloubes, supplied by Wouter de Jong and Joen Luirink.

Competing interests

M. J. H. Gerritzen and M. Stork are employees of Intravacc and are co-inventors of a patent application for the use of increased dissolved oxygen tension as trigger for sOMV production (Patent Application No. EP17205138).

Ethics approval and consent to participate

Not applicable.

Funding

This work has been funded by the Ministry for Health, Welfare and Sports (The Netherlands).

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Author information

Authors and Affiliations

Corresponding author

Additional file

Additional file 1: Figure S1.

Increased dissolved oxygen tension triggers OMV release in E. coli. Changestat of E. coli (A) shows growth at dissolved oxygen tensions up to 200% air saturation in a changestat with aDOT = 1.5%/h. OMV release is directly related to the increased oxygen concentration.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The Creative Commons Public Domain Dedication waiver (http://creativecommons.org/publicdomain/zero/1.0/) applies to the data made available in this article, unless otherwise stated.

About this article

Cite this article

Gerritzen, M.J.H., Maas, R.H.W., van den Ijssel, J. et al. High dissolved oxygen tension triggers outer membrane vesicle formation by Neisseria meningitidis. Microb Cell Fact 17, 157 (2018). https://doi.org/10.1186/s12934-018-1007-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s12934-018-1007-7