Abstract

A tiny number of Zn atoms were deposited on Si(111)-(7×7) surface to study the evolution process of Zn-induced nanoclusters. After the deposition, three types (type I, II, and III) of Zn-induced nanoclusters were observed to occupy preferably in the faulted half-unit cells. These Zn-induced nanoclusters are found to be related to one, two, and three displaced Si edge adatoms, and simultaneously cause the depression of one, two, and three closest Si edge adatoms in the neighboring unfaulted half-unit cells at negative voltages, respectively. First-principles adsorption energy calculations show that the observed type I, II, and III nanoclusters can reasonably be assigned as the Zn3Si1, Zn5Si2, and Zn7Si3 clusters, respectively. And Zn3Si1, Zn5Si2, and Zn7Si3 clusters are, respectively, the most stable structures in cases of one, two, and three displaced Si edge adatoms. Based on the above energy-preferred models, the simulated bias-dependent STM images are all well consistent with the experimental observations. Therefore, the most stable Zn7Si3 nanoclusters adsorbed on the Si(111)-(7×7) surface should grow up on the base of Zn3Si1 and Zn5Si2 clusters. A novel evolution process from Zn3Si1 to Zn5Si2, and finally to Zn7Si3 nanocluster is unveiled.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Design and fabrication of nanoclusters is a new inspiring field because of their amazing features that are remarkably different from classical materials [1–4]. The beneficial electronic, optical, magnetic, and chemical properties of nanoclusters can be employed in many fields, such as optoelectronic devices [5, 6], single-electronic devices [7], ultrahigh-density magnetic recording [8–10], and quantum computing. From the viewpoint of practical applications, it is necessary to fabricate stable, ordered, and identical-sized nanoclusters. In the past decade, utilizing the natural template of Si(111)-(7×7) surface, a number of metal nanoclusters with identical sizes and shapes have been successfully fabricated, such as group IA metals (Na) [11, 12], group IB metals (Au) [13], group IIB metals (Zn) [14], group IIIA metals (Al, Ga, Tl, and In) [15–20], group IV metals (Pb) [21], and even some 3d ferromagnetic metals (Fe, Co, and Ni) [22–24]. By using the ultrahigh-vacuum (UHV) scanning tunneling microscopy (STM) technology combined with the first-principle theoretical simulations, the stable structural configurations of the identical-sized nanoclusters on Si(111)-(7×7) surface have been clearly illustrated. It was found that the atomic structures of these identical-sized nanoclusters had a characteristic of the varying valence. For instance, group IIIA metals (Al, Ga, and In) tend to form the stable Al6Si3, Ga6Si3, and In6Si3 nanoclusters with six metal atoms and three displaced Si edge adatoms connecting as a hollow triangle [15–20]. However, group IIB metal, Zn, tends to form the stable Zn7Si3 nanoclusters with an excess Zn atom characteristically occupying the center of the hollow triangle [14]. Although the structural configurations have been clearly clarified, the evolution process of these metal nanoclusters was rarely addressed. That is, how these nanoclusters gradually evolve and finally grow up to the intact Ga6Si3 or Zn7Si3 nanoclusters? For the controlled synthesis and device design, it is desirable to carefully investigate the evolution process of metal nanoclusters on Si(111)-(7×7) surface.

In this paper, three types of Zn-induced nanoclusters were grown at room temperature on the clean Si(111)-(7×7) surface with a tiny number of Zn atoms. Using in situ STM technology for real-space imaging, these nanoclusters are systematically characterized at both the positive and negative bias voltages. Taking into account the adsorption energies of different structural models derived from the first-principles calculations, the experimental atomic configurations of these three types of nanoclusters are identified to be Zn3Si1, Zn5Si2, and Zn7Si3. Furthermore, these structures are further confirmed by theoretically simulated STM images. Accordingly, a novel evolution process from Zn3Si1 to Zn5Si2, and finally to Zn7Si3 nanocluster is unveiled.

2 Methods

The experiments were performed within an ultrahigh-vacuum system (OMICRON MBE-SPM system) which consists of a growth chamber and an analysis chamber with a base pressure of about 2.0 × 10−10 mbar. Atomically clean Si(111)-(7×7) surface was prepared by standard flashing to about 1200 °C while keeping the vacuum at a pressure better than 1 × 10−9 mbar [21]. High-purity Zn (99.9999 %) was evaporated from a boron nitride crucible onto the Si(111)-(7×7) surface. A tiny number of Zn atoms were deposited through the control of Zn source temperature and evaporation time. The sample was then transferred to the analysis chamber and imaged by an OMICRON STM using chemically etched tungsten tips [25, 26]. All STM images reported here were recorded under a constant tunneling current of 0.05 nA.

In order to identify the structural configurations of the observed nanoclusters, the adsorption energies and STM images were calculated by the first-principles simulations within the framework of the generalized gradient approximation [27, 28], using the plane-wave density functional theory Vienna Ab Initio Simulation Package [29–31]. The structural models were periodically repeated by an atomic slab consisting of 4 Si layers (200 Si atoms), with n Zn atoms adsorbed on the top and 49 H atoms bonded at the bottom. A 12-Å-thick vacuum layer was applied for separating the slabs to form a surface. Ionic potentials were described by ultrasoft pseudopotentials, and the plane-wave cutoff energy was set at 330 eV. The surface Brillouin zone was sampled at the point only. The Zn-3d4s and Si-3s3p were employed as the valence electrons. Structural optimizations were carried out by relaxing all the atomic geometries using the conjugate gradient algorithm [32]. The forces on all the atoms were converged within 0.01 eV/Å.

3 Results and Discussion

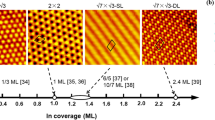

For observing the evolution process of Zn-induced nanoclusters, a tiny number of Zn atoms were deposited on the clean Si(111)-(7×7) surface, as shown in Fig. 1a. The faulted (F) and unfaulted (U) triangular halves of 7×7 unit cell are denoted separately in the surface. Due to the different atomic structures in two triangular halves [33], Si adatoms in the faulted half-unit cells (FHUCs) show a little brighter than that in the unfaulted half-unit cells (UHUCs) at the negative bias voltages, as shown in Fig. 1. After Zn deposition, three types of Zn-induced nanocluster structures appear on the surface, as denoted, respectively, by the green (type I), pink (type II), and blue (type III) triangles in Fig. 1b and c. Most of the nanoclusters are observed to adsorb on the FHUCs of the Si(111)-(7×7) surface. This preference is attributed to the lower adsorption energy in the FHUC for the dimer-adatom-stacking (DAS) fault model of the Si(111)-(7×7) surface [33]. For the filled-state STM images of type I nanoclusters, as shown in Fig. 1b, it seems that one Si edge adatom is pushed toward the center of the FHUC. And one closet Si edge adatom in the neighboring UHUC becomes dark as denoted by a green dotted circle. For the filled-state STM images of type II nanocluster, as shown in Fig. 1c, it exhibits a triangular big bright dot in the center of the FHUC. Moreover, careful comparison shows that two closet Si edge adatoms in the neighboring UHUCs become dark, as denoted by the pink dotted circles. For type III nanocluster, as shown in Fig. 1b and c, it is also apt to occupy the center of FHUC with a bright triangular morphology in filled-state STM images. Simultaneously, the three closet Si edge adatoms in the neighboring uncovered UHUCs are almost darkened, as indicated by the blue dotted circles. It is thus clear that the formation of type I, II, and III nanoclusters causes, respectively, one, two, and three darkened closest Si edge adatoms in neighboring UHUCs in the filled-state STM images. Therefore, three types of Zn-induced nanoclusters should have the similar formation mechanism in the atomic configurations.

The filled-state STM images of Si(111)-(7×7) surface a before the deposition of Zn atoms (V S = −0.5 V, 15 nm × 15 nm) and b, c after a tiny number of Zn atoms were deposited (V S = −1.5 V, 15 nm × 15 nm). The faulted (F) and unfaulted (U) triangular halves of 7×7 unit cell are denoted separately. Three types of Zn-induced nanoclusters observed in b and c are denoted, respectively, by the green (type I), pink (type II), and blue (type III) triangles. The darkened closet Si edge adatoms in neighboring UHUCs are denoted, respectively, by the green, pink, and blue dotted circles. (Color figure online)

To better understand the gradual evolution process of Zn-induced nanoclusters, we systematically studied the geometric structures of three types of observed nanoclusters. A series of empty- and filled-state STM images were taken at different bias voltages of +1.5, +1.0, +0.5, −0.5, −1.0, and −1.5 V on the same surface area with one Zn-induced nanocluster in the FHUC, as shown in Fig. 2. For type III nanocluster, two groups of empty- and filled-state STM images shown in Fig. 2a–d exhibit almost the same topographic evolution as the previous research [14]. Combined with the results of the simulated STM images as shown in Fig. 5, we deduce that type III nanoclusters should be the Zn7Si3 nanoclusters. The structural configuration of Zn7Si3 nanocluster, as shown in Fig. 3d, exhibits that three adsorbed Zn atoms replace the three Si edge adatoms in the FHUC, meanwhile the replaced Si atoms and other three Zn atoms connect into a hexagon, with another characteristic Zn atom occupying the center. Considering the observed STM images and the structural configuration results, we deduce that the depression of the three closet Si edge adatoms in neighboring UHUCs, as shown in the filled-state STM images in Fig. 2b and d, is attributed to three displaced Si edge adatoms in the FHUC. That is, when one Si edge adatom in the FHUC is replaced by Zn atoms, the closet Si edge adatom in neighboring UHUC exhibits a darkened filled-state STM image.

Experimental empty (a, c) (9 nm × 9 nm) and filled (b, d) (9 nm × 11.5 nm) state STM images of three types of Zn-induced nanoclusters in the FHUCs recorded at bias voltages of +1.5, +1.0, +0.5, −0.5, −1.0, and −1.5 V, respectively. Three types of Zn-induced nanoclusters observed in Fig. 1b and c are denoted, respectively, by the green, pink, and blue triangles. The closet Si edge adatoms in neighboring UHUCs are denoted, respectively, by the green, pink, and blue dotted circles. (Color figure online)

a Top view of the DAS model of the Si(111)-(7×7) surface. b, c, and d are, respectively, the top view of the proposed Zn3Si1, Zn5Si2, and Zn7Si3 models in this work. The green balls are Zn atoms. The blue and pink balls are Si adatoms and rest atoms, respectively. The center, edge, and corner Zn atoms are marked as 1, 2, and 3, respectively. (Color figure online)

For type I nanocluster, denoted by the green triangle, it exhibits a “U” shape pattern in the center of FHUC at the bias voltage of +1.5 V. Then the cluster changes to the pattern consisting of two bright and one dim dots at the bias voltage of +1.0 V. Different from the “U” shape pattern, the cluster exhibits a “V” shape pattern at the bias voltages of −1.5 and −1.0 V. As the voltage further reduces to ± 0.5 V, the cluster images transform to the pattern with two bright dots and one vanished Si edge adatom. Careful observation shows that the two bright dots should come from the two unaltered Si edge adatoms. Therefore, the formation of type I nanocluster is relative to one Si edge adatom and none of the other two intact Si edge adatoms in the FHUC. In the empty-state STM images, three closet Si edge adatoms in the neighboring UHUCs are almost unaltered as compared with the clean Si(111)-(7×7) surface. As for the negative voltage of −0.5 V, one of the three closet Si edge adatoms exhibits a dark image, as marked by a green dotted circle in Fig. 2b, whose position is just opposite of the disappeared Si edge adatom in the FHUC. Since one displaced Si edge adatom in the FHUC would induce the depression of the closet Si edge adatom in neighboring UHUC in the filled-state STM image, the formation of type I nanocluster is obviously relative to one displaced Si edge adatom in the FHUC and the other two Si edge adatoms are almost kept unaltered. The observed dim dot at the bias voltage of +1.0 V, as shown in Fig. 2a, should be the displaced Si edge adatom. However, due to the uncertainty of the number and the position of adsorbed Zn atoms, the structural configuration of type I nanocluster is still not clear. Therefore, it is necessary to further employ the theoretical calculation and simulation, which would be discussed below.

Type II nanocluster, denoted by the pink triangle, shows a shape of isosceles triangle at the bias voltage of +1.5 V. As the voltage reduces from +1.5 to +0.5 V, the size and brightness of the base of isosceles triangle decrease gradually. And the cluster transforms to the pattern with one bright dot and two vanished Si edge adatoms. Careful observation shows that the bright dot should come from the unaltered Si edge adatom. The formation of type II nanocluster should be related to two Si edge adatoms and none of the other intact Si edge adatom in the FHUC. Different from the isosceles triangle pattern, the cluster exhibits an equilateral triangle pattern at the bias voltages of −1.5 and −1.0 V. As the voltage further reduces to −0.5 V, the cluster also transforms to the pattern with one bright dot and two almost absent Si edge adatoms. Three closet Si edge adatoms in the neighboring UHUCs show also almost unaltered images in the empty-state STM images as compared with the clean Si(111)-(7×7) surface. Only two of the three closet Si edge adatoms tune to be the dark pattern at a negative voltage of −0.5 V, and their positions are also just opposite of the dispersed Si edge adatoms in the FHUC. Therefore, similar to type I and III nanoclusters, the formation of type II nanocluster is obviously related to two displaced Si edge adatoms in the FHUC and the other one Si edge adatom is almost kept unaltered. Two base angles of the isosceles triangle at the bias voltage of +1.5 V, as shown in Fig. 2c, could be deduced to be the two displaced Si edge adatoms. Similarly, the structural configuration of type II nanocluster is also not clear due to the uncertainty of the number and the position of adsorbed Zn atoms. But the above systematical structural analysis provides us the useful information for constructing preferable models for type I and II nanoclusters.

According to above structural information, type I nanocluster is related to one displaced Si edge adatom in the FHUC. Taking into account the bonding symmetry, two most possible cluster models of Zn1Si1 and Zn3Si1 (as shown in Fig. 3b) are constructed to be considered as type I nanocluster in the FHUC. In order to compare the stability of the proposed cluster structures, the adsorption energy E a(n) of the cluster is written as

where E slab(n), E clean, and E atom are the total energies of the n adsorbates of the adsorbed surface, the clean surface, and the isolated adsorbate atom, respectively [34]. Figure 4 aligns the calculated adsorption energies of the proposed Zn-induced nanoclusters. The calculated adsorption energy E a(n = 3) of Zn3Si1 structure is −1.416 eV/adatom, while that of Zn1Si1 E a(n = 1) is −0.124 eV/adatom. Therefore, the Zn3Si1 nanocluster is much more stable than Zn1Si1. From the perspective of Zn–Si bonding, the atomic structure of Zn3Si1 cluster exhibits a characteristic of the valence. It is well known that the tetravalent Si adatoms and the rest atoms are partially filled, resulting in the dangling bonds on the Si(111)-(7×7) surface. As a transition group element, Zn likely has a variable valence state when reacting with nonmetallic atoms. Hence, in Zn3Si1 structure, one displaced Si edge adatom tends to bond with three Zn atoms and one Si atom below it. Consequently, the Zn3Si1 structure is relatively the stable configuration of Zn-induced nanoclusters on Si(111)-(7×7) surface with one displaced Si edge adatom in the FHUC.

Accordingly, type II nanocluster is related to two displaced Si edge adatoms in the FHUC. Therefore, four possible cluster structures of Zn2Si2, Zn3Si2, Zn4Si2, and Zn5Si2 (as shown in Fig. 3c) are constructed to be considered as this type of nanocluster in the FHUC. Zn5Si2 nanocluster has the lowest adsorption energy E a(n = 5) of −1.412 eV/adatom among the four possible clusters, as shown in Fig. 4. The lowest adsorption energy indicates that the Zn5Si2 nanocluster is the most stable atomic structure among the three proposed configurations. Therefore, Zn5Si2 structure is relatively the stable configuration of Zn-induced nanoclusters on Si(111)-(7×7) surface with two displaced Si edge adatoms in the FHUC. In addition, the adsorption energy of Zn5Si2 is a little larger than that of Zn3Si1 structure. From the point of saturating the surface dangling bonds of Si edge adatoms, there are three Zn atoms bonding to one displaced Si edge adatom in a Zn3Si1 cluster. In a Zn5Si2 cluster, while there also are three Zn atoms binding to one displaced Si edge adatom, one of the five Zn atoms bind simultaneously to two displaced Si edge adatoms. Thus, with respect to the Zn3Si1 cluster, the five Zn atoms in Zn5Si2 cluster are insufficient for saturating two displaced Si edge adatoms, resulting in a little higher adsorption energy.

Based on above theoretical results, Zn3Si1 cluster is the most stable structure in the case of one displaced Si edge adatom, while Zn5Si2 cluster is the most stable structure in the case of two displaced Si edge adatoms. Furthermore, the adsorption energies of Zn6Si3 and Zn7Si3 clusters with three displaced Si edge adatoms are, respectively, calculated to be −1.372 and −1.430 eV/adatom, as shown in Fig. 4. Among the four cluster models just mentioned above, the adsorption energy of Zn7Si3 is the lowest, and therefore Zn7Si3 cluster is the most stable configuration adsorbed on Si(111)-(7×7) surface. Among the other three clusters, the adsorption energy of Zn3Si1 is 0.004 eV/adatom lower than that of Zn5Si2, while the adsorption energy of Zn5Si2 is curiously 0.04 eV/adatom lower than that of Zn6Si3. From the point of saturating the surface dangling bonds of Si edge adatoms, there are three Zn atoms bonding simultaneously to two displaced Si edge adatoms, therefore the highest adsorption energy of Zn6Si3 cluster can also be attributed to the insufficient saturation of the three displaced Si edge adatoms. As a result, Zn3Si1 and Zn5Si2 clusters are, respectively, the most stable structures in the case of one and two displaced Si edge adatoms, while Zn7Si3 cluster is the most stable structure in the case of three displaced Si edge adatoms. Moreover, the adsorption energy alignment in Fig. 4 shows that there are three minimal adsorption energies as the adsorbed Zn atoms increasing from one to seven. Thus, from the view point of the preferred energy, the most stable Zn7Si3 nanoclusters should grow up on the base of Zn3Si1 and Zn5Si2 clusters as the increasing of the adsorbed Zn atoms in the triangular half 7×7 unit cell. Furthermore, we compare the experimental distributions of these three kinds of Zn-induced nanoclusters at different coverage of Zn atoms. It is found that all the Zn3Si1, Zn5Si2, and Zn7Si3 clusters could be observed with the tiny number of Zn atoms adsorbed, and the Zn3Si1 and Zn5Si2 clusters gradually disappear when increasing the Zn deposition. As the content of Zn atoms further increases to 0.03 mL, almost no Zn3Si1 and Zn5Si2 clusters are observed, while the surface is dominated by Zn7Si3 clusters, as shown in our previous work [14]. Therefore, we could deduce that, as the increasing of Zn deposition, the additional Zn atoms could gradually merge into the initially formed Zn3Si1 clusters, leading to the formation of Zn5Si2 and finally the Zn7Si3 clusters. In other words, the most stable Zn7Si3 nanocluster adsorbed on the Si(111)-(7×7) surface should be evolved continuously from Zn3Si1 and Zn5Si2 clusters.

It is known that STM actually probes the charge distribution near the Fermi level within an energy range determined by the sample bias. Therefore, Tersoff and Hamann [35] proposed that the STM images taken at different bias voltages could be simulated by integrating the partial charge densities in the energy window from the Fermi level to the sample bias. Thus, to further identify the configurations of the proposed Zn-induced nanoclusters and understand the evolution process at the different bias voltages, the topographic empty- and filled-state STM images of the clean, Zn3Si1, Zn5Si2, and Zn7Si3 nanoclusters-adsorbed Si(111)-(7×7) unit cells were further simulated, as shown in Fig. 5. For Zn7Si3 nanocluster-adsorbed Si surface, the filled-state images at the bias voltages of −1.5 and −1.0 V, only three displaced edge Si adatoms are visible, thus, the cluster appears as a big bright triangle. And at the bias voltages of ±0.5 V, all the Zn and Si atoms in the cluster are invisible. As the voltage increases to +1.0 V, the calculated empty-state images show typical tripod shape consisting of the center Zn atom and the three edge Zn atoms. Furthermore, in the neighboring uncovered UHUCs, the closest Si edge adatoms are almost darkened for all the filled-state STM images, comparing with the simulated STM image of clean Si(111)-(7×7). All above observed patterns based on the Zn7Si3 model are of remarkable quality, in agreement with the experimental images as shown in Fig. 2.

The simulated empty (a) and filled-state (b) STM images of the clean, Zn3Si1, Zn5Si2, and Zn7Si3 nanoclusters-adsorbed Si(111)-(7×7) unit cells. The same bias voltages as in experiments (+1.5, +1.0, +0.5, −0.5, −1.0, and −1.5 V) are used in the calculations. The colors indicate the height of the images, blue being low and yellow being high. (Color figure online)

For the Zn3Si1 nanocluster, the empty-state image at the bias voltage of +1.5 V shows that the displaced Si adatom and two edge Zn atoms are visible, whereas the corner Zn atom is invisible, combined with two unaltered Si edge adatoms. The cluster appears as a “U” shape pattern in the center of FHUC. At the bias voltage of +1.0 V, only the displaced Si edge adatom is visible and the cluster changes to one dim dot. As the voltage further reduces to +0.5 V, all the Zn and displaced Si atoms made up of Zn3Si1 cluster are invisible. At the bias voltages of −1.5 and −1.0 V, only the displaced Si edge adatom is visible, combined with the other two unaltered Si edge adatoms, forming a “V” shape pattern in the center of FHUC. As the voltage further reduces to −0.5 V, the Zn3Si1 cluster is almost invisible, leaving two intact Si edge adatoms in the center of FHUC. Furthermore, the closet Si edge adatom in the neighboring UHUC, which just on the opposite of the displaced Si edge adatom, exhibits dark images at the negative voltages. The suppression of the closest edge Si adatoms in the nearest neighboring uncovered UHUCs in filled-state STM images is mainly attributed to the displaced Si edge adatom, which is indicative of the charge transfer from the closest edge Si adatoms to the Zn nanocluster to further stabilize the cluster. Obviously, the simulated STM images of Zn3Si1 model in Fig. 5 are of remarkable quality, in agreement with the experimental results in Fig. 2a, which further demonstrates the rationality configuration for Zn3Si1 cluster.

For the Zn5Si2 nanocluster, the acquired STM image at the bias voltage of +1.5 V shows that two displaced Si edge adatoms are visible, combined with one unaltered Si edge adatom. The cluster displays as an isosceles triangular shape pattern forming in the center of FHUC. As the voltage reduces from +1.5 to +0.5 V, the size and brightness of the cluster decrease gradually and finally almost invisible, leaving one intact Si edge adatom in the center of FHUC. On the other hand, at the bias voltages of −1.5 and −1.0 V, only two displaced edge adatoms are acquired, combined with one other unaltered Si edge adatom, exhibiting as an equilateral triangle in the center of FHUC. As the voltage further reduces to −0.5 V, the cluster is almost invisible, leaving one intact Si edge adatom. Furthermore, at the negative voltages, two closet Si edge adatoms in the neighboring UHUC, which just on the opposite of the two displaced Si edge adatoms, exhibit two dark dots with the comparison of clean Si(111)-(7×7) surface. The suppression of the closest edge Si adatoms in the nearest neighboring uncovered UHUCs in filled-state STM images is also related to the displaced Si edge adatoms. Thus, the simulated STM images of Zn5Si2 model in Fig. 5 are of remarkable quality, in agreement with the experimental results in Fig. 2b, which further demonstrates the rationality configuration for the Zn5Si2 cluster.

According to the above systematical analysis of the bias-dependent STM images, combined with the total energy calculation and accurate STM topographic simulation, the observed type I, II, and III nanoclusters, as denoted by the green, pink, and blue triangles in Fig. 1b and c, can reasonably be assigned as the Zn3Si1, Zn5Si2, and Zn7Si3 clusters, respectively. Moreover, from the view point of the preferred energy and the experimental distributions of these three Zn-induced nanocluster in different Zn coverage, we could deduce that the most stable Zn7Si3 nanocluster adsorbed on the Si(111)-(7×7) surface should be formed by the evolution of Zn3Si1 and Zn5Si2 clusters.

4 Conclusions

In summary, a tiny number of Zn atoms were deposited on Si(111)-(7×7) surface to study the evolution process of Zn-induced nanoclusters. The formation of type I, II, and III nanoclusters causes, respectively, one, two, and three darkened closest Si edge adatoms in the neighboring UHUCs. The systematical bias-dependent structural analysis suggests that type III nanocluster is the Zn7Si3 cluster and the formation of type I and II nanoclusters is related to one and two displaced Si edge adatoms in the FHUC, respectively. First-principles adsorption energy calculations show that Zn3Si1 and Zn5Si2 clusters are, respectively, the most stable structures in the case of one and two displaced Si edge adatoms, while Zn7Si3 cluster is the most stable structure in the case of three displaced Si edge adatoms. Using the proposed structural models of Zn3Si1, Zn5Si2, and Zn7Si3, the simulated bias-dependent STM images are all well consistent with the experimental observations. Therefore, the observed type I, II, and III nanoclusters can reasonably be assigned as the Zn3Si1, Zn5Si2, and Zn7Si3 clusters, respectively. The most stable Zn7Si3 nanoclusters adsorbed on the Si(111)-(7×7) surface should grow up on the base of Zn3Si1 and Zn5Si2 clusters. A novel evolution process from Zn3Si1 to Zn5Si2, and finally to Zn7Si3 nanocluster is unveiled.

References

W.J. Cho, Y. Kim, J.K. Kim, Ultrahigh-density array of silver nanoclusters for SERS substrate with high sensitivity and excellent reproducibility. ACS Nano 6(1), 249–255 (2012). doi:10.1021/nn2035236

S.F. Li, X.J. Zhao, X.S. Xu, Y.F. Gao, Z.Y. Zhang, Stacking principle and magic sizes of transition metal nanoclusters based on generalized Wulff construction. Phys. Rev. Lett. 111(11), 115501 (2013). doi:10.1103/PhysRevLett.111.115501

M.C. Patterson, B.F. Habenicht, R.L. Kurtz, L. Liu, Y. Xu, P.T. Sprunger, Formation and stability of dense arrays of Au nanoclusters on hexagonal boron nitride/Rh(111). Phys. Rev. B 89(20), 205423 (2014). doi:10.1103/PhysRevB.89.205423

J. Pal, M. Smerieri, E. Celasco, L. Savio, L. Vattuone, M. Rocca, Morphology of monolayer MgO films on Ag(100): switching from corrugated islands to extended flat terraces. Phys. Rev. Lett. 112(12), 126102 (2014). doi:10.1103/PhysRevLett.112.126102

A.O. Orlov, I. Amlani, G.H. Bernstein, C.S. Lent, G.L. Snider, Realization of a functional cell for quantum-dot cellular automata. Science 277(5328), 928–930 (1997). doi:10.1126/science.277.5328.928

R.P. Andres, T. Bein, M. Dorogi, S. Feng, J.I. Henderson, C.P. Kubiak, W. Mahoney, R.G. Osifchin, R. Reifenberger, “Coulomb staircase” at room temperature in a self-assembled molecular nanostructure. Science 272(5266), 1323–1325 (1996). doi:10.1126/science.272.5266.1323

T.W. Kim, D.C. Choo, J.H. Shim, S.O. Kang, Single-electron transistors operating at room temperature, fabricated utilizing nanocrystals created by focused-ion beam. Appl. Phys. Lett. 80(12), 2168–2170 (2002). doi:10.1063/1.1458685

S.H. Sun, C.B. Murray, D. Weller, L. Folks, A. Moser, Monodisperse FePt nanoparticles and ferromagnetic FePt nanocrystal superlattices. Science 287(5460), 1989–1992 (2000). doi:10.1126/science.287.5460.1989

K. Koike, H. Matsuyama, Y. Hirayama, K. Tanahashi, T. Kanemura, O. Kitakami, Y. Shimada, Magnetic block array for patterned magnetic media. Appl. Phys. Lett. 78(6), 784–786 (2001). doi:10.1063/1.1345804

T. Koide, H. Miyauchi, J. Okamoto, T. Shidara, A. Fujimori, H. Fukutani, K. Amemiya, H. Rakeshita, S. Yuasa, T. Katayama, Y. Suzuki, Direct determination of interfacial magnetic moments with a magnetic phase transition in Co nanoclusters on Au(111). Phys. Rev. Lett. 87(25), 257201 (2001). doi:10.1103/PhysRevLett.87.257201

K.H. Wu, Y. Fujikawa, T. Nagao, Y. Hasegawa, K.S. Nakayama, Q.K. Xue, E.G. Wang, T. Briere, V. Kumar, Y. Kawazoe, S.B. Zhang, T. Sakurai, Na adsorption on the Si(111)-(7×7) surface: from two-dimensional gas to nanocluster array. Phys. Rev. Lett. 91(12), 126101 (2003). doi:10.1103/PhysRevLett.91.126101

J.R. Ahn, G.J. Yoo, J.T. Seo, J.H. Byun, H.W. Yeom, Electronic states of two-dimensional adatom gas and nanocluster array: Na on Si(111)7×7. Phys. Rev. B 72(11), 113309 (2005). doi:10.1103/PhysRevB.72.113309

Y.P. Wu, Y.H. Zhou, C.J. Zhou, H.H. Zhan, J.Y. Kang, Atomic structure and formation mechanism of identically sized Au clusters grown on Si(111)-7×7 surface. J. Chem. Phys. 133(12), 124706 (2010). doi:10.1063/1.3481483

C.J. Zhou, Q.K. Xue, J.F. Jia, H.H. Zhan, J.Y. Kang, Structural and electronic properties of identical-sized Zn nanoclusters grown on Si(111)-(7×7) surfaces. J. Chem. Phys. 130(2), 024701 (2009). doi:10.1063/1.3046682

J.F. Jia, J.Z. Wang, X. Liu, Q.K. Xue, Z.Q. Li, Y. Kawazoe, S.B. Zhang, Artificial nanocluster crystal: lattice of indentical Al clusters. Appl. Phys. Lett. 80(17), 3186–3188 (2002). doi:10.1063/1.1474620

R.W. Li, J.H.G. Owen, S. Kusano, K. Miki, Dynamic behavior and phase transition of magic Al clusters on Si(111)-7×7 surfaces. Appl. Phys. Lett. 89(7), 073116 (2006). doi:10.1063/1.2337522

V.G. Kotlyar, A.V. Zotov, A.A. Saranin, T.V. Kasyanova, M.A. Cherevik, I.V. Pisarenko, V.G. Lifshits, Formation of the ordered arrays of Al magic clusters on Si(111)7×7. Phys. Rev. B 66(16), 165401 (2002). doi:10.1103/PhysRevB.66.165401

M.Y. Lai, Y.L. Wang, Self-organized two-dimensional lattice of magic clusters. Phys. Rev. B 64(24), 241404 (2001). doi:10.1103/PhysRevB.64.241404

L. Vitali, M.G. Ramsey, F.P. Netzer, Nanodot formation on the Si(111)-(7×7) surface by adatom trapping. Phys. Rev. Lett. 83(2), 316–319 (1999). doi:10.1103/PhysRevLett.83.316

J.L. Li, J.F. Jia, X.J. Liang, X. Liu, J.Z. Wang, Q.K. Xue, Z.Q. Li, J.S. Tse, Z.Y. Zhang, S.B. Zhang, Spontaneous assembly of perfectly ordered identical-size nanocluster arrays. Phys. Rev. Lett. 88(6), 066101 (2002). doi:10.1103/PhysRevLett.88.066101

S.C. Li, J.F. Jia, R.F. Dou, Q.K. Xue, I.G. Batyrev, S.B. Zhang, Borderline magic clustering: the fabrication of tetravalent Pb cluster arrays on Si(111)-(7×7) surfaces. Phys. Rev. Lett. 93(11), 116103 (2004). doi:10.1103/PhysRevLett.93.116103

M.A.K. Zilani, H. Xu, T. Liu, Y.Y. Sun, Y.P. Feng, X.S. Wang, A.T.S. Wee, Electronic structure of Co-induced magic clusters grown on Si(111)-(7×7): scanning tunneling microscopy and spectroscopy and real-space multiple-scattering calculations. Phys. Rev. B 73(19), 195415 (2006). doi:10.1103/PhysRevB.73.195415

M.A.K. Zilani, Y.Y. Sun, H. Xu, L. Liu, Y.P. Feng, X.S. Wang, A.T.S. Wee, Reactive Co magic cluster formation on Si(111)-(7×7). Phys. Rev. B 72(19), 193402 (2005). doi:10.1103/PhysRevB.72.193402

J. Alvarez, A.L.V. Deparga, J.J. Hinarejos, J. Delafiguera, E.G. Michel, C. Ocal, R. Miranda, Initial stages of the growth of Fe on Si(111)7×7. Phys. Rev. B 47(23), 16048–16051 (1993). doi:10.1103/PhysRevB.47.16048

M.K.J. Johansson, S.M. Gray, L.S.O. Johansson, Studies of low coverage adsorption of Li on Si(001): observation of negative differential resistance and electron trapping. J. Vac. Sci. Technol., B 14(2), 1015–1018 (1996). doi:10.1116/1.588445

N.P. Guisinger, M.E. Greene, R. Basu, A.S. Baluch, M.C. Hersam, Room temperature negative differential resistance through individual organic molecules on silicon surfaces. Nano Lett. 4(1), 55–59 (2004). doi:10.1021/nl0348589

J.P. Perdew, J.A. Chevary, S.H. Vosko, K.A. Jackson, M.R. Pederson, D.J. Singh, C. Fiolhais, Atoms, molecules, solids, and surfaces: applications of the generalized gradient approximation for exchange and correlation. Phys. Rev. B 46(11), 6671–6687 (1992). doi:10.1103/PhysRevB.46.6671

Y. Wang, J.P. Perdew, Correlation hole of the spin-polarized electron gas, with exact small-wave-vector and high-density scaling. Phys. Rev. B 44(24), 13298–13307 (1991). doi:10.1103/PhysRevB.44.13298

G. Kresse, D. Joubert, From ultrasoft pseudopotentials to the projector augmented-wave method. Phys. Rev. B 59(3), 1758–1775 (1999). doi:10.1103/PhysRevB.59.1758

G. Kresse, J. Furthmüller, Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys. Rev. B 54(16), 11169–11186 (1996). doi:10.1103/PhysRevB.54.11169

G. Kresse, J. Furthmüller, Efficiency of ab initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput. Mater. Sci. 6(1), 15–50 (1996). doi:10.1016/0927-0256(96)00008-0

M.C. Payne, M.P. Teter, D.C. Allan, T.A. Arias, J.D. Joannopoulos, Iterative minimization techniques for ab initio total-energy calculations: molecular dynamics and conjugate gradients. Rev. Mod. Phys. 64(4), 1045–1097 (1992). doi:10.1103/RevModPhys.64.1045

K. Takayanagi, Y. Tanishiro, M. Takahashi, S. Takahashi, Structural analysis of Si(111)-7×7 by UHV-transmission electron diffraction and microscopy. J. Vac. Sci. Technol., A 3(3), 1502–1506 (1985). doi:10.1116/1.573160

G. Lee, C.G. Hwang, N.D. Kim, J. Chung, J.S. Kim, S. Lee, Ab initio study of thallium nanoclusters on Si(111)-7×7. Phys. Rev. B 76(24), 245409 (2007). doi:10.1103/PhysRevB.76.245409

J. Tersoff, D.R. Hamann, Theory of the scanning tunneling microscope. Phys. Rev. B 31(2), 805–813 (1985). doi:10.1103/PhysRevB.31.805

Acknowledgments

The authors gratefully acknowledge the National Natural Science Foundation of China (Grant Nos.: 91321102, 11304257, 61227009, 11104229), the financial support from the Natural Science Foundation of Fujian Province (Grant Nos.: 2011J05006, 2009J05149, 2014J01026), the financial support from Department of Education of Fujian Province (Grant No.: JA09146), Huang Hui Zhen Foundation of Jimei University (Grant No.: ZC2010014), and the Scientific Research Foundation of Jimei University (Grant Nos.: ZQ2011008, ZQ2009004).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Zhou, C., Wu, Y., Chen, X. et al. Novel Evolution Process of Zn-Induced Nanoclusters on Si(111)-(7×7) Surface. Nano-Micro Lett. 7, 194–202 (2015). https://doi.org/10.1007/s40820-015-0036-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40820-015-0036-6