Abstract

An active distribution system power-supply planning model considering cooling, heating and power load balance is proposed in this paper. A regional energy service company is assumed to be in charge of the investment and operation for the system in the model. The expansion of substations, building up distributed combined cooling, heating and power (CCHP), gas heating boiler (GHB) and air conditioner (AC) are included as investment planning options. In terms of operation, the load scenarios are divided into heating, cooling and transition periods. Also, the extreme load scene is included to assure the power supply reliability of the system. Numerical results demonstrate the effectiveness of the proposed model and illustrate the economic benefits of applying distributed CCHP in regional power supply on investment and operation.

Similar content being viewed by others

1 Introduction

Active distribution system (ADS) [1, 2] is a distribution system that can control and manage distributed energy resources (DER) within the network. DER includes distributed generation (DG), energy storage system, controllable load [2], where DG consists of clean energy like distributed photovoltaic, wind generation and gas-turbine combined cooling, heating and power (CCHP).

Compared with traditional distribution system planning [3–7], ADS planning must take effects of DER into consideration, including the variation of power flow [8], node voltage [9, 10], even power reliability [11] and steady-state security [12] of the distribution network. The research on ADS planning integrated with the planning of DG has drew lots of researchers’ attention since years ago. Many effective methods have been applied for ADS expansion planning and reconfiguration, sitting and sizing of DG, such as genetic algorithm [13] and simulated annealing algorithm [14], mixed integer programming model [15], bi-level programming model [16].

In the aspect of power-supply planning of ADS, it is obvious that building up CCHP in urban area could be beneficial in improving energy efficiency and economy of operation, reducing CO2 emission [17]. With the growth of CCHP in ADS, it’s necessary to consider the impact on their capability on supplying cooling and heating load. However, related research was on the sizing of CCHP system itself. A comprehensive review was given in [18] on models considering the optimization and planning of CCHP in a short-term (a given time period) or long-term (over the plant useful life) level, most of which aimed at optimizing the energy cost or CO2 emissions of CCHP itself. For example, [19] presented an approach to CCHP planning based on evaluating how different energy vectors can be transformed into equivalent electricity and heat loads. [20, 21] studied the impacts brought by the uncertainties of energy loads and prices’ evolution on the cogeneration system planning which spans a multi-year time interval.

There were also researches on the operation optimization [22–24] and planning [25–28] of microgrid and distribution system containing CCHP. The multiple energy system expansion planning approach including “Energy Hub”, which consists of combined heat and power, natural gas furnaces and other infrastructures has been proposed and proved to be effective in [26]. In [27], a model was proposed to minimize the annual cost of distribution power grid company. The distributed wind turbine, photovoltaic and CCHP were considered as environmental-friendly planning options to balance the increasing load. Similarly, a multi-objective planning model was proposed with variable weight coefficient to solve the optimal sizing and siting problem of DG in distribution system in [28]. However, the expansion planning cost of distribution system was not considered in previous research except in [26]. Besides, the cost of equipment supplying cooling load, e.g. air conditioner (AC), was not included, as well as the cooling load balance condition.

Therefore, a power-supply planning model considering cooling, heating and power load balance implemented for ADS is proposed in this paper. The main contributions are as follows.

-

1)

Offering an approach to evaluate the probable benefit of a company which is in charge of the ADS regional energy service considering its investment and operation cost. In terms of ADS planning, expansion of substations, CCHP, gas heating boiler (GHB) and AC are all considered as investment options.

-

2)

In terms of ADS operation, the scenario analysis is formulated with the division of heating, cooling and transition period in time interval. The extreme load scenario is also included to ensure system energy-supply reliability. Thus the operation cost is calculated more accurately.

The remainder of this paper is organized as follows: Section 2 outlines the framework of the model. Detailed model formulation is in Section 3, where the objective function and constraints are described. Numerical cases are discussed in Section 4 to illustrate and prove the effectiveness of the model. Further discussion and conclusions are in Section 5.

2 Proposed planning approach and scheme

The proposed approach of comprehensive power-supply planning for ADS considering cooling, heating and power load balance is illustrated as follows.

-

Step 1: Get the urban planning data of the region.

-

Step 2: Predict the cooling, heating and power load based on the plan of land use and construction area.

-

Step 3: Divide the whole area into several blocks. Plan energy-supply equipment, including the sizing of CCHP, transformer in substations, AC, GHB for each block based on the proposed model.

-

Step 4: Location selection for the construction of big equipment.

-

Step 5: Plan the network of distribution feeders and hot, cold water pipeline based on the selected location for each equipment.

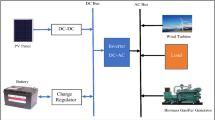

Step 1 and 2 are preliminary work. It should be noted that urban land planning and corresponding heating, cooling, power load prediction in Step 1 and 2 are essential for common urban planning, thus is not discussed in this paper. Besides, the power load prediction data does not include the load of AC and electric heating boiler here. Moreover, Step 4, 5 must be implemented by taking actual construction condition survey into consideration, which will not be discussed in this paper. Proposed comprehensive power-supply planning scheme of ADS considering cooling, heating and power load balance in Step 3 is shown in Fig. 1.

Overall, loads need to be balanced are categorized as power, cooling and heating load, respectively. The load scenes include transition period, cooling period and heating period. The cooling period (heating period), which is usually summer time (winter time) of a year, refers to the period in each year when there is significant cooling load (heating load) to be supplied. The transition period refers to other time of a year when there is only electric power load needs to be supplied.

It’s assumed that power, cooling and heating load of this area are balanced by trading electric power from substations or operating CCHP and GHB, and the fuel of which is natural gas. The power-supply options are as follows.

-

1)

Constructing new substations or expanding old substations to satisfy part of the power load

-

2)

Investing on AC, the power of which is supplied by the substations, to satisfy part of the cooling load.

-

3)

Building up CCHP, which is able to generate power, supply cooling and heating load at the same time.

-

4)

Building up GHB to supply part of the heating load.

Therefore, the variables in the model are categorized as follows.

-

1)

Investment decision variables, most of which are binary variables, including decisions on substation expansion \(x^{\text{SUB}},\) building up CCHP \(x_{d,D}^{\text{CCHP}},\) GHB \(x_{d,D}^{\text{GHB}},\) where the subscript d means in block d, and D stands for the sizing selection of equipment. The investment on AC is continuous variable, because obviously there is no sizing selection problem involved.

-

2)

Operation strategy variables, which are all continuous variables, including the power trading from substations \(g_{s}^{\text{SUB}}\) in load scene s, the power generated by CCHP \(g_{s}^{\text{CCHP}},\) cooling load supplied by AC \(q_{c}^{\text{AC}},\) CCHP \(q_{c}^{\text{CCHP}}\) in cooling period, heating load supplied by GHB \(q_{h}^{\text{GHB}},\) CCHP \(q_{h}^{\text{CCHP}}\) in heating period.

The mathematical model is summarized as in Fig. 2.

It’s noteworthy that the economy of operation is evaluated by typical load scene in three periods: transition period (s = t), cooling period (s = c), and heating period (s = h). Meanwhile, an extreme load scene (s = e) is from cooling period, which is usually summer peak hours according to common sense, to ensure the power-supply reliability in extreme conditions.

3 Problem formulation

3.1 Objective

The objective of the proposed planning model is the minimum of investment and operation cost on supplying the power, cooling and heating load in this area. Thus, the objective function can be categorized as:

-

1)

Investment cost \(C_{\text{INV}}\)

The investment cost \(C_{\text{INV}}\) includes the cost of substation expansion, building up CCHP, building up GHB, and investment on AC, which is shown as

$$\begin{aligned} C_{\text{INV}} = &\sum\limits_{{J \in \varphi_{{}}^{\text{SUB}} }} {M_{J}^{\text{SUB}} x_{J}^{\text{SUB}} } + \sum\limits_{d \in \Omega } {\sum\limits_{{D \in \varphi_{d}^{\text{CCHP}} }} {M_{d,D}^{\text{CCHP}} x_{d,D}^{\text{CCHP}} } } + \hfill \\ &\;\; \sum\limits_{d \in \Omega } {\sum\limits_{{D \in \varphi_{d}^{\text{GHB}} }} {M_{d,D}^{\text{GHB}} x_{d,D}^{\text{GHB}} } } + M^{\text{AC}} \sum\limits_{d \in \Omega } {x_{d}^{\text{AC}} } \hfill \\ \end{aligned}$$(1)where \(M_{J}^{\text{SUB}}\) is the substation expansion cost scheme J; \(x_{J}^{\text{SUB}}\) the corresponding binary decision variable, which means that corresponding construction scheme is implemented if \(x_{J}^{\text{SUB}} = 1\); \(\Omega\) the set of blocks; and \(\varphi_{d}^{\text{CCHP}}\), \(\varphi_{d}^{\text{GHB}}\) the sets of sizing options for CCHP and GHB, respectively. Thus \(M_{d,D}^{\text{CCHP}}\)or \(M_{d,D}^{\text{GHB}}\) represents cost of building up CCHP or GHB in block d for sizing option D. \(x_{d,D}^{\text{CCHP}}\), \(x_{d,D}^{\text{GL}}\) are related binary variables. The unit of AC is much smaller than that of other equipment, thus its investment cost is set to be continuous variable \(x_{d}^{\text{AC}}\), then multiplied by the per-unit cost \(M^{\text{AC}}.\)

-

2)

Operation cost \(C_{\text{OPE}}\)

The operation cost \(C_{\text{OPE}}\) ignored the maintenance and depreciation cost of facilities, mainly focused on the fuel cost of CCHP, GHB and the cost of purchasing electric power from the utility grid:

$$C_{\text{OPE}} = \sum\limits_{y} {\frac{y}{{(1 + i)^{y} }}} \sum\limits_{d \in \Omega } {\sum\limits_{s = c,h,t} {\varepsilon_{s} (P^{\text{GAS}} V_{s,d}^{\text{fuel}} } + P^{\text{SUB}} g_{s,d}^{\text{SUB}} )}$$(2)where y is the planning years, \(\sum\limits_{y} {\frac{y}{{(1 + i)^{y} }}}\) calculates the total present value coefficient of the operation cost for each year, with the discount rate i; and \(\varepsilon_{s}\) is the proportion of load scene s in the whole planning period. Take a municipality in China as an example, its heating period is from 15 November to 15 March each year, hence \(\varepsilon_{s} = 4/ 1 2= 0. 3 3 3\); the cooling period is assumed from 15 June to 15 September, hence \(\varepsilon_{s} = 3/ 1 2 = 0. 2 5.\) The rest of load scene are transition period, \(\varepsilon_{s} = 5/ 1 2= 0. 4 1 7.\) For load scene s of block d, \(V_{d,s}^{\text{fuel}}\) is the gas fuel consumption per-unit time, consisting of the gas consumed by the GHB and CCHP, which could be calculated as:

$$V_{s,d}^{\text{fuel}} = \sum\limits_{{D \in \varphi_{d}^{\text{CCHP}} }} {V_{s,d,D}^{\text{CCHP}} } + \sum\limits_{{D \in \varphi_{d}^{\text{GHB}} }} {V_{s,d,D}^{\text{GHB}} }$$(3)where \(g_{s,d}^{\text{SUB}}\) is the power trading from utility grid through substation per unit time, and \(P^{\text{GAS}}\), \(P^{\text{SUB}}\) are the prices of natural gas and utility grid electric power, respectively, which already consider the coefficient converter the per-unit time to the total time of the planning period.

-

3)

Value of lost load \(C_{\text{VOLL}}\)

$$C_{\text{VOLL}} = P^{\text{VOLL}} \sum\limits_{d \in \Omega } {\sum\limits_{s = c,h,t,e} {r_{s,d} } }$$(4)where \(P_{{}}^{\text{VOLL}}\) is the price of lost load’s value, and \(r_{s,d}\) is the load not served in load scene s in block d. It should be noted that \(P^{\text{VOLL}}\) should be set to a relatively high constant to avoid load-shedding in any load scene.

In summary, the objective function is:

3.2 Constraints

3.2.1 Power, cooling, heating load balance

There should be load balance constraints in every block d. However, there would be some difference between different type of load and load scene s.

-

1)

Power load balance \((s = c,h,t,e)\)

$$r_{s,d} + g_{s,d}^{\text{SUB}} = l_{s,d} + l_{s,d}^{\text{AC}} - g_{s,d}^{\text{CCHP}}$$(6)This constraint should be set up for every load scene s, where \(l_{s,d}\) is the power load without load of AC \(l_{s,d}^{\text{AC}}\). The ability of CCHP supply power between different blocks is ignored in this paper.

-

2)

Cooling load balance \((s = c,e)\)

Cooling load is supplied by AC and the lithium bromide refrigeration unit of CCHP. Thus we can get:

$$q_{s,d}^{\text{Load}} = q_{s,d}^{\text{CCHP}} + q_{s,d}^{\text{AC}}$$(7)This constraint should be set up in load scene \(s = c,e\), where \(q_{s,d}^{\text{Load}}\) is the cooling load demand; \(q_{s,d}^{\text{CCHP}}\) is the load supplied by the lithium bromide refrigeration unit of CCHP, and \(q_{s,d}^{\text{AC}}\) is the load supplied by AC.

-

3)

Heating load balance \((s = h)\)

Heating load is supplied by CCHP and GHB.

$$q_{s,d}^{\text{Load}} = q_{s,d}^{\text{CCHP}} + q_{s,d}^{\text{GHB}}$$(8)This constraint should only be set up in load scene \(s = h\), where \(q_{h,d}^{\text{Load}}\) is the heating load demand; \(q_{h,d}^{\text{CCHP}}\) the heating load supplied by CCHP, and \(q_{h,d}^{\text{GL}}\) the heating load supplied by GHB.

3.2.2 CCHP modeling and constraints

3.2.2.1 Internal-combustion engine

The main working principle of gas internal-combustion engine (ICE) CCHP is: burning fuel gas to generate power and waste heat of flue gas and cylinder water. The influence of altitude and environment temperature on CCHP’s character is not significant, which can be ignored in the planning model. Therefore, the characteristic function of ICE is linearized and summarized as follows [28, 29].

-

1)

Burning fuel gas:

$$Q_{s,d,D}^{\text{CCHP}} = V_{s,d,D}^{\text{CCHP}} \frac{{\theta^{\text{LHV}} }}{3.6}$$(9) -

2)

Power generation:

$$g_{s,d,D}^{\text{CCHP}} = \alpha_{d,D}^{\text{GE}} Q_{s,d,D}^{\text{CCHP}} + \beta_{d,D}^{\text{GE}}$$(10) -

3)

Available waste heat value of flue gas:

$$q_{s,d,D}^{\text{GAS}} = \alpha_{d,D}^{\text{GAS}} Q_{s,d,D}^{\text{CCHP}} + \beta_{d,D}^{\text{GAS}}$$(11) -

4)

Available waste heat value of cylinder water:

$$q_{s,d,D}^{\text{WA}} = \alpha_{d,D}^{\text{WA}} Q_{s,d,D}^{\text{CCHP}} + \beta_{d,D}^{\text{WA}}$$(12)The relationship between per-unit-time fuel gas inflows \(V_{s,d,D}^{\text{CCHP}}\) (m3/h) and per-unit-time fuel heat \(Q_{s,d,D}^{\text{CCHP}}\) (MJ/h) is presented in (9). \(\theta^{\text{LHV}}\) is the low heating value of fuel gas (32.967 MJ/m3 for natural gas), which is a known parameter. The relationship of fuel gas heating value and generated power, available waste heat is described in (10)∼(12). \(q_{s,d,D}^{\text{GAS}},\) \(q_{s,d,D}^{\text{WA}}\) are available heat power of flue gas and cylinder water in ICE, respectively. α, \(\beta\) are known characteristic parameters of ICE.

-

5)

Minimum, maximum power output limits

$$\sum\limits_{{D \in \varphi_{d}^{\text{CCHP}} }} {x_{d,D}^{\text{CCHP}} g_{{\hbox{min}},d,D}^{\text{CCHP}} } \le g_{d,D}^{\text{CCHP}} \le \sum\limits_{{D \in \varphi_{d}^{\text{CCHP}} }} {x_{d,D}^{\text{CCHP}} g_{{\hbox{max}},d,D}^{\text{CCHP}} }$$(13)where \(g_{\hbox{min} }^{\text{CCHP}},\; g_{\hbox{max} }^{\text{CCHP}}\) are minimum and maximum limits of CCHP’s power output \(g_{d,D}^{\text{CCHP}}.\) And (13) is related with planning decision variable \(x_{d,D}^{\text{CCHP}}.\)

-

6)

Planning option constraint

$$\sum\limits_{{D \in \varphi_{d}^{\text{CCHP}} }} {x_{d,D}^{\text{CCHP}} } \le 1$$(14)

If there’s limited space for placing power-supply devices, at most one type of CCHP will be built up in one block d in the whole planning period.

3.2.2.2 Lithium bromide absorption chiller heater

The lithium bromide absorption chiller heater (Li-Br ACH) of CCHP can use available waste heat \(q^{\text{R}}\)(kW) to produce cooling value \(q_{c}\) or heating value \(q_{h}.\) These characteristics are illustrated with cooling and heating coefficient of performance (COP), i.e. \(\eta_{{{\text{COP}},c}}^{\text{BR}}, \; \eta_{{{\text{COP}},h}}^{\text{BR}}.\)

-

Cooling:

$$q_{c} = \eta_{{{\text{COP}},c}}^{\text{BR}} q^{\text{R}}$$(15)$$q_{c,\hbox{min} } \le q_{c} \le q_{c,\hbox{max} }$$(16) -

Heating:

$$q_{h} = \eta_{{{\text{COP}},h}}^{\text{BR}} q^{\text{R}}$$(17)$$q_{h,\hbox{min} } \le q_{h} \le q_{h,\hbox{max} }$$(18)where \(q_{c},\; q_{h}\) (kW) is the cooling/heating value produced by Li-Br ACH, and \(q_{c,\hbox{max} },\; q_{c,\hbox{min} }, \; q_{h,\hbox{max} } , \; q_{h,\hbox{min} }\) are their limits. According to actual engineering experience, \(\eta_{{{\text{COP}},c}}^{\text{BR}} = 1.2,\; \eta_{{{\text{COP}},h}}^{\text{BR}} = 0.9.\) We could further obtain:

$$q^{\text{R}} \le q^{\text{GAS}} + q^{\text{WA}}$$(19)

3.2.3 Gas heating boiler

The operation efficiency of the boiler is related to the load rate. If the load rate is under 80% or above 100% of rated power of GHB, the efficiency would be significantly reduced. Without linearity loss of the planning model, the operation of GHB is limited between 80% and 100% of the rated power, the rated efficiency of which can be 0.92. Thus the constraints are generated as:

Equation (23), which is similar to (14), can guarantee that only one type of GHB will be built up in one block d in the whole planning period.

3.2.4 Air conditioner

where \(\eta_{\text{COP}}^{\text{AC}}\) is the COP of AC, which is usually set to be 4, and \(q_{s,d}^{\text{AC}},\; l_{s,d}^{\text{AC}}\) are the cooling load and power load in corresponding block d and load scene s. Eq. (25) denotes that the total AC investment should be larger than the amount which is essential to supply the cooling load in the extreme scene.

3.2.5 Substations

The key to modeling substation is that the total supply capacity should be within the range of the product of load and corresponding capacity-load ratio \(\gamma_{\hbox{min}} \sim \gamma_{\hbox{max}}\):

where (26) should be set up in extreme load scene s (\(s = e\)), in which \(g_{0}^{\text{SUB}}\) is the initial capacity of substation, \(\sum\limits_{{J \in \varphi^{\text{SUB}} }} {x_{J}^{\text{SUB}} g_{J}^{\text{SUB}} }\) is the expansion capacity decided by investment decision variable \(x_{J}^{\text{SUB}}\) and planning options \(g_{J}^{\text{SUB}}\) selected from the set \(\varphi^{\text{SUB}}\). We used \(\gamma_{\hbox{min} } = 1.8\), \(\gamma_{\hbox{max} } = 2.1\) according to Planning Guidelines of State Grid Corporation of China. Eq. (27) guarantees that only one option of expansion for substations will be implemented.

4 Case study

4.1 Case conditions

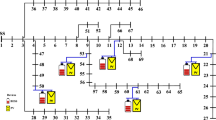

The case study was based on an actual demonstration project in a new development zone of a municipality city in China. The division of blocks and load data has been obtained as in Fig. 3 and Table 1. Note that power load in Table 1 doesn’t include the load of AC.

The power-supply planning options for these blocks are shown in Table 2. The characteristic coefficients of CCHP [29, 30] are listed in Table 3. Other parameters include 32.967 MJ/m3 heating value of natural gas, which is Ұ 3.23 m3, and the average price of utility grid power is Ұ 0.9923 kWh. The total planning time is set to be 10 years, and the discount rate on operation cost for each year, i, is set to be 5%. \(P^{\text{VOLL}}\) is set to be Ұ 10000 × 106/MW in each case.

4.2 Calculation method

The model is formulated with the YALMIP tool in MATLAB and calculated with the optimization software Gurobi Optimizer. Numerical test was carried on a laptop computer with CPU intel I5-3230M 2.6 GHZ, the total consumption time of modeling and optimization is less than 30 s. The convergence index is the relative gap between upper bound and lower bound of MIP is less than 0.001%.

4.3 Results and analyses

Two cases are compared in Table 4.

-

Case 1: No CCHP is integrated.

-

Case 2: CCHP is considered as planning options.

For the initial investment, in Case 2, there would be one 9.5 MW CCHP built up in each of the 7 blocks, which adds Ұ 718.2 × 106 in total. As a result, the expansions of substations could be reduced from 6 × 50 to 3 × 50 MVA, and Ұ 24 × 106 would be reduced. CCHP is exploited to replace part of AC when supplying cooling load, thus Ұ 52.88 × 106 cost of AC is reduced. Meanwhile, part of GHB is replaced by CCHP when supplying heating load, thus another Ұ 285.78 × 106 is reduced. However, the total investment cost of Case 2 is still Ұ 355.54 × 106, which is more than that of Case 1.

In the operation, during the whole planning period (10 years), the fuel cost of CCHP is Ұ 4355.34 × 106 in Case 2. The power generated from CCHP is used to replace part of power from utility grid, thus the cost of purchasing electric power is reduced by Ұ 6118.54 × 106. The fuel cost of GHB is also reduced by Ұ 522.36 × 106. As a result, the total operation cost of Case 2 is Ұ 2285.56 × 106, which is less than that of Case 1.

Above all, with the integration of CCHP, the total cost of power-supply on infrastructure investment and operation could be reduced by Ұ 1930.02 × 106.

5 Conclusion

A power-supply planning model for ADS considering cooling, heating and power load balance is proposed in this paper. A regional energy service company is assumed to be in charge of the investment and operation for the system in the model. On the aspect of infrastructure investment, the expansion of substations, building up CCHP, GHB and AC are included as planning options. On the aspect of operation, the load scenarios are divided into heating, cooling and transition periods, the extreme load scene is included to assure the power supply reliability of the system. Thus, the total cost of planning and operation are calculated more accurately. Here it’s assumed that ADS can contribute to the smart control of a variety of flows like electric power, cooling and heating flow, producing an optimal energy supply system.

Numerical tests based on a demonstration project in China prove the effectiveness of the proposed model and illustrate the economic benefits of applying distributed CCHP in regional power supply on investment and operation. It should be noted that whether CCHP can reduce the power-supply cost depends on complex factors such as the property of CCHP, the price of utility gird power and natural gas.

The proposed planning model, which is closely associated with latest Chinese reform policy on power systems, can measure and optimize the comprehensive energy consumption and the cost of some urban area with the assumption that a regional power-supply company is established. Moreover, the model has offered a novel idea that with the integration of balance on electric power, cooling and heating load, respectively, the traditional approaches of distribution system planning such as substation expansion planning can be significantly improved. The proposed model has ignored the difference of investment on distribution lines between power-supply schemes. A further research that is related to the concept of “Comprehensive Energy Network” promoted by some researchers should be carried out in the future, which can explicitly research on the co-optimization of electric, cooling, heating, gas network planning and operation.

References

D’Adamo C, Jupe S, Abbey C (2009) Global survey on planning and operation of active distribution networks: Update of CIGRE C6.11 working group activities. In: Proceedings of the CIRED 20th international conference and exhibition on electricity distribution (CIRED’09), Part 1, Prague, Czech, 8–11 June 2009, 4 pp

Fan MT, Zhang ZP, Su AX et al (2013) Enabling technologies for active distribution systems. P CSEE 33(22):12–18 (in Chinese)

Kong T, Cheng HZ, Li G et al (2009) Review of power distribution network planning. Power Syst Technol 33(19):92–99 (in Chinese)

Leung LC, Khator SK, Schnepp JC (1995) Planning substation capacity under the singer-contingency scenario. IEEE Trans Power Syst 10(3):1442–1447

Wall DL, Tompson GL, Northcote-Green JED (1979) Optimization model for planning radial distribution networks. IEEE Trans Power Appl Syst 98(3):1061–1068

Hindi KS, Brameller A (1977) Design of low-voltage distribution networks: a mathematical programming method. IEE Proc 124(1):54–58

Gonen T, Foote BL (1981) Distribution system planning using mixed-integer programming. IEE Proc 128(2):70–79

Yang XY, Duan JD, Yang WY et al (2009) Power flow calculation based on power losses sensitivity for distribution system with distributed generation. Power Syst Technol 33(18):139–143 (in Chinese)

Wang ZQ, Zhu SZ, Zhou SX et al (2004) Impacts of distributed generation on distribution system voltage profile. Autom Electr Power Syst 28(16):56–60 (in Chinese)

Zhao Y, Hu XH (2008) Impacts of distributed generation on distribution system voltage sags. Power Syst Technol 32(14): 5–9, 18 (in Chinese)

Esau Z, Jayaweera D (2014) Reliability assessment in active distribution networks with detailed effects of PV systems. J Mod Power Syst Clean Energy 2(1):59–68. doi:10.1007/s40565-014-0046-2

Jayaweera D, Islam S (2014) Steady-state security in distribution networks with large wind farms. J Mod Power Syst Clean Energy 2(2):134–142. doi:10.1007/s40565-014-0052-4

Zhang J, Yuan XD, Yuan YB (2014) A novel genetic algorithm based on all spanning trees of undirected graph for distribution network reconfiguration. J Mod Power Syst Clean Energy 2(2):143–149. doi:10.1007/s40565-014-0056-0

Wang CS, Chen K, Xie YH et al (2006) Siting and sizing of distributed generation in distribution network expansion planning. Autom Electr Power Syst 30(3):38–43 (in Chinese)

Haffner S, Pereira LFA, Pereira LA et al (2008) Multistage model for distribution expansion planning with distributed generation—part I: problem formulation. IEEE Trans Power Deliv 23(2):915–923

Fang C, Zhang X, Cheng HZ et al (2014) Framework planning of distribution network containing distributed generation considering active management. Power Syst Technol 38(4):823–829 (in Chinese)

Mancarella P (2012) Distributed multi-generation options to increase environmental efficiency in smart cities. In: Proceedings of the 2012 IEEE Power and Energy Society general meeting, San Diego, CA, USA, 22–26 July 2012, 8 pp

Chicco G, Mancarella P (2009) Distributed multi-generation: a comprehensive view. Renew Sustain Energy Rev 13(3):535–551

Chicco G, Mancarella P (2008) Evaluation of multi-generation alternatives: an approach based on load transformations. In: Proceedings of the 2008 IEEE Power and Energy Society general meeting: conversion and delivery of electrical energy in the 21st century, Pittsburgh, PA, USA, 20–24 July 2008, 6 pp

Carpaneto E, Chicco G, Mancarella P et al (2011) Cogeneration planning under uncertainty, part I: multiple time frame approach. Appl Energy 88(4):1059–1067

Carpaneto E, Chicco G, Mancarella P et al (2011) Cogeneration planning under uncertainty, part II: decision theory-based assessment of planning alternatives. Appl Energy 88(4):1075–1083

Wang R, Gu W, Wu Z (2011) Economic and optimal operation of a combined heat and power microgrid with renewable energy resource. Autom Electr Power Syst 35(8):22–27 (in Chinese)

Zhou RJ, Ran XH, Ma FL et al (2012) Energy-saving coordinated optimal dispatch of distributed combined cool, heat and power supply. Power Syst Technol 36(6):8–14 (in Chinese)

Wang CS, Hong BW, Guo L et al (2013) A general modeling method for optimal dispatch of combined cooling, heating and power microgrid. Proc CSEE 33(31):26–33 (in Chinese)

Yang YH, Pei W, Qi ZP (2012) Planning method of hybrid energy microgrid based on dynamic operation strategy. Autom Electr Power Syst 36(19): 30–36, 52 (in Chinese)

Zhang X, Shahidehpour M, Alabdulwahab A et al (2015) Optimal expansion planning of energy hub with multiple energy infrastructures. IEEE Trans Smart Grid 6(5):2302–2311

Fu LW, Wang SX, Zhang YW et al (2012) Optimal selection and configuration of multi-types of distributed generators in distribution network. Power Syst Technol 36(1):79–84 (in Chinese)

Zhang Q (2008) Siting and sizing of DG in distributed network planning. Master Thesis, Shandong University, Jinan, China (in Chinese)

Li JX, Zheng JH, Zhu SZ et al (2014) Economic operation research of CCHP system based on interior point method. East China Electr Power 42(2):424–430 (in Chinese)

Lu W (2007) Optimal planning of distributed CCHP system in urban energy environment. Master Thesis, Institute of Engineering Thermophysics, Chinese Academy of Sciences, Beijing, China (in Chinese)

Acknowledgement

This project is supported by National High Technology Research and Development Program of China(863 Program) (No. 2014AA051902).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

SHEN, X., HAN, Y., ZHU, S. et al. Comprehensive power-supply planning for active distribution system considering cooling, heating and power load balance. J. Mod. Power Syst. Clean Energy 3, 485–493 (2015). https://doi.org/10.1007/s40565-015-0164-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40565-015-0164-5