Abstract

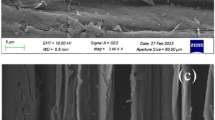

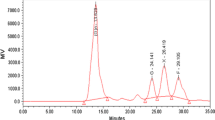

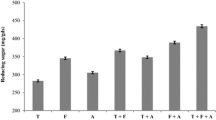

The present study compared dilute acid and alkaline pretreatment of corn husk. It showed that maximum reducing sugar production was obtained when biomass was pretreated using dilute sodium hydroxide. Further, effectiveness of dilute alkaline pretreatment was evaluated through Fourier transform infrared spectroscopy (FTIR), X-ray diffraction (XRD), scanning electron microscopy (SEM), and biochemical composition study. Batch enzymatic hydrolysis of dilute alkaline pretreated biomass was carried out using several combinations of different cellulases (Trichoderma, Fusarium, and Aspergillus). Maximum reducing sugar production was obtained when pretreated biomass was hydrolyzed using mixture of Trichoderma, Fusarium, and Aspergillus cellulases. Further, batch enzymatic hydrolysis process was optimized using CCD (central composite design)-based RSM (response surface methodology). In addition, using mixture of different cellulases, batch and fed-batch enzymatic hydrolysis processes were compared. It showed that 14.34-mg/mL higher reducing sugar production was obtained in the case of fed-batch process compared to batch process.

Similar content being viewed by others

References

Teymouri F, Laureano-Pérez L, Alizadeh H, Dale BE (2004) Ammonia fiber explosion treatment of corn stover. Appl Biochem Biotechnol 113-116:951–963

Saito K, Horikawa Y, Sugiyama J, Watanabe T, Kobayashi Y, Takabe K (2016) Effect of thermochemical pretreatment on lignin alteration and cell wall microstructural degradation in Eucalyptus globulus: comparison of acid, alkali, and water pretreatments. J Wood Sci 62:276–284

Sindhu R, Binod P, Pandey A (2016) Biological pretreatment of lignocellulosic biomass—an overview. Bioresour Technol 199:76–82

Jönsson LJ, Martin C (2016) Pretreatment of lignocellulose: formation of inhibitory by-products and strategies for minimizing their effects. Bioresour Technol 199:103–112

Chen Y, Stevens MA, Zhu Y, Holmes J, Xu H (2013a) Understanding of alkaline pretreatment parameters for corn stover enzymatic saccharification. Biotechnol Biofuel 6

Kim JS, Lee YY, Kim TH (2016) A review on alkaline pretreatment technology for bioconversion of lignocellulosic biomass. Bioresour Technol 199:42–48

Mathews AK, Parameshwaran B, Sukumaran RK, Pandey A (2016) An evaluation of dilute acid and ammonia fiber explosion pretreatment for cellulosic ethanol production. Bioresour Technol 199:13–20

Sharma S, Sharma V, Kuila A (2016) Cellulase production using natural medium and its application on enzymatic hydrolysis of thermo chemically pretreated biomass. 3 Biotech 6:1–11

Chen Y, Sharma-Shivappa RR, Keshwani D, Chen C (2007) Potential of agricultural residues and hay for bioethanol production. Appl Biochem Biotechnol 142(3):276–290

Chang VS, Holtzapple MT (2000) Fundamental factors affecting biomass enzymatic reactivity. Appl Biochem Biotechnol 84-86:5–37

McIntosh S, Vancov T (2011) Optimisation of dilute alkaline pretreatment for enzymatic saccharification of wheat straw. Biomass Bioenergy 35:3094–3103

Chen Y, Stevens MA, Zhu Y, Holmes J, Xu H (2013b) Understanding of alkaline pretreatment parameters for corn stover enzymatic saccharification. Biotechnol Biofuel 6:8

Seo J, Park TS, Kim JN, Ha JK, Seo S (2014) Production of endoglucanase, beta-glucosidase and xylanase by Bacillus licheniformis grown on minimal nutrient medium containing agriculture residues. Asian-Australas J Anim Sci 27:946–950

Elgharbawy AA, Alam MZ, Moniruzzaman M, Goto M (2016) Ionic liquid pretreatment as emerging approaches for enhanced enzymatic hydrolysis of lignocellulosic biomass. Biochem Eng J 109:252–267

Sun S, Sun S, Cao X, Sun R (2016) The role of pretreatment in improving the enzymatic hydrolysis of lignocellulosic materials. Bioresour Technol 199:49–58

Tai C, Voltan DS, Keshwani DR, Meyer GE, Kuhar PS (2016) Fuzzy logic feedback control for fed-batch enzymatic hydrolysis of lignocellulosic biomass. Bioprocess Biosyst Eng 39:937–944

Adsul M, Sharma B, Singhania RR, Saini JK, Sharma A, Mathur A, Gupta R, Tuli DK (2014) Blending of cellulolytic enzyme preparations from different fungal sources for improved cellulose hydrolysis by increasing synergism. RSC Adv 4:44726–44732

Saini JK, Singhania RR, Satlewal A, Saini R, Gupta R, Tuli DK, Mathur A, Adsul M (2016) Improvement of wheat straw hydrolysis by cellulolytic blends of two Penicillium spp. Renew Energ 98:43–50

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Yang H, Yan R, Chen H, Zheng C, Lee DH, Liang DT (2006) In-depth investigation of biomass pyrolysis based on three major components: hemicellulose, cellulose and lignin. Energ Fuel 20:388–393

Timung R, Deshavath NN, Goud VV, Dasu VV (2016) Effect of subsequent dilute acid and enzymatic hydrolysis on reducing sugar production from sugarcane bagasse and spent citronella biomass. J Energ 2016:1–12

Segal L, Creely JJ, Martin AE, Conrad CM (1959) An empirical method for estimating the degree of crystallinity of native cellulose using the x-ray diffractometer. Text Res J 29:786–794

Kuila A, Mukhopadhyay M, Tuli DK, Banerjee R (2011) Production of ethanol from lignocellulosics: an enzymatic venture. EXCLI J 10:85–96

Xiao LP, Sun ZJ, Shi ZJ, Xu F, Sun R (2011) Impact of hot compressed water pretreatment on the structural changes of woody biomass for bioethanol production. Bioresources 6:1576–1598

Padmavath V, Vasudevan P, Dhingra SC (2003) Thermal and spectroscopic studies on sorption of nickel (II) ions on protonated baker’s yeast. Chemosphere 52:1807–1817

Ávila-Lara AI, Camberos-Flores JN, Mendoza-Pérez JA, Messina-Fernández SR, Saldaña-Duran CE, Jimenez-Ruiz EI, Sánchez-Herrera LM, Pérez-Pimienta JA (2015) Optimization of alkaline and dilute acid pretreatment of agave bagasse by response surface methodology. Front Bioeng Biotechnol 3

Keshav PK, Naseeruddin S, Rao LV (2016) Improved enzymatic saccharification of steam exploded cotton stalk using alkaline extraction and fermentation of cellulosic sugars into ethanol. Bioresour Technol 214:363–370

Akanksha K, Prasad A, Sukumaran RK, Nampoothiri MK, Pandey A, Rao SS, Parameswaran B (2014) Dilute acid pretreatment and enzymatic hydrolysis of sorghum biomass for sugar recovery—a statistical approach. Ind J Exp Biol 52:1082–1089

Mahmood H, Moniruzzaman M, Yusup S, Akil HM (2016) Pretreatment of oil palm biomass with ionic liquids: a new approach for fabrication of green composite board. J Clean Prod 126:677–685

Perrone OM, Colombari FM, Rossi JS, Moretti MMS, Bordignon SE, Nunes CCC, Gomes E, Boscolo M, Da-Silva R (2016) Ozonolysis combined with ultrasound as a pretreatment of sugarcane bagasse: effect on the enzymatic saccharification and the physical and chemical characteristics of the substrate. Bioresour Technol 218:69–76

Yu Q, Zhuang X, Wang W, Qi W, Wang Q, Tan X, Kong X, Yuan Z (2016) Hemicellulose and lignin removal to improve the enzymatic digestibility and ethanol production. Biomass Bioenergy 94:105–109

Sosnowski P, Wieczorek A, Ledakowicz S (2003) Anaerobic co-digestion of sewage sludge and organic fraction of municipal solid wastes. Adv Environ Res 7:609–616

Kim Y, Kreke T, Hendrickson R, Parenti J, Ladisch MR (2013) Fractionation of cellulase and fermentation inhibitors from steam pretreated mixed hardwood. Bioresour Technol 135:30–38

Gupta R, Kumar S, Gomes J, Kuhad RC (2012) Kinetic study of batch and fed-batch enzymatic saccharification of pretreated substrate and their subsequent fermentation to ethanol. Biotechnol Biofuel 5

Acknowledgements

Authors sincerely acknowledge Prof. Aditya Shastri, Vice Chancellor, Banasthali University, for research facilities and infrastructure.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Funding

Authors declared that no funding has been received for the conduction of this study and/or preparation of this manuscript.

Rights and permissions

About this article

Cite this article

Sharma, S., Sharma, V. & Kuila, A. Thermochemical pretreatment of corn husk and enzymatic hydrolysis using mixture of different cellulases. Biomass Conv. Bioref. 8, 179–188 (2018). https://doi.org/10.1007/s13399-017-0255-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-017-0255-9