Abstract

Vapor phase hydrogenolysis of glycerol was studied over Ru catalysts supported on TiO2–ZrO2 binary oxide. Ru catalysts with various ruthenium loadings from 1.0 to 6.0 wt% were prepared by deposition–precipitation method on the TiO2–ZrO2 mixed oxide support. These catalysts were characterized by X-ray diffraction, H2 temperature-programmed reduction, NH3 temperature-programmed desorption, transmission electron microscopy, BET surface area, XPS and CO chemisorption measurements. The catalysts exhibited superior performance for the vapor phase hydrogenolysis of glycerol at moderate temperature and atmospheric pressure. The mixed oxide support plays a significant role in improving the catalytic activity for the production of propanediols. The glycerol conversion and the selectivity of various products depend on the catalyst preparation method and also on the Ru content. The influence of acidity of the catalyst and its correlation to the catalytic performance (selectivity and conversion) has been studied. The weak and strong acidic sites of the catalysts measured by NH3-TPD play a key role in selective formation of 1,2-propanediol and 1,3-propanediol. XRD, TEM, XPS and CO chemisorption studies revealed that ruthenium was well dispersed on TiO2–ZrO2 which further contributed to the superior catalytic activity for glycerol hydrogenolysis.

Similar content being viewed by others

Introduction

Glycerol acts as a top building block that probably serves as an important biorefinery feedstock [1, 2]. In addition, it is a byproduct from the production of biodiesel from vegetable oils [3]. Conversion of glycerol into valuable chemicals by a green catalytic process is a challenging area of present research. Glycerol is normally generated at the rate of 1 mol for every 3 mol of methyl esters synthesized [4]. Hydrogenolysis of glycerol is a catalytic chemical reaction that breaks a chemical bond in an organic molecule with the simultaneous addition of a hydrogen atom to the resulting molecular fragments. Through the selective hydrogenolysis of glycerol in the presence of metallic catalysts and hydrogen, 1,2-propanediol (1,2-PD), 1,3-propanediol (1,3-PD), and ethylene glycol (EG) could be obtained [5]. Therefore, catalytic hydrogenolysis of glycerol is another alternative route to increase the profitability of biodiesel production plants as the products of glycerol hydrogenolysis can easily replace the chemical compounds, which at present are industrially produced mainly by using non-renewable sources. Propanediol, i.e., 1,2-PD, a three-carbon diol with a stereogenic center at the central carbon atom, is an important medium-value commodity chemical with a 4 % annual growth in the market size. It is used for polyester resins, liquid detergents, pharmaceuticals, cosmetics, tobacco humectants, flavors and fragrances, personal care, paints, animal feed, antifreeze, etc. [6]. Traditionally, it is produced by the hydration of propylene oxide derived from propylene by either the chlorohydrin process or the hydroperoxide process. There has been a rapid expansion of the market for 1,2-PD as an antifreeze and de-icing agent because of the growing concern over the toxicity of ethylene glycol-based products to humans and animals. 1,3-PD is also another product obtained during glycerol hydrogenolysis, which is a high-value specialty chemical that is mainly used in specialty polyester fibers, films, and coatings. 1,3-PD is copolymerized with terephthalic acid to produce the polyester SORONA1 from DuPont, or CORTERRA1 from Shell, which has unique properties in terms of chemical resistance, light stability, elastic recovery, and dyeability [7, 8]. 1,3-PD is currently catalytically produced [9]. The production of these chemicals from bio-renewable glycerol can be both environmentally and economically attractive.

The glycerol hydrogenolysis reaction is suggested to proceed via dehydration of glycerol to acetol and 3-hydroxypropanal by acid catalysis and subsequent hydrogenation to the glycols by metal catalysts [6–9]. Besides the hydrogenolysis reaction, degradation reactions involving C–C breaking also occur. The products from C–C cracking are mainly ethylene glycol, methanol, ethanol and methane. Therefore, the selective conversion of glycerol to propanediols requires a suitable catalyst with acid sites/metal surface, favoring the cleavage of the glycerol C–O bonds (dehydration/hydrogenation) by hydrogen. Many supported metal catalysts have been reported for this type of reaction in liquid phase. Tomishige and co-workers [6–9] reported the use of supported group VIII metals (especially Ru/C and Rh/SiO2) catalysts in combination with a strong solid acid (Amberlyst 15, 70) at mild temperatures of 120. 8 °C and H2 pressures of 4–8 MPa. Chary et al. have demonstrated the vapor phase hydrogenolysis of glycerol reaction by using Ru-supported catalysts on supports like SBA-15 [12], MCM-41 [13], TiO2 [14]. Feng et al. [15] investigated the effect of various supports (Al2O3, TiO2, and ZrO2) on Cu/ZnO/MOx catalysts and found that the support material can influence the metal particle size and the reaction routes, with TiO2 and Al2O3 yielding the most selective catalysts for propanediols production in the vapor phase glycerol hydrogenolysis reaction. Vasiliadou et al. [16] investigated the Ru-based (γ-Al2O3, SiO2, ZrO2) catalysts were prepared by different precursors and found that among the tested catalysts, Ru catalyst prepared with the chloride precursor exhibited the highest activity towards glycerol hydrogenolysis.

In many instances, the active Ru is supported on oxides such as Al2O3, SiO2, ZrO2, and TiO2 in combination with Zn or other transition metals such as Cu and Fe. The disadvantages of these supports are their low surface areas, high surface acidities, low activities, and phase transitions at higher temperatures, which make them unsuitable for industrial applications. The use of mixed oxide support or stabilization of these supports can overcome these problems [10]. The choice of a suitable Ru precursor and optimized activation conditions also allows the controlled preparation of small ruthenium particles on mixed oxide support to yield better results on glycerol hydrogenolysis on vapor phase reactions. To the best of our knowledge, development of supported Ru on mixed oxide materials for vapor phase hydrogenolysis of glycerol in aqueous medium has not been reported elsewhere.

In the recent past, the mixed oxide supports have been synthesized by co-precipitation, and sol–gel methods and explored for a number of catalytic processes. The correlation between catalytic activity and acid–base properties of TiO2–ZrO2 [11–14] has been investigated extensively. The TiO2–ZrO2 mixed oxide seems to be an interesting support material for ruthenium and is employed for vapor phase hydrogenolysis of glycerol.

In the present investigation, we report the catalytic behavior of Ru/TiO2–ZrO2 catalysts for the vapor phase hydrogenolysis of glycerol. The catalysts were also characterized by BET surface area, XRD, TPR, NH3-TPD, TEM, XPS and CO chemisorption method. The aim of this research is to use the mixed oxide TiO2–ZrO2 as a support material in order to improve the conversion and selectivity of glycerol hydrogenolysis to 1,2-propanediol and 1,3-propanediol under mild reaction conditions. The effect of various loadings over Ru/TiO2-ZrO2 catalysts such as reaction time and recyclability were investigated to find out the optimum reaction conditions.

Experimental

Catalyst preparation

The TiO2–ZrO2 mixed oxide (1:1 wt%) support was prepared by the co-precipitation method. The requisite quantities of titanium isopropoxide in 2-propanol, zirconium(IV) propoxide in propanol, and NH3 (40 % aqueous solution) were continuously stirred for 6 h at 70 °C. The precipitation was completed after 4–5 h of stirring at which the pH of the solution was 9. The precipitate thus obtained was then filtered, washed several times with deionized water until it was free from the base, dried overnight at 120 °C, and finally calcined at 500 °C for 6 h. The TiO2–ZrO2 support (Brunauer–Emmett–Teller (BET) surface area 170 m2/g) is used for the preparation of supported ruthenium catalysts with varying Ru loadings from 1 to 6 wt% by deposition–precipitation method using an aqueous solution containing RuCl3·nH2O (Aldrich) as precursor. In the DP method, the support was suspended in an aqueous solution of 20–30 mL of de-ionized water and RuCl3·nH2O; Ru(OH)3 was exclusively precipitated at 40 °C on the support by the slow addition of 1 M Na2CO3 solution until the pH of the solution was reached to 10.5. The resultant solid was filtered and washed with deionized water several times until no chloride ion was detected in the filtrate. The solid thus obtained was oven dried at 120 °C for 12 h. Prior to the catalyst characterization the catalysts are reduced under pure H2 flow (50 mL/min) at 573 K for 3 h.

Catalyst characterization

X-ray diffraction patterns was obtained on Rigaku miniflex diffractometer using graphite filtered Cu Kα (K = 0.15406 nm) radiation. Determination of the ruthenium phase was made with the help of JCPDS data files.

The surface area, pore size distribution studies of the prereduced catalysts was estimated using N2 adsorption isotherms at 77 K by the multipoint BET method taking 0.0162 nm2 as its cross-sectional area using Autosorb 1 (Quantachrome instruments, USA).

The morphological analysis was carried out using transmission electron microscopy (TEM on a JEOL 100S microscope at high resolution (HR) on a JEOL 2010 microscope). Samples for both TEM analyses were prepared by adding 1 mg of reduced sample to 5 ml of methanol followed by sonication for 10 min. A few drops of suspension were placed on a hollow copper grid coated with a carbon film made in the laboratory.

Temperature-programmed reduction (TPR) experiments were carried out on AutoChem 2910 (Micromeritics, USA) instrument. In a typical experiment ca. 100 mg of oven dried Ru/TiO2–ZrO2 sample (dried at 110 °C for 12 h) was taken in a U-shaped quartz sample tube. Prior to TPR studies the catalyst sample was pretreated in an inert gas (Argon, 50 mL/min) at 200 °C. After pretreatment, the sample was cooled to ambient temperature and the carrier gas consisting of 5 % hydrogen balance argon (50 mL/min) was allowed to pass over the sample raising the temperature from ambient to 700 °C heating at the rate of 10 °C/min. The vapors produced during the reduction were condensed in a cold trap immersed in liquid nitrogen and isopropanol slurry. The hydrogen concentration in the effluent stream was monitored with the TCD and the areas under the peaks were integrated using GRAMS/32 software.

NH3-TPD experiments were also conducted on the AutoChem 2910 instrument. Prior to TPD analysis the sample was pretreated by passage high purity (99.999 %) helium (50 mL/min) at 300 °C for 1 h. After pretreatment, the sample was saturated with 10 % NH3 balance He mixture (75 mL/min) at 80 °C for 1 h and subsequently flushed at 105 °C for 2 h to remove physisorbed ammonia. TPD analysis was carried out from ambient temperature to 750 °C at a heating rate 10 °C/min. The amount of NH3 desorbed was calculated using GRAMS/32 software.

X-ray photoelectron spectroscopy was used to study the chemical composition and oxidation state of catalyst surfaces. The XPS spectra of the catalysts were measured on a XPS spectrometer (Kratos-Axis 165) with Mg Kα radiation (hλ) 1253.6 eV) at 75 W. The Ru 3d and 3p core-level spectra were recorded and the corresponding binding energies were referenced to the C 1 s line at 284.6 eV (accuracy within (0.2 eV)). The background pressure during the data acquisition was kept below 10−10 bar.

CO chemisorption measurements were carried out on AutoChem 2910 (Micromeritics, USA) instrument. Prior to adsorption measurements, ca. 100 mg of the sample was reduced in a flow of hydrogen (50 mL/min) at 300 °C for 3 h and flushed out subsequently in a pure helium gas flow for an hour at 300 °C. The sample was subsequently cooled to ambient temperature in the same He stream. CO uptake was determined by injecting pulses of 9.96 % CO balanced helium from a calibrated on-line sampling valve into the helium stream passing over the reduced samples at 300 °C. Ruthenium surface area, percentage dispersion and Ru average particle size were calculated assuming the stoichiometric factor (CO/Ru) as 1. Adsorption was deemed to be complete after three successive runs showed similar peak areas.

Catalytic activity

Hydrogenolysis of glycerol (>99 % MERCK Chemicals) was carried out over the catalysts in a vertical down-flow glass reactor at 230 °C and operating under normal atmospheric pressure. In the typical reaction ca. 500 mg of the catalyst, diluted with double the amount of quartz grains was packed between the layers of quartz wool. The upper portion of the reactor was filled with glass beads, which served as pre-heater for the reactants. Prior to the reaction, the catalyst was reduced in a flow of hydrogen (100 mL/min) at 300 °C for 3 h. After reduction the reactor was fed with glycerol at 230 °C. Hydrogen and an aqueous solution of glycerol were introduced into the reactor through a heated evaporator. The liquid products were collected in a condenser to be analyzed every 60 min by GC fed. The reaction products were analyzed by Shimadzu-GC 2014 gas chromatograph equipped with a carbowax capillary column with a flame-ionization detector (FID). The products were also identified using HP-5973 quadrupole GC-MSD system using carbowax capillary column.

Results and discussion

Characterization of Ru deposited on TiO2–ZrO2

The X-ray diffraction patterns of various Ru catalysts supported on TiO2–ZrO2 are shown in Fig. 1. As can be seen from Fig. 1, ruthenium supported on TiO2–ZrO2 did not show any reflections due to ZrO2 or TiO2 (1:1) catalysts, which confirms that the TiO2–ZrO2 phase is an amorphous or poorly crystalline material [10]. It is also observed that 1, 3 wt% Ru/TiO2–ZrO2 samples show a reflection at around the 2θ range of 34°, 44° due to the amorphous ruthenium [4]. This peak becomes sharp from 5Ru/TiO2–ZrO2 and gives a clear reflection at 6Ru/TiO2–ZrO2 indicating the crystallization of ruthenium beyond 5Ru/TiO2–ZrO2. This indicates the formation of Ru0 phase [14]. Another sharp reflection at 2θ range of 65° represents the ruthenium combined with the mixed oxide phase of TiO2–ZrO2 support [17].

Temperature-programmed reduction profiles of various Ru/TiO2–ZrO2 are shown in Fig. 2 and the hydrogen consumption during TPR are reported in Table 1. The TPR profiles reveal that the catalysts exhibited main reduction peak at 147–260 °C related to reduction of Ru3+/Ru0. These peaks are broad possibly due to location of ruthenium ions in different environments. But at low ruthenium loading 1–3 wt% the signal was split in two (α,β) and these peaks are with in the range of first T max of the other samples. The first peak in TPR of these low loading samples (1–3 wt% Ru) is due to unsupported ruthenium chloride and the second one is due to reduction of supported ruthenium chloride. The high temperature peak around 550 °C is attributed to Ru strongly interacting with the support. The T max of the main reduction peak tend to increase with ruthenium loading indicating the crystallization of ruthenium particles, i.e., larger particles tend to reduce at slightly higher temperature [4].

The ammonia TPD profiles of the various Ru/TiO2–ZrO2 catalysts are presented in Fig. 3. Temperature-programmed desorption of ammonia was performed on all the catalysts to obtain the information about differences in the surface structure of the catalyst. The ammonia uptake values and the T max values are given in Table 2. In the present study ammonia TPD method was adopted to study the acidity of Ru/TiO2–ZrO2 catalysts. As can be seen from Fig. 3 that the acidic sites are distributed in maximum three T max regions, one due to low acid strength (low T max region), one due to moderate acid strength (medium T max region) and other is due to strong acid strength (high T max region). 3Ru/TiO2–ZrO2 exhibit more number of acidic sites confined to weak and strong acid strength. In case of catalysts 5Ru/TiO2–ZrO2 and 6Ru/TiO2–ZrO2, moderate and strong acid sites are found to increase with the increase of ruthenium loading. It is interesting to note that the acidity values of 3Ru/TiO2–ZrO2–6Ru/TiO2–ZrO2 are decreasing due to increase in Ru-metal percentage on acidic titania–zirconia support [18–24].

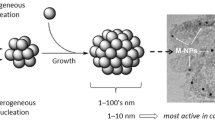

The catalysts Ru/TiO2–ZrO2 (Fig. 4) show the presence of metal particles on external surface of the support. The particle sizes of the Ru/TiO2–ZrO2 catalysts were estimated from TEM and CO chemisorption. The TEM images of 1Ru/TiO2–ZrO2 and 3Ru/TiO2–ZrO2 catalysts reveal the presence of highly dispersed Ru particles confined to TiO2–ZrO2 support oxide which is not the same in 6Ru/TiO2–ZrO2. The average particle size of ruthenium particles estimated from CO chemisorption is in good agreement with that of estimated from the TEM results.

The nature of surface species of the Ru/TiO2–ZrO2 catalysts was investigated by the XPS technique. Figure 5a–c show Ti 2p, Zr 3d and Ru 3p XPS of various Ru/TiO2–ZrO2 catalysts. Figure 5a show the binding energies of Ti 2p photoelectron peaks at 458.5 and 464.4 eV for Ti 2p3/2 and Ti 2p1/2 lines, respectively, and these are in agreement with the values reported in the literature [19, 25, 26]. Figure 5b show the Zr 3d5/2 and Zr 3d3/2 binding energy values in the range of 182.3 and 184.7 eV, respectively, which is in agreement with the values reported in the literature [25]. The binding energies of Zr 3d5/2 and its full width at half-maximum (FWHM) values are reported in Table 3. The constant FWHM values are found to be around 1.6, implying that only one type of doublet is present in the XPS spectrum. This provides an evidence for the presence of a single type of zirconium oxide with an oxidation state of 4+. The intensities of the Zr 3d core-level spectra do not change much with increase in ruthenium loading.

a Ti 2p XPS spectra of various Ru/TiO2–ZrO2 catalysts a 1Ru/TiO2–ZrO2, b 3Ru/TiO2–ZrO2, c 5Ru/TiO2–ZrO2, d 6Ru/TiO2-ZrO2 . b Zr 3d XPS spectra of various Ru/TiO2–ZrO2 catalysts a 1Ru/TiO2–ZrO2, b 3Ru/TiO2–ZrO2, c 5Ru/TiO2–ZrO2, d 6Ru/TiO–ZrO2.c Ru 3p XPS spectra of various Ru/TiO2–ZrO2 catalysts a1Ru/TiO2–ZrO2, b 3Ru/TiO2–ZrO2, c 5Ru/TiO2–ZrO2, d 6Ru/TiO2–ZrO2

The binding energy values of Zr 3d and Ti 2p did not changed much with varying ruthenium loadings, indicating the integrity of the support structure, which was not modified by ruthenium deposition. The binding energies of Ti 2p3/2 and its FWHM values are reported in Table 3. The constant binding energies of Ti 2p3/2 and its FWHM values indicate the presence of one type of titanium oxide with an oxidation state of 4+. Figure 5c represents the XPS of various ruthenium supported TiO2–ZrO2 catalysts for Ru 3p5/2 and Ru 3p3/2 indicating the electronic state and environment of Ru0 species present in supported catalysts. The binding energies and their FWHM values are reported in Table 3. Generally Ru0 possess the binding energy values 463.0–462.5 eV [26]. The BE values for Ru 3p5/2 (484.0–484.5 eV) and Ru 3p3/2 (463.5–462.5 eV) in supported ruthenium catalysts are significantly higher than that of Ru0 (Fig. 5). Generally, this phenomenon can be understood as the strong metal–support interaction (SMSI) effect.

With increase in ruthenium loading the binding energy of Ru 3p5/2 and Ru 3p3/2 shifted towards lower side up to 3 wt% and remains constant at higher Ru loadings. Since smaller ruthenium particles have higher binding energy and larger particles have lower binding energy [26]. This might be due to interaction of small ruthenium particles strongly with the support. These results clearly suggest that with increase of Ru loading the metal–support interaction decreases and the dispersion also decreases. The XPS intensity ratios of Ru 3p5/2/Zr 3d5/2 for various Ru/TiO2-ZrO2 catalysts are reported in Table 3. The intensity ratio increases with increasing of ruthenium loading up to 3 wt% and did not change appreciably with further increase in Ru loading. These results suggest that number of active Ru sites increase up to 3 wt% with increasing Ru loading and no significant effect at higher loadings is noticed due to the formation of large agglomeration of Ru0 crystallites. Thus, a low dispersion of ruthenium is noticed at higher loadings by CO chemisorption method. The present XPS results are in well agreement with the dispersion of ruthenium determined by XRD and CO chemisorption method.

The BET surface area of pure Titania–Zirconia is 170.0 m2/g. The surface area (Table 4) tends to decrease with the increase of ruthenium loading on Titania–Zirconia mixed oxide support. The particle size of ruthenium also increases smoothly up to 3 wt% and tends to increase exponentially from 5 to 6 wt%. The increase in the crystallite size beyond 5 wt% indicates that the overloading of the metal lead to increase in the crystallite size due to agglomeration of ruthenium particles.

The physical properties of catalysts such as dispersion, metal surface area and average particle size obtained from CO chemisorption are given in Table 4. Assuming the particle to be cubic with five sides exposed to the gas plane is the dispersion of Ru was calculated from CO chemisorption using the following equation:

The ruthenium metal areas were determined using the equation S CO = n Sm X m n −1s , where S CO is the total metallic surface area, n Sm is the CO consumption and X m is chemisorption stoichiometry at monolayer coverage, and n −1s is the number of ruthenium atoms per unit surface area. It can be observed from the Table 4 that the dispersion of ruthenium and metal area of the catalyst decreases with increase of the ruthenium loading on TiO2–ZrO2 support. However, the particle size of ruthenium increases linearly up to 3 wt% and tend to increase exponentially at higher loading. The metal area per gram of ruthenium and number of active sites available per gram of the catalyst tend to increase up to 3 wt% and tends to decrease slightly from 5 wt% loading. The decrease in metal area and the number of available active sites at higher loadings in 6Ru/TiO2–ZrO2 is due to overloading of the catalysts which lead to agglomeration of ruthenium particles to larger particles, which is in good agreement with TEM and XRD results. The same can be observed from the CO uptake values, which increased up to at higher loading catalyst 6Ru/TiO2–ZrO2.

The catalytic performance of TiO2–ZrO2 supported Ru catalysts in the vapor phase glycerol hydrogenolysis reaction was carried out at 230 °C and at normal atmospheric pressure. The Fig. 6 shows the results of hydrogenolysis activity of various Ru/TiO2–ZrO2 catalysts. From the Fig. 6, it is clear that the hydrogenolysis activity increases up to 3 wt% and tends to decline at further ruthenium loadings. The hydrogenolysis activity expressed in terms of (%) conversion increased from 40 % for 1 wt% to 52 % for 3 wt% and tends to decrease slightly at further ruthenium loadings (Table 5). However, the selectivity as shown from the Fig. 6 represents 1,2-propanediol—35 %, 1,3-propanediol—15 %, 2-propanol—8 %, 1-propanol—14 % with 10 % of dehydration product hydroxyacetone, 9 % of ethylene glycol, 4 % ethanol and 5 % methanol are degradation products. Miyazawa et al. [27] used a combination of Ru/C together with the cation exchange resin amberlyst-15 as acid catalyst. They observed the formation of both 1,2-propanediol and 1,3-propanediol. It was suggested that glycerol is first dehydrated through an acid-catalyzed reaction to acetol or 3-hydroxypropionaldehyde and that the subsequent hydrogenation of the intermediates leads to 1,2-propanediol and 1,3-propanediol, respectively. A common feature of all these studies is the low selectivity to 1,3-propanediol. According to Schlaf et al. [28], acid-catalyzed hydrogenolytic cleavage of –OH group occurs through an initial protonation of the hydroxyl group that leads to the formation of a carbocation and water. Thermodynamically, the formation of a secondary carbocation is more favored than the formation of a primary carbocation. Therefore, operating under acid conditions should bring about higher selectivity to 1,3-propanediol. The fact that product distribution is usually shifted towards 1,2-propanediol seems to be a complex function of operating conditions, catalyst and starting materials. Another factor that must be taken into account in propanediols formation is the higher stability of the intermediate acetol compared to 3-hydroxypropionaldehyde, which is readily hydrogenated to 1,3-propanediol or dehydrated to acrolein [29]. These better conversions/selectivities exhibited by lower Ru loading catalysts viz., 1Ru/TiO2–ZrO2 and 3Ru/TiO2–ZrO2 are also due to the formation of nano Ru particles, acidic support and high dispersion as evidenced from the findings of BET surface area, CO chemisorption and TPR measurements. The catalytic activity exhibited by various Ru/TiO2–ZrO2 catalysts was found to be superior in vapor phase hydrogenolysis reaction at low hydrogen flow rates [140 mL/min] at normal atmospheric pressure. In the case of 6Ru/TiO2-ZrO2 catalyst conversion (35 %) and selectivity (1,2-PD-24 %, 1,3-PD-5 %, 1-Propanol-7 % and Ethylene glycol-22 %) has decreased due to the formation of ruthenium particles as crystallites which are evidenced from XRD, TEM, TPR and CO chemisorption data. Martin et al. [30] studied Ru and Pt catalysts on batch run glycerol hydrogenolysis reaction and observed Ru catalyst showed better activity and stability compared to Pt catalysts. Therefore, the superior activity of Ru/TiO2–ZrO2 is probably due to higher dispersion of Ru on TiO2–ZrO2 than Ru on other supports and also due to strong metal–support interaction between Ru with TiO2–ZrO2 support. Tomishige et al. [31] proposed the reaction mechanism for glycerol hydrogenolysis in liquid phase on various Ru catalysts [12] with better conversion and selectivities. The activity of the catalysts at lower loadings (1–3 Ru/TiO2–ZrO2) is rather high due to their strong interaction with TiO2-ZrO2 as seen from the TPR patterns showing the presence of ruthenium active sites for the formation of desired hydrogenolysis products of glycerol reaction. Thus, the findings of BET, CO chemisorption further support the catalytic properties exhibited by various Ru/TiO2–ZrO2 catalysts during glycerol hydrogenolysis reaction. However, the TPR patterns also reveal the formation of bulk ruthenium leading to sharp reduction peaks for 6.0 wt% Ru catalysts.

Effect of ruthenium loading

Catalytic activity tests with the bare supports under the similar conditions used in this study resulted in very low conversion (<10 %), also the initial rates of conversion of glycerol and formation of propanediol have a proportional increase with the catalyst amount. However, as the reaction time increases, the excess catalyst further promotes excessive hydrogenolysis reaction converting glycerol to propanediols. Hence, to obtain a good conversion of glycerol with high selectivity to propanediols an optimal amount of catalyst active sites [31, 32] should be available depending on the reaction time. From Fig. 6 it can be inferred that the conversion of glycerol increases with Ru loading up to 3 wt% and decreases slightly at higher Ru loadings. However, the selectivity towards 1,2-propanediol, 1,3-propanediol increased up to 3 wt% and decreases slightly beyond this loading. This is probably due to the presence of strong and weak acid sites which favors the formation of 1,2-propanediol and 1,3-propanediol, respectively [33, 34]. Feng et al. also reported similar findings [13]. The decrease of glycerol conversion at higher Ru loadings is probably due to weak metal–support interaction between ruthenium and support as evidenced from TPR and CO chemisorption measurements [35, 36]. The catalytic behavior of various Ru catalysts with varying parameters discussed in terms of the findings of surface characterization techniques.

Dependence of catalytic properties on reaction time

The time on stream studies on the 1–6 wt% Ru/TiO2-ZrO2 catalysts were investigated to understand the stability of catalysts during glycerol hydrogenolysis and the results are shown in Fig. 7. These results show that 3Ru/TiO2–ZrO2 exhibit higher conversion (52 %) and showed stability compared to other catalysts. The catalysts prepared by DP method exhibited better conversions and good selectivities towards propanediols. The results suggest that 6Ru/TiO2–ZrO2 show lower conversion and selectivity than 3Ru/TiO2–ZrO2, due to their increased particle sizes. Although the initial activity is better for 6Ru/TiO2–ZrO2 catalysts, the activity abruptly dropped from 35 to 20 % within 7 h of operation. The 1Ru/TiO2–ZrO2 and 3Ru/TiO2–ZrO2 catalysts exhibit initial activity of 40 and 52 % but they decreased to 35 and 52 % with time compared to other catalysts, suggesting that 3Ru/TiO2–ZrO2 was a best catalyst for the vapor phase glycerol hydrogenolysis of our present investigation. The reasons for faster deactivation of catalyst 6Ru/TiO2–ZrO2 are probably due to carbon deposition and agglomerisation during the reaction. The catalytic activity is correlated with the crystallite size of Ru on different catalysts. The 6Ru/TiO2–ZrO2 catalyst is attributed to the decrease in the number of active sites of ruthenium on TiO2–ZrO2 due to agglomeration as evident from XRD, TPR and CO chemisorption results. The stability of the 3Ru/TiO2–ZrO2 catalyst during the hydrogenolysis of glycerol was investigated over 7 h time on stream at 230 °C and the results are showed in Fig. 7. In a time interval of 7 h, glycerol conversion decreased from 35 to 19 % for 6Ru/TiO2–ZrO2 catalyst. It can be seen from Fig. 7 that conversion of glycerol remains steady till 7 h for 3Ru/TiO2–ZrO2 catalyst. This decline in conversion might be due to the structural changes in the catalyst due to the deactivation of the catalyst leading to the agglomerisation of Ru active metal species.

Effect of temperature

Temperature has a significant effect on the overall yield of the propanediol. In the present work, the reactions were carried out at 230 and 280 °C and at hydrogen flow rate of 140 mL/min in the presence of best activity 3Ru/TiO2-ZrO2 catalyst. The effect of temperature on the conversion and selectivity of the reaction are shown in Fig. 8. As the temperature of the reaction increased from 230 to 280 °C, there is a marginal increase in the conversion of glycerol. However, the selectivity of 1,2-propanediol (23 %), 1,3-propanediol (4 %) and ethylene glycol (11 %), 2-P (5 %), 1-P (<5 %), ethyl alcohol (8 %) and methanol (13 %) also decreased considerably at reaction temperature 280 °C. Our present study suggests that at 230 °C, the hydrogenolysis of glycerol reaction provides optimum yields towards desired hydrogenolysis products. The reason for the increase in degradation products at higher temperatures is probably due to further hydrogenolysis of propanediols to yield lower alcohols [33, 34].

Effect of glycerol concentration

The effect of glycerol concentration or water content on glycerol hydrogenolysis was studied. The results presented in Fig. 9 clearly show a considerable decline in the glycerol conversion with increase in glycerol concentration. It is known that glycerol conversion and selectivity was higher at low glycerol concentration. The selectivities obtained towards 1,2-Propanediol (35 %), 1,3-Propanediol (15 %), EG(9 %), 2-propanol(8 %), 1-propanol (14 %), ethyl alcohol (4 %) and methanol (5 %) at lower glycerol concentration—20 wt% (WHSV-2.09 h−1). The low conversion and selectivities at high glycerol concentration-40 wt% (WHSV-2.19 h−1) for the respective products are 1,2-Propanediol (31 %), 1,3-Propanediol (4 %) and Ethylene glycol (8 %), 2-P (7 %), 1-P (<5 %), Ethyl alcohol (9 %) and Methanol (12 %) as expected, since the available number of Ru sites is constant [32].

Effect of H2 flow rate

The role of H2 flow rate hydrogenolysis was studied. The results presented in Fig. 10 clearly show a considerable decline in glycerol conversion with increase in glycerol concentration. It is known that glycerol conversion/selectivity was higher at low glycerol concentration. The selectivities obtained at H2 flow rate 100 mL/min were 1,2-propanediol (18 %), 1,3-propanediol (8 %) and ethylene glycol (9 %), 2-P (7 %), 1-P (<8 %), Ethyl alcohol (10 %) and Methanol (13 %). The low conversion and selectivity at low H2 flow rate (100 mL/min) is as expected, since the availability of hydrogen required for the hydrogenation of hydroxyacetone formed during the reaction is less [32].

Effect of feed flow rate

The influence of feed flow rate on glycerol hydrogenolysis was examined and the results are presented in Fig. 11. It shows that decrease in glycerol conversion was noticed with increase of glycerol flow rate from 1 mL/h (WHSV—2.09 h−1) to 3 mL/hr (WHSV—6.27 h−1). It is known that glycerol conversion is higher at low glycerol flow rate of 1 mL/h. The selectivities obtained for glycerol hydrogenolysis products at glycerol flow rate of 3 mL/h is 1,2-propanediol (11 %), 1,3-propanediol (3 %) and ethylene glycol (7 %), 2-P (6 %), 1-P (<5 %), Ethyl alcohol (6 %) and Methanol (10 %) at higher feed flow rate of glycerol. The low conversion and selectivities at high glycerol feed flow rate is as expected, since the available number of Ru sites remain unchanged [32].

Recyclability studies of catalyst 3Ru/TiO2–ZrO2 and its structural aspects

The results of two successive reactions of best activity catalyst 3Ru/TiO2–ZrO2 were summarized in Fig. 12. After a typical run at 230 °C and at normal atmospheric pressure for 7 h, the recyclability of the catalyst was investigated. The hydrogenolysis of 3Ru/TiO2–ZrO2 was carried out under relatively different conditions. There is a possibility of structural changes during the reaction and poisoning of the active metal sites. A simple switch off the coked 3Ru/TiO2–ZrO2 catalysts to a flow of 20 vol% air flow and dried at the temperature (350 °C) was sufficient for a full regeneration of the deactivated 3Ru/TiO2–ZrO2 catalyst shown in Fig. 8. Another reaction was carried out using the recycled catalyst, fresh glycerol feed under the same conditions. The recovered 3Ru/TiO2–ZrO2 catalyst was found to be very active in the repeated run. Moreover, the conversion of glycerol increased marginally in the repeated reaction. The selectivity also remained increased slightly for all the retested catalysts. This suggested that a sort of metal activation affect such as in situ reduction occurred during the repeated reaction.

The used catalysts were characterized by TEM, BET surface area and the results were compared with values of the fresh catalysts in Figs. 12, 13 and Table 6. The TEM patterns and their particle sizes of the fresh, used and recycled catalysts are presented in Fig. 13 and Table 6. Both fresh and recycled catalysts showed similar TEM patterns. This suggests that the catalyst structural features were intact during the reaction. The fresh and used catalysts of 3 and 6Ru/TiO2–ZrO2 showed change in particle size, surface area and TEM patterns. This suggests that the structural features of 3Ru/TiO2-ZrO2 catalysts were intact during the reaction whereas structural features of 6Ru/TiO2–ZrO2 catalyst slightly varied. These findings showed that the activity of 3Ru/TiO2–ZrO2 was increased during repeated reaction due to the formation of active particle of metallic ruthenium. There was no indication of any agglomeration during the glycerol hydrogenolysis in the 3Ru/TiO2–ZrO2 catalyst. These results further suggest that the structural stability of the 3Ru/TiO2–ZrO2 catalyst did not affect under the glycerol hydrogenolysis conditions and 6Ru/TiO2–ZrO2 catalyst showed no structural stability due to the agglomeration.

The carbonaceous species formed on the catalysts are analyzed by a CHN analyzer and the results are listed in Table 7. Considerable amounts of carbon deposits were formed on the catalysts during the catalytic reaction. The textural property of the catalyst plays also an important role in coking. Table 7 shows the amount of coke accumulated on the catalysts after reaction at 230 °C. A lower coke deposition was found on 3Ru/TiO2–ZrO2 catalyst and even much lower coke loadings were detected on 1Ru/TiO2–ZrO2 compared to 6Ru/TiO2–ZrO2 catalyst due to the agglomeration. The carbon percentage of the carbonaceous deposits formed on 5Ru/TiO2–ZrO2 (5.11) and 6Ru/TiO2–ZrO2 (5.43) are higher than the 3Ru/TiO2–ZrO2 (4.32) catalyst. The large difference in the amount of coke deposits and in the H/C ratios appears to correlate with the effective pore widths and particle size of the catalysts. 6Ru/TiO2–ZrO2 catalysts have shown more carbonaceous deposits than the other catalysts, indicating the agglomeration of the active sites. As can be seen from the Table 7, a decrease in the surface areas and particle size has been observed in used catalysts, than those of the fresh catalysts. This may be due to pore blockage during the glycerol hydrogenolysis reaction which leads to deactivation of the catalyst. From Table 7, it is quite interesting to note that the average particle size and surface area greatly decreased in case of 5 and 6Ru/TiO2–ZrO2 catalysts in comparison to the other catalysts. This might be due to small pores easily covered by the coke deposits and is well correlated by the CHN analysis (Scheme 1).

Conclusions

Ruthenium catalysts supported on TiO2–ZrO2 are found to be highly active and selective for the hydrogenolysis of glycerol to propanediols. Catalysts prepared by the DP method showed good conversions as well as selectivity for the hydrogenolysis of glycerol. Low Ru content is sufficient to achieve maximum conversion if the catalysts were prepared by the DP method. The TiO2–ZrO2 support provides a platform for good dispersion of nano size Ru particles, which are responsible for high catalytic properties. However, as ruthenium loading increases the selectivity towards the 1,2-propanediol, 2-propanol, 1,3–propanediol and 1-propanol increases. The varying intrinsic activity of active Ru sites nicely correlates with metal particle size. CO chemisorption, TEM studies and TPR results further suggest that the reducibility of ruthenium increases with ruthenium loading and exhibit strong metal–support interaction (SMSI) at lower ruthenium loadings. Higher activity and selectivity can be realized with 3Ru/TiO2–ZrO2 catalyst due to the presence of more acidic sites which is evidenced from NH3 to TPD results. The decrease in the conversion and selectivity of higher loading 6Ru/TiO2–ZrO2 can be attributed to the agglomerisation of active Ru particles as evidenced from the BET surface area analysis, and TEM studies. Formation of carbonaceous species on the surface results in loss of active sites and also decreases of catalytic activity. Further, the conversion of glycerol and the selectivity to hydrogenolysis products 1,2-propanediol, 1,3-propanediol also depend on the reaction time and catalyst loadings. The spent catalysts (3 and 6Ru/TiO2–ZrO2) were also characterized by BET surface area and TEM analysis. These results show that there is a significant decrease in the active sites of the 6Ru/TiO2–ZrO2 spent catalyst which resulted a decrease in the conversion and selectivity of the catalyst.

References

Zhou CH, Beltramini JN, Fan YX, Lu GQ (2008) Chemoselective catalytic conversion of glycerol as a biorenewable source to valuable commodity chemicals. Chem Soc Rev 37:527–549

Miyazawa T, Koso S, Kunimori K, Tomishige K (2007) Glycerol hydrogenolysis to 1,2-propanediol catalyzed by a heat-resistant ion-exchange resin combined with Ru/C. Appl Catal A Gen 329:30–35

Fernando S, Adhikari S, Chandrapal C, Murali N (2006) Biorefineries: current status, challenges, and future direction. Energy Fuels 20:1727–1737

Hamzah N, Nordin NM, Nadzri AHA, Nik YA, Kassim MB, Yarmo MA (2012) Enhanced activity of Ru/TiO2 catalyst using bisupport, bentonite-TiO2 for hydrogenolysis of glycerol in aqueous media. Appl Catal A Gen 420:133–141

Miyazawa T, Koso S, Kunimori K, Tomishige K (2007) Development of a Ru/C catalyst for glycerol hydrogenolysis in combination with an ion-exchange resin. Appl Catal A Gen 318:244–251

Zhu S, Gao X, Zhu Y, Zheng H, Li Y (2013) Promoting effect of boron oxide on Cu/SiO2 catalyst for glycerol hydrogenolysis to 1,2-propanediol. J Catal 303:70–79

Furikado I, Miyazawa T, Koso S, Shimao A, Kunimori K, Tomishige K (2007) Catalytic performance of Rh/SiO2 in glycerol reaction under hydrogen. GreenChem 9:582–588

Miyazawa T, Kusunoki Y, Kunimori K, Tomishige K (2006) Glycerol conversion in the aqueous solution under hydrogen over Ru/C+ an ion-exchange resin and its reaction mechanism. J Catal 240:213–221

Chaminand J, Djakovitch LA, Gallezot P, Marion P, Pinel C, Rosier C (2004) Glycerol hydrogenolysis on heterogeneous catalysts. Green Chem 6:359–361

Zhua S, Qiuc Y, Zhua Y, Haod S, Zhengd H, Li Y (2013) Hydrogenolysis of glycerol to 1,3-propanediol over bifunctional catalysts containing Pt and heteropolyacids. Catal Today 212:120–126

Dasari MA, Kiatsimkul PP, Sutterlin WR, Suppes GJ (2014) Low-pressure hydrogenolysis of glycerol to propylene glycol. Appl Catal A Gen 281:225–231

Pavan Kumar V, Srikanth ChS, Nageswara Rao A, Chary KVR (2014) Vapour phase hydrogenolysis of glycerol over nano Ru/SBA-15 catalysts on the effect of preparatory routes and metal precursors. JNN 143:137–3146

Pavan Kumar V, Kumar A, Srinivasa Rao G, Chary KVR (2015) Vapor-phase hydrogenolysis of glycerol over nanostructured Ru/MCM-41 catalysts. Catal Today 250:226–238

Pavan Kumar V, Harikrishna Y, Nagaraju N, Chary KVR (2014) Characterization and reactivity of TiO2 supported nano ruthenium catalysts for vapour phase hydrogenolysis of glycerol. Indian J Chem A 53:516–523

Feng Y, Yin H, Wang A, Shen L, Yu L, Jiang L (2011) Gas phase hydrogenolysis of glycerol catalyzed by Cu/ZnO/MOx (MOx = Al2O3, TiO2, and ZrO2) catalysts. Chem Eng J 168:403–412

Vasiliadou ES, Heracleous E, Vasalos IA, Lemonidou AA (2009) Ru-based catalysts for glycerol hydrogenolysis-effect of support and metal precursor. Appl Catal B Environ 92:90–99

Chary KVR, Vidya Sagar G, Naresh D, Kalyana Seela K, Sridhar B (2005) Characterization and reactivity of copper oxide catalysts supported on TiO2–ZrO2. J Phys Chem B 109:9437–9444

Nakano Y, Hattori H, Tanabe K (1979) Surface properties of zirconium oxide and its catalytic activity for lsomerization of I-butene. J Catal 57:1–10

Wu JC, Chung CS, Ay CL, Wang I (1984) Nonoxidative dehydrogenation of ethylbenzene over TiO2–ZrO2 catalysts. J Catal 87:98–107

Wang I, Wu JC, Chung CS (1958) Dehydrogenation of ethylbenzene and ethylcyclohexane over mixed binary oxide catalysts containing titania. Appl Catal 16:89–101

Arata K, Akutagawa S, Tanabe K (1976) New solid acids and bases: their catalytic properties. Bull Chem Soc Jpn 49:390

Lungang C, Yulei Z, Hongyan Z, Zhang C, Li Y (2012) Catalytic degradation of aqueous Fischer–Tropsch effluents to fuel gas over oxide-supported Ru catalysts and hydrothermal stability of catalysts. J Chem Technol Biotechnol 87:1089–1097

Srikanth CHS, Pavan Kumar V, Viswanadham B, Chary KVR (2011) Hydrodechlorination of 1,2,4-trichlorobenzene over supported ruthenium catalysts on various supports. Catal Commun 13:69–72

Watanabe S, Ma X, Song C (2009) Characterization of structural and surface properties of nanocrystalline TiO2–CeO2 mixed oxides by XRD, XPS, TPR, and TPD. J Phys Chem C 113:14249–14557

Adeeva V, Lei GD, Sachtler WHM (1994) Isomerization of 13C labeled butane over Fe, Mn promoted sulfated ZrO2 catalyst. Appl Catal A 118:L11–L15

Chakroune N, Viau G, Ammar S, Poul L, Veautier D, Chehimi MDM, Mangeney C, Villain F, Fievet F (2005) Acetate- and thiol-capped monodisperse ruthenium nanoparticles: XPS, XAS, and HRTEM studies. Langmuir 21:6788–6796

Kusunoki Y, Miyazawa T, Kunimori K, Tomishige K (2005) Highly active metal–acid bifunctional catalyst system for hydrogenolysis of glycerol under mild reaction conditions. Catal Commun 6:645–649

Schlaf M (2006) Selective deoxygenation of sugar polyols to a, x-diols and other oxygen content reduced materials-a new challenge to homogeneous ionic hydrogenation and hydrogenolysis catalysis. Dalton Trans 39:4645–4653

Dam JT, Hanefeld U (2011) Renewable chemicals: dehydroxylation of glycerol and polyols. Chem Sustain Chem 4:1017–1034

Martin A, Armbruster U, Gandarias I, Arias PL (2013) Glycerol hydrogenolysis into propanediols using in situ generated hydrogen—a critical review. Eur J Lipid Sci Technol 115:9–27

Nakagawa Y, Tomishige K (2011) Heterogeneous catalysis of the glycerol hydrogenolysis. Catal Sci Technol 1:179–190

Balaraju M, Rekha V, Prabhavathi Devi BLA, Prasad RBN, Sai Prasad PS, Lingaiah N (2010) Surface and structural properties of titania-supported Ru catalysts for hydrogenolysis of glycerol. Appl Catal A Gen 384:107–114

Quesada DE, Ortiz MIM, Jimenez JJ, Castellon ER, Lopez AJ (2006) Catalysts based on Ru/mesoporous phosphate heterostructures (PPH) for hydrotreating of aromatic hydrocarbons. J Mol Catal A 255:41–48

Liu Q, Guo X, Li Y, Shen W (2009) Synthesis of hollow Co structures with netlike framework. Langmuir 25:6425–6430

Priya SS, Kumar VP, Kantam ML, Bhargava SK, Chary KVR (2014) Vapour-phase hydrogenolysis of glycerol to 1,3-propanediol over supported Pt catalysts: the effect of supports on the catalytic functionalities. Catal Lett. doi:10.1007/s10562-014-1395-1

Priya SS, Kumar VP, Kantam ML, Bhargava SK, Chary KVR (2014) Catalytic performance of Pt/AlPO4 catalysts for selective hydrogenolysis of glycerol to 1,3- propanediol in the vapour phase. RSC Adv 4:51893–51903

Acknowledgments

The authors thank Council of Scientific & Industrial Research, New Delhi, India and Director, CSIR-IICT, Hyderabad for her encouragement.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Kumar, V.P., Beltramini, J.N., Priya, S.S. et al. Catalytic functionalities of nano Ru catalysts supported on TiO2–ZrO2 mixed oxide for vapor phase hydrogenolysis of glycerol to propanediols. Appl Petrochem Res 6, 73–87 (2016). https://doi.org/10.1007/s13203-015-0136-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13203-015-0136-8